2

CONTENTS

SAFETY PRECAUTIONS..........................................................3

NOTE FOR SCHEMATIC DIAGRAM.........................................4

TECHNICAL SPECIFICATIONS................................................5

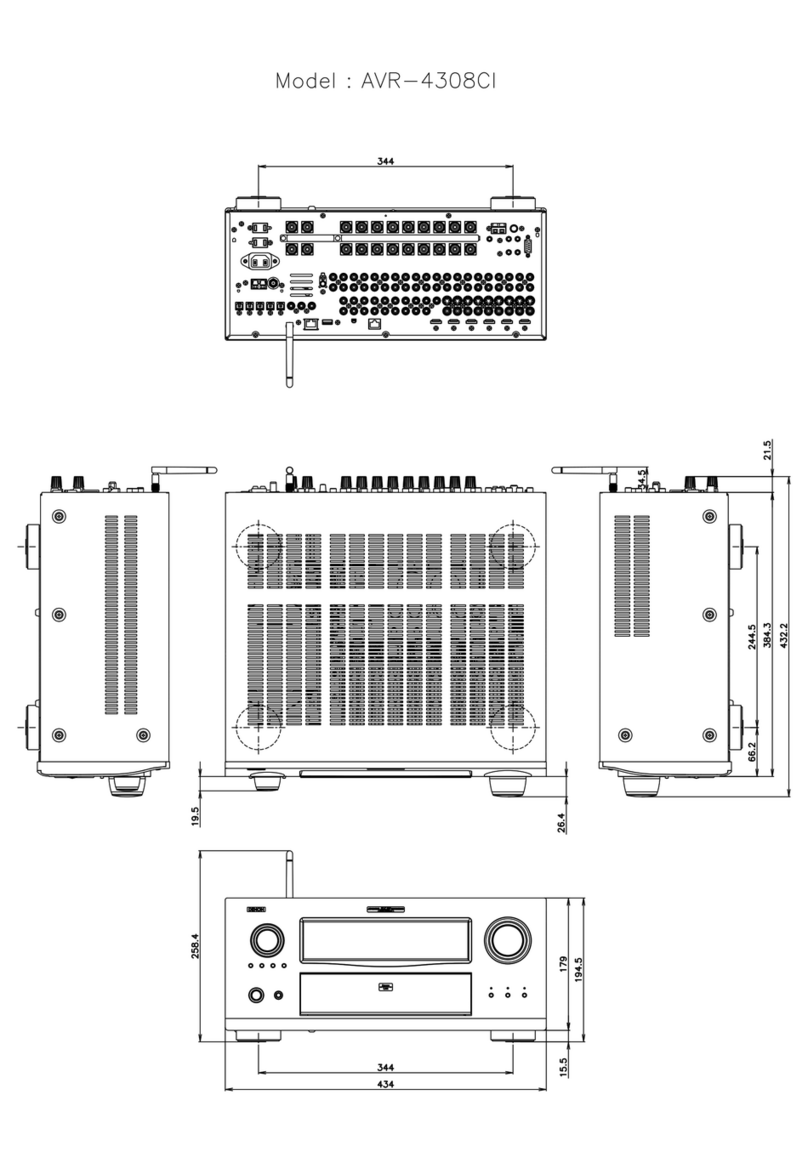

DIMENSION...............................................................................5

CAUTIONS IN SERVICING .......................................................6

Initializing INTEGRATED NETWORK AV RECEIVER ..............6

Service Jig.................................................................................6

DISASSEMBLY..........................................................................7

1. FRONT PANEL ASSY ...........................................................9

2. HEAT SINK ASSY ...............................................................10

3. HDMI UNIT ASSY................................................................12

4. TRANS MAIN......................................................................15

SPECIAL MODE......................................................................16

Special mode setting button....................................................16

1. µcom/DSP Version display mode........................................17

2. Errors checking mode (Displaying the protection history)...20

3. Remote ID Setup mode.......................................................22

PROTECTION DIAGRAM........................................................23

4. DIAGNOSTIC MODE

(Video/Audio (signal) path conrmation mode) ...................24

BLOCK DIAGRAM...................................................................29

JIG FOR SERVICING ..............................................................63

WHEN THE MICROPROCESSOR IS

REPLACED WITH A NEW ONE.............................................67

PROCEDURE FOR UPGRADING

THE VERSION OF THE FIRMWARE ....................................67

ADJUSTMENT.........................................................................74

SURROUND MODES AND PARAMETERS............................75

TROUBLE SHOOTING............................................................81

1. POWER...............................................................................81

2. Analog video........................................................................82

3. HDMI/DVI............................................................................88

4. AUDIO.................................................................................97

5. Network/USB.....................................................................100

6. SMPS................................................................................103

CLOCK FLOW & WAVE FORM IN DIGITAL BLOCK...........106

LAEVEL DIAGRAM...............................................................107

PRINTED WIRING BOARDS.................................................113

7CH AMP (COMPONENT SIDE) ..........................................113

7CH AMP (FOIL SIDE)..........................................................113

SMPS (COMPONENT SIDE)................................................114

SMPS (FOIL SIDE) ...............................................................114

SPK_PREOUT (COMPONENT SIDE)..................................115

SPK_PREOUT (FOIL SIDE) .................................................116

INPUT (COMPONENT SIDE) ...............................................117

INPUT (FOIL SIDE)...............................................................118

FUSE (COMPONENT SIDE).................................................119

F_WIDE (COMPONENT SIDE).............................................119

RS232C_CNT (COMPONENT SIDE)...................................119

FUSE (FOIL SIDE) ................................................................119

F_WIDE (FOIL SIDE) ............................................................119

RS232C_CNT (FOIL SIDE)...................................................119

POSISTOR (COMPONENT SIDE)........................................119

POSISTOR (FOIL SIDE) .......................................................119

FRONT (COMPONENT SIDE)..............................................120

V.AUX (FOIL SIDE) ...............................................................120

FRONT (FOIL SIDE) .............................................................120

V.AUX (COMPONENT SIDE)................................................120

GUIDE L (COMPONENT SIDE)............................................121

HDMI FFC (COMPONENT SIDE).........................................121

GUIDE TOP (COMPONENT SIDE).......................................121

HDMI FFC (FOIL SIDE) ........................................................121

GUIDE TOP (FOIL SIDE) ......................................................121

GUIDE L (FOIL SIDE) ...........................................................121

USB (COMPONENT SIDE)...................................................121

HP (COMPONENT SIDE).....................................................121

GUIDE R (COMPONENT SIDE)...........................................121

HP (FOIL SIDE).....................................................................121

GUIDE R (FOIL SIDE)...........................................................121

USB (FOIL SIDE) ..................................................................121

SELECTOR (COMPONENT SIDE).......................................122

RS232C (COMPONENT SIDE).............................................122

SELECTOR (FOIL SIDE) ......................................................122

RS232C (FOIL SIDE) ............................................................122

SIDE_CNT (COMPONENT SIDE) ........................................123

SIDE_CNT (FOIL SIDE)........................................................123

VIDEO (COMPONENT SIDE)...............................................124

VIDEO (FOIL SIDE) ..............................................................125

FRONT CNT (COMPONENT SIDE) .....................................126

FRONT CNT (FOIL SIDE).....................................................127

HDMI (COMPONENT SIDE).................................................128

HDMI (FOIL SIDE) ................................................................129

SCHEMATIC DIAGRAMS......................................................130

USB UNIT..............................................................................130

FRONT UNIT.........................................................................130

AMP UNIT (1/2).....................................................................131

AMP UNIT (2/2).....................................................................132

SPK/PREOUT/REG UNIT (1/4).............................................133

SPK/PREOUT/REG UNIT (2/4).............................................134

SPK/PREOUT/REG UNIT (3/4).............................................135

SPK/PREOUT/REG UNIT (4/4).............................................136

CNT/RS232C UNIT (1/4).......................................................137

CNT/RS232C UNIT (2/4).......................................................138

CNT/RS232C UNIT (3/4).......................................................139

CNT/RS232C UNIT (4/4).......................................................140

INPUT UNIT..........................................................................141

VIDEO UNIT..........................................................................142

SMPS UNIT...........................................................................143

DIGITAL UNIT (1/16).............................................................144

DIGITAL UNIT (2/16).............................................................145

DIGITAL UNIT (3/16).............................................................146

DIGITAL UNIT (4/16).............................................................147

DIGITAL UNIT (5/16).............................................................148

DIGITAL UNIT (6/16).............................................................149

DIGITAL UNIT (7/16).............................................................150

DIGITAL UNIT (8/16).............................................................151

DIGITAL UNIT (9/16).............................................................152

DIGITAL UNIT (10/16)...........................................................153

DIGITAL UNIT (11/16) ...........................................................154

DIGITAL UNIT (12/16)...........................................................155

DIGITAL UNIT (13/16)...........................................................156

DIGITAL UNIT (14/16)...........................................................157

DIGITAL UNIT (15/16)...........................................................158

DIGITAL UNIT (16/16)...........................................................159

WIRING DIAGRAM................................................................160

EXPLODED VIEW..................................................................161

PARTS LIST OF EXPLODED VIEW......................................163

PACKING VIEW.....................................................................166

PARTS LIST OF PACKING & ACCESSORIES.....................167

SEMICONDUCTORS.............................................................168

1. IC's ....................................................................................168

2. FL DISPLAY.......................................................................199

PARTS LIST OF P.C.B. UNIT ................................................201

PCB FRONT ASSY ...............................................................201

PCB 7CH_AMP ASSY...........................................................203

PCB CNT ASSY ....................................................................208

PCB MAIN ASSY...................................................................209

PCB INPUT ASSY.................................................................213

PCB VIDEO ASSY ................................................................215

PCB SMPS ASSY .................................................................217

PCB HDMI ASSY ..................................................................219