Detcon 610-N4X-SA User manual

Model 610-N4X-SA

NEMA 4 X Control Enclosure

RESET/ACK

BUTTON

Model 610-N4X www.detcon.com

d e t c o n I n c .

Detcon Inc.

www.detcon.com Houston Texas

Gas Detection Control System

www.detcon.com Houston Texas

Detcon Inc.

Operator’s Installation and Instruction Manual

Covers 3 and 5 relay, Stainless and Fiberglass Enclosures

DETCON, Inc.

3200 Research Forest Dr.,

The Woodlands, Texas 77387

Ph.281.367.4100 / Fax 281.298.2868

www.detcon.com

July 15, 2005• Document #3001• Revision 0.1

Model 610-N4X-SA

This page left intentionally blank

610-N4X-SA Instruction Manual ii

Model 610-N4X-SA

Table of Contents

1.0 Introduction.............................................................................................................................................. 1

1.1 Description ........................................................................................................................................... 1

1.2 Specifications ....................................................................................................................................... 1

1.3 Relay Logic Description....................................................................................................................... 2

1.4 Front Panel Alarm Reset ...................................................................................................................... 2

2.0 Installation................................................................................................................................................ 3

2.1 Start Up ................................................................................................................................................ 6

3.0 Maintenance & Repair ............................................................................................................................ 6

4.0 Spare Parts List........................................................................................................................................ 8

5.0 Warranty .................................................................................................................................................. 8

Table of Figures

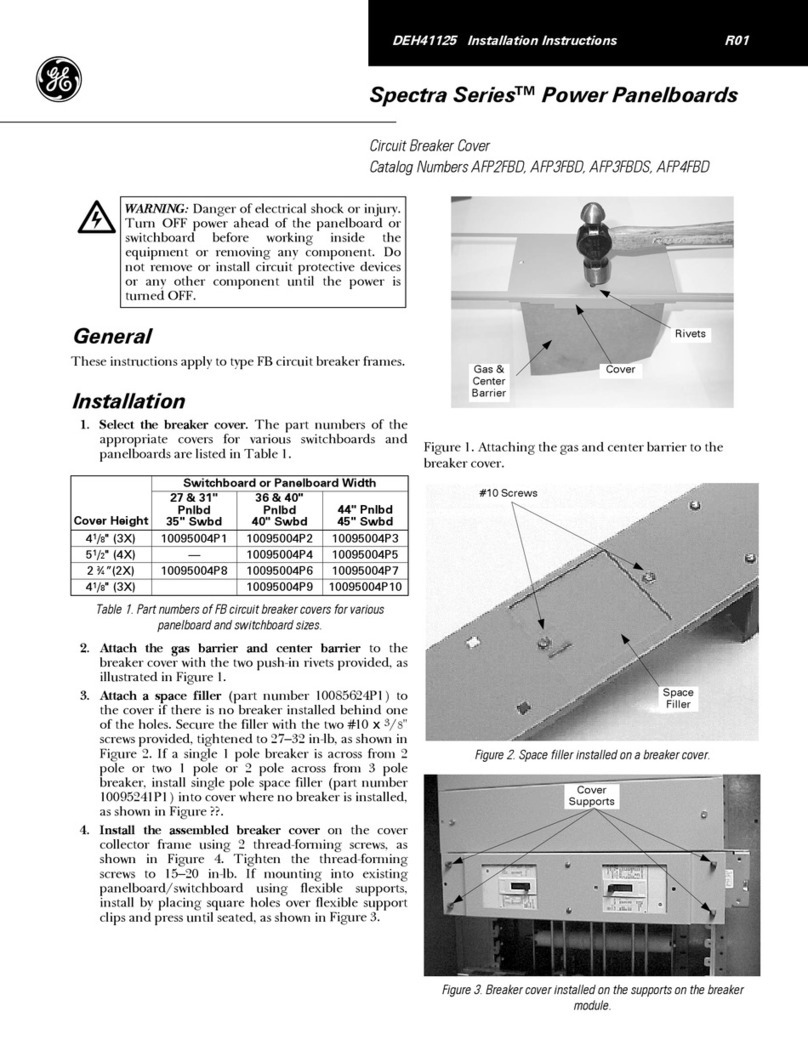

Figure 1 Mounting................................................................................................................................................ 3

Figure 2 Motherboard Schematic Wiring Diagram.............................................................................................. 4

Figure 3 Component Layout................................................................................................................................. 5

Figure 4 Alarm Wiring......................................................................................................................................... 5

Figure 5 Typical Dry Contact Connections.......................................................................................................... 6

Figure 6 Input Power Connections....................................................................................................................... 6

Figure 7 Backplane Configuration Jumpers......................................................................................................... 7

610-N4X-SA Instruction Manual iii

Model 610-N4X-SA

This page left intentionally blank

Shipping Address: 3200 A-1 Research Forest Dr., The Woodlands Texas 77381

Mailing Address: P.O. Box 8067, The Woodlands Texas 77387-8067

610-N4X-SA Instruction Manual iv

Model 610-N4X-SA

1.0 Introduction

Detcon Model 610-N4X-SA Gas Detection System consists of 3 major assemblies:

1. The 610-N4X-SA Fiberglass or Stainless Steel control enclosure.

2. The Model 10 single channel digital control modules.

3. The remote mount gas sensor assemblies.

The NEMA 4X control enclosure is detailed in this manual, the Model 10 digital control modules are detailed

in the Detcon Model 10 Operators Installation and Instruction Manual, and applicable sensor assemblies in

their corresponding Operators Installation and Instruction Manual.

1.1 Description

Detcon Model 610-N4X-SA control enclosure, along with Model 10 digital control modules, is designed to

serve as a host assembly for up to six remote mount gas detection sensor assemblies. The control enclosure is

rated NEMA 4X, which is by definition rain tight and therefore suitable for outdoor location in electrically

non-hazardous environments. The single channel modular design supports application flexibility wherein one

or two gas detection systems are configured dependent on the three or five alarm relay model. All control

modules are plug-in front panel accessible for easy maintenance and repair. The system is powered by

120VAC unless otherwise specified at the time of order.

Discrete output terminal strips located on the controller motherboard are provided for sensor terminations. The

4-20 mA outputs for remote recording devices and an RS-485 serial ModBus™ output are located on the

motherboard. The VDC power in, and remote alarm reset terminations are also provided on the Motherboard.

Din Rail mounted terminal block outputs are provided for two or four alarm and one fault relays.

Terminations for AC power-in are also provided on a Din Rail.

All Relays on the Model 10 digital control modules are configured as Latched, Normally Energized in No-

Alarm/No-Fault condition. These relays control the state of the Alarm Relays mounted on the motherboard.

Each Alarm Relay is a DPDT relay with one set of contacts for annunciator power and one set of dry contacts

for customer use. Three – 5Amp Fuse Blocks are provided for each alarm, providing the ability to connect up

to three annunciators for each alarm condition (including Fault).

1.2 Specifications

Electrical Classification

NEMA 4X

Dimensions

24''W x 24''H x 10 1/2''D

Capacity

6 single channels

Power Input

220VAC/117VAC/24VDC

Power Consumption

<5 watts per channel (includes gas sensor and control modules. Does not include annunciators.)

Outputs

Discrete Analog 4-20 mA DC

Serial RS-485 Modbus™

Discrete or zoned alarm relays (Alarm 2 Timer(s))

Discrete alarm relays K1, K3 (and if applicable K4)

Resistive load: 7.5A, 240 VAC; 10A, 30 VDC

610-N4X-SA Instruction Manual Rev. 0.1 Page 1 of 8

Model 610-N4X-SA

Inductive load: 5A, 240 VAC; 7.5A, 30 VDC

Max. operating current: 10A

Time delay relays K2 (and if applicable K5)

Resistive load: 10A, 240 VAC; 10A, 30 VDC

Inductive load: 7A, 240 VAC; 7.5A, 30 VDC

Max. operating current: 10A

Operating Temperature Range

-40°C to +175°C

Battery Backup (If applicable)

2ea. 12V 2.9Ah batteries in series; ½ hour minimum operating time

Warranty

One year

1.3 Relay Logic Description

Relay Assignments

The 610-N4X-SA comes with 3 or 5 Alarm Relays for use with one or two gases respectively. One or two of

these relays are timer relays (Dependent on one or two gas). (Refer to Figure 3) In this typical system the

Relays are:

K1 – Alarm 1 – H2S Low Relay

K2 – Alarm 2 – H2S High Time delay relay

K3 – Fault relay (Common Fault for three and five relay systems)

K4 – Alarm 1 – LEL Low Relay (If applicable)

K5 – Alarm 2 – LEL High Time delay Relay (If Applicable)

Alarm 1 – H2S/LEL Low

During Alarm 1 conditions, the Normally Energized coil(s) on the control modules will de-energize. This will

energize Alarm 1 Relay, K1 (or K4 if applicable), applying power to annunciators attached to alarm 1 (H2S or

LEL Low). Alarm 1 conditions can be Acknowledged and Reset via the RESET/ACK Switch on the front

panel of the unit.

Alarm 2 – H2S/LEL High

During Alarm 2 conditions the Normally Energized coil(s) on the control modules will de-energize. This will

energize the Alarm 2 Relay K2 (or K5 if applicable) applying power to annunciators attached to alarm 2 (H2S

or LEL High). The time delay relay controlling the annunciators will energize for a number of minutes

determined by the setting of the relay, and will then release. Alarm 2 conditions can be Acknowledged and

Reset via the RESET/ACK Switch on the front panel of the unit.

Fault Alarm

During Fault conditions, when any controller goes into fault, or upon loss of power, the Normally Energized

coil(s) on the control modules will de-energize. This will de-energize the Fault Relay K3, applying power to

the annunciators attached to the Fault relay.

1.4 Front Panel Alarm Reset

A Front Panel mounted, normally open, momentary switch is used to reset the alarms of all Model 10

controllers. The reset function is effective when the Model 10’s respective alarms have been programmed in

610-N4X-SA Instruction Manual Rev. 0.1 Page 2 of 8

Model 610-N4X-SA

the latching position and alarm conditions have passed. Each Model 10 controller also has its own discrete

alarm reset switch, which is discussed further in the Model 10 Instruction Manual.

2.0 Installation

1. Securely mount the 610-N4X-SA Enclosure in accordance with figure 1. Stainless Steel version

mounting footprint is the same as that shown.

22.75in [577.85mm]

26.8in [681.99mm]

Detcon Inc.

www.detcon.com

RESET/ACK

BUTTON

Houston Texas

Gas Detection Control System

www.detcon.com Houston Texas

Detcon Inc.

10.4in [263.91mm]

27.8in [707.39mm]

25.59in [649.94mm]

Mounting Holes R0.28in [R7.14mm]

Reset/Ack Push Button

ALM 2

ALM 1

FAULT

MODEL 10

ALARM

RESET

TEST

ALM 2

ALM 1

FAULT

MODEL 10

ALARM

RESET

TEST

ALM 2

ALM 1

FAULT

MODEL10

ALARM

RESET

TEST

ALM 2

ALM 1

FAULT

MODEL 10

ALARM

RESET

TEST

ALM 2

ALM 1

FAULT

MODEL 10

ALARM

RESET

TEST

ALM 2

ALM 1

FAULT

MODEL 10

ALARM

RESET

TEST

ALM 2

ALM 1

FAULT

ALARM

RESET

TEST

ALM 2

ALM 1

FAULT

ALARM

RESET

TEST

ALM 2

ALM 1

FAULT

ALARM

RESET

TEST

ALM 2

ALM 1

FAULT

ALARM

RESET

TEST

ALM 2

ALM 1

FAULT

ALARM

RESET

TEST

ALM 2

ALM 1

FAULT

ALARM

RESET

TEST

MODEL 10MODEL 10MODEL10MODEL 10MODEL 10MODEL 10

Model 610-N4X www.detcon.com

d e t c o n I n c .

Figure 1 Mounting

2. Refer to installation and wiring detail of remote mount sensor assemblies as detailed in the Sensor

Instruction Manual. Terminate field wiring from sensors on the 610-N4X-SA motherboard. Terminals

are labeled “Sensor” (mA, + and –, Figure 2).

3. If applicable, terminate the discrete 4-20 mA outputs to external device(s). Terminals are labeled “4-

20 Out” (+ and –, Figure 2).

4. If applicable, terminate the RS-485 serial output to external device(s). Terminals are labeled “RS-

485” (A+, B–, and Shield, Figure 2). If applicable, terminate RS-485 Shield to Earth Ground via the

jumper tab located to the left of the RS-485 terminals. Place the jumper on the bottom 2 contacts to tie

RS-485 shield to Earth Ground or place the jumper tab on the top two terminals for storage.

5. There are three fused 5Amp 120VAC outputs for every Alarm Relay and the Fault Relay. These Fuse

Block Terminals are located near the bottom center of the enclosure (Figure 3 and Figure 4). To the

left of the Fuse Blocks are as many Thru-blocks tied to Neutral. Based on the application and use of

relay contact outputs, all annunciators should be connected to these output terminals. All wiring

610-N4X-SA Instruction Manual Rev. 0.1 Page 3 of 8

Model 610-N4X-SA

terminations should be completed prior to application of power. Shut-in controls may be omitted until

system test is complete.

14

13

12

11

10

9

8

7

6

5

4

3

2

1

14

13

12

11

10

9

8

7

6

5

4

3

2

1

CH1 P12-P16

CH1

4-20mA

FAULT

VDC-

Alarm 2

Alarm 1

Fault

Out

+

-

COM

NC

ALM1

ALM2

GND

Shld

B(-)

A(+)

VDCVAC

GND

VDC

-

N

L1

-

+

+

RED +

BLK -

-

+

N

L1

Sensor

NO

COM

NO

NC

COM

NO

NC

mA

-

Typ. x 6

+

P11

Jumpers

Typical

CH2-CH6

GND-GRN

N-WHT

L1-BLK

PS VAC

Figure 2 Motherboard Schematic Wiring Diagram

610-N4X-SA Instruction Manual Rev. 0.1 Page 4 of 8

Model 610-N4X-SA

TB1

AC INPUT ALARM OUTPUTS

DRY CONTACTS

ALARM RELAYS K1 - K5

H2S LOW H2S HIGH FAULT LEL LOW LEL HIGH

21 22 23 30 32 33 34 35

24 25 26 27 28 29

36

37

38

45

46

47

48

49

50

39

40

41

42

43

44

7

8

9

10

16

17

18

19

20

5

6

1

2

3

11

12

13

14

15

4

ALM 2

ALM 1

FAULT

MODEL 10

ALARM

RESET

TEST

ALM 2

ALM 1

FAULT

MODEL 10

ALARM

RESET

TEST

ALM 2

ALM 1

FAULT

MODEL 10

ALARM

RESET

TEST

ALM 2

ALM 1

FAULT

MODEL 10

ALARM

RESET

TEST

ALM 2

ALM 1

FAULT

MODEL 10

ALARM

RESET

TEST

ALM 2

ALM 1

FAULT

MODEL 10

ALARM

RESET

TEST

K1 K2 K3

865431

27

865431

27

865431

27

865431

27

K5K4

865431

27

CH1-6:4-20mA

SENSORINPUTS

610 - Mother Board

A1

ALM 1

GND

ALM COIL

COMMON ALARMS

ALM 1

FAULT

VDC-

ALM 2

-

+

RS-485

ALM POWER

L1

N

+

-

N

GND

A(+)

B(-)

Shld

OUT

4-20 FAULT

-

NO

+

C

NC

NO

C

VDC IN

ALM RESET

L1

-

+

SENSORALM2

NC

NO

C

NC

mA

-

CH1

+

CH2 CH3 CH5CH4 CH6

VAC IN

P4

P5

P7

P7

P8

P9

P10

N

GND

L1

PS VAC

P3

PS DC

-

+P2

BRKR

-

+P1

Low Voltage

Cut-Off

TB2

TB3

Battery

Backup

Figure 3 Component Layout

AC INPUT ALARM OUTPUTS

H2S LOW H2S HIGH FAULT

DRY CONTACTS

123 4 567891011121314 15 16 17 18 19 20 21 22 23

TB1 - 3 Relay Unit

Neutral

Rtn

H2S LOW

H2S HIGH

FAULT

42

43

44

50

46

45

48

47

49

22

H2S LOW

ALARM OUTPUTS

TB1 - 5 Relay Unit

Neutral

Rtn

8

AC INPUT

3

2

1

4

6

5

7

19

13

12

11

10

9

15

14

18

17

16

20

21

40

H2S HIGH

DRY CONTACTS

LEL LOWH2S HIGH FAULT

24

23 26

25 28

27 29 30

LEL HIGH

H2S LOW

33

32 35

34

39

38

37

36

FAULT

LEL LOW

LEL HIGH

50

45

43

44

41

42

49

47

48

46

Figure 4 Alarm Wiring

610-N4X-SA Instruction Manual Rev. 0.1 Page 5 of 8

Model 610-N4X-SA

6. Each alarm has an associated set of dry contacts from the Alarm/Fault relay’s (Figure 3 and Figure 5).

These dry contact terminals consist of a Common relay connection through a terminal disconnect, and

the NC and NO Contacts via through terminals (Figure 4).

24 25 26

COM

NC

NO

Disconnect Terminal Block

Through Terminal Block

COM - Common

NC - Normally Closed

NO - Normally Open

Figure 5 Typical Dry Contact Connections

7. If applicable, connect a 24VDC source or standby battery to the terminal strip labeled “VDC IN” (+

and –) on the Motherboard (Figure 2).

8. Connect 117VAC input to the Circuit Breaker labeled “VAC IN” in the lower left of the enclosure

(Figure 3 and L1, N, EARTH in Figure 6). If applicable, connect 220VAC. The power supply will

accept both voltages.

9. Connect Earth Ground to Terminal TB1-1, and Neutral to terminal TB1-5 (Figure 6).

7

8

9

5

6

1

2

3

Ground / Earth

VAC Input / L1

Neutral / N

20Amp

Brkr

4

ON

Figure 6 Input Power Connections

2.1 Start Up

Upon completion of all field wiring: Apply power to the 610-N4X-SA by turning the 20Amp Circuit Breaker

ON. Note that each Model 10 controller digital display illuminates. Note; varying readings may occur during

sensor warm-up. A 10 second alarm delay will occur on power up. Refer to the applicable Sensor Instruction

Manual for additional sensor start-up details.

3.0 Maintenance & Repair

The Detcon Model 610-N4X-SA’s modular design allows for minimum ‘down-time’ during maintenance

and/or repair.

610-N4X-SA Instruction Manual Rev. 0.1 Page 6 of 8

Model 610-N4X-SA

Adding/Removing Control Modules

When adding or removing Control Modules it is imperative that the backplane jumpers are correctly removed

or added to insure proper operation of the fault alarm circuitry (see Figure 7). When removing a Control

Module, the jumpers for Fault (JPx-G, H, and I) directly to the left of the module being removed, must be

installed to allow proper signal flow and fault operation. When a Control Module is being added to the

configuration, the jumpers (JPx-G, H, and I) directly to the left of the module being installed, must be removed

to insure that the signal does not bypass the new module. Incorrect placement of jumpers will cause the fault

alarm circuit to operate incorrectly.

CH4CH3 CH5 CH6

Jumpers installed for Control

Modules not installed in unit.

JP9

A

B

C

D

E

F

G

H

I

JP8

A

B

C

D

E

F

G

H

I

JP7

A

B

C

D

E

F

G

H

I

JP6

A

B

C

D

E

F

G

H

I

Jumpers removed for

Control Modules 7 and 8.

Fault Jumper positions

G, H, and I.

1

2

3

4

5

6

7

9

9

10

11

12

13

14

1

2

3

4

5

6

7

9

9

10

11

12

13

14

1

2

3

4

5

6

7

9

9

10

11

12

13

14

1

2

3

4

5

6

7

9

9

10

11

12

13

14

FAULT Output to Fault Relay

Figure 7 Backplane Configuration Jumpers

Model 10 Control Modules

A Model 10 control module may be changed by simply loosening its mounting screw and sliding the module

out of its card cage. See the Model 10 Instruction Manual for more information on the Model 10 controller.

Circuit Breaker/Power Switch

If the circuit breaker should trip due to a high current or over voltage, the circuit breaker can be reset by

cycling the breaker ‘OFF’ and back ‘ON’. If the breaker trips again, a problem has occurred that will need to

be alleviated before power can be restored.

Replacement of the circuit breaker is accomplished by disconnecting power from the unit, disconnecting the

wires going to the breaker, and removing the breaker from the Din-Rail. Replace the breaker and reconnect

the wires to the new breaker.

Power Supply

Replacement of the power supply is accomplished by, removing the 10 screws that secure the 610-N4X-SA

face plate, disconnect the two power supply plugs from their respective headers, remove the three screws

holding the power supply bracket to the Motherboard. Remove the four screws that hold the power supply

bracket to the power supply; disconnect the wires from the power supply and reassembly with the new power

supply. Reference Figure 6 for wiring details.

610-N4X-SA Instruction Manual Rev. 0.1 Page 7 of 8

Model 610-N4X-SA

4.0 Spare Parts List

Part # Description

363-752400-000 110 watt, 24 VDC switcher power supply

0224 Gold plated jumper tab

305-300410-000 Din-Rail Mounted Fused Terminal

0302 5Amp 3AG Slow-Blo Fuse

3309 DPDT 8 Pin Octal 10A Relay

330-901100-024 DPDT Hermetically Sealed 8 Pin Octal 10A Relay

330-794500-124 DPDT 8 Pin Octal Timer Relay

226-910120 20 Amp Circuit Breaker

500-505000-000 Low Voltage Cut-off PCB (If applicable)

3423-2 12V 2.9Ah Battery (If applicable)

5.0 Warranty

Detcon Inc., as manufacturer, warrants under intended normal use each new Model 610-N4X-SA NEMA 4X

control enclosure to be free from defects in material and workmanship for a period of one year. The warranty

period begins from the date of shipment to the original purchaser and ends one year thereafter. All warranties

and service policies are FOB the Detcon Inc. facility located in The Woodlands, Texas.

610-N4X-SA Instruction Manual Rev. 0.1 Page 8 of 8

Table of contents

Popular Enclosure manuals by other brands

Lindy

Lindy 42901 user manual

CommScope

CommScope FOSC-500-AA Installation instruction

HP

HP STORAGEWORKS ALL-IN-ONE STORAGE SYSTEM reference guide

Icy Dock

Icy Dock ToughArmor MB991U3-1SB user manual

StarTech.com

StarTech.com S2510BPU337 user manual

Harmonic

Harmonic Spectrum MediaDirector Component replacement guide

OWC

OWC Express Quick installation guide

Kingston Technology

Kingston Technology StorCase Technology Data Express DE75i-A user guide

Lucent Technologies

Lucent Technologies J85504D-1 List 16 product manual

Addonics Technologies

Addonics Technologies External USB2.0 user guide

GE

GE Spectra Series AFP2FBD installation instructions

Kicker

Kicker SOLO-BARIC DS12L7 owner's manual