Polar Compressor Rotary Screw Compressors

Revision July.2015 www.eatoncompressor .com 877.283.7614

2 | P a g e

Contents Page No

Variable Speed Drive Information..............1

Model Specification Charts.....................2-3

Safety Information ......................................4

Tag Definitions........................................4

Basic Guidelines .....................................4

Breathable Air .........................................4

Pressurized Components........................4

Personal Protective Equipment...............4

Inspection....................................................5

Forklift Safety..........................................5

Lifting Safety...........................................5

Installation...................................................6

Area........................................................6

Piping......................................................6

Safety Steps............................................6

Installing..................................................6

Oil Check .............................................7-8

Electrical Installation................................8

Motor Rotation.........................................9

System Description.....................................9

Air Process..............................................9

Lubrication Process.................................9

System Components ..................................9

PLC (Programmable Logistical Control) ..9

Setting:oC/oF; BAR/PSI; Lang; Time/Date.10

Working Pressures................................11

Clock Timer Settings.............................11

Working Timer –Unloading Delay.........12

Maintenance Notifications .....................13

Resetting Maintenance Alarms.........13-15

Mechanical Components..................16-19

Resetting Overload Protection...............16

Operation...................................................19

Safety Rules.....................................19-20

Initial Checks.........................................20

Start-Up.................................................21

Power Outages .....................................21

Storage .................................................21

Restarting Procedure.............................21

Maintenance ..............................................21

Safety Steps.................................... 21-22

Lubricating Oil .......................................22

Belts……………………………………22

Changing Oil..........................................22

Oil Capacities........................................22 23

System Pressure...................................23

Safety Valve..........................................23

Air/Oil Separator Filter...........................23

OPTIONAL: Cabinet Intake Filter(s) ......23

Maintenance Schedule..............................24

Troubleshooting.................................. 25-29

Wiring Diagrams........................................29

Warranty ....................................................34

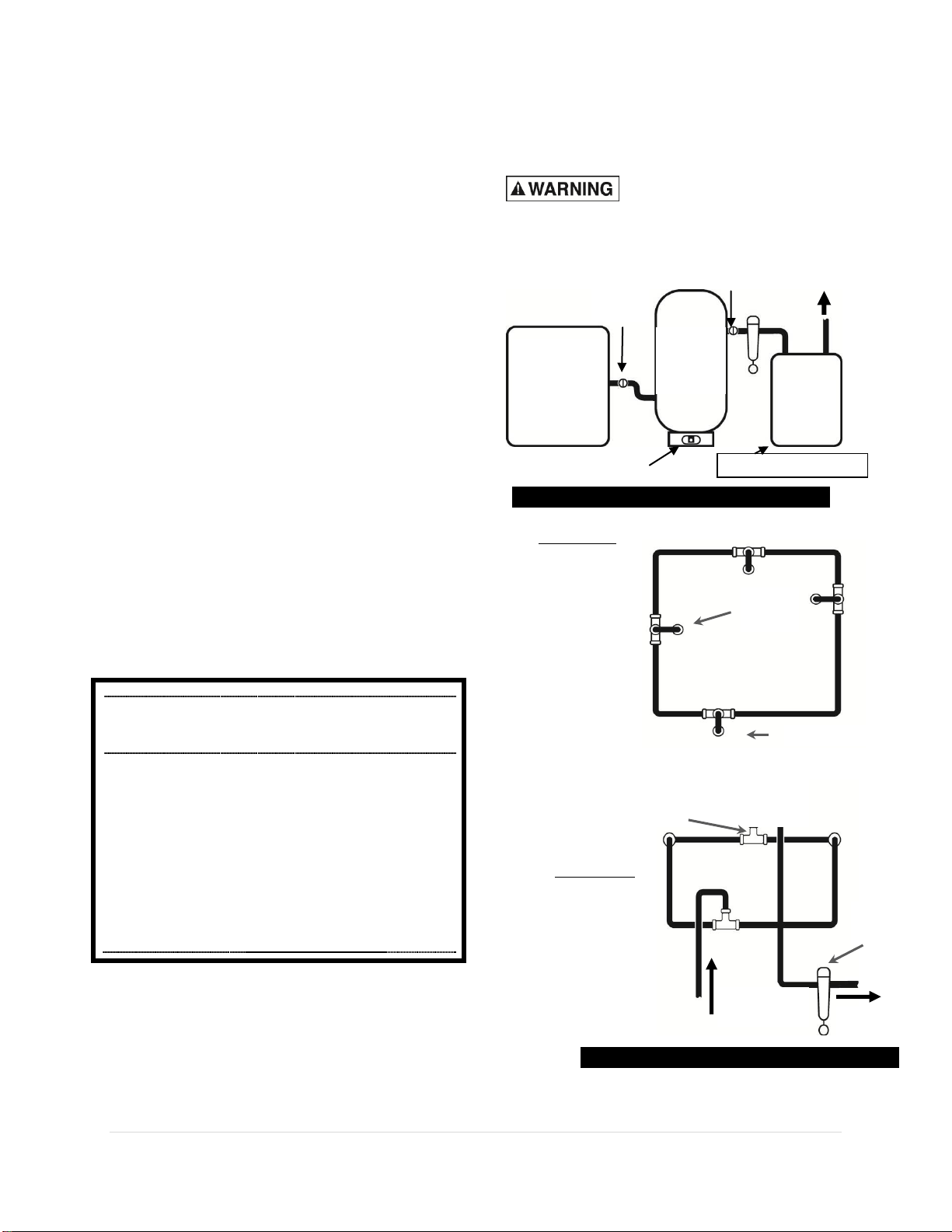

Variable Speed Drive

The variable speed drive is an auxiliary feature

available on all Polar Air compressors. A variable

speed drive or VSD regulates amp draw during start-

up and motor speed during operation according to air

demand.

All Polar Air compressors are equipped with a VSD

compliant motor, ventilated electrical box &

adequate space in compressor cabinet for easy

installation. The electronic controller (PLC) for the

compressor unit provides start/stop command and

display fault status for the VSD device.

Be sure to install VSD in a clean,

dust-free environment.

To convert to Variable speed drive, contact

Polar Air customer service for more

information, 1-877-283-7614

Each compressor cabinet has built-in VSD compartment