Derale 20561 User manual

INSTALLATION INSTRUCTIONS

DIRECT FIT TRANSMISSION COOLER

PART # 20561

(Page 1)

Please read these instructions completely before beginning installation

KIT CONTENTS

QTY. DESCRIPTION

1 Cooler Assembly

1 Inner Frame J Bracket

1 Outer Frame C Bracket

1 Cooler Feed Hose

1 Cooler Return Hose Assembly

4 Double Hose Support

1 Thermostat Switch

1 In-Line Thermostat Housing

12ft Black Wire Loom

12ft RED Wire

QTY. DESCRIPTION

1 5/16”-18 x 5” Bolt

1 5/16”-18 x 1 1/4” Bolt

1 5/16”-18 x 1” Bolt

6 5/16” SAE Flat Washers

3 5/16”-18 Lock Nuts

3 1/4”-20 x 3/4” Bolts

3 1/4” SAE Flat Washers

3 1/4” Star Washers

3 1/4”-20 Lock Nuts

2 Stainless Hose Clamps

QTY. DESCRIPTION

4 Plastic Mounting Rods

4 Plastic Retainer Clips

8 1 x 1 Foam Pads

1 20 Amp Fuse Holder

1 Blue Wire Splice Connector

1 Blue Butt Connector

2 Blue Female Connector

1 Blue Ring Terminal

1 #10 Sheet Metal Screw

4 6” Zip Ties

12 4” Zip Ties

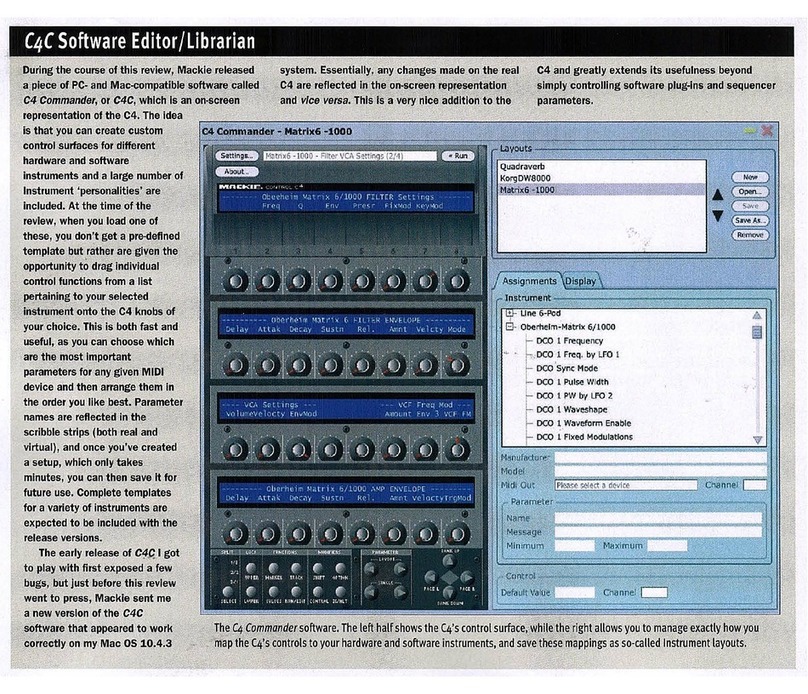

IDENTIFYING COMPONENTS

APPLICATIONS

1987-1996

Jeep

Wrangler YJ

1997-2006

Jeep

Wrangler TJ

Thermostat Switch (1)

Plastic

Mounting Rods (4)

Plastic Retainer

Clips (4) 1 x 1 Foam

Pads (8)

Inner Frame Bracket

(J-Bracket) (1)

Outer Frame Bracket

( -Bracket)C (1)

Cooler Assembly (1)

Cooler Feed Hose (1) Cooler Return

Hose Assembly (1)

Double Hose

Support (4)

In-Line Thermostat

Housing (1)

Black Wire Loom

(Convoluted Tubing) ( )

12ft

RED Wire (12ft)

5/16”-18 x 5” Bolt (1)

5/16”-18 x 1-1/4” Bolt (1)

5/16”-18 x 1” Bolt (1)

1/4”-20 x 3/4” Bolt (3)

5/16” SAE Flat Washers (6)

1/4” SAE Flat Washers (3)

1/4” Star Washers (3)

5/16”-18 Lock Nuts (3)

1/4”-20 Lock Nuts (3) 20Amp Fuse Holder (1)

Stainless

Hose Clamps (2)

Blue Wire Splice

Connector (1)

Blue Butt

Connector (1)

Blue Ring

Terminal (1) 6” Zip Ties (4)

4” Zip Ties (12)

#10 Sheet

Metal Screw (1)

Blue Female

Connector (2)

PRE-INSTALLATION

1. Using a flat table or workbench, lay the Cooler Assembly on a flat

surface (Electric Fan facing up as shown in Section: Identifying

Components).

1. Identify the In-line Thermostat Housing and the Thermostat Switch.

2. Using Loctite or a suitable sealant, carefully screw the Thermostat

Switch into the In-line Thermostat Housing turning the switch

clockwise. (Hand Tighten Only) See Diagram #1

DO NOT USE A WRENCH TO TIGHTEN THE

THERMOSTAT SWITCH; OVERTIGHTENING WILL

DAMAGE STUD AND VOID WARRANTY.

1. Identify the Inlet Port on the Cooler Assembly. When facing the ports

on the cooler it will be on the right side. See Diagram #2

2. Take the In-line Thermostat Housing and Thermostat assembly and

identify the female threads. Carefully screw the female side onto the

Inlet Port of the Cooler Assembly. See Diagram #2

3. Using a 7/8” wrench and a 1-1/16” backup wrench tighten

Thermostat Housing.

THERMOSTAT INSTALLATION

WARNING:

Diagram #1

Thermostat

Switch In-Line

Thermostat

Housing

CAUTION

Silver/Red

Label

Positive Wire: Black

Serial No.: 000000232446

AIRFLOW

Customer P/N:

Diagram #2

Inlet Port

Blue Female

Connector(s)

Red Wire

Black Wire Loom

(Red Wire Inside)

To Chassis

Ground

PRE-INSTALLATION (Continued)

IDENTIFYING THE POSITIVE & NEGATIVE WIRES ON THE ELECTRIC FAN

PRE-WIRING THE COOLER ASSEMBLY

1. Locate the Red/Silver label on the Electric Fan. See Diagram #3

2. This label identifies the airflow direction and the color of the Positive Fan wire. In this application the positive wire can be the

black wire so make sure to check label.

3. Once you have determined the color of the positive and negative wires continue with the following steps, Pre-wiring the

Cooler Assembly.

1. Take the 12 feet of RED Wire and 12 feet of Black Split Wire Loom supplied.

2. Install the RED wire into the Black Wire Loom

3. Using a Blue Butt Connector supplied, attach one end of the Blue Butt Connector to either end of the RED wire using the

proper crimping tool. See Diagram #4

4. Attach the Blue Female Connector to EITHER terminal on the Thermostat Switch. See Diagram #4

5. Using a Blue Butt Connector supplied, attach the Blue Female Connector to the Positive Wire on the Electric Fan. See

Diagram #4

6. Attach the Blue Female Connector to the remaining Thermostat Switch wire. See Diagram #4

Diagram #3 Diagram #4

Thermostat

Switch &

In-Line

Housing

(Page 2)

Frame Rail

Bolts, Washers,

Star Washers & Nuts

Outer Frame C Bracket Frame Rail

Drivetrain

Cooler

Assembly

Inner Frame J Bracket

Exhaust

Skid Plate Rear Tire

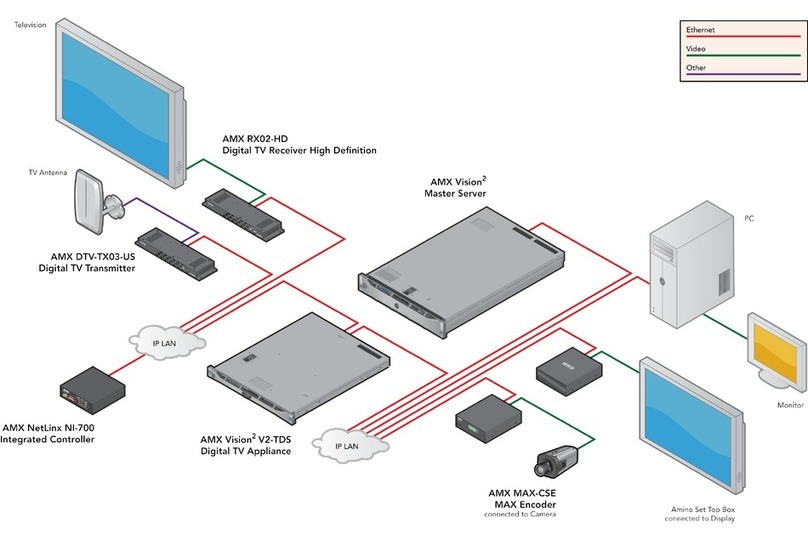

VEHICLE INSTALLATION

COOLER LOCATION

VEHICLE PREP

The Cooler Assembly mounts on the drivers

side frame between the rear trailing arm and the

transmission/transfer case skid plate. See

Diagram #5

1. Park vehicle on a solid, level surface and

allow vehicle to completely cool before

beginning installation.

2. Disconnect Positive lead on the vehicles

battery.

3. With the transmission in park, engage the

emergency brake. Carefully raise the

vehicle using the appropriate floor

jack/lifting device.

4. Properly place four jack stands, one for

each corner of the vehicle. Refer to the

vehicles owners manual for the proper

lifting locations.

Diagram #5

MOUNTING THE COOLER ASSEMBLY

1. Identify the Inner Frame J Bracket and the

Outer Frame C Bracket.

2. Identify the following hardware, (1) 5/16-18 x 5” Bolt, (1) 5/16-

18 x 1 1/4” Bolt, (1) 5/16-18 x 1” Bolt, (6) 5/16 SAE Flat

Washers, (3) 5/16-18 Lock Nuts

3. Take the Inner Frame J Bracket. The longer leg sets on the top

of the vehicles frame allowing the shorter leg to butt up against

the side of the frame just below the vehicles fuel/brake lines.

See Diagram #6

4. Take the Outer Frame C Bracket. This bracket slides from the

outside of the vehicles frame over the top of the Inner Frame

Bracket and around the vehicles frame. See Diagram #6

5. Using a 5/16” SAE Flat Washer, take the 5” bolt and install it

into the bottom hole closest to the vehicles frame sliding it all

the way up through the inside upper hole. Install a 5/16” SAE

Flat washer and 5/16-18 Lock nut on the top of the bracket

assembly and hand tighten. See Diagram #6

6. Using the 5/16-18 x 1” Bolt, SAE Washers, and 5/16-18 Lock

Nut, install this bolt in the upper outside hole and hand tighten.

7. Using the 5/16-18 x 1 1/4” Bolt, SAE Washers and 5/16-18

Lock Nut install this bolt in the bottom outside remaining hole

and hand tighten. See Diagram #6

The frame brackets can be moved forward or back

along the frame to assure clearance of the Cooler Assembly.

8. Identify the following hardware, (3) 1/4-20 x 3/4” Bolts, (3) 1/4”

SAE Flat Washers, (3) 1/4” Star Washers, (3) 1/4-20 Lock Nuts

9. Take the Cooler Assembly and hold it up to the Inner Frame

Bracket Assembly and Install 1/4-20 Bolts, Flat Washers, Star

Washers and Lock Nuts as shown in Diagram #7

Cooler Assembly has a built in pivot mounting

system. This will allow you to pivot the cooler to not only clear

all vehicles obstructions but to allow you to improve airflow on

vehicles with extra body clearance. Always adjust Cooler

Assembly with the maximum angle without touching any of the

vehicles components.

10. Once Cooler Assembly is in the desired location, be sure to go

back and tighten all mounting hardware.

Outer Frame C Bracket is designed to bend up against

the Inner Frame J Bracket causing a clamping effect.

NOTE:

IMPORTANT:

NOTE:

(Page 3)

Diagram #7

Frame Rail

Inner Frame

J Bracket

Outer Frame

C Bracket

5/16-18 x 1”

5/16-18

x 1-1/4”

5/16-18 x 5”

Factory Fuel/

Brake Lines

Diagram #6

Forward Mounting Back Mounting

Engine

Radiator

Remove Factory

Transmission Return Hose

Fan Shroud

Pulley

Engine

Radiator Cooler Feed Hose

Cooler Return Hose Assembly

Fan Shroud

Pulley

Plastic Hose Connector

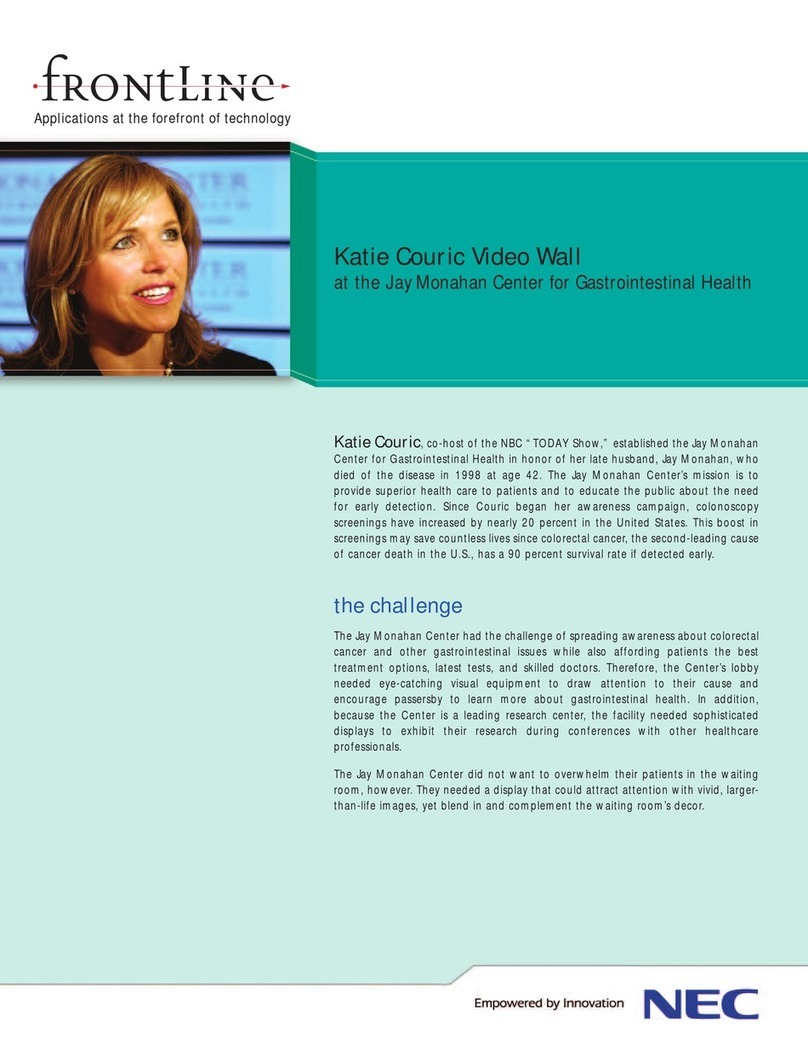

VEHICLE INSTALLATION (Continued)

COOLER HOSE INSTALLATION

1. Identify the Cooler Feed Hose and the Cooler Return Hose

Assembly. Both hoses have one end with a 90 degree fitting.

2. Take the Cooler Feed Hose and install the 90 degree fitting

onto the Inlet Port of the Cooler Assembly. See Diagram #8

3. Take the Cooler Return Hose and install the 90 degree fitting

onto the Outlet Port of the Cooler Assembly. See Diagram #8

4. Route both hoses together and along the inner frame rail of

the vehicle. See Diagram #8

5. Identify the following hardware, Plastic Mounting Rods, Plastic

Retainer Clips, Double Hose Support, 1 x 1 Foam Pads and

6” Zip Ties.

6. Using Diagram #9 as a reference, Insert a 1 x 1 Foam Pad

onto the Plastic Mounting Rod sliding the tip of the rod thru

the factory Fuel/Brake lines.

7. Install another 1 x 1 Foam Pad, Double Hose Support and

finally a Plastic Retainer Clip. See Diagram #9

8. Install the two hoses running along the frame into the Double

Hose Support.

9. Cinch the Plastic Retainer Clip until completely tight slightly

compressing the foam pads.

10. Cut excess mounting rods.

11. Use the 6” Zip Ties to secure hoses in areas making sure

hoses are away from Hot or moving obstructions.

12. Repeat steps 5-10 along the frame rail up to the front of the

vehicle.

13. Route hose up to the bottom of the vehicles radiator.

14. Disconnect the factory rubber transmission return hose from

both ends and remove. One end-radiator fitting, Other end-

Steel Transmission Line. See Diagram #10

15. Install a Hose Clamp supplied onto the Cooler Return Hose

Assembly. Connect the short hose coming off the 180 degree

fitting to the existing transmission line and tighten clamp. See

Diagram #11

16. Install a Hose Clamp supplied onto the Cooler Feed Hose.

Connect the hose onto the existing radiator fitting and tighten

clamp. See Diagram #11

17. Route Cooler Feed Hose to the bottom of the engine fan

shroud and install in plastic hose connector. See Diagram #11

(Page 4)

Factory Fuel/Brake

Line Brackets

Plastic

Mounting

Rod

Foam Pads

Double Hose

Support

Plastic Retainer

Clips

Frame

Rail

Diagram #9

Diagram #11

Diagram #10

Frame Rail

Cooler

Assembly

Cooler Return

Hose

Cooler Feed

Hose

Factory Fuel

Brake Line

Brackets

Black Wire

Loom

Double Hose

Support

Zip Tie

Outlet Port

Inlet Port

Diagram #8

Warning: Installation of accessories should only be undertaken by those with mechanical knowledge and are familiar with working on

vehicles. Always use eye protection (goggles, safety glasses or shield). Park the vehicle in a well lit area, on level ground and apply the

parking brake. Only work on a cold vehicle that has been sitting overnight, failure to do so will result in severe burns and injury. Before starting

the vehicle, make sure no tools or any other items are left under hood that could interfere with or be drawn into moving parts of the engine.

Failure to follow instructions can lead to severe damage and personal injury.

(Page 5)

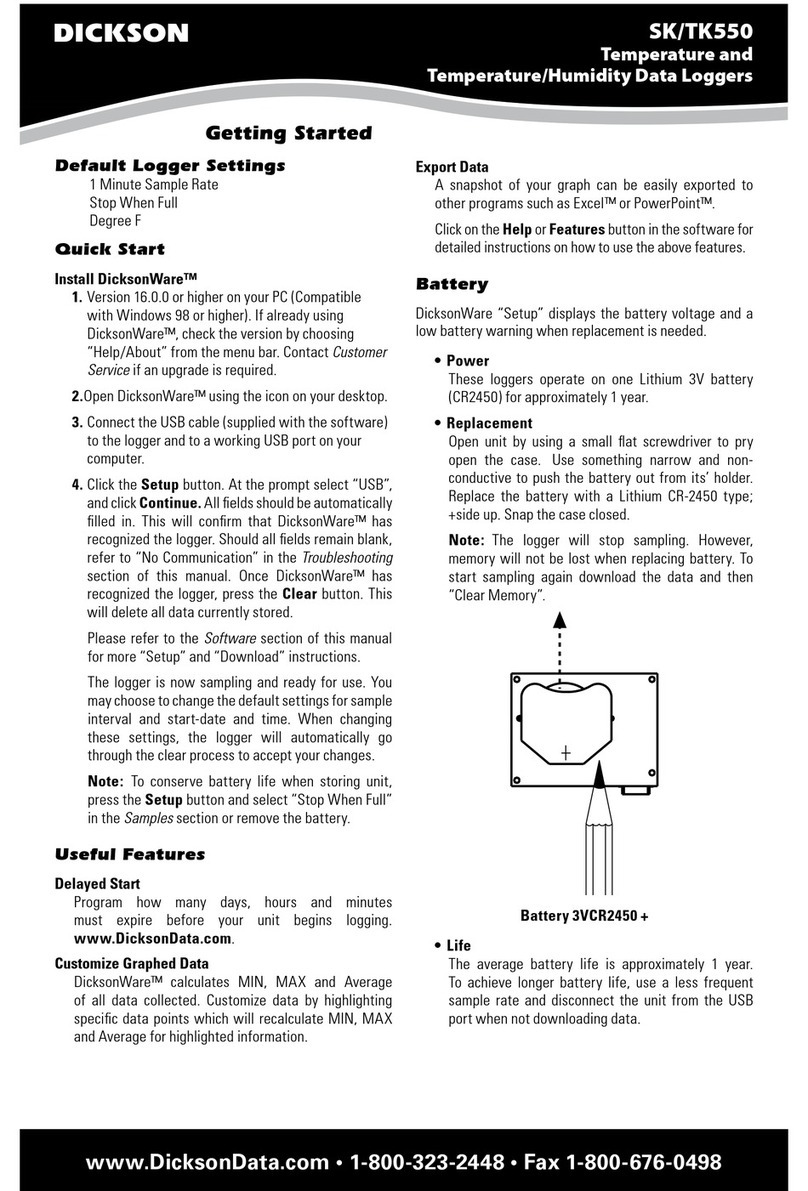

VEHICLE INSTALLATION (Continued)

WIRING THE ELECTRIC FAN

1. Locate the negative wire on the electric fan. Look in the area

of the Cooler Assembly along the vehicles frame or body and

locate a good chassis ground.

2. Identify the Blue Ring Terminal Supplied.

3. Use the proper crimping tool; install the Blue Ring Terminal

onto the Ground Wire of the electric fan.

4. Using the #10 Sheet Metal Screw supplied, install the

negative wire.

5. Route the Black Wire Loom with the Red wire inside along

the vehicles frame up to the vehicles firewall.

6. Using the 4” Zip Ties supplied attach the Black Wire Loom to

the vehicles fuel line underneath the new transmission cooler

hoses. See Diagram #12

7. The Red wire needs to be connected to the vehicles switched

ignition source. An ignition source can be found in a few

locations. 1. Under the dash 2. In the vehicles fuse box.

8. Using a test light identify a switched ignition source. Route Red wire to the ignition source.

9. Using the 20 amp fuse holder, Blue Butt Connector and Blue Wire Splice Connector supplied, install Red wire onto the

switched ignition wire.

Wiring fan directly to a 12V constant source will allow the fan to run after the vehicles ignition switch has been turned off.

It is recommended to always use a switched ignition source.

1. Reconnect the positive battery cable

2. Carefully remove the jack stands and lower vehicle onto a flat surface.

3. Before starting vehicle, add 1 quart of fluid into the transmission.

4. With the parking brake applied, start vehicle and shift transmission several times from reverse to drive and then back to

Park.

5. Check the transmission fluid level and add fluid as needed.

1. Inspect all hose connections for leaks.

2. Drive vehicle 1-2 blocks and then recheck fluid levels.

3. Let vehicle completely warm up and then check to make sure electric fan turns on. Please note that it may take some time

for cooler to warm up enough for electric fan to start. Driving vehicle several miles may be required.

Note:

AFTER INSTALLATION

SYSTEM CHECK

Frame Rail

Cooler

Assembly

Cooler Return

Hose

Cooler Feed

Hose

Factory Fuel

Brake Line

Brackets

Black Wire

Loom

Double Hose

Support

Zip Tie

Outlet Port

Inlet Port

Diagram #12

Learn more about transmission parts on our website.

Table of contents

Popular Other manuals by other brands

Dickson

Dickson SK550 Getting started

Painless Performance Products

Painless Performance Products 90542 installation instructions

Thermo King

Thermo King TouchPrint user manual

Samsung

Samsung XE800ZBA user manual

Nilfisk-Advance

Nilfisk-Advance Advance Retriever 2060 Service manual

WEG

WEG DWA-160 Assembly instructions