DeZurik ANSI/AWWA C540 User manual

DeZURIK ANSI/AWWA C540

HYDRAULIC CYLINDER

FOR G-SERIES ACTUATORS

Instruction

D10296

March 2017

DeZURIK

ANSI/AWWA C540 Hydrualic Cylinder for G-Series Actuators

D10296 © 2017 DeZURIK, Inc.

Instructions

These instructions provide information about ANSI/AWWA C540 Hydraulic Cylinders. They are for use

by personnel who are responsible for installation, operation and maintenance of ANSI/AWWA C540

Hydraulic Cylinders.

Safety Messages

All safety messages in the instructions are flagged with an exclamation symbol and the word Caution,

Warning or Danger. These messages indicate procedures that must be followed exactly to avoid

equipment damage, personal injury or death. Safety label(s) on the product indicate hazards that can

cause equipment damage, personal injury or death.

Safety label(s) on the product indicate hazards that can cause equipment damage, personal injury or

death. If a safety label becomes difficult to see or read, or if a label has been removed, please contact

DeZURIK for replacement label(s).

Personnel involved in the installation or maintenance of valves should be constantly

alert to potential emission of pipeline material and take appropriate safety precautions.

Always wear suitable protection when dealing with hazardous pipeline materials. Handle

valves, which have been removed from service with suitable protection for any potential

pipeline material in the valve.

Inspection

Your ANSI/AWWA C540 Hydraulic Cylinder has been packaged to provide protection during shipment,

however, it can be damaged in transport. Carefully inspect the unit for damage upon arrival and file a

claim with the carrier if damage is apparent.

Parts

Recommended spare parts are listed on the assembly drawing. These parts should be stocked to

minimize downtime.

Order parts from your DeZURIK sales representative, or directly from DeZURIK. When ordering parts,

please include the 7-digit part number and 4-digit revision number (example: 9999999R000) located on

the data plate attached to the valve assembly. Also include the part name, the assembly drawing

number, the balloon number and the quantity stated on the assembly drawing.

DeZURIK Service

DeZURIK service personnel are available to install, maintain and repair all DeZURIK products.

DeZURIK also offers customized training programs and consultation services.

For more information, contact your local DeZURIK sales representative or visit our website at

www.dezurik.com.

DeZURIK

ANSI/AWWA C540 Hydrualic Cylinder for G-Series Actuators

March 2017 Page 3 D10296

Table of Contents

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

4

Supply - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

4

Required Tools - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

4

Lubrication - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

4

Closed Position Adjustment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

4

Disassembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

4

Reassembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

5

DeZURIK

ANSI/AWWA C540 Hydrualic Cylinder for G-Series Actuators

D10296 Page 4March 2017

Description

The ANSI/AWWA C540 Hydraulic Cylinder for use with G-Series Actuators is intended for water

hydraulic service. This cylinder can be used with Pumpcheck accessories.

Supply

The maximum cylinder supply pressure is 150 psi. The supply medium is clean water.

Required Tools

The cylinder is assembled with SAE fasteners. Tools required for adjustment and disassembly include

a set of combination wrenches, a flat-tipped screwdriver and a small hammer.

This cylinder is a pressure vessel. Supply pressure must be disconnected from the

cylinder and the cylinder completely relieved of pressure before disassembling the

cylinder. Failure to release pressure may result in personal injury and/ or damage to

other equipment.

Lubrication

If the cylinder is disassembled, lubricate the cylinder wall, piston seal, U-cup and U-cup groove using

one of these lubricants.

•Dow Corning Molykote No. 44 (recommended)

•Shell Retinax AM (alternate)

•Shell Lithall MDS (alternate)

Closed Position Adjustment

The set screw in the end of the cylinder is used to limit the cylinder stroke.

1. Turn the set screw in the end of the cylinder counterclockwise about five turns.

2. Close the valve. See Valve Instructions to determine closed position.

3. Turn the set screw clockwise until you feel resistance as it contacts the piston rod.

4. Lock the set screw in place with the nut. Be sure the thread seal is positioned properly.

Disassembly

Follow the steps below to disassemble the cylinder.

•Servicing the actuator while the pipeline is under pressure can cause personal injury or

equipment damage. Relieve pipeline pressure before servicing the actuator.

•Accidental operation of power actuator can cause personal injury or equipment

damage. Disconnect and lock out power to actuator before servicing.

DeZURIK

ANSI/AWWA C540 Hydrualic Cylinder for G-Series Actuators

March 2017 Page 5 D10296

Disassembly (continued)

1. Shut off the water pressure supply to the cylinder.

2. If the actuator is powered, disconnect and lock out the pneumatic, hydraulic, or electrical power

to prevent accidental operation of the actuator.

3. Relieve pressure in the cylinder.

4. Disconnect the cylinder tubing.

5. Remove nuts and washers from the tie rods, and remove cylinder cap.

6. Rotate the cylinder tube while pulling it from the piston.

7. Remove the nut on the piston rod.

8. Remove the piston.

9. Remove extension cap from other end of gear box housing.

10. Remove nuts and spring washers from the rack rod.

11. Pull the piston rod, complete with rack rod, from the cylinder head.

12. Take out the four screws and separate the cylinder head from the actuator housing.

13. Remove the seal in the cylinder head.

Reassembly

1. Install the piston rod seal as shown in Figure 1.

Figure 1—Piston Rod Seal Placement

a. Inspect the scraper in the isolation plate and replace if damaged.

b. Be sure vent near isolation plate is clear.

c. Clean groove in cylinder head and lubricate all parts.

d. Insert U-cup in the groove. Make sure the groove in the U-cup faces the piston end of

the cylinder head.

DeZURIK

ANSI/AWWA C540 Hydrualic Cylinder for G-Series Actuators

D10296 Page 6March 2017

Reassembly (continued)

2. Attach the isolation plate, then the cylinder head to the actuator. See Figure 2.

Figure 2—Cylinder Parts Location

3. Carefully install the rack rod and piston rod.

4. Eccentric valves: Install the spacer, spring washers and nuts on the rack rod. See Table B and

Figure 4 for spring washer arrangement.

All other valves: Install the jam nuts on the rack rod.

5. Eccentric valves: Tighten the nut until the spring washers are completely compressed, and then

back off until they return to their normal uncompressed shape.

All other valves: Tighten the first nut.

6. Tighten the second nut.

7. Install the extension cap.

8. Put the piston on the piston rod and install the nut.

9. Remove the piston seal and its O-ring. Clean the O-ring, seal and groove. Lubricate the O-ring and

seal and install them. Use new O-ring and seal if necessary.

10. Lubricate the cylinder tube.

11. Carefully slide the cylinder over the piston. The seal and the cylinder must be well lubricated.

12. On 6-inch and larger cylinders, remove one or two of the tie rods.

DeZURIK

ANSI/AWWA C540 Hydrualic Cylinder for G-Series Actuators

March 2017 Page 7 D10296

Reassembly (continued)

13. Start the tube at a 45-degree angle and rotate the tube onto the piston. See Figure 3.

Figure 3—Installing Cylinder Tube

14. Clean the O-ring groove in the cylinder cap.

15. Lubricate and install the O-ring in the cylinder cap. Use a new O-ring if necessary.

16. Assemble the cylinder cap, lock washers and nuts. Tighten tie rod nuts to the torque specified in

Table A.

Table A: Tie Rod Nut Torques

Cylinder Size Torque

(ft lbs) (cm/kg) (Nm)

4” 12 175 16

6” & 8”

16

225

22

10” &12” 20 275 27

14” 38 526 52

17. If the actuator is a powered actuator, reconnect power to the actuator.

DeZURIK

ANSI/AWWA C540 Hydrualic Cylinder for G-Series Actuators

D10296 Page 8March 2017

Reassembly (continued)

Table B: Rack Rod Spring Washer Arrangement

Valve Size

Actuator Size

Direct Pressure

Reverse Pressure

4

5

6

All

All

All

A

B

B

A

B

B

8 G6

G12

B

A

B

A

10 G6

G12 B

A B

B

12 G6

G12

G16

B

B

A

B

B

A

14 G12

G16 B

A B

A

16

18

20

All

All

All

B

B

B

B

B

B

24 G16-C8

G16-C10

G16-C12

B

B

B

C

B

C

30 G16-C8

G16-C10

G16-C12

C

B

B

C

B

C

Reverse Pressure: When the higher-pressure is at the seat end.

Direct Pressure: When the higher-pressure is opposite the seat.

Other manuals for ANSI/AWWA C540

1

Table of contents

Other DeZurik Plumbing Product manuals

Popular Plumbing Product manuals by other brands

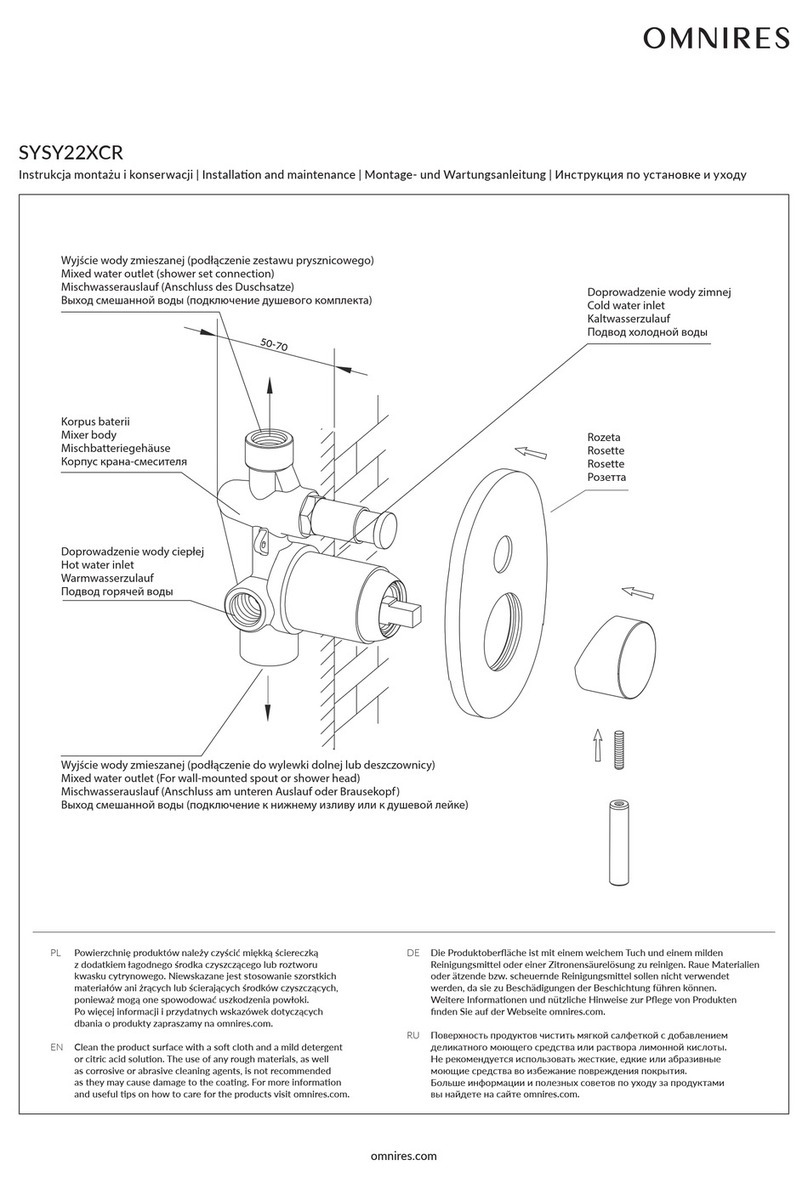

Omnires

Omnires SYSY22XCR Installation and Maintenance

Crosswater

Crosswater KL322DC installation instructions

Teuco

Teuco P400 Assembly instructions

flamco

flamco Flamcovent Clean Installation and operating instructions

Hans Grohe

Hans Grohe Croma 1jet Series Assembly instructions

Villeroy & Boch

Villeroy & Boch ProDetect 2 installation instructions

spalina

spalina INDRA WAVE instructions

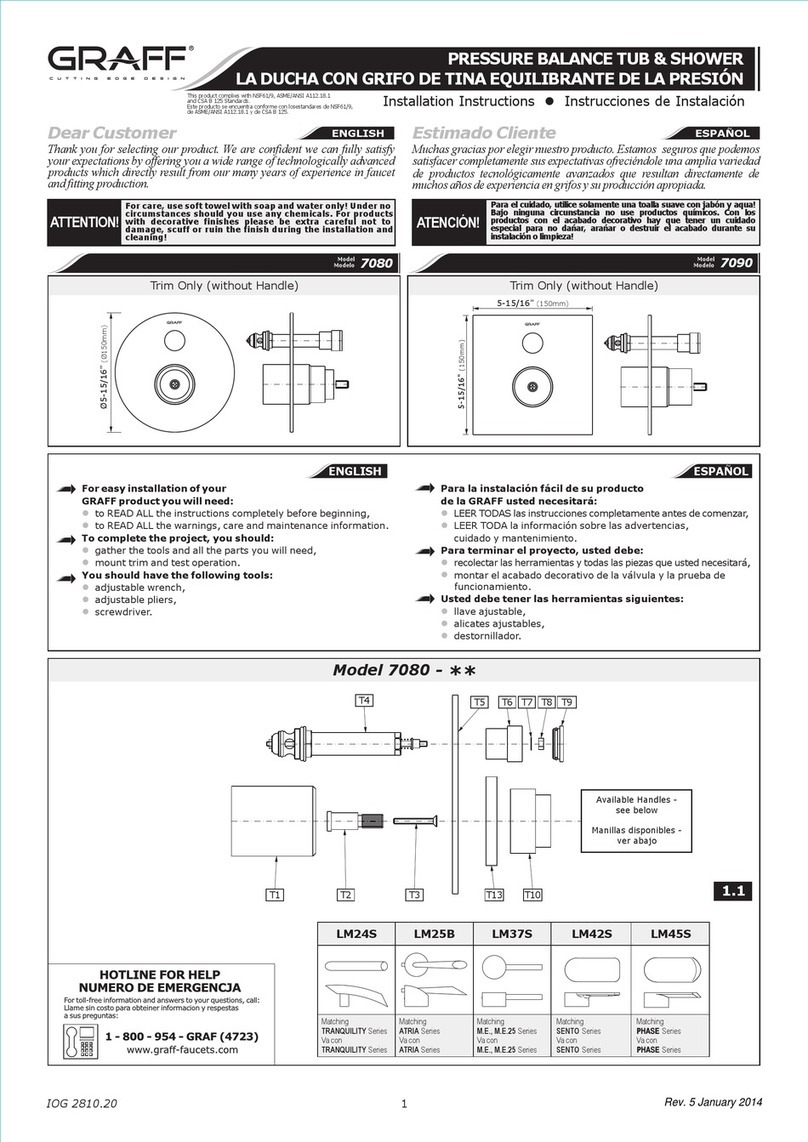

Graff

Graff 7090 installation instructions

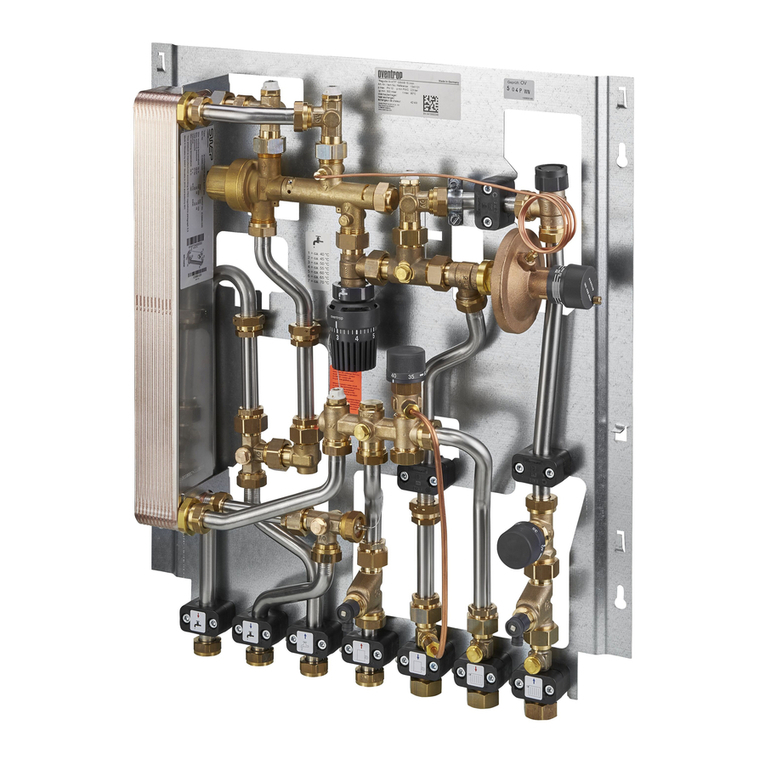

oventrop

oventrop Regudis W GSWB Installation and operating instructions

Glacier bay

Glacier bay 65416W-6004 Installation and care guide

Axor

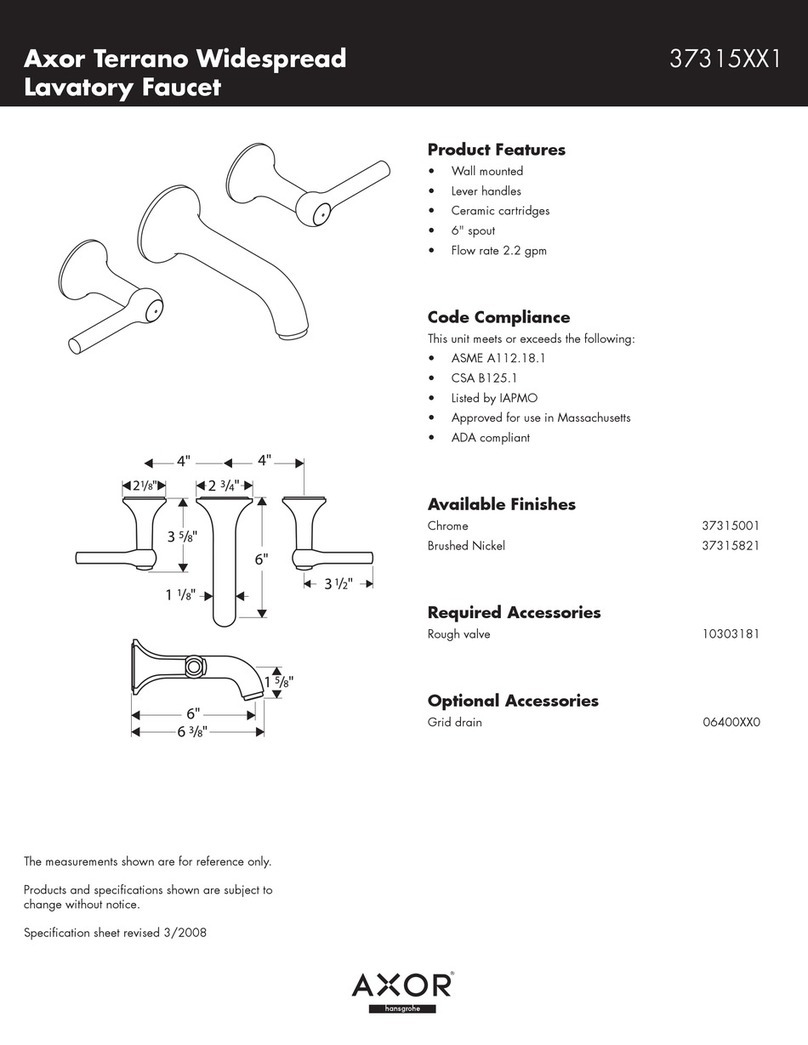

Axor Brushed Nickel 37315821 Specification sheet

Luxier

Luxier BSH03-SB quick start guide