Der Jet Model DerJet F-35 Lighting User manual

INSTRUCTION MANUAL

Specication

Wingspan.................................. 1,340mm

Length......................................... 1,960mm

Scale............................................. 1:8

Equipment required

Turbine: .......................100-120N

Radio: ...........................Minimum 9 channel radio system.

Servos:.........................Elevators - 2 x 20Kg+ servos

..........................................Ailerons - 2 x 10Kg

..........................................Rudders - 2 x 4Kg+ midi servos

..........................................Nosewheel steering - 1 standard size servo.

Valves: .........................3 x Dual action electronic valves (Jet Tronic)

..........................................1x Brake valve.

Gyro:..............................3 Axis gyro system (Powerbox iGyro3e)

General: ......................Various adhesives, radio extension leads, fuel

accessories, scale pilot.

Der Jet Model

No. 178-1, Sec. 2, Nantun Rd., Nantun Dist.,

Taichung City 408, Taiwan.

www.derjetmodel.com

WARNING

This F-35A model is not suitable for aeromodellers without experience in building,

operating and ying technically complicated airframes. Success requires care

and consideration. Assembling this ying model requires the builder and persons

operating it to understand DerJet Model have no control on how it is assembled

and the equipment chosen is installed. For this reason it cannot accept loss or

liability brought about from incorrect assembly or incompetence in operation of the

kit and the companies’ total liability cannot be greater than the amount paid for this

model. This applies to personal injury, death, damage to buildings or property, loss

of turnover, interruption of business and any other direct or indirect consequential

damages.

By operating this model aeroplane you assume full responsibility for your actions.

Operating any jet turbine powered model aeroplane requires the persons to

understand the risks involved and they should check with the relevant authority in

the country the aircraft will be operated in. In the USA this is the AMA, UK BMFA,

Germany DMFV, it is your responsibility to nd the relevant authority where you will

operate the F-35 model.

The persons should understand the danger zones particularly behind and in front

of the aircraft and keep people or animals clear. A suitable re extinguisher should

always be manned and before any ight the safety systems should be checked in

accordance to the relevant manufactures instructions.

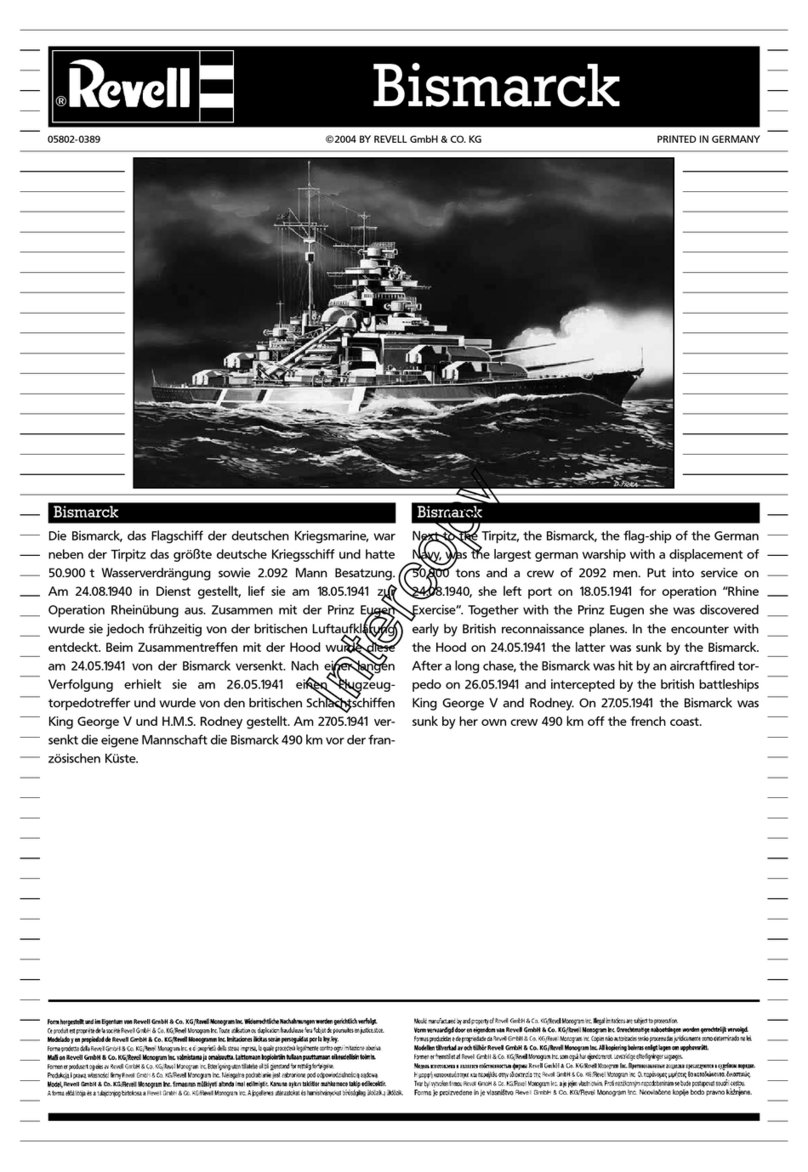

INTRODUCTION

Thank you for choosing the DerJet

F-35A model of one the World’s latest

multirole, all weather ghters. The full

scale was developed in conjunction

with several prominent companies who

supplied power units and electronic

equipment to the Lockheed designed

airframe. The full scale airframe features

a lot of composite materials in its

construction, much like our 1/8th scale

model!

Being of single engine design, it is a

perfect subject to model, the lifting

design fuselage produces a lightly

loaded airframe in the air and simple all

moving horizontal tail control surfaces

and large twin vertical ns oer fabulous

control authority and ight stability.

DerJet’s attention to detail keeps the airframe weight low, making it possible

to power this near 2m long aircraft with a 100N turbine. Turbines in the 100 to

120N class are recommended. Fitting a larger turbine is neither necessary nor

recommended. The instruction manual airframe has a JetCat P-90Rxi (105N thrust)

DerJet have replicated the undercarriage and gear door layout, the

main gear twists into position, the mechanism making it very dicult to

use rams to close the rear doors. Small springs are provided for these,

with air rams closing the cycled front main door section. The twin nose

doors are also closed using two air cylinders provided. No valves are

provided as there are several options open to the builder, individual

servo operated valves, individual electronic valves, all in one UP valves

or the EV-5 valve. Two valves are required for the doors as the nose

doors stay open and the front main doors cycle, being closed when

the gear is in the up and down position.

NB It is important that all the door pairs are set at the same angle. The

large area and near vertical open position, mean that they can easily

act as turning vanes or rudders if they are not matched.

The F-35A is a great modelling

platform as the undercarriage

stays in the fuselage making

transport easy.

NB: The valve used on the

undercarriage must hold

pressure on the rams to keep the

gear locked down in transport.

Assembly at the eld is also easy

with a single servo plug and

screw to x on each wing. The

design allows internal linkages

throughout, no ugly control

horns protruding from any of the

surfaces.

BEFORE YOU BEGIN

Every eort is made to pack the airframe carefully for the journey from the factory to

your workshop. Please inspect all parts of the aircraft before commencing assembly. The

airframe has been assembled in the factory to ensure a good t.

Although every care has been taken to assemble the undercarriage parts correctly,

please check each part for security, before commencing the build. Axles will require

xing with locking uid.

Note: The twist and turn main units need carefully checking for smooth operation. There

are several processes that need to happen for reliable operation. The locking cylinders

need to have air pressure applied when the gear is down to keep the main gear locked.

When the gear operates the locking cylinders need to operate ahead of the main leg

cylinder for retraction. This can be achieved with dierent lengths of airline, or additional

valves that are timed dierently.

It is critical the gear works reliably, the lifting fuselage does not respond well to airow

interruptions created by stuck legs or open doors. Before each ying session we

recommend you cycle the gear before ying. Reliable operation on the instruction

manual airframe is achieved at 110psi. The gear retracts forward, so travelling at a high

airspeed when you start the retraction sequence will slow down the retraction and could

restrict it completely. When the main front doors open there is a reduction in lift, since

there is a large hole in the lifting section! A good technique is to retract the gear while

ying straight and level, slow the speed and then cycle the gear. Once clear, you can

accelerate into a normal ying routine.

The F-35 is not for inexperienced pilots.

ASSEMBLY

Use good quality epoxy glue for any joints. Hysol 9462 is perfect.

All hardware is metric, so a set of high quality metric Allen keys will be required.

Assembling the two fuselage parts is easier with a long 3mm Ball end driver. The Bondus

Pro Hold type or some form of magnication will help to hold the screw on the tool until

tightened.

The split fuselage makes access easy until the two halves are joined. Several steps are

required before joining. The fuel tanks are easier to position before joining the two halves,

the fuel system needs to be plumbed and tested as access is restricted once the two

halves of the fuselage are joined. Mounting positions of any ancillary items should be

considered to allow access to the screws with a ball ended 3mm driver.

Access to the outer fuselage joint xing screws is via the gear door openings, the centre

screws are accessible with the turbine removed.

WINGS

The wings are relatively simple, as

they have a single control surface

and there are no air systems in the

wing panels. A single servo with a

torque of at least 10kg is required.

Because of the wing fairing shape,

a servo with a maximum depth

below the mounting lugs of 27mm

is required.

Fit a 16mm arm and

mount the aileron

servo with the servo

spline towards the

leading edge. A

hole must be drilled

(minimum 10mm) to

allow the servos lead

to be routed through the servo mounting plate.

Mark the aileron control horn position with some masking tape, a slot needs

cutting in the face of the aileron to take the control horns. The control horn should

be installed as close to the lower skin as possible (furthest away from the hinge

line). Some shaping of the control horn maybe required to match the curved

surface of the aileron.

Because the aileron hinge line is not at 90 degrees to the control linkage a ball

link must be used at the control surface end. Use an M3 forked spring steel clevis

at the servo end. The wings are held in position with screws accessed through

the rear gear door openings, from below. These are screwed into the wing spar,

through the wooden blocks.

FINS

The ns mount on two aluminium pegs that are tapped M3 in the

end. Fixing screw holes are accessed by removing the elevator servo

cover plates and xing the two screws. Ensure you use the two large

washers provided. It is good policy to use a small amount of loctite or

UHU por glue on the threads to ensure they never work out.

(NB-if you use loctite, a spot no larger than the diameter of the screw

is required)

Rudder servos should be 4.5kg

minimum, metal geared servos are

recommended. It is imperative the

rudders are slop free.

The rudders are centrally hinged with

hinge point type hinges. Epoxy these

into the rudder rst, before mixing

any glue, ensure the hinge holes are

central on the surface thickness. The

hinge pins must be in line with the wire

control rod pivot inserted in the base of

the rudder. The steering arm is metal

and a slop free linkage is required to

resist utter on the angled ns.

Temporarily t the rudder servos to

establish the line your rudder pushrod

will take. Some trimming of the wooden

former may be required for a clear path.

Cut down the supplied brass steering arm so that it ts in the space, match the

servo arm centres to the steering arm hole centres. The F-35 rudders are quite

powerful, so 6-8mm movement each way is sucient. A ball link is required on

the brass rudder horn steering arm, because of the angles. A clevis is used on the

servo arm at 11-12mm radius. The spacer sleeve needs supporting to

guarantee a solid, slop free linkage.

ELEVATOR/FLYING TAILPLANE HALVES

The F-35 is unusual in that the elevators are hinged o the rear face of

the fuselage. The hinges are factory tted along with the control horns.

The elevators pivot on two 3mm pins. Ensure the hinge is free before

connecting the servo and linkage, the large elevators will produce

large trim changes if they do not return to neutral exactly each time.

For this reason high quality servos with known centring should be

used. We used JR 8711 and JR 8911 servos in the prototype models.

Remove the two cover plates located in the rear lower fuselage and

mount two metal geared 20kg+ servos on the brackets provided.

Connect the servo to the surface with the M3 pushrods and ball links

provided. The servos should be tted with metal control arms - nylon

arms are not suitable. Keep the servo arm radius as short as possible.

20-22mm is sucient to get full travel.

The large area elevators give powerful control inputs-check that the

linkages move freely, any friction must be removed for smooth ight.

Elevator neutral is with the leading edge point just above (1.0mm) the

fuselage side datum edge.

UNDERCARRIAGE

Before starting the undercarriage t out,

remove the wheels and brake units. After

checking each part re-assemble with a small

amount of grease on the O rings and brake

surface. This will provide a perfect seal and

reduce brake snatching.

The wheel axle should have a small at added

where the xing grub screw seats. Ensure the

wheel axles are greased before assembly. The

F-35 has a high ground speed, so the wheel

bushes need to be regularly lubricated. Use

a small amount of blue loctite on the M4 set

screw that retains the

axle.

When installing

the nose unit, use

plywood packing

pieces under it

as shown right to

increase the model’s

angle of attack.

The main leg cylinder

swivels as the gear retracts, lubricate the swivel to ensure a smooth operation.

The nose unit should be inspected before installation, screws checked and xed

with loctite. The pivot boss should be lubricated with grease before installation

in the unit-ensure the clamping screw is tightened suciently to retain the boss -

but not so tight that the leg will not turn! The nose wheel bushes need lubricating

with grease or Teon oil.

Undercarriage operation

Some care and thought is required when routing the airlines from the main

legs and units. Operate the legs multiple times so that you can understand the

path taken by the various air connections. Some will twist and move quite some

distance during the retraction process, so allowance in the tubing

free lengths will be critical. There are various trap points that occur,

particularly with the lock ram assembly. Reliable operation requires

equal tube lengths either side of the airframe. Each airline should be

routed to ensure no chance of kinked lines.

NOTE! The small locking cylinder must operate before the main

cylinder, when the gear retracts. This breaks the straight locking link,

so that the main cylinder can pull the leg up. We achieve this with

a split retracting (up) airline of unequal length. Keep the retraction

airlines coming from the valve as short as possible before a T or

Y piece splitting it. Make the line going to the main large cylinder

retraction nipple side 300-350mm longer than the line going to

the small locking cylinder. This will make the small locking cylinder

operate before the lift cylinder. The extension phase can have equal

length lines to the main cylinder base and lock cylinder extension side.

The air system valves can either be mounted inverted on the fuselage

top surface, between the fuselage break and the cockpit opening.

Mounting the valves on a plate that is Velcroed to the fuselage allows

it to be easily removed for access. Alternatively there is space on either

side of the cockpit opening.

The air tanks can be

mounted in the rear

fuselage section,

above the fuel tanks,

centred on the

fuselage. We mount

the air ller valves on

one side of the turbine

access hatch.

The F-35 gear doors are all angled slightly in the airow. This makes cylinder

force critical for resisting blowback. The main door (front doors) cylinders are

horizontally mounted to the main former, ensure the line of leverage gives the

maximum possible in each direction.

The nose cylinders

are mounted vertically

to the fuselage side,

small notches in the

radio tray may be

required for clearance.

The rear doors are

mechanically operated

by the main legs.

Springs are provided

and these can be xed

to the leg, or wrapped

around the leg, so that

the retracting leg pulls

the door closed.

Small cams maybe

required to keep the

door clear of the leg

during the initial retraction phase. We made these of 2mm thick scrap plywood

glued to the bottom edge of the door.

UNDERCARRIAGE

& GEAR DOOR

DETAILS

A selection of four

images that detail

the layout of the pipe

work to the main gear,

brakes and doors.

Use these to plan your

installation.

CANOPY &

COCKPIT

There is very little clearance under the cockpit tub base, you can gauge the space

available before you join the fuselage halves-shine a torch forward from the

fuselage split. Most of the equipment can be mounted behind, or to one side of

the cockpit opening.

To achieve the required balance without additional weight we used a 5000mAh

2 s Li-Po for the Turbine ECU and 2 x 2200 2s Li-Po supplying a Powerbox Sensor

switch, all three batteries are mounted in the nose area. The receiver and gyro are

mounted on the rear radio plate, just under the canopy opening. A small Powerbox

unit like the Mercury

would be an excellent

solution, since it

includes the 3 axis

gyro and sequencing

required for the gear

doors.

Note the fuselage

shape and cockpit

opening gives the

impression that the

radio plate is not level

with the datum, it is.

This can be veried by

using a small bubble

gauge level. Mount the

gyro on the back edge

of the radio tray over

the rear former, which

provides an ideal stable

mounting surface.

Any cables should

be clipped to the

fuselage sides to avoid

any chance of them

becoming tangled

in the nose retract

mechanics. The nose

steering servo passes

through the elongated

hexagon opening in the

radio tray.

FUEL TANKS

Each fuel tank is approximately 1.9 litres. These should be connected in parallel

via a T piece to the supplied hopper tank. The main tanks sit on two at plywood

plates, located just behind the fuselage split. They should be retained

by Velcro straps. We recommend you place some Velcro under the

tanks to ensure they do not slide around.

Before assembling the tanks ensure they are completely clean and

free from debris. Clean the sharp edge from around the opening, then

ush with alcohol cleaner

(water will take a very

long time to evaporate)

and place in a clean

environment while you

assemble the tank ttings.

Weighted clunks are

supplied, but an absorbent

type clunk (felt clunk) can

be substituted to ensure

continuous fuel

supply to the hopper

tank. Use a clunk line

suitable for immersion

in kerosene. We used

Tygon 4040 tube with

a 3.2mm bore and a

high ow felt clunk

(minimum internal hole

2.7mm)

Pressure check the tanks before installation, as access to the ttings

requires splitting the fuselage joint.

Before nal positioning of the fuel tanks, retract the main

undercarriage legs as the main wheels will contact the tanks if

positioned too far out. We placed Velcro on the mounting plate and

fuel tank base and then added a Velcro strap around the tank. This is

accessible through the main gear door openings.

The tanks should be mounted as far back on the plate as possible.

Note: It is important to keep both fuel lines from the tanks equal in

length, so they ll and empty as equally as possible. Thought should

be given to the position of the overow vent in the fuselage lower

surface. The sculptured shape allows an overow tting to be tted

close to the centre of the fuselage and still be clear of the ground in

the event of a gear up landing.

The kit includes a hopper tank, mount this or your favoured type

towards the back of the canopy opening. Use large bore tube

throughout the fuel system.

TAIL PIPE TUBE

The supplied tailpipe is suitable for use on turbines from 100-120N

thrust. It is a dual wall unit to keep fuselage temperatures down.

The rear is supported by the supplied cut away wooden ring, the cut

outs allow some airow through this area. This is screwed to the tail

cone former. The tail pipe outer wall is not xed to the former as it

must be free to expand and contract with temperature.

The tail pipe mounting straps at the front should be screwed to the

turbine mounting rails, or folded 90 degrees and xed to the former.

The turbine to tube gap should be provided by your chosen brand of

turbine, but 25-30mm is common. This is turbine tailcone back edge, to

the start of the steel tailpipe tube.

The bre glass tailcone assembly is screwed to the rear fuselage

former, there is space around the tailpipe tube to access the screws

using a long screwdriver.

The overall length of pipe supplied suits

smaller short turbines like the JetCat

P-100Rx. If you use a larger longer turbine

the pipe can be reduced in length to suit.

Use protective gloves and glasses before

cutting metal with any tools.

The tailpipe should nish with the outer

tube (cool wall) ush with the tail cone

back edges. The inner pipe must be

8-10mm short of the outer pipe to draw

air through the tailpipe

tube and cool it.

Final centring of the

turbine in the tail pipe

tube is critical for even

heat on the pipe wall.

Mount the turbine on

the wooden rails rst

and use the tail pipe

straps to adjust the

tailpipe height.

FINAL ASSEMBLY

Balance Point

Balance position 30mm in front of the turbine hatch lip, with the hopper full and

approximately 25% fuel in main tanks.

Control Throws

Control movements are measured elevator leading edge point. Ailerons at the tip,

rudder at the base.

Elevator neutral is the leading edge point 1.0mm above the side fuselage ridge

(slightest down elevator).

Settings of control movements

Normal ight condition:

Aileron: 14 mm each way, using 35% expo

Elevator: 55 mm up/30 mm down, using 40% expo

Rudder: 6-8 mm each way 0-15% expo

Take o ap: 8-10mm, with no elevator compensation.*

Low:

Aileron: 10 mm each way, using 25% expo

Elevator: 50 mm up/30 mm down, using 35-40% expo

Rudder: 6 mm each way 0-15% expo

We recommend tting a 3 axis gyro like the Powerbox iGyro 3e. To get the best

from this unit set the internal gyro gains with elevator and rudder at 80%, leave

the ailerons at 100%. If using a switched gain channel set the gain at 35% which

is safely below the setting we achieved of 40-45% Using the iGyro 3e the F-35

ies best in the heading hold position. Using a knob or slider you can set 35%

either side of neutral , so one way is rate mode and the opposite is heading hold.

Landings are best when ying in heading hold as the F-35 wants to land nose high

and the HH setting will naturally maintain this.

Before ying the F-35 it is critical the gear and gear doors work reliably. The door

angles are such that if one does not open a large yaw angle is likely to occur. The

lifting fuselage design becomes less ecient when the doors are open! Cycling

the gear before each ying session is strongly recommended.

FLYING

The F-35 is a modern design, where the full scale

aircraft is made super manoeuvrable using an

‘unstable’ balance point and computer control.

This is like a super gyro, which even the best

model gyro cannot replicate.

The model balance point is well forward of the full

scale position, this makes the model F-35 stable in

pitch, but means the balance is well forward of the

main wheel/rotation point. As a result the model

F-35 requires a reasonably long take o run at

higher than normal ground speeds to provide the

elevators enough leverage for rotation. We would

not recommend operating the F-35 from strips

shorter than 180m (540’)

We recommend test ying the F-35 on a calm day,

with smooth air as this will aid trimming and gyro

set up. Set your Tx timer for 7 ½-8 minutes, which

is a safe ight time for the test phase.

Takeo is best performed with the ailerons

drooped 6-7mm (at tip) to increase lift, holding at

least 50% of the available up elevator throughout

the take o roll, you can sense the nose wheel

starting to skip/lift and at this point pull for a

normal rotation. Immediately after take-o clear

the ap and y a steady circuit gear down - Flight

characteristics of the F-35 are markedly dierent

clean or dirty due to the lifting fuselage design

being aected when the gear doors are open. It is

best to retract the gear while ying straight and level at a reduced airspeed. Trim

the aeroplane in the dirty stage (gear down, but main doors closed) y another

circuit and clear the gear away ying past into wind, this allows you to observe the

gear goes cleanly.

Keep in mind the gear legs all retract forward into the airow, excess airspeed

will slow the cycle speed. Once the F-35 is clean, any further trimming should

be performed. The instruction manual airframe with JR servos ies well with the

Powerbox iGyro 3e set at 40% gain.

The F-35 ies typical multiple roll ghter manoeuvres very well, it looks especially

good in high G turns, but note the huge drag and requirement to add power with

applied G.

Landing is performed with the ailerons level. The airframe has plenty of drag

‘dirty’, so landing speeds are very low, with throttle being the primary height

control once the nose is pulled up on approach. Because of the airframe design

requiring a high alpha approach, landing with the iGyro in Heading hold mode

helps maintain the nose high sit.

The F-35 should be ‘own’ onto the ground, the lifting section fuselage requires

a positive angle of attack to produce lift. Throttle use is important for smooth

touchdowns, use power to bring the F-35 to the point of touchdown, always main

wheels rst. The wheel position means the nose quickly comes down, so landings

are very unlikely to bounce.

We hope you enjoy your F-35A model, if you have any questions regarding the

build or operation feel free to contact us at in[email protected]

This manual suits for next models

1

Table of contents

Other Der Jet Model Toy manuals

Popular Toy manuals by other brands

Fisher-Price

Fisher-Price POWER WHEELS P8812 Owner's manual & assembly instructions

Fisher-Price

Fisher-Price T5126 instruction sheet

Eduard

Eduard Weekend Edition Mirage IIICJ Assembly instructions

m2model

m2model Discovery micro Assembly instructions

Hasbro

Hasbro Transformers Toys Generations War for Cybertron: Earthrise Voyager WFC-E21 Decepticon Snapdragon Triple... manual

Betzold

Betzold 760491 instructions