KOBE

PROFESSIONAL

AIR TOOLS

KOBE AIRLINE ACCESSORIES

10

Max Tool Bore x Order Code

Weight Length Rating KBE-280

1.5kg

6 x 700mm

150PSI -1000K

Order Code

Description

KBE-280

1/4

BSP Mini Oiler -1400K

MINI OILER feeds oil directly into the airline ensuring

your air tool is well lubricated at all times preventing

corrosion. The clear body reservoir allows immediate

inspection of the oil level. All brass construction.

RETRACTABLE AIR HOSE

BALANCER with adjustable

tension return retracts

when the air tool is

released leaving the

workplace clear of

unwanted lengths of air

hose. Ideally suited for in

line production.

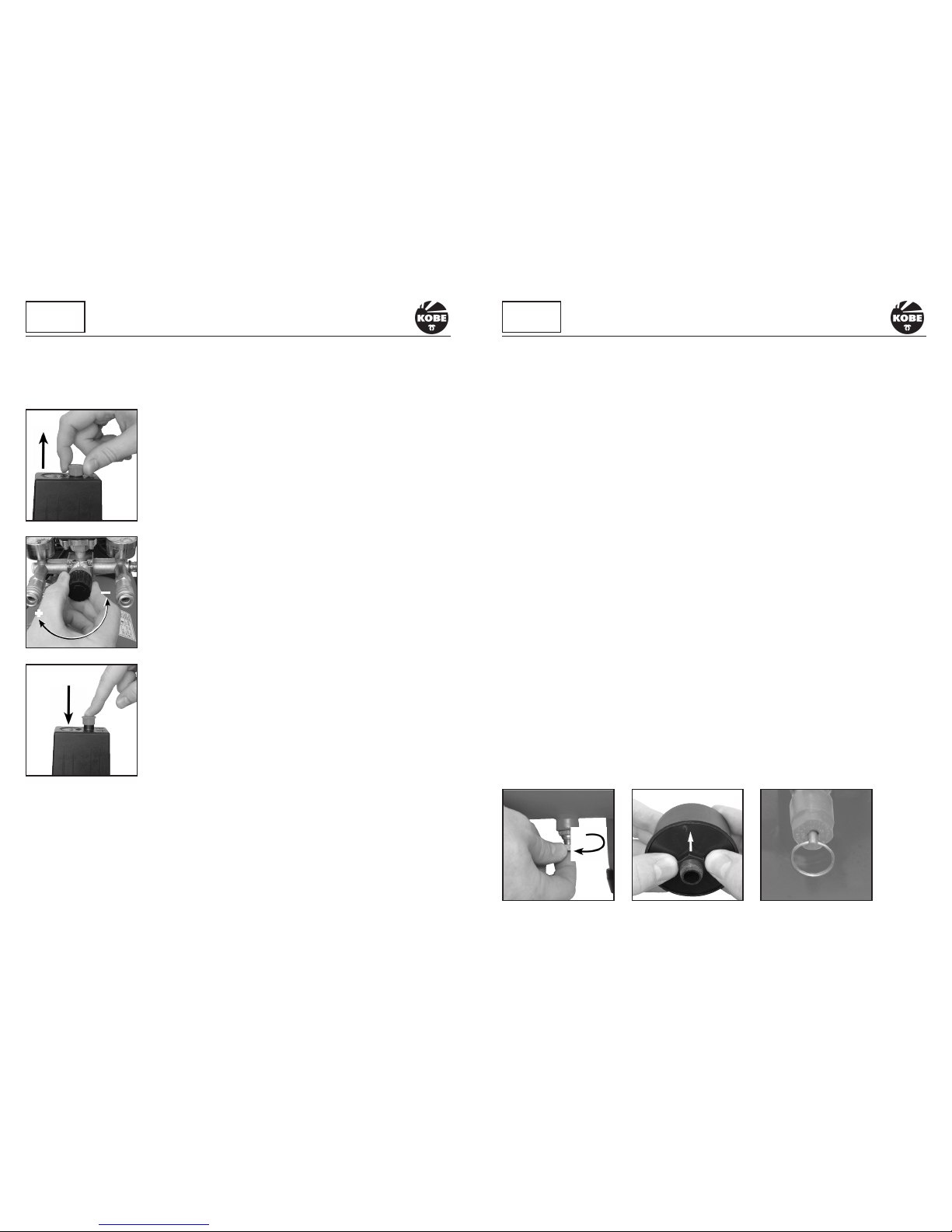

WATER SEPARATOR continuously removes

moisture from the air supply helping to prevent

corrosion to the internal components of the air

tool. The spring

valve allows

immediate

draining of

reservoir

without

any down time.

HI-FLEX POLYURETHANE AIR HOSE with brass 360°

swivel couplings, ideal for use in awkward access

areas. Recoils to a fraction of its working length leaving

the workpiece clear of entanglement hazards.

WHIP HOSE AND ADAPTOR used

to supply air between the air tool

and supply point. Prevents

vibration damage to couplings and

the tool user.

EXHAUST HOSE ASSEMBLY deflects

the tool exhaust away from the

immediate work area and helps to

reduce sound levels. Suitable

for Kobe air tools. Thread size

1/4

” NPT. Overall length 80cm.

HEAVY DUTY NYLON AIR HOSE recoils to a

fraction of its working length when not in use

leaving the workplace clear of entanglement

hazards. Solid brass couplings with 360°swivel

and spring protectors allow use in any direction.

Order Code

Description

KBE-280

1/4

BSP Water Separator -1900K

Overall Order Code

Thread Length KBE-280

1/4

” NPT

650mm

-1360K

Inside Head Suitable for Order Code

Diameter Kobe Air Tool models KBE-298

GES2506L, GDA2206L, FDG090,

20mm FDG115,

FDG180m & FDG180e. -5421S

DP2210, DPR1810, DP513, DPR813,

DAR1510, DS4510L, SH120,

25mm SP1825K, GD2206L, GD22LK,

-5420S

FPD500, FPD375 & X-GD16.

PU Outside Normal Order Code

Connector Diameter Length Rating KBE-280

1/4

BSPT 6mm 7.5m 150PSI -1160K

3/8

BSPT 10mm 7.5m 150PSI -1320K

Nylon Outside Normal Order Code

Connector Diameter Length Rating KBE-280

1

/4

BSPT 6mm 7.5m 150PSI -1140K

3/8

BSPT 10mm 7.5m 150PSI -1300K

KOBE

PROFESSIONAL

AIR TOOLS

SAFETY INSTRUCTION CONTINUED

3

Never use air tools on ladders. Ensure correct

platforms are used.

Never leave inflammable objects near the

compressor.

Never run the air compressor in areas exposed

to water or in damp conditions.

Never direct jets of water or flammable liquids

over the air compressor.

Never use the air compressor near naked

flames.

PERSONAL PROTECTION

Always wear approved eye protection during

operation. Use safety glasses or goggles which

conform to BSEN136 or CE equivalent that

provide protection from the front and side. The

operator of the air compressor and air tool is

responsible for following accepted eye, face,

respiratory, hearing and body protection.

Always wear approved footwear and headgear

when working on a building site or when heavy

weights and overhead working is involved.

Always ensure that all long hair and loose

clothing, ties, scarves, jewellery, etc., are

secured or removed.

Always use approved hearing protection. High

sound levels can cause permanent hearing loss.

Always avoid inhaling dust or handling debris

from work processes which can be harmful to

your health

Always consult a doctor if numbness, tingling,

pain or whitening of the skin occurs. Repetitive

work motions, awkward positions and exposure

to vibration can cause “Repetitive Strain

Injuries”.

Never operate the air compressor or air tools

near other people unless they are wearing

appropriate safety equipment also.

Never direct air at yourself, anyone else or at

animals.

SPECIFIC OPERATING HAZARDS

Always use recommended attachments or parts.

Always use the handle to move the compressor.

Do not move it by any other means.

Always place the air compressor on a firm and

level surface.

Always discharge the air from the air receiver

tank, when the compressor is not in use.

Always ensure the electric cable is not damaged

before connecting the air compressor to the

electricity supply.

Always use hoses, fittings and couplings

designed for use with air compressors.

Always discharge the air receiver tank before the

air compressor is transported.

Always depress the pressure switch when the air

compressor is not in use. This will avoid any

unintentional starting.

Always close the tap and discharge residual

pressure in the air hose before disconnecting the

air hose from the compressor.

Always check for damaged or loose hoses and

fittings. Whipping hoses can cause serious

injury.

Always be careful when handling the compressor

as components such as the delivery pipe and the

cooling fins of the cylinder head can become very

hot and remain hot for some time after use.

Never tamper with, or attempt to adjust the

pressure switch or the safety valve. The air

compressor must always be serviced by an

authorised agent.

Never use the air compressor without the air

filter attached.

Never deface the certification plate which is

attached to the end of the receiver tank.

Never pull the air compressor by the high

pressure hose or electric cable.

Never make any alterations to the air

compressor and only use it for the task for which

it has been designed.

Never leave air tools connected to the air hose,

when not in use.

Never leave the air compressor connected to the

electric supply when unattended.

Never insert objects or your fingers inside the

safety grating of the cover to avoid physical injury

and also damage to the compressor.

Never operate the air compressor without all

guards or safety features in place and in proper

working order.

Never cover the air compressor or restrict air flow

around the machine whilst operating.

Never use the air compressor for filling breathing

tanks, diving tanks or for pharmaceutical, food or

health applications.