Diagram 3D D277 User manual

Great Northern Railway (GNR)

Third Brake (D277)

4mm scale (“OO” “EM” or “P4”)

GN04-D277

GNR

Third Brake (D277)

Website:

www.Diagram3D.com

Includes Smartframe.

Adhesive, paint not included. Wheels, axleguards, buffers etc. not included.

4mm scale kit suitable for “OO” “EM” “P4” etc.

Laser cut

MDF and card kit

www.Diagram3D.com

Assembly Instrucons

Great Northern Railway Third Brake (D277)

4mm scale (“OO” “EM” or “P4”)

© Copyright 2021 Diagram3D, All

rights reserved

Page 1

Introduction

Contents of this

kit

MDF Parts

MDF parts are supplied pre-cut, partially attached to the panel which preserves

their integrity and ensures that the right parts are present. Please do not separate

the parts until it is time to use them.

MDF Parts

SmartFrame

Upper and lower

frame plus align-

ment clips.

MDF Parts

1x ceiling

2 x stretchers

2 x solebars

6 x roof support

6 x plain partition

1 x glazing stop

1 x guard end

1 x floor

1 x step end

Cardboard panels

The card panels are

packaged within the

SmartFrame for protec-

tion.

The card panels are

identified by the printed

legend on the panels

e.g. “Side 1 of 2” etc.

Cardboard panels – a total of 7 panels as described below:

There are four layers for the sides.

There are three layers for the ends.

Layer Description

Layer 1 Window Frames and droplights

Layer 2 Coach side

Layer 3 Middle and upper panelling

Layer 4 Lower panels beading detail

3D printed

Parts. A 3D printed roof (PLA random colour) , 2 x duckets (guards lookout)

Glazing

Acrylic glazing:

2x guard inserts, 2 x side glazing

2x end glazing

Layer Description

Layer 2 Brake End Outer, ducket (2)

Layer 3 Brake End panelling, ducket panelling, Coach End

Layer 4 Brake End beading, ducket beading, Coach End

panelling, steps, ducket tops

www.Diagram3D.com

Assembly Instrucons

Great Northern Railway Third Brake (D277)

4mm scale (“OO” “EM” or “P4”)

© Copyright 2021 Diagram3D, All

rights reserved

Page 2

Not included

Adhesive to attach the parts. PVA is recommended for the MDF parts.

Craft knife, Clamps, weights or other tools.

Paint and filler

Wheels, bearings, Buffers, couplings etc.

Intended Audience This kit is intended to reduce the time, complication and labour associated with the

construction of a detailed model of a carriage body using accurate pre-cut layers

which can be conveniently assembled in the supplied SmartFrame without special-

ist knowledge to give the same quality, or better, as traditional methods.

This is not a complete kit of parts. The choice of underframe and other details is

left to the modeller.

Hints on assembly

Separate parts by

cutting the reverse

side of the fret.

Pre-assemble and

check parts at each

stage.

Seal Cardboard com-

ponents.

Video and Gallery

Separating MDF components cleanly is more easily accomplished by completing

the half etched portions on the reverse of the fret rather than cutting from the front.

Do not separate components from layers until assembly is complete or instructed

to do so.

At each stage, once the required components have been separated from the frets,

test the assembly without glue to ensure that the parts are trimmed correctly and fit

properly before final assembly with adhesive.

Allow as much time as needed for the adhesive to set.

Fill any gaps and smooth surfaces for optimal results

It is advised that cardboard parts are sealed before assembly.

The assembly steps below are strong recommendations but should not be

taken as definitive or prescriptive.

Copyright Statement The entire contents of this document including but not restricted to the text,

images, drawings and components, method of construction, design and

intellectual content are the copyrighted property of Diagram3D. No part of

this document or design may be used altered or copied without the express

written consent of the design and copyright owners. This document was

originally published in 2021 CE.

Current Documents The current version of documentation for this and any other of our products

can be downloaded from www.Diagram3D.com in PDF format.

Feedback

We welcome your comments and suggestions, especially images of models “in

progress” or completed.

www.Diagram3D.com

Assembly Instrucons

Great Northern Railway Third Brake (D277)

4mm scale (“OO” “EM” or “P4”)

© Copyright 2021 Diagram3D, All

rights reserved

SmartFrame

Preparation

(Applies to all

versions of

SmartFrame)

Total prepara-

tion and as-

sembly time

about 2

minutes.

Attach the clips to the bottom section of the SmartFrame as shown below:

Hint: Partially insert the clips into the slots and gently press the clips into position on

each side. An extra clip is provided. Avoid excessive pressure. Visit our website for

further constructional information including a video and gallery of models.

SmartFrame

General Hints

on using the

SmartFrame

The following diagram illustrates how to use the SmartFrame:

Position the layers of the same description in ascending order on the lower frame

beginning with the first layer. The layers have the legend “1 of x”, “2 of x” and so on.

Hint: Do not force the individual layers into position, assemble each layer at an angle

so that one side is in position and then gently position the other side into place. When

in position, extra pressure can be applied with rubber bands or “bulldog clips” on the

ends of the frame.

Page 3

www.Diagram3D.com

Assembly Instrucons

Great Northern Railway Third Brake (D277)

4mm scale (“OO” “EM” or “P4”)

© Copyright 2021 Diagram3D, All

rights reserved

Page 4

Carriage

Sides

Total preparation

and assembly

time about 5

minutes.

Allow sufficient

time for the

adhesive to dry

thoroughly

There are four layers for the sides. Insert these into the SmartFrame in order as de-

scribed above.

Apply adhesive and put aside until dry. Hint: The individual layers can be painted in

advance to simulate the window frames, main body and lining detail. When thoroughly

dry, detach the carriage sides using a sharp craft knife.

To form the tumblehome, use a section of tubing and gently roll the cardboard on a

rubber mat or similar surface. Alternately the tumblehome can be formed by using

finger-pressure against a suitably curved surface. Hint: Practice this on some scrap

card first.

Carriage

Ends

Total preparation

and assembly

time about 5

minutes.

Allow sufficient

time for the

adhesive to dry

thoroughly

There are four layers for the ends.

Insert these layers into the SmartFrame in order as described above.Apply adhesive and put aside

until dry. Hint: The individual layers can be painted in advance. The steps can now be detached and

place into the pre-cut holes individually in one end. The other end has communication cord equipment.

When thoroughly dry, detach the coach ends from the frame using a sharp craft knife

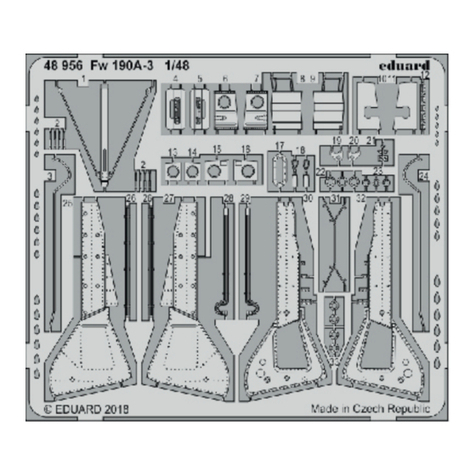

”Exploded”

Diagram

MDF Body

Shell

Total preparation

and assembly

time about 10-15

minutes.

Allow sufficient

time for the

adhesive to dry

thoroughly

Insert the partitions into the floor and glue into position. When set, attach the ceiling, side stretch-

ers and ends as shown below. Attach the glazing stop as shown below.

Hint: This is an appropriate time to paint and otherwise complete the interior of this model. Note: GNR third class

compartments had green rep upholstery. First Class had Blue upholstery. Smoking compartments had “drab”

upholstery according to contract specifications produced in the late 19th century.

Layer Description

Layer 1 Window Frames and droplights

Layer 2 Coach side

Layer 3 Middle and upper panelling

Layer 4 Lower panels beading detail

Layer Description

Layer 1 Brake End Inner

Layer 2 Brake End Outer, ducket(2)

Layer 3 Brake End panelling, ducket panelling, Coach End

Layer 4 Brake Ends Beading, ducket beading, Coach End panelling,

steps, ducket tops

The diagram shows the

main components of

this kit. The sides and

ends are pre-printed

and assembled as

described above.

The body is assembled

from MDF components.

The roof is 3D printed.

www.Diagram3D.com

Assembly Instrucons

Great Northern Railway Third Brake (D277)

4mm scale (“OO” “EM” or “P4”)

© Copyright 2021 Diagram3D, All

rights reserved

Page 5

Glazing &

final asembly

Total prepara-

tion and as-

sembly time

about 20

minutes.

Allow sufficient

time for the adhe-

sive to dry thor-

oughly

Note that this vehicle is not symmetric over its length so there is only one way

to position the roof.

Attach the sides to the body, taking care to align with the floor and allow to set.

Finally the ducket is attached to the centre of the vehicle. The curve of he ducket matches

the tumblehome.

The long window glazing bars supplied fit into the slots (one per side) which are pre-cut

into the partitions.

The end panels overlap the sides and fits into the recess in the roof under the moulded

cornice. Attach the ends taking care to centralise these components with the roof.

Roof

Total prepara-

tion and as-

sembly time

about 15

minutes.

Allow sufficient

time for the adhe-

sive to dry thor-

oughly

The 3D printed roof is designed to fit over the ceiling and attach to the

(optional) roof supports which locate in the ceiling. It is possible to make the

roof removable.

The roof will need some cleaning up and final painting before installation.

Although positioning holes are provided for ventilators throughout, vehicles

were fitted with alternate ventilators and lighting throughout their working lives

and a reference photograph will assist in determining which, if any, of the venti-

lators should be used for a given era.

The cornices were originally “teak colour”.

Underframe

The underframe is assembled by inserting the lugs on the solebars into the

corresponding holes in the floor of the vehicle.

The bogies are assembled according to the instructions in the kit D3D-06 which

is suitable for this vehicle.

Suitable wheels for “OO” are D3D-02 (four axles Mansell wheels).

Paint the 3D printed ducket overlay with

a suitable shade of “teak” - an orangey

brown colour. The pre-printed overlay /

panelling is attached to the outer sur-

face.

As shown, the small glazing pieces snap

into the 3D printed ducket lengthways.

www.Diagram3D.com

Assembly Instrucons

Great Northern Railway Third Brake (D277)

4mm scale (“OO” “EM” or “P4”)

© Copyright 2021 Diagram3D, All

rights reserved

Page 6

Historical

Notes

Originally designated as E48 and later as diagram 277, this short 45 foot coach was one of several types which

were designed by Howlden for the GNR in the late 1890’s. Twelve of these vehicles were in service in the early

20th century. The carriage was a logical extension of existing design on the GNR. It had a wooden underframe.

This vehicle is described in “Historic Carriage Drawings” Volume 1 by N. Campling. ISBN 1 899816 04 6 page

94.

Some example vehicle numbers for the GN period were:

366, 791, 808, 1628, 1635, 1645 which became 4366, 4791… 41645 at grouping.

No. 366 was rebuilt as a bullion van. These were long lived vehicles, most survived until nationalisation of the

railways in 1948 and beyond, including all the vehicles quoted above.

Underframe This was a bogie coach. The diagram wheelbase was 28 feet 11½ inches between

bogie centres. They were equipped with gas lighting, vacuum brakes and heating

apparatus. Originally they were equipped with Fox’s pattern bogies and later on with

standard Gresley bogies

Finally…

Congratulations on completing this kit. We hope you enjoyed making it as much as

we did.. If you enjoyed making this kit then take time to visit www.Diagram3D.com to

find similar items. Our website has free downloads of historical information. Down-

loadable assembly instructions for all of our products

Email: info@Diagram3D.com E&OE document updated Feb. 2022

GNR livery was varnished teak with gold lettering

and lining shaded blue. Earlier livery had the class

designation with the GN crest in the lower panel of

the door. In later years this was replaced by a large

numeral. Eventually, post-grouping, the class

designation numeral moved to the lower panel, the

crest and lining was omitted for surviving stock. It

was customary for a “pattern coach” to be provided

for inspection by external contractors.

In 1896, Moore’s Journal noted that GNR teak

vehicles were of uniform colouring, unlike other

companies that used varnished teak.

According to contract specifications the under-

frame was painted “teak” colour, ironwork was

black and the roof was painted white. However

a section of the visible roofline was painted

“teak” colour.

Depending on the frequency of washing the

visible roof colour could be anything from “teak”

to black, giving rise to various rumours about

the colour of GNR roofs and the apparent

discrepancy in colour between main line and

suburban stock. After 1905 or thereabouts

onwards roofs were painted white.

Other Diagram 3D Toy manuals