9

www.DentalEZ.com 866-DTE-INFO

9

PN: 1045DOC_E

Site Requirements

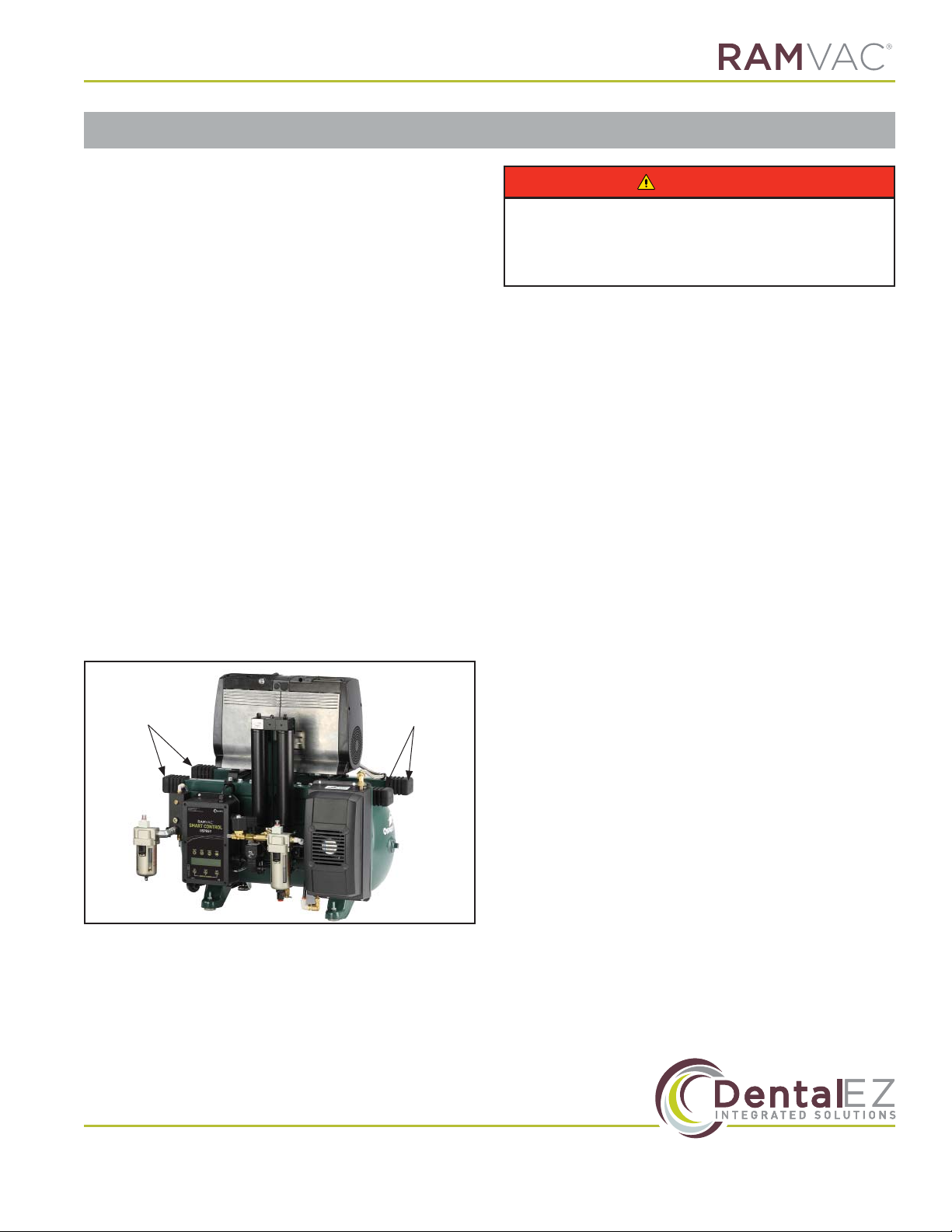

Before the compressor can be properly installed,

the following utilites must be supplied.

This device requires proper electrical grounding

for safe operation. A licensed electrician should

always complete the electrical portion of the

installation process.

Electrical

• Follow NEC, NFPA 99C, and all local codes.

• Compressors are shipped with a 6-foot

electrical whip of the appropriate size for the

compressor.

• Qualied personnel must install a dedicated

electrical circuit of suicient capacity. See

Section I Introduction, Specications in this

manual for additional electrical information.

• Any means provided to isolate this device

from the supply mains shall isolate all poles

simultaneously.

• The disconnection means and overcurrent

protection are to be provided by the installer

(qualied electrician) in accordance with

applicable local and national electric codes.

This device should always be attached to

a dedicated circuit with appropriate wiring

and circuit protection. If this device is being

installed as a replacement, always have a

licensed electrician inspect the existing facility

electrical and complete the electrical portion of

the device installation.

Plumbing

• Attach drain tubing to tting on bottom of

coalescing lter and direct it into oor drain for

proper disposal of water.

• Connect compressor air outlet to facility

plumbing with provided supply hose (3/8" ×

3/8" MPT, 6 feet in length).

• Install particulate lter to the facility shut-o

valve using plumbing kit connectors provided.

• Install fresh air manifold and connect fresh air

intake kit supplied to external air source per

NFPA 99C recommendations.

• This device should always be installed with

the appropriate plumbing and fresh air intake

systems. If this device is being installed as a

replacement, always have a licensed plumber

inspect the existing facility plumbing and

complete the plumbing portion of the device

installation.

Section II Preinstallation

• To avoid risk of electric shock, this

equipment must only be connected to a

supply mains with protective earth.

WARNING

• This air compressor has been designed to

operate within the following voltage ranges;

115V systems, 103 to 126V AC; 230V systems,

208 to 253V AC. Failure to provide suicient

voltage to this device could result in damage

to electrical components and reduced

service life.

NOTICE

• During the performance of any service

procedures that may involve the

disconnection of a ground wire, take extra

precautions to verify the ground wire has

been properly re-connected. Never leave a

ground wire disconnected, since this can

create a signicant safety issue.

CAUTION