HYDROLOGICAL SERVICES PTY LTD

_______________________________________________________________________________________

II UNPACKING YOUR HS-55

The carton should include:

CModel HS-55 Gas Purge System

CThis Instruction Manual

CAny Accessories you have ordered

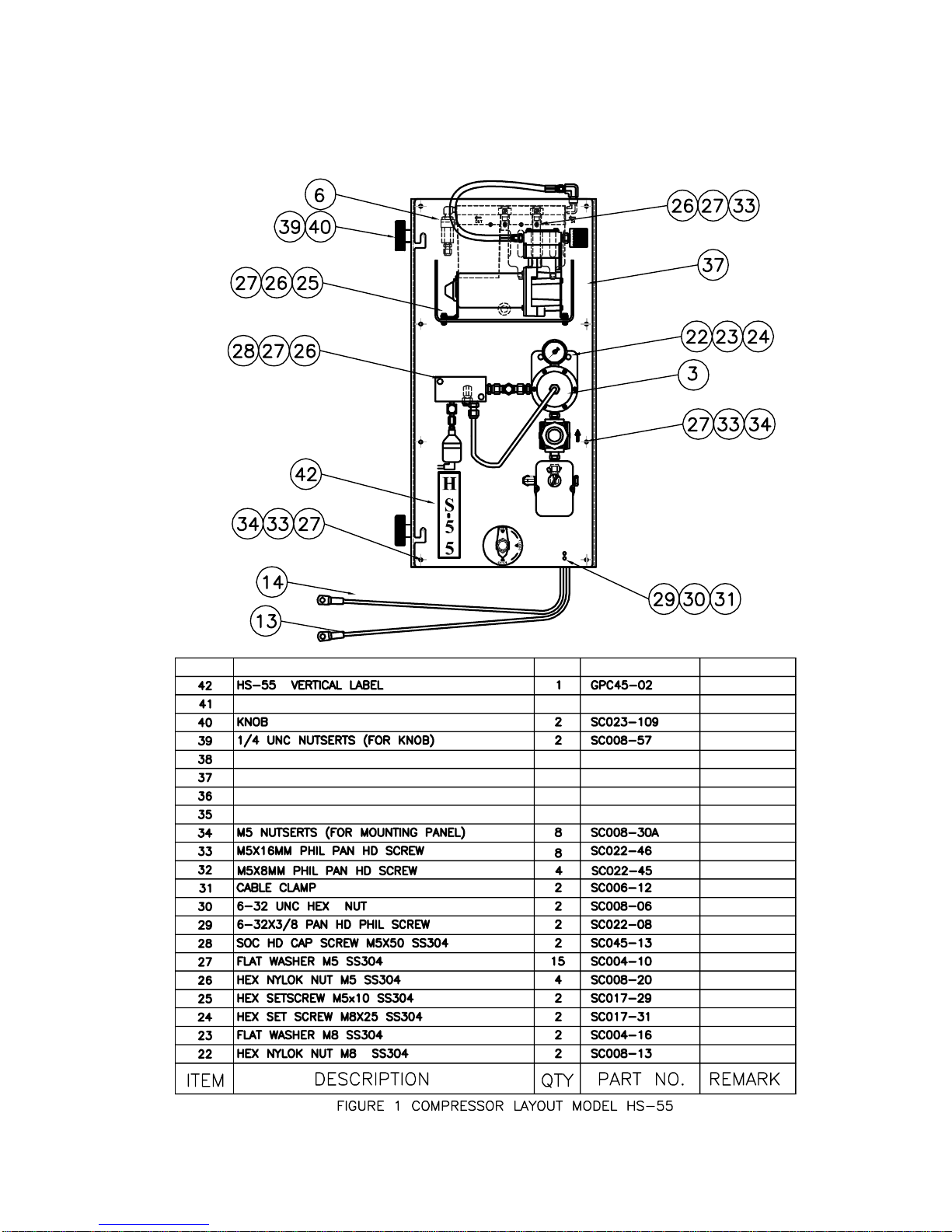

Please verify you have received these items. It is recommended that you visually inspect the

HS-55 to verify all components and connections are secure. For more details about HS-55

Purge System (see page 8 to 13 for item details ).

III TESTING YOUR SYSTEM

Before installing the HS-55, you may wish to test the system prior to going to the field. Testing

the HS-55 will familiarize you with the compressor in an environment where it is easy to work.

The HS-55 is designed to be mounted in a vertical position. The water /oil separator will not

function properly if the unit is in a horizontal position. Once the HS-55 is positioned, connect

the power leads to an appropriate power supply (12VDC, 38 Amp Hour minimum). Turn on power

switch to start the compressor pumping. The pump will take approximately 4 minutes to fill the

air tank to maximum pressure of 85 p.s.i, (600 Kpa) and will then automatically switch off.

Connect to the outlet port (see figure 6) a short piece of river line tubing and secure the end into

a container of water. Check the bubble rate setting as required (factory setting is equivalent to 80

bubbles per minute). If the bubble rate requires adjustment, (see page 16 for instructions).

Please note, if the HS-55 is to be tested without a pressure transducer fitted, then the red valve on

the instrument port (see figure 6) is to be closed prior to the test operation commencing.

There are two pressure gauges fitted to the HS-55. The unit attached to the pressure regulator

(figure 2, №44) indicates the set feed pressure (factory set at 400 Kpa) this pressure should be

retained at this setting, however, if adjustment is required, pull the supply regulator knob (figure

2, №49) and turn it until the required setting is achieved, once finished, push the knob back in

place. The second pressure gauge (figure 1, №10) is located on the side of the HS-55, indicates

the air tank pressure.

To test the purge operation, press the red button. Purge duration should be 5 seconds maximum

during testing.

Gas Purge Compressor Issue 7: 16/12/03

© Copyright HS55 100-04