Dialight Medium Intensity Instruction manual

Document No: 9100-127-1958-99 Rev F

Release Date: 10/8/15

1501 Route 34

South, Farmingdale, NJ 07727 Tel: (732) 919-3119 Fax:

(732) 751-5778 www.dialight.com

•DO NOT let any supply cords touch hot

surfaces higher than cord ratings.

•DO NOT mount near gas or electric heaters

•Equipment should be mounted in locations and

at heights where it will not be subjected to

tampering by unauthorized personnel.

•The use of accessory equipment not

recommended by the manufacturer may cause

unsafe conditions.

•DO NOT use this equipment for other than

intended use.

•DO NOT look into the Infrared (IR) LEDs. These

five IR LEDs on top of the unit (if applicable) will

not appear to be ON, but can be verified using

most digital cameras.

•Pictures are required for

commissioning the install. Failure to

provide could VOID all warranties

SAVE THESE INSTRUCTIONS!!

•The operation and maintenance must be carried

out by authorized personnel.

•Repairs and Installation must only be carried out

by a qualified electrician.

•Only genuine Dialight replacement parts must be

used when unforeseen repairs are required.

•Observe the national safety rules and regulations

during installation!

•Earth Grounding is required throughout the

install process. Failure to do so could void all

warranties!

•No alterations should be done without the

agreement from Dialight Corp. Alterations other

Than written in this manual will void all

warranties.

Instructions must be kept with the system installed

Introduction:

This manual is for orientation of the controller, configuration and definitions of the Dual

Strobe system or Dual Strobe + Infrared (IR) system.

Refer to the installation manual for the following information

•Installing the Controller and the pre drilled holes

•Dimensions of the Controller

•Securing the cables to the structure

•Connection of either AC or DC input voltages

•Connection of the Side lights and calibration

•Photocell connections

•Flashhead connections for both the 4 conductor and the 8 conductor versions

•Proper bonding of the Strobe cable

•Mounting the Flashhead.

Medium Intensity Quick Start Manual

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

Document No: 9100-127-1958-99 Rev F

1501 Route 34 South, Farmingdale, NJ 07727 Tel: (732)

919-3119 Fax: (732) 751-5778 www.dialight.com

Included in this manual:

•System overview

•Installation Tips and requirements

•System Descriptions

•RS485 Communication Connections

•Installing the RS485 to additional power supplies

•Controller layouts

•Navigating the LCD Display oLCD startup display screens oSetup Screens

(Configuration) oMain Menu Screens oManual Lighting inspection test

•Controller Status LED’s

•Dry contact connections

•Controller electrical Parameters

•Resetting, ext sync option, and serial numbers

•Replacement part numbers

•Display Events and Alarm Descriptions

•Alarm list and possible causes

System Overview:

Document No: 9100-127-1958-99 Rev F

1501 Route 34 South, Farmingdale, NJ 07727 Tel: (732)

919-3119 Fax: (732) 751-5778 www.dialight.com

Installation Tips and requirements:

For the Mains cable, it is recommended that the electrician or installer calculate the wire

requirements based on the amount of Flash heads being installed. It is recommended

that no install utilizes less than 16AWG wire with at least a 90ºC temperature rating. See

electrical parameters.

For RS485 cabling; 3 cores of 18AWG, drain wire plus a shield and braid for adequate

grounding and signals are required. RS485 is only required for E1+1 and larger

structures where multiple Strobes are required.

Cable between the Flash head and the controller must be a minimum of 14AWG and 4

conductors with foil and braid. Maximum distance between the controller and the Flash

head is 630feet.

NOTE: Failure to do any of the above could void all factory warranties. If in doubt please

contact your sales agent or representative.

During installing on the tower proper grounding techniques should be utilized.

The system has built in Lightning and RF immunity at each section, but for it to be

effective proper ground connection techniques must be used. For more details or

contact your local sales rep.

System Descriptions that are covered in the manual:

D1RW-C13-009-CTR = consists of:

•D1RW-FH009 (Flash Head)

•D1RW-CTR009 (Controller/Supply)

Gen5 dual red/white with AC input , 48volt

sidelights and 8 conductor flash head cable

required

D1RW-C13-409-CTR = consists of:

•D1RW-FH409 (Flash Head)

•D1RW-CTR409 (Controller/Supply)

Gen5 dual red/white with AC input , 48volt

sidelights and 4 conductor flash head cable

required

D1RW-C14-009-CTR = consists of:

•D1RW-FH009 (Flash Head)

•D1RW-CTR049 (Controller/Supply)

Gen5 dual red/white with 48VDC input , 48volt

sidelights and 8 conductor flash head cable

required

D1RW-C14-409-CTR = consists of:

•D1RW-FH409 (Flash Head)

•D1RW-CTR449 (Controller/Supply)

Gen5 dual red/white with 48VDC input , 48volt

sidelights and 4 conductor flash head cable

required

D1RW-C17-009-CTR = consists of:

•D1RW-FH009 (Flash Head)

•D1RW-CTR079 (Controller/Supply)

Gen5 dual red/white with AC input , AC sidelights

and 8 conductor flash head cable required

D1RW-C17-409-CTR = consists of:

•D1RW-FH409 (Flash Head)

•D1RW-CTR479 (Controller/Supply)

Gen5 dual red/white with AC input , AC sidelights

and 4 conductor flash head cable required

D1CW-C13-409-CTR = consists of:

•D1CW-FH409 (Flash Head)

•D1CW-CTR409 (Controller/Supply)

Gen5 dual red/white + Infrared (IR) with AC input ,

48volt sidelights and 4 conductor flash head cable

required

D1CW-C14-409-CTR = consists of:

•D1CW-FH409 (Flash Head)

•D1CW-CTR449 (Controller/Supply)

Gen5 dual red/white + Infrared (IR) with 48VDC

input , 48volt sidelights and 8 conductor flash head

cable required

Document No: 9100-127-1958-99 Rev F

1501 Route 34 South, Farmingdale, NJ 07727 Tel: (732)

919-3119 Fax: (732) 751-5778 www.dialight.com

RS485 Communication Connections:

NOTE: The below is common between all the controllers covered in the manual.

The connection of the RS485 cable is vitally important to the operation of the system.

This connection provides all the events and alarms to the Master controller that is being

used with the installation.

Factory connected wiring color code:

Boards are Labeled Description Color Code

Label “A”

Communications “A”

Grey

Common

Common for RS485

Yellow

Label “B”

Communications “B”

Blue

Option 1: RS485 consisting of 3 conductors, a drain wire and foil shield and braid.

Install Cable Connected to Description Color Code

Conductor 1

Label “A”

Communications “A”

Grey

Conductor 2

Common

Common for RS485

Yellow

Conductor 3

Label “B”

Communications “B”

Blue

Drain wire

Ground stud

Ground

Bare wire

Foil Shield and

Braid

Clamping terminal

Ground

Connected when

cable enters the

enclosure and must

be secured to the

plate

Option 2: RS485 consisting of 2 Conductors, a drain wire and either a shield or

braid is used.

Install Cable Connected to Description Color Code

Conductor 1

Label “A”

Communications “A”

Red

Drain Wire

Common

Common for RS485

Bare Wire

Conductor 2

Label “B”

Communications “B”

Black

Shield or Braid

Clamping Terminal

Ground

Connected when

cable enters the

enclosure and must

be connected to

plate

WARNING: For Color Codes not shown the installer must take note of the colors used

for these connections since it is required that all A, Common and B terminals be

connected the same throughout the system.

Document No: 9100-127-1958-99 Rev F

1501 Route 34 South, Farmingdale, NJ 07727 Tel: (732)

919-3119 Fax: (732) 751-5778 www.dialight.com

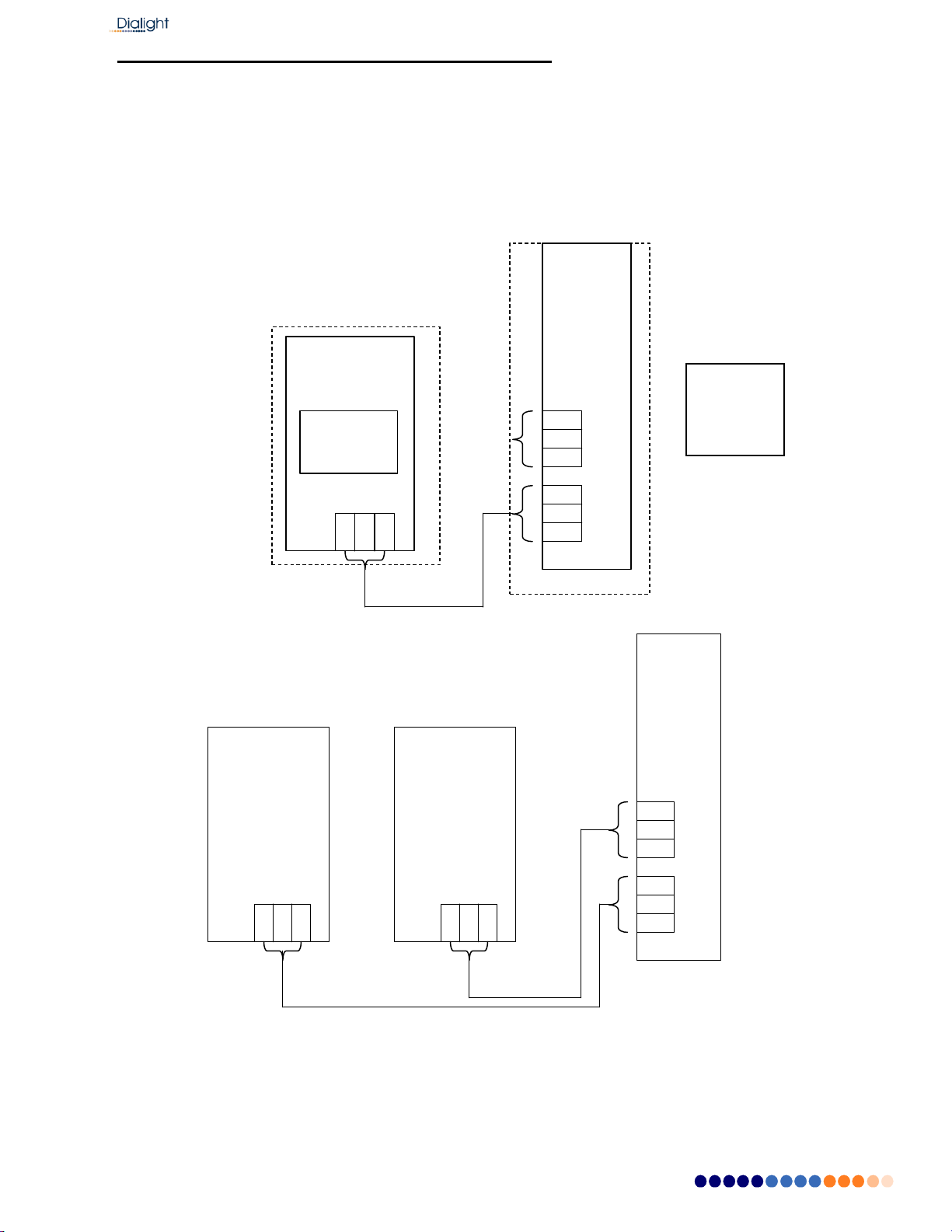

Installing the RS485 to additional power supplies

NOTE: For an E1 system there is no externally connected RS485.

NOTE: For structures lager than the above additional external communications need to

be added between the RS485 surge board and the translator boards in each of the

additional power supplies.

NOTE: For systems larger than E2 daisy chaining between the translator boards is

required.

NOTE: Translator boards are located in power supply enclosures NOTE:

The controller translator board is to be set to zero.

RS485

Located in

Controller

E2, D2 and A2

Translator

Board#1

Translator

Board#2

RS485

Junctio

n

Board

E1+1,

D1+1 and A1+1

RS485

Junction

Board

Translator

Board#1

Located in

power

supplies

Document No: 9100-127-1958-99 Rev F

1501 Route 34 South, Farmingdale, NJ 07727 Tel: (732)

919-3119 Fax: (732) 751-5778 www.dialight.com

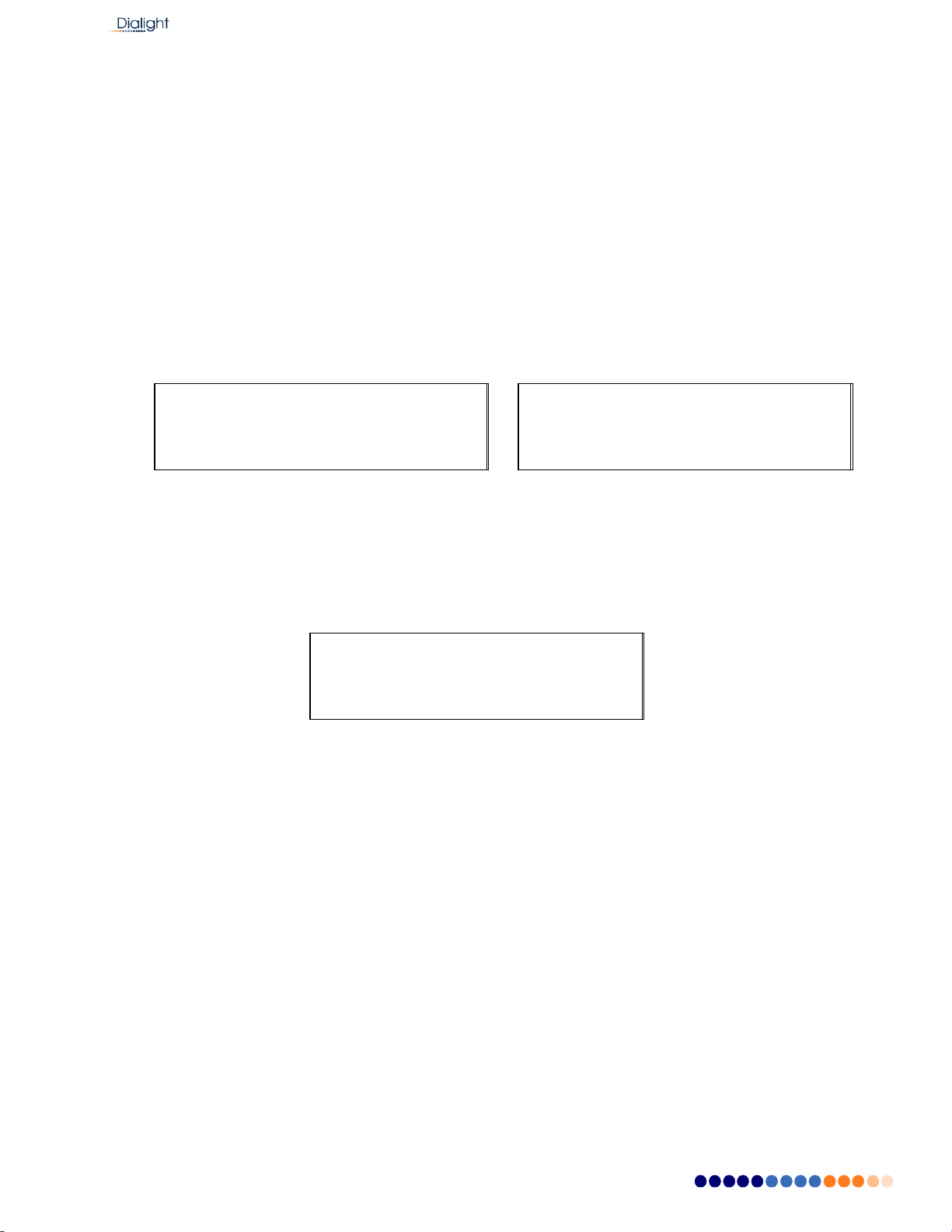

D1xW-C13-x09-CTR Controller:

Requirements

NOTE: See electrical parameters for power consumption

Attach output of Photocell to side light monitor board (Marker) board J4

Connect the RS485 to the Junction Board when additional power supplies are

connected.

Document No: 9100-127-1958-99 Rev F

1501 Route 34 South, Farmingdale, NJ 07727 Tel: (732)

919-3119 Fax: (732) 751-5778 www.dialight.com

D1RWC17409CTR Controller:

Requirements

NOTE: See electrical parameters for power consumption

Attach output of Photocell to monitor board (Marker) board J4

Connect the RS485 to the Junction Board when additional power supplies are

connected.

Document No: 9100-127-1958-99 Rev F

1501 Route 34 South, Farmingdale, NJ 07727 Tel: (732)

919-3119 Fax: (732) 751-5778 www.dialight.com

LCD Start up Display Screens:

Once power is turned on the next 2 screens will be displayed automatically.

The Startup Screen displays:

Dialight MI Ctrl

REV. x Build: xx

NOTE: The Site manager and Installer should take a note of this screen including the

REV number and the Build number if any future troubleshooting is required. x’s indicate

revision levels and will appear as numbers on the display.

The Initializing Screen:

This screen shows a countdown for the initial 15 flashes for E and D type structures For

A red only systems the countdown starts at 45.

NOTE: In some cases this screen will go back to the Startup screen if synchronization

was faulty.

Initial 15 Flashes In

Process

Document No: 9100-127-1958-99 Rev F

1501 Route 34 South, Farmingdale, NJ 07727 Tel: (732)

919-3119 Fax: (732) 751-5778 www.dialight.com

Setup Screens:

These screens are used for properly configuring system based on the structure type that

is being installed. By using the “UP” and “DWN” buttons the user or maintenance

personnel can view and edit the configuration as applicable by pressing the “ENTR”

button after the selecting the desired choice the next screen will be entered.

Configuration Type Screen:

A) To change configuration of controller go to ‘Config Type’ screen’ and press

“ENTR”. This will enable you to select either an “E” “A” or “D” tower type. Sub

categories such as E1, E2 etc. will be addressed later in the configuration

menu.

CONFIG TYPE X

‘Enter to change’

B) Use the “UP” and “DWN” buttons to scroll and select tower style A, D, or E.

Then press “ENTR”.

NOTE: If ‘Tower Style D’ is selected, the system will automatically proceed to

step F, skipping steps D and E since side markers (L810) are not used in D style

configurations. Any information previously in the system as indicated in omitted

steps will be changed to “0” if switched back to an E or A style configuration and

will have to be re-entered to match what is installed on the tower.

NOTE: System will reset when tower style is changed.

Tower style = E

‘enter’ to change

C) Select for the presence of an External GPS using the “UP” and “DWN” buttons,

“YES” indicates an external GPS is being used, “NO” is the standard

configuration without an external GPS. Press “ENTR” after selection.

Ext GPS = NO

u/d=chg, enter=done

Document No: 9100-127-1958-99 Rev F

1501 Route 34 South, Farmingdale, NJ 07727 Tel: (732)

919-3119 Fax: (732) 751-5778 www.dialight.com

D) Select the number of Side Marker (L810 or RTO) Tiers that are connected to

the system. 0 through 4 can be selected; the number input shall represent the

number of tiers present. Press “ENTR”.

Num of 810 TIERS=0

u/d=chg, enter=done

E) Select the number of Side Marker s (L810’s, RTO’s) that will connected to P1

(Tier 1) 0 through 4 can be selected, then press “ENTR”

NOTE: Repeat for ports 2 through 4.

NOTE: Each port represents one tier.

NUM 810 P1/T1= 0

u/d=chg, enter=done

F) Select the number of beacons (864/5’s) that will be connected to the system. 1

through 9 beacons can be supported. Press “ENTR”

Number of 864/5 = 1

u/d=chg, enter=done

G) Select the number of side light boards that are connected to the system, 1

through 9 and the press “ENTR”.

NOTE: Additional sidelight monitor boards are available for special applications;

most configurations will only have one board and this will remain set to “1”

Number of SD BDs=1

u/d=chg, enter=done

Document No: 9100-127-1958-99 Rev F

1501 Route 34 South, Farmingdale, NJ 07727 Tel: (732)

919-3119 Fax: (732) 751-5778 www.dialight.com

H) Select the status of side lights. Use “UP” and “DWN” buttons to change from

STEADY, DISABLED and FLASHING, depending on what is needed of the

sidelights.

NOTE: This is a global change that will affect all tiers of sidelights; individual

tiers are not able to have statuses changed.

L810 stat = STEADY

u/d=chg, enter=done

L810 stat = Disabled

u/d=chg, enter=done

L810 stat = Flashing

u/d=chg,

enter=done

I) Select red mode flash rate of the beacons as well as the sidelights when

specified to be flashing as indicated in step H. Selections available are 20, 30,

and 40. Use “UP” and “DWN” buttons to change, and them press “ENTR”

NOTE: Factory default is 30fpm

NOTE: This is a global change that will affect all tiers of sidelights at once.

NOTE: This change will not affect white flashes.

Flash per min = 30

u/d=chg, enter=done

J) If sidelights are to be calibrated at this time (if not calibrated as per the previous

section of this manual or the quantity or wiring of sidelights has changed since

previous calibration), use “UP” and “DWN” buttons to change from “NO” to

“YES”, and then press “ENTR.” The system will reset and the sidelight board

will perform its calibration sequence.

NOTE: This step should only be selected if all tiers of sidelights are fully installed

and connected to the controller.

RECAL L810 = NO

u/d=chg, enter=done

Document No: 9100-127-1958-99 Rev F

1501 Route 34 South, Farmingdale, NJ 07727 Tel: (732)

919-3119 Fax: (732) 751-5778 www.dialight.com

K) If the Photocell mode transition alarm (18 hour alarm) is not needed as an

alarm this selection can disable it.

NOTE: Typically used where there long day or night operations.

Selecting YES: If the photocell does not detect day or night after 18 hours, the

system will alarm after 18 hours and will switch to Day mode. To clear this alarm the

system requires a local reset or a forced operation change locally or remotely.

Selecting NO: After 18 hours of not transitioning the system will log an event in the

log but the system will continue to operate normally based on light conditions. No

alarm via dry contact or mod bus will be generated.

Trans PEC Alrm = YES

u/d=chg, enter=done

Trans PEC Alrm = NO

u/d=chg, enter=done

Use “UP” and “DWN” buttons to change from “NO” to “YES”, and then press “ENTR.”

L) The Beacon can be made steady burn in Red night mode

BCN Steady RNite= NO

u/d=chg, enter=done

Once the selection for the Beacon steady red Night is completed the next screen to be

displayed is the “Config Type”.

NOTE: Typically used outside of the US. FAA regulations require the beacon to be

flashing so most typical installation will have this selection set to “NO” to ensure a

flashing beacon.

Document No: 9100-127-1958-99 Rev F

1501 Route 34 South, Farmingdale, NJ 07727 Tel: (732)

919-3119 Fax: (732) 751-5778 www.dialight.com

After about 2 minutes the system will reset on its own to save the configured

information.

CONFIG TYPE X

‘Enter to change’

The Reset button located in the middle bottom of the board can also be pressed to reset

the system.

Resetting is required so the controller saves the configured information to throw alarms

on changes occurring during the operation of the system.

Main Menu Screens:

The next screens are paged through using the “UP” and “DWN” buttons. The user or

maintenance personnel can view and edit the configurations as applicable by pressing

the “ENTR” button to enter into each main menu screen.

Pressing the “CLR” in the selected screens takes the user back to the main screens.

Upon resetting or powering and powering up the system this is the first screen that is

displayed.

•Status Screen –Config type:

CONFIG TYPE X

‘Enter to change’

•Screen: Tower style:

This screen displays what the Base Controller has been configured for, if the amount of

beacons configured does not match what is actually connected then alarms will be

generated as “config” alarms. Only powered fixtures and fixtures connected to the

RS485 will be detected. The “B y” in second line will indicate the firmware level of main

controller.

NOTE: If the installer selects 3 beacons and only 1 is powered AL1 (config ERR) will be

lit and recorded in the alarm log.

Tower Style: X X

86X ,X 810 B y

Document No: 9100-127-1958-99 Rev F

1501 Route 34 South, Farmingdale, NJ 07727 Tel: (732)

919-3119 Fax: (732) 751-5778 www.dialight.com

•Screen: Mode of operation –Day or Night

NOTE: These modes change according to the user’s photocell operation. There are no

options for preprogramming mode change times.

Mode: Options are Day or Night , T= controller temperature (C)

Active: Options are Wht or Red

NOTE: On this screen the controller can be forced in DAY or NIGHT (using the

push buttons located under the down button marked White and Red). NOTE:

S3 will blink till system is restored to normal operation

MODE: Night T=X C

ACTIVE: RED 864

MODE: Night Forced

‘Clear to restore

•Status Screen - Alarms:

This screen allows the user access to the Alarm Log. By pressing the “ENTR” button,

current and previous alarms the system has encountered are able to be viewed, starting

with the most current alarm. Alarms can be scrolled through using the “UP” and “DWN”

buttons. Each alarm occurrence is dated and time stamped. Up to 999 alarm entries

can be stored in the controller.

NOTE: If an Alarm is found, the Status screen will change from “NORMAL” to “ALARM”

thus indicating there is an active Alarm.

By pressing “ENTR” you will be able to view alarm logs. Time stamps are actual times

that the alarm occurred. Refer to interpretation of the logs for further details.

Status: Normal

‘Enter’ to view Alrm

Status: ALARM

‘Enter’ to view Alrm

•Date and Time Screen - Setting the real time clock:

By selecting “ENT” the user can set the actual time and date of the Base Controller.

NOTE: Date and time settings are stored in the controller; if power is lost, internal

battery backup ensures settings will not be erased.

MMM DD,YY “Time”

‘Enter’ to set Clock

Document No: 9100-127-1958-99 Rev F

1501 Route 34 South, Farmingdale, NJ 07727 Tel: (732)

919-3119 Fax: (732) 751-5778 www.dialight.com

•Manual Lighting Inspection Screen

The user can perform a manual lighting inspection to ensure proper operation of the

system in its entirety.

NOTE: Discreet and Modbus alarms will be generated during this test, a if NOC is

actively monitoring at the time of test, they will see the generated alarms.

Test will time out after 2 minutes of no user input during the manual test. The test relies

on user input to complete the necessary checks.

Manual LI TEST

‘enter’ to Test

•Status Screen Event Log:

This screen allows the user access to the Event Log. By pressing the “ENTR” button,

current and previous events the system has encountered are able to be viewed, starting

with the most current event. Events can be scrolled through using the “UP” and “DWN”

buttons. Each event occurrence is dated and time stamped.

NOTE: While viewing the event log, real time events are to be viewed by pressing the

“CLR” button to exit the log and then press the “CLR” key to return to log, indicating the

latest recorded event.

Press ‘Enter’ Key to

view event log.

After this display when pressing the up button the Config display is the next one shown.

Document No: 9100-127-1958-99 Rev F

1501 Route 34 South, Farmingdale, NJ 07727 Tel: (732)

919-3119 Fax: (732) 751-5778 www.dialight.com

Manual Lighting Inspection Test for Firmware Versions B6 or higher:

The user can perform a manual lighting inspection to ensure proper operation of the

system in its entirety.

NOTE: Discreet and Modbus alarms will be generated during this test, if NOC is actively

monitoring at the time of test, they will see the generated alarms.

Test will time out after 2 minutes of no user input during the manual test. The test relies

on user input to complete the necessary checks.

NOTE: A lighting inspection can be done remotely but the Auto lighting inspection is

required. The auto does not require covering of the photocell or pressing the selected

mode during the auto test.

System needs to be in Day mode before test is started

Press “ENTR” to initiate LI test

Manual LI TEST

‘enter’ to Test

Press enter

MLI ‘CLR’ to exit Push

WHT BTN

Press’ TEST WHITE’ button located under the ‘Down’ on the LCD control board A

series of test will be automatically performed.

Manual LI TEST IN

PROCESS WHT

Cover photocell; wait until beacon turns Red or White Night.

This can be confirmed by monitoring AL8 on the dry contact board. Once the AL8 is off

the system is in Night mode.

Wait for 15 flashes and then press the TEST RED button.

MLI ‘CLR’ to exit

push RED BTN

Document No: 9100-127-1958-99 Rev F

1501 Route 34 South, Farmingdale, NJ 07727 Tel: (732)

919-3119 Fax: (732) 751-5778 www.dialight.com

The displays will indicate the test is in process and state which mode of night operation

the system is presently configured to.

A and E Structures D Structures

Manual LI TEST IN

PROCESS RED

OR

Manual LI TEST IN

PROCESS NWHT

Once the test is complete one of the 2 displays will be shown.

OR

Manual LI TEST

LIT DONE

System will return to configuration screen when test is completed.

System will reset within 5 minutes after the completion of the test

NOTE: If the test is not completed due to prompts not being followed, tests will time out

after 5 minutes and display:

Manual LI TEST LIT

NOT DONE

Manual LI TEST

PASS : )

Manual LI TEST FAIL

: (

Document No: 9100-127-1958-99 Rev F

1501 Route 34 South, Farmingdale, NJ 07727 Tel: (732)

919-3119 Fax: (732) 751-5778 www.dialight.com

After the Lighting inspection (LI) test is done the user can check the LI list in the Alarm

log and it should be as follows:

For an “E” style system: For a “D” style system:

1. LIT log start 1. LIT log start

2. 865 SYNC 1 ACT 2. 865 SYNC 1 ACT

3. TRNS RS232 1 ACT 3. TRNS RS232 1 ACT

4. TRNS Comm 1 ACT 4. TRNS Comm 1 ACT

5. TRNS Comm 1 CLR 5. TRNS Comm 1 CLR

6. TRNS RS232 1 CLR 6. TRNS RS232 1 CLR

7. 865 SYNC 1 CLR 7. 865 SYNC 1 CLR

8. 1 865 W25% BACT 8. 1 865 W25% BACT

9. 1 865 W25% 1 CLR 9. 1 865 W25% 1 CLR

10. 1 865 W25% 2 CLR 10. 1 865 W25% 2 CLR

11. L810 CAL error ACT 11. PCE LOST ACT

12. L810 CAL error CLR 12. SDLT Comm ACT

13. 1 ALL L810 TX ACT 13. SDLT Comm CLR

14. PCE LOST ACT 14. PCE LOST CLR

15. SDLT Comm ACT 15. LIT log end

16. SDLT Comm CLR

17. PCE LOST CLR

18. 1 ALL L810 TX CLR

19. 1 864 R25% ACT

20. 1 864 R25% CLR

21. LIT log end

For an “A” style system:

1. LIT log start

2. 865 SYNC 1 ACT

3. TRNS RS232 1 ACT

4. TRNS Comm 1 ACT

5. TRNS Comm 1 CLR

6. TRNS RS232 1 CLR

7. 865 SYNC 1 CLR

8. 1 ALL L810 TX ACT

9. L810 CAL error ACT 10. L810 CAL error CLR

11. PCE LOST ACT

12. SDLT Comm ACT

13. SDLT Comm CLR

14. PCE LOST CLR

15. 1 ALL L810 TX CLR

16. 1 864 R25% ACT

17. 1 864 R25% CLR

18. LIT log end

Document No: 9100-127-1958-99 Rev F

1501 Route 34 South, Farmingdale, NJ 07727 Tel: (732)

919-3119 Fax: (732) 751-5778 www.dialight.com

Controller Status LED’s; Located on Main Controller Board with LCD display

Note: Actual colors shown may not match system being installed Note:

There are labels located on the enclosure door stating the alarm

descriptions.

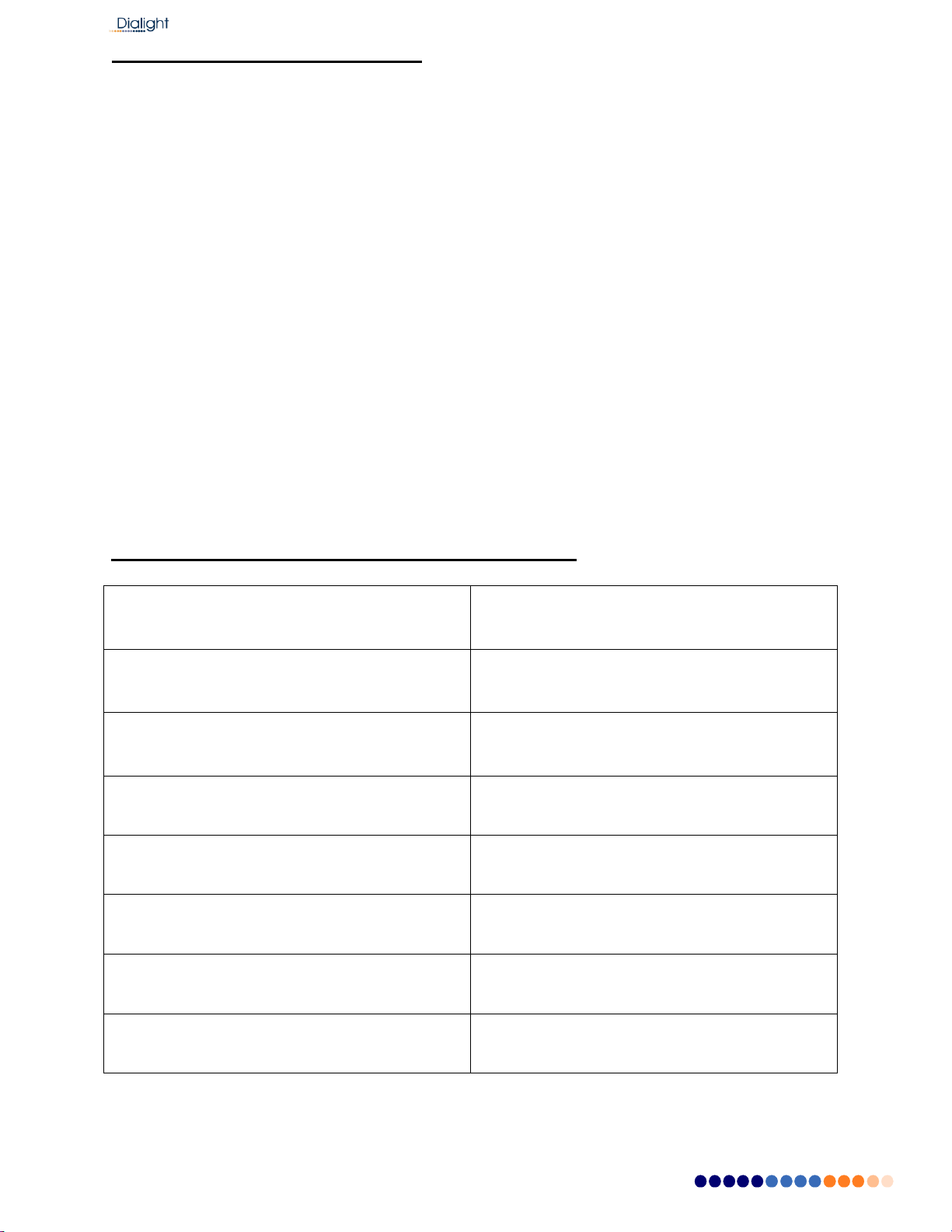

STATUS LED ASSIGNMENTS

S7

S6

S5

S4

S3

S2

S1

COMM SYNC 25% LED ALL 810 OFF Photocell

EXT SYNC Heartbeat

Failure

Failure Failure Failure Failure Day/Night

Failure Flashes

RED RED RED RED RED

AMBER GREEN

Relay Board Alarm Dry Contact LED’s:

STATUS LED/dry contact ASSIGNMENTS

AL8 AL7 AL6 AL5 AL4 AL3 AL2 AL1

PEC

MODE

L 810

FAILURE

Trans

COMM

Day/Night

transition

PEC LOST

25%

FAILURE

Sync

Config or

COMM

Amber

Red

Failure

Red

Failure

Red

* not used

when PEC

Trans is set

to NO

Red

Red

For

either

white or

red fails

Failure

Red

Failure

Red

Dry Contact monitoring Installation:

Cable requirements:

A minimum of 22AWG wire should be used for connecting the relays

Document No: 9100-127-1958-99 Rev F

1501 Route 34 South, Farmingdale, NJ 07727 Tel: (732)

919-3119 Fax: (732) 751-5778 www.dialight.com

1. The relays can be wired individually or multiplexed for alarm monitoring.

2. The relays can be wired as normally open or normally closed.

To monitor the dry contacts on the relay board, the dry contact readers will have to be

wired in to the relay contacts marked (Com, NO, and NC). Relays are marked as if

there is no power is applied to the system.

WARNING: It is highly recommended that by using a multi-meter the dry contacts be

measured for “open” or “closed” by using the OHM setting on the meter.

The relays can measured for open or closed with power applied to the base controller.

NOTE: If only one dry contact reader is present then the relays need to be multiplexed

together to give one output as shown below:

NOTE: If less than 7 dry contact readers then 1 or more dry contacts can be

multiplexed together.

NOTE: Dry contact Relay 8 is only for Day and night monitoring and not Alarm relay

but indication of the mode the system is currently in.

Wiring for Multiplexing a single dry contact reader.

relay7 relay6 relay5 relay4 relay3 relay2 relay1

To Reader (input1) To Reader (input2)

Controller Box Electrical Parameters:

Wattage below is with no side lights attached; wattage from side lights must be added.

Nominal Supply Voltage (VAC)

Conditions

Peak Watts

230Vac 50/60Hz

Day mode (E1 system)

90W

C N

O

N

C

C

N

O

N

C

C N

O

N

C

C N

O

N

C

C N

O

N

C

C N

O

N

C

C N

O

N

C

This manual suits for next models

8