TABLE OF CONTENTS

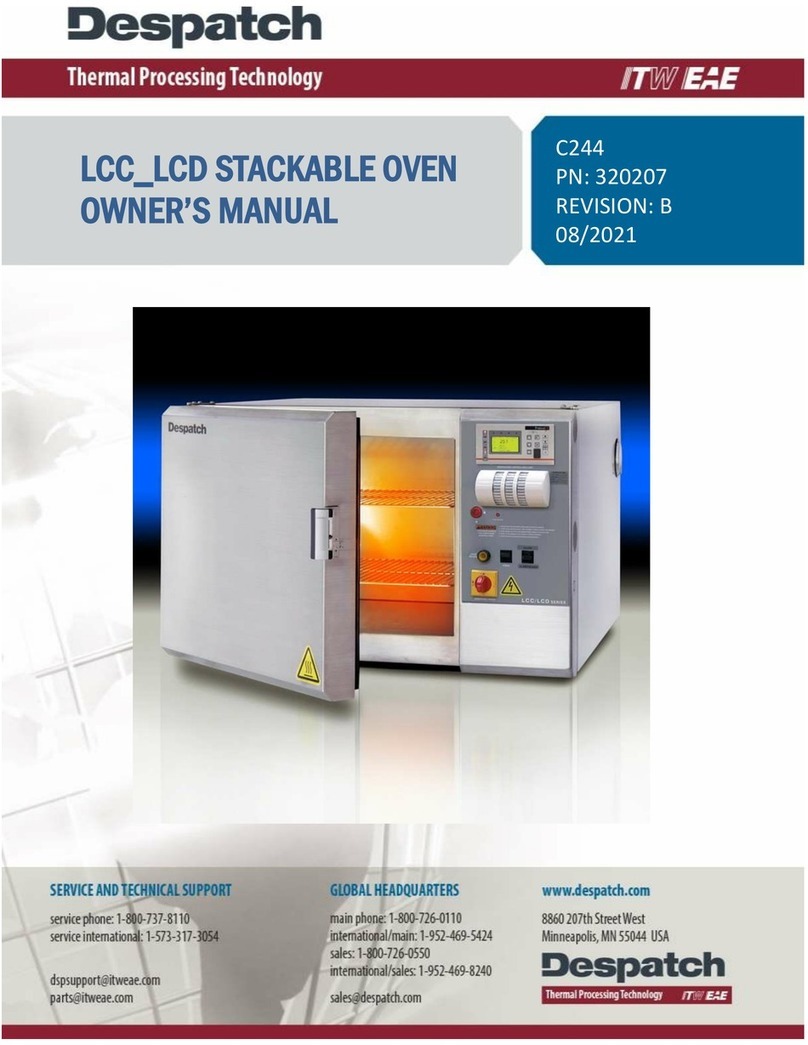

INTRODUCTION............................................................................................................. 1

Special Features ..................................................................................................1

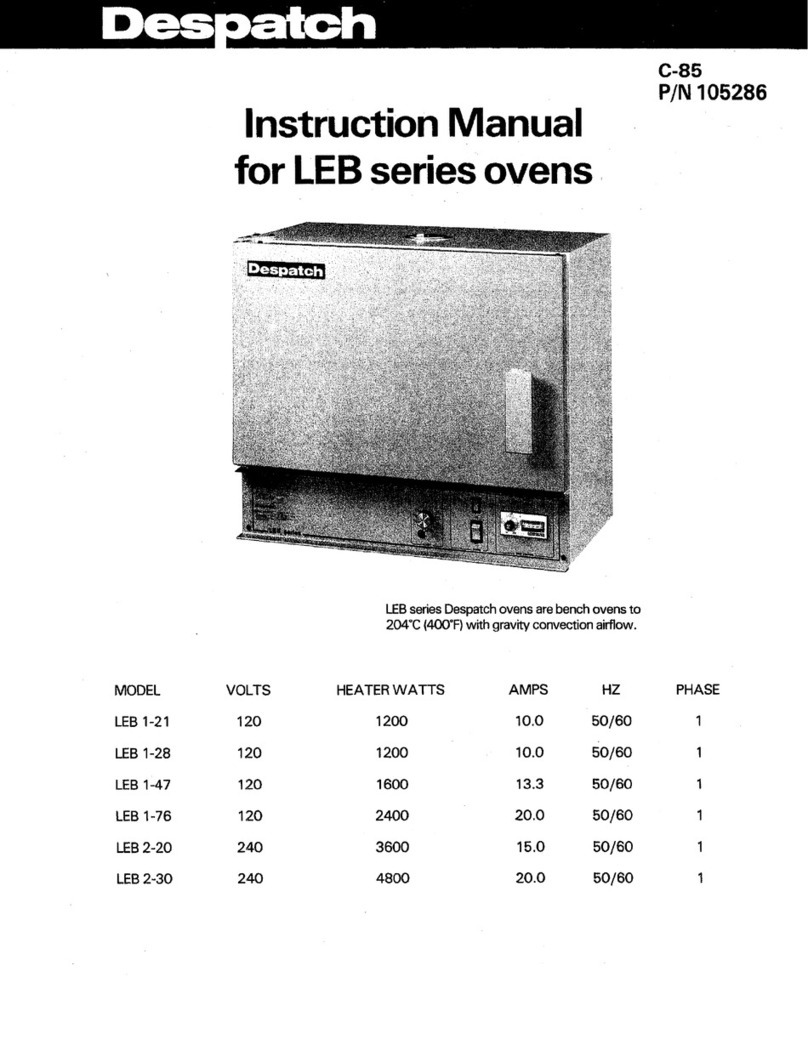

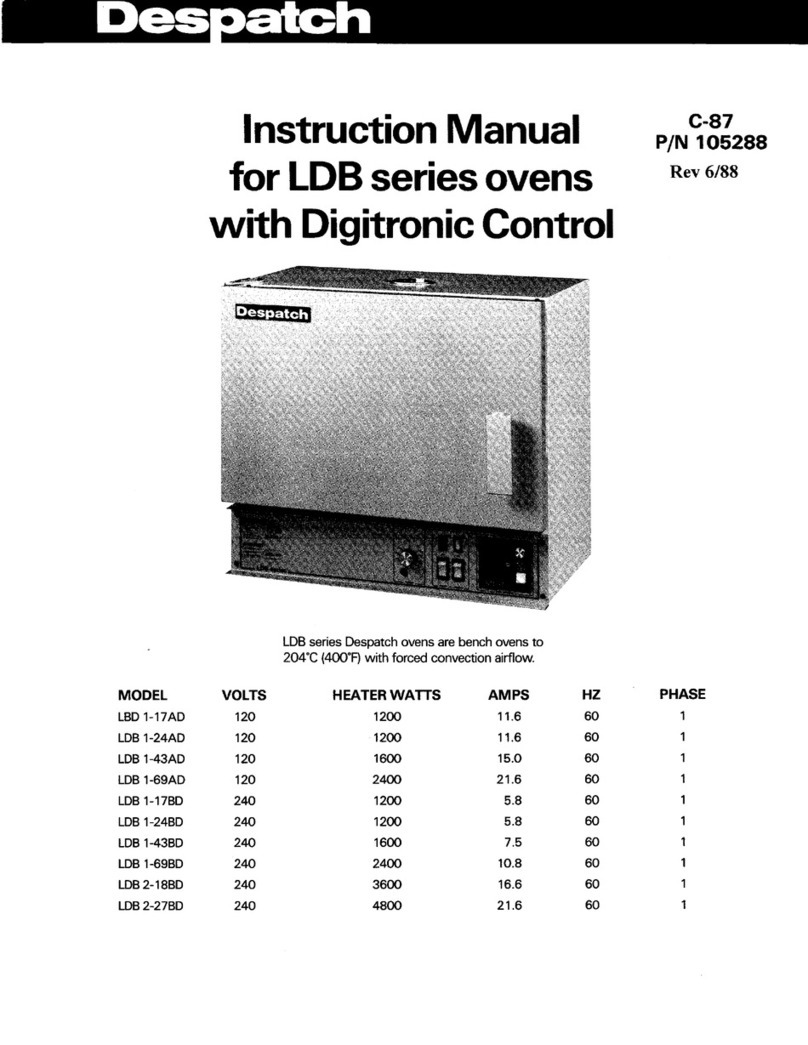

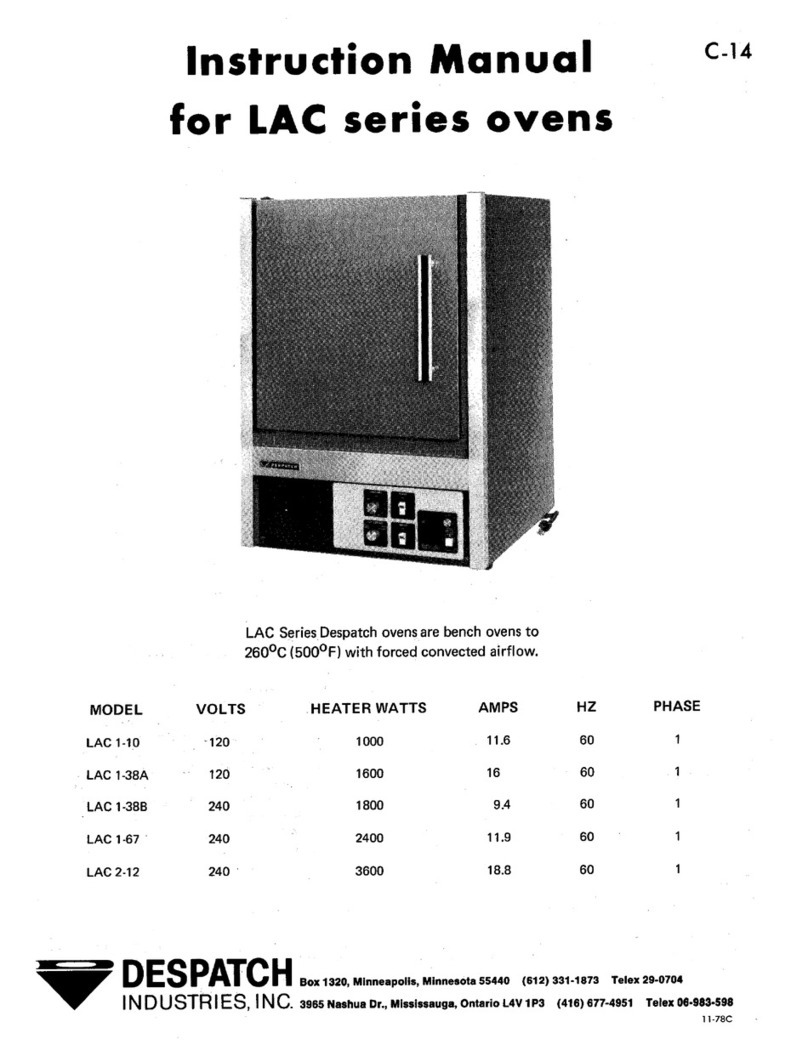

SPECIFICATIONS ..........................................................................................................2

Dimensions........................................................................................................... 2

Capacities............................................................................................................. 3

Power...................................................................................................................3

Temperature.........................................................................................................4

THEORY OF OPERATION.............................................................................................5

Construction ......................................................................................................... 6

Cooling.................................................................................................................6

Inert Atmosphere.................................................................................................. 6

HEPA Filters.........................................................................................................7

Definitions..................................................................................................7

Packaging and Shipping............................................................................7

Handling..................................................................................................... 8

HEPA Filter Validation Testing .................................................................. 8

D.O.P. Testing ................................................................................8

Class 100 Testing ...........................................................................8

Validation Testing ...........................................................................9

The Necessity of the Burn-off Process...................................................... 9

Filter Unit Replacement ............................................................................9

CONTROL Instrument........................................................................................ 10

HIGH LIMIT Instrument ...................................................................................... 10

Product High Limit Instrument .................................................................10

Oven High Limit Instrument ..................................................................... 11

INSTRUCTIONS ........................................................................................................... 12

Unpacking and Inspection.................................................................................. 12

Set-up.................................................................................................................13

HEPA Filter Installation............................................................................15

HEPA Filter Burn-off................................................................................16

OPERATING.................................................................................................................18

Loading the Oven............................................................................................... 18

Pre-Startup Checklist..........................................................................................19

Startup................................................................................................................19

Shut Down...............................................................................................22

Maintenance.......................................................................................................23

Checklist..................................................................................................23

Tests................................................................................................................... 24

Nitrogen Supply Check ...........................................................................24