DHP 1 Horsepower User manual

Dansereau

Compressor

Owners Manual

1 Horsepower

Manufactured at: 250 E. Harrison Street, Corona 92879

USA Phone: (800) 423-5657

International Phone: (909) 549-1400

Fax: (909) 549-1411

Website: WWW.DHPDENTAL.COM

DHP Air Compressor - General Information - Section 1

Section 1 - General Information

Section 2 - Special Services

Section 3 - Terms and Conditions

Section 4 - Pre-installation Guide and Floor Plan

Section 5 - Dental Air Compressor Specifications

Section 6 - Unpacking and Installation

Section 7- Maintenance

Section 8 - Trouble Shooting Guide

World Wide Toll-Free Access

DHP has instituted a toll free telephone service in the United States, Canada and Mexico. Our

telefax line (909) 549-1411 is available 24 hours a day.

Toll Free Phone:

U.S.A. and Puerto Rico 1-800-423-5657

Canada 1-800-423-5657

Mexico 095-800-423-5657

Customer Service

DHPcustomerservicein-housetechnicianshaveaminimumof10yearsexperienceinthemanu-

facturing, installation and maintenance of the DHP Dental Air Compressor.

Approved Testing Laboratories

ETL Testing Laboratories File Number (ETL) - 82327

Canadian Standards Association File Number (CSA) - 82327

Payment Procedures

All DHP products are prepaid. Dansereau Health Products accepts personal checks issued in

U.S.A. funds, Mastercard and Visa credit cards. Financing terms are also available.

Shipping Procedures

All DHP Dental Air Compressors are shipped via common carrier (truck line). Freight is not

included in the cost of the DHP Dental Air Compressor.

DHP Air Compressor - Pre-installation Guide-Section 4

LOCATION

The DHP Dental Air Compressor should be installed in a well ventilated area. The DHP Dental

Air Compressor is air cooled and without proper air circulation the lifespan of the Dental Air

Compressor could be shortened significantly. The sound level of the Dental Air Compressor,

when in operation, should be considered when locating an area within the dental office for the

Dental Air Compressor. It is strongly recommended that insulation should be added to the walls

adjacent to the Dental Air Compressor. The ambient temperature in the dental office equipment

room should never exceed 40 degrees Fahrenheit minimum and 100 degrees Fahrenheit maxi-

mum. The dental office equipment room will require a minimum of 5 air changes per hour which

can be met with a 50 CFM vent fan in a 5' x 5' x 9' room. The DHP Dental Air Compressor can

be located outside of the dental office, however it is extremely important the air compressor be

covered from the elements as well as have the proper ventilation as previously mentioned. It is

strongly recommended that visual inspections of the air compressor be done on a weekly basis.

When locating the air compressor outside of the dental office serious consideration should be

taken to secure the dental air compressor to discourage theft and or vandalism.

The above Dental Air Compressor is a typical installation. The recommended Dental

Equipment Room design is covered in Section 9 of this manual.

It should be noted that local building codes will supersede any recommended installation

guidelines in this manual.

DHP Air Compressor Pre-installation Guide (Cont.)

ELECTRICAL REQUIREMENTS - LINE VOLTAGE - Single phase 120v/60hz or 240/60hz elec-

tricity is required for proper operation of the DHP Dental Air Compressor. All electrical sources

to the DHP Dental Air Compressors MUST BE PROPERLY GROUNDED! All DHP Dental Air

Compressors are available in either 120 volt or 240 volt, however the DHP one Horsepower

model is standard 120 volt and the DHP two Horsepower model is standard 240 volt. The DHP

one horsepower model is available in 240 volt upon written request - verbal requests will not be

accepted.

ELECTRICALCIRCUIT -All DHPDental AirCompressors requirea dedicated20 ampservice.

It is acceptable to use a 120 volt or 240 volt switch (depending upon which of the DHP models

areordered)toactivatethe DentalAirCompressor, howeveritis stronglyrecommendedthatthe

electricalpanel fusebreakernotbeusedtoactivate theDental AirCompressor asit willdeterio-

rate the fuse and significantly shorten the lifespan of the fuse.

PLUMBING REQUIREMENTS

AIR LINE - A 1/2" copper male pipe thread fitting on the utility closet end of the air line to the

operatories is required to attach the Dental Air Compressor supply line to.

NOTE:The DHPDental AirCompressor regeneratingdesiccant dryingsystem willexpel amini-

mal amount of moisture and it is recommended that the 1/4" poly - tubing be situated in either a

floor sink, drain or small bucket that can be emptied as needed.

Dental Air Compressor Specifications

Total Horsepower - 1

Total air delivery at 80 - 100 PSI - 4.7 CFM

Air Tank Capacity - 11 gallons

Sound level - 68db

Maximum Users - 2

Weight and Dimensions

Weight - 200 lbs. / 240 lbs. w/pallet

Height - 31 inches

Width - 19 inches

Length - 23 inches

Electrical Requirements

Voltage requirements:

1 horsepower - 120 volts/15 amp dedicated circuit

2 horsepower - 240 volts/10 amp dedicated circuit

Recommended:

Wire Size - 12 AWG

Circuit Breaker - 20 Amp

DHP Air Compressor Unpacking and Installation - Section 6

The DHP one horsepower dental air compressor weighs 200 lbs..

The DHP two horsepower dental air compressor weighs 285 lbs..

1) Open the top of the Dental Air Compressor crate with a knife, remove all the internal packing

material and Dental Air Compressor accessories package and set aside - DO NOT DISCARD

ANY OF THE PACKING MATERIAL OR PACKAGING PRODUCTS UNTIL THE DENTAL AIR

COMPRESSOR HAS BEEN COMPLETELY INSTALLED.

2) With Dental Air Compressor crate on the floor use a knife to open the box. Do not attempt

to lift the Dental Air Compressor simply dislodge the cardboard crate from the wooden pallet.

3) With the cardboard crate removed from the wooden pallet locate the four bolts attaching the

Dental Air Compressor to the wooden pallet and using a 7/16" open wrench remove the bolts

from the pallet.

4) Carefully slide the Dental Air Compressor off the wooden pallet and situate it in the desired

location.

5) Locate the Dental Air Compressor accessories plastic bag housing the four rubber isolation

feet and attach them to the Dental Air Compressor. See diagram below.

DHP Air Compressor Unpacking and Installation (cont.)

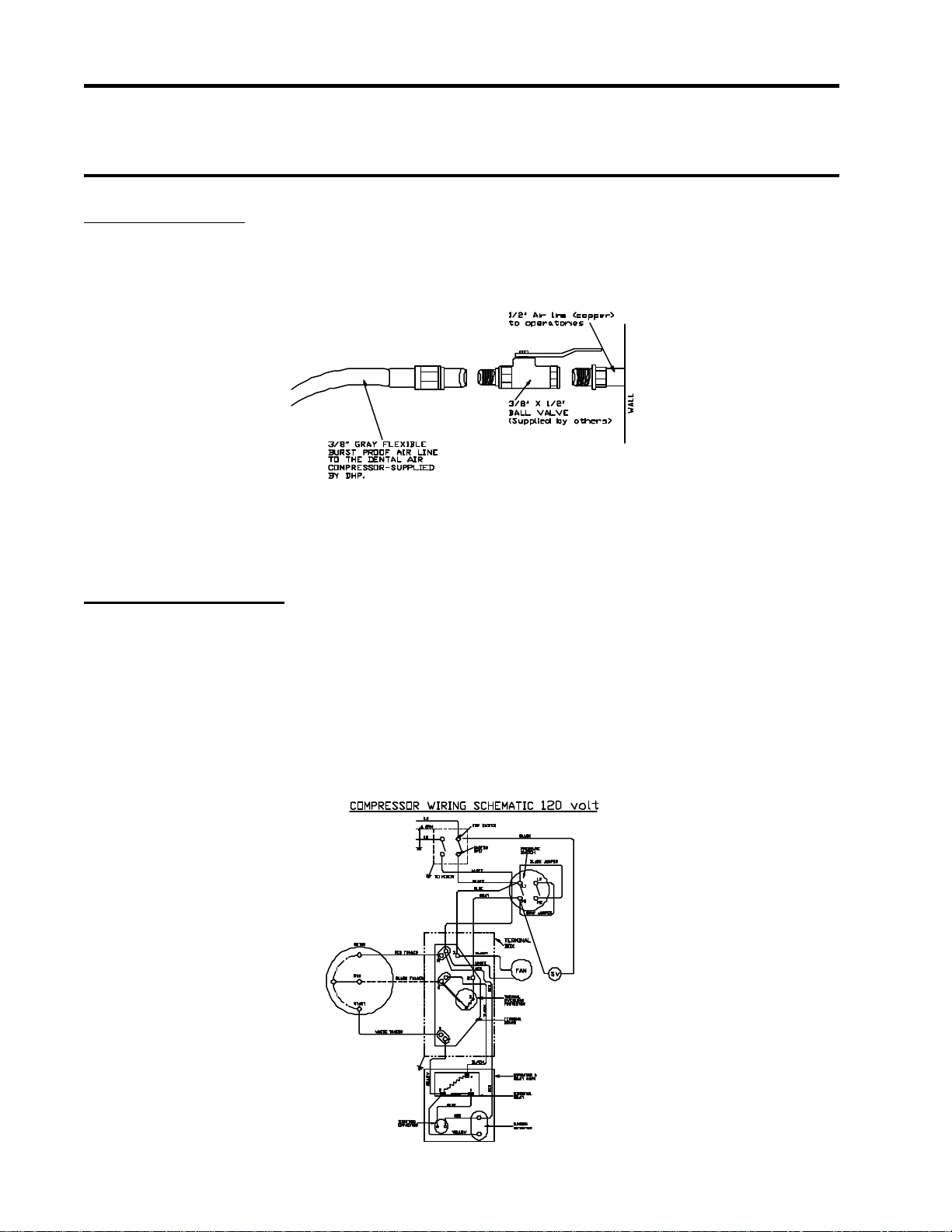

Air Line Connection

6) Locate the Gray burst proof 3/8" tubing (attached to the exhaust/supply side of the Dental Air

Compressor) and attach it to the air line supplying air to the operatories. See diagram below.

IT IS STRONGLY RECOMMENDED THAT A LICENSED ELECTRICIAN COMPLETE

THE WIRING INSTALLATION OF ANY DHP DENTAL AIR COMPRESSOR

Electrical Connections

1) TheDHP onehorsepowerDentalAirCompressorisshipped asa standard120 volts(unless

it is specified in writing a 240 volt model is required). The DHP two horsepower Dental Air

Compressor is shipped as a standard 240 volts (the two horsepower Dental Air Compressor is

available in 240 volt only).

2) A wiring schematic for the DHP one horsepower is shown below and two horsepower Dental

Air Compressor is shown on the following page as well as on the inside of the DHP Dental Air

Compressor's control box.

DHP Air Compressor Maintenance - Section 7

The DHP Dental Air Compressors are all reduced maintenance products. They are specifically

engineered for minimal maintenance based on standard projected use. Excessive use of the

DHPDentalAirCompressorwillrequiremorescheduledmaintenancethanthestandardrecom-

mended maintenance listed below.

Daily Maintenance-Dental Air Compressor

1)TheDHPDentalAirCompressordoesnotrequireanydailymaintenance,however,itisstrongly

recommended that periodic visual inspections as well as listening for any ' unusual ' noises be

done on a daily basis. The DHP Dental Air Compressor should operate (cycle on) when in use.

Iftheaircompressorcyclesonwhendentisthasnotusedanyair outofthestoragetanktheirmay

be an air leak in the air system. If you notice any ' unusual ' noises or cycling problems contact

DHP customer service immediately.

Weekly Maintenance-Dental Air Compressor

1) The DHP Dental Air Compressor does not require any weekly maintenance, however it is

strongly recommended that periodic visual inspections as well as listening for any 'unusual '

noises be done on a weekly basis.

Monthly Maintenance-Dental Air Compressor

1) Visually inspect the oil level and add oil as required. See Diagram below

DO NOT OVER FILL THE OIL IT WILL CAUSE SERIOUS DAMAGE TO THE MOTOR

DO NOT USE OTHER INDUSTRIAL OIL IN THE DHP DENTAL AIR COMPRESSOR IT WILL

CAUSE SERIOUS DAMAGE TO THE MOTOR

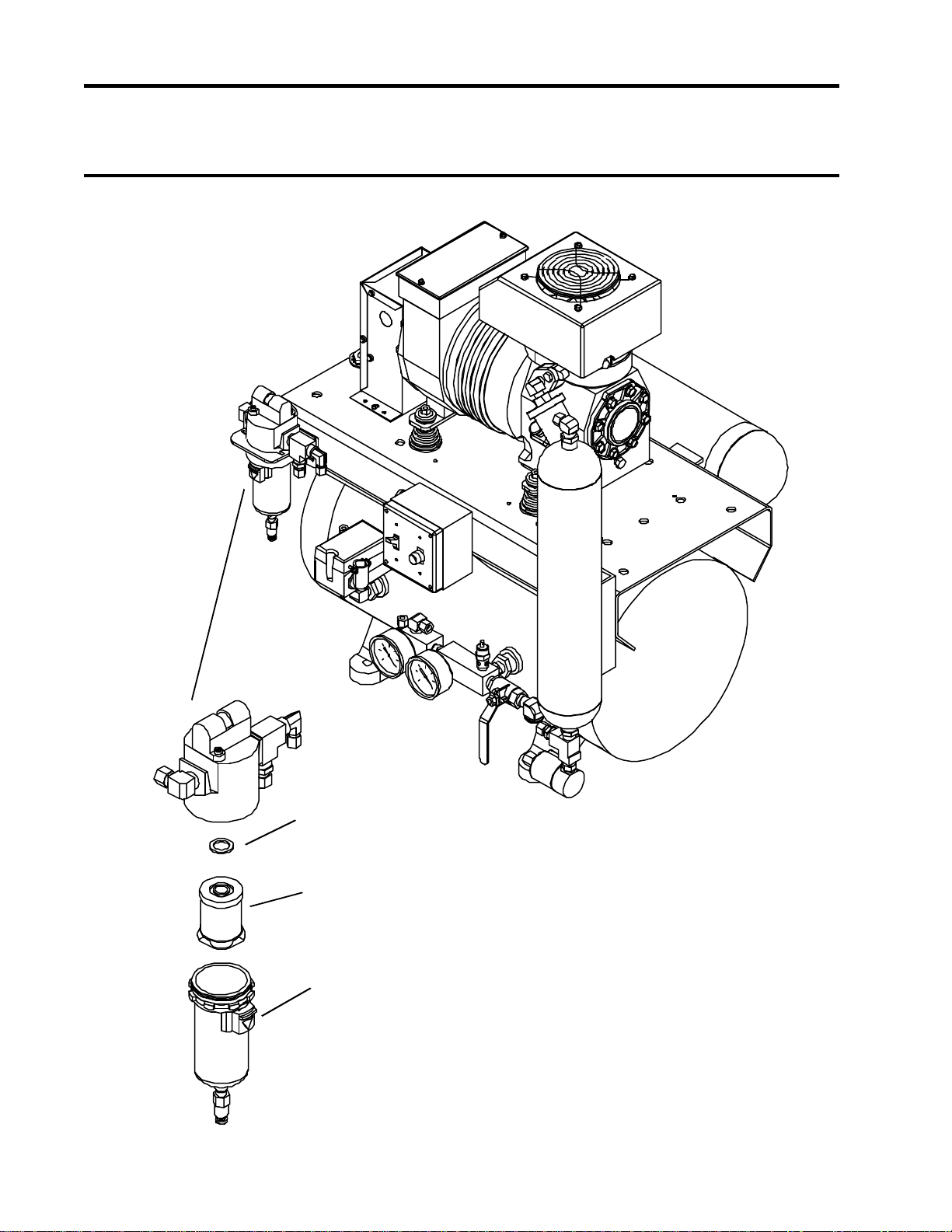

DHP Air Compressor Filter Replacement

1) Coalescing Filter

replacement Push

Down

LatchandTwistLower

Cannister

2) Unscrew Filter

Element

Make Sure O ring is

Note Displaced

3) After Filter Element is re-

placed re-insert Cannister and

twist until locked - Make sure

cannister O ring is note dis-

placed.

DHP Air Compressor Trouble Shooting Guide - Section 8

The DHP Dental Air Compressors addressed in this manual are all the industry standard Lubricated

Copelmatic Air Compressors. They are extremely durable, and with the proper maintenance should operate

trouble free for many years. This section of the DHP Dental Air Compressor manual is designed to assist the

owner/end user in diagnosing simple problems in their Dental Air Compressor system and rectifying the

problem with relative ease.

Dental Air Compressor does not operate

1) Check the electrical source

A - Locate the electrical panel and verify if the electrical breaker has ' tripped '. Prior to resetting the electri-

cal breaker fuse visually inspect the dental air compressor for any unusual conditions (oil and or air leaks,

loose electrical connections etc.). You may attempt to reset the fuse if you are experienced in this proce-

dure. If you are not comfortable with this procedure it is strongly recommended that you contact an electri-

cian or another person who is experienced in this procedure.

B - If you have attempted to reset the electrical breaker fuse and the breaker does not reset or ' trips ' again

- DO NOT ATTEMPT TO RESET THE BREAKER FUSE AGAIN - CONTACT AN ELECTRICIAN IMMEDI-

ATELY!

C - If after the previously recommended visual inspection with no unusual conditions noticed and the electri-

cal breaker fuse does reset upon the first attempt, monitor the situation as you may have an undersized or

defective electrical breaker fuse and it should be replaced as soon as possible by a licensed electrician.

2) Electrical Source is intact-dental air compressor has power

A - Turn off the electrical power to the dental air compressor and CAREFULLY FEEL THE SIDE OF THE

DENTAL AIR COMPRESSOR MOTOR-BE EXTREMELY CAUTIOUS AS IT MAY BE VERY HOT.

If the dental air compressor motor is hot contact DHP immediately!

B - If the dental air compressor is not hot contact DHP for further instructions.

Dental Air Compressor does not supply enough air

1) Verify dental air compressor is undersized for the required demand of air.

A - Check if the users versus the horsepower rating of the dental air compressor are proper. If the number

of users outweigh horsepower of the dental air compressor you will receive inadequate air.

B - Check the Dental Air Compressor for air leaks. The Dental Air Compressor motor should operate, without

any operatories or handpieces in use, for approximately 3 to 4 minutes building the air pressure in the storage

tank. IftheDental AirCompressor motoroperatesfor morethan 5minutesattempting tobuildup airpressure in

the storage tank there is an air leak in the air compressor system. If the Dental Air Compressor motor operates

for the estimated 3 to 4 minutes building the air pressure in the storage tank, shuts off temporarily and turns on

again without any of the dental operatories or handpieces being operated you have a small air leak in the air

compressor.

1) Check the air compressor for loose fittings.

2) Check the dental operatories dental unit junction boxes for air leaks.

3) Check the dental unit delivery system head for leaks.

DHP Air Compressor Trouble Shooting Guide - Section 8

NOTE: IN ANY OF THE PREVIOUSLY LISTED SOLUTIONS YOU MAY SIMPLY LISTEN FOR

THEAIR LEAK.CAUTIONSHOULDBETAKEN WHENCHECKING THEAIRCOMPRESSOR

FOR AIR LEAKS AS THE DENTAL AIR COMPRESSOR MOTOR COULD BE HOT. IF YOU

ARE AT ALL UNCOMFORTABLE WITH DIAGNOSING A PROBLEM REGARDING THE DHP

DENTAL AIR COMPRESSOR CONTACT DHP IMMEDIATELY!

Dental Air Compressor does not supply enough air to one operatory

1) Verify by consulting the dental units owners manual that the dental unit is operating properly.

2) If the dental unit is operating properly verify the dental unit in question does not have any

additional filtration system that may require maintenance.

3) Checkthe dentalunit junctionand visuallyinspectforeitherairleakor'kinked 'orbent hosing.

NOTE: IF ANY OF THE PREVIOUSLY LISTED SOLUTIONS DO NOT REMEDY THE PROB-

LEM CONTACT DHP IMMEDIATELY!

Dental Air Compressor does not operate-motor humming noise is evident

1) The dental air compressor motor is frozen as a result of lack of oil. Verify if the dental air

compressor head has sufficient oil by visually inspecting the motor oil site glass as per the dia-

gram in Section 6 (oil sight glass location). DO NOT ATTEMPT TO OPERATE THE DENTAL

AIR COMPRESSOR FURTHER CONTACT DHP IMMEDIATELY AS YOU MAY DAMAGE THE

MOTOR BEYOND REPAIR.

DentalAirCompressordoesnotoperate-motorhummingnoiseisevident.(cont.)

2) The dental air compressor motor does not have the proper electrical voltage. Verify if the

dental air compressor is 120 volts or 240 volts and using the proper electrical testing equipment

verify the electrical source is sufficient.

Dental Air Compressor motor operates but does not provide any air

1) The dental air compressorsystem hasanopen airline. Turn on thecompressor andlistenfor

the air leak. Verify and correct the problem. Do not attempt to adjust any of the air lines on the

dental air compressor contact the DHP factory customer service representative for additional

information.

2) The dental air compressor motor shaft has broken. DO NOT ATTEMPT TO OPERATE THE

DENTALAIR COMPRESSORCONTACTTHE DHP FACTORYCUSTOMERSERVICE REP-

RESENTATIVE IMMEDIATELY FOR ADDITIONAL INSTRUCTIONS.

The DHP dental air compressor has one function to supply clean dry air for use in a dental office

application. The dental air compressor is simple by design, however complex in operation. The

DHPdental aircompressor couldbe hazardousto workon. If youare notconfident inyour ability

to trouble shoot any problem, it is strongly recommended that you contact a DHP factory cus-

tomer service representative for additional information. Our factory trained customer service

representatives are available at 1-800-423-5657 between 7:00 am and 3:30 P.M. Pacific Stan-

dard Time.

Table of contents

Popular Air Compressor manuals by other brands

Craftsman

Craftsman 919.184192 owner's manual

Ingersoll-Rand

Ingersoll-Rand 125-200 Operator's instruction manual

DeWalt

DeWalt DXCMLA3706056 instruction manual

MPS

MPS R60S Installation and operating instructions

Emerson

Emerson Copeland Scroll ZR18K Series Application guidelines

Draper

Draper DA6/169 Instructions for

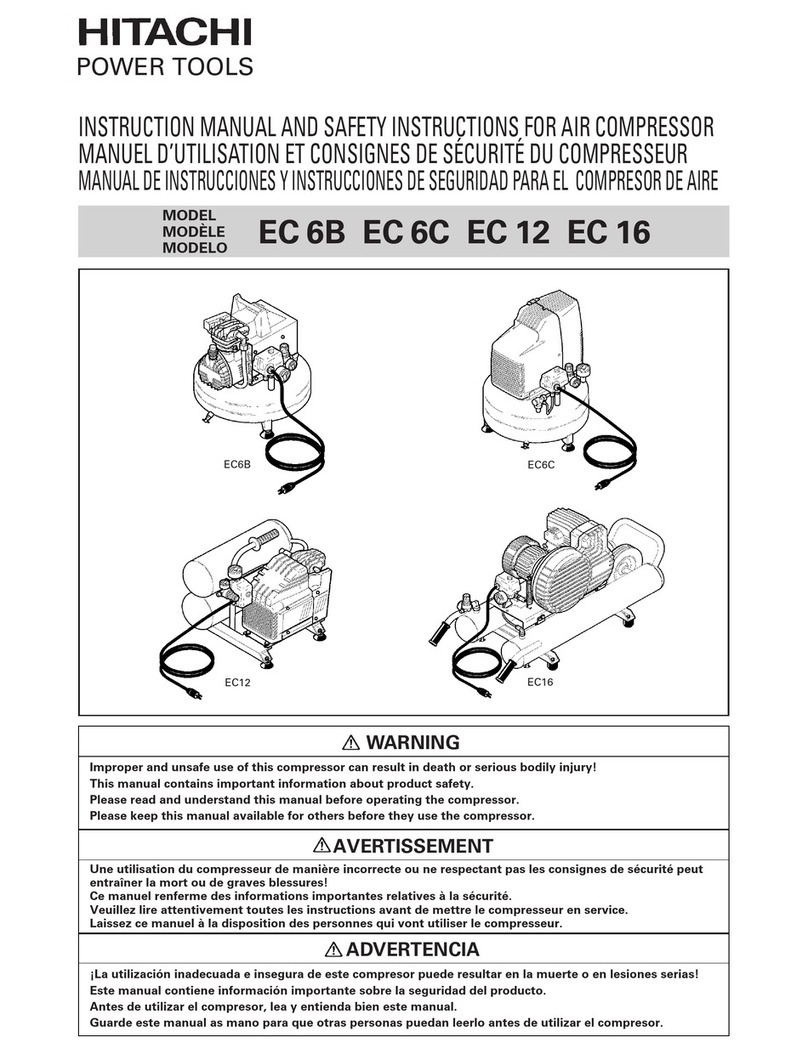

Hitachi

Hitachi EC6B instruction manual

Vixen Horns

Vixen Horns VXA7211B installation guide

EINHELL

EINHELL LE-AK 12/250 operating instructions

Iwata

Iwata Silver JET IS50 Operating instructions manual

Husky

Husky 835-522 parts manual

Scheppach

Scheppach Air Force 3 Translation from the original instruction manual