Bopp & Reuther N/F User manual

Strainer

N/F

N/A

NC

Operating Manual

P 401.003 rus

ПО ВОПРОСАМ ПРОДАЖ И ПОДДЕРЖКИ ОБРАЩАЙТЕСЬ:

Архангельск (8182)63-90-72

Астана +7(7172)727-132

Белгород (4722)40-23-64

Брянск (4832)59-03-52

Владивосток (423)249-28-31

Волгоград (844)278-03-48

Вологда (8172)26-41-59

Воронеж (473)204-51-73

Екатеринбург (343)384-55-89

Иваново (4932)77-34-06

Ижевск (3412)26-03-58

Казань (843)206-01-48

Калининград (4012)72-03-81

Калуга (4842)92-23-67

Кемерово (3842)65-04-62

Киров (8332)68-02-04

Краснодар (861)203-40-90

Красноярск (391)204-63-61

Курск (4712)77-13-04

Липецк (4742)52-20-81

Магнитогорск (3519)55-03-13

Москва (495)268-04-70

Мурманск (8152)59-64-93

Набережные Челны (8552)20-53-41

Нижний Новгород (831)429-08-12

Новокузнецк (3843)20-46-81

Новосибирск (383)227-86-73

Орел (4862)44-53-42

Оренбург (3532)37-68-04

Пенза (8412)22-31-16

Пермь (342)205-81-47

Ростов-на-Дону (863)308-18-15

Рязань (4912)46-61-64

Самара (846)206-03-16

Санкт-Петербург (812)309-46-40

Саратов (845)249-38-78

Смоленск (4812)29-41-54

Сочи (862)225-72-31

Ставрополь (8652)20-65-13

Тверь (4822)63-31-35

Томск (3822)98-41-53

Тула (4872)74-02-29

Тюмень (3452)66-21-18

Ульяновск (8422)24-23-59

Уфа (347)229-48-12

Челябинск (351)202-03-61

Череповец (8202)49-02-64

Ярославль (4852)69-52-93

сайт: www.boppreuther.nt-rt.ru || единый адрес: brp@nt-rt.ru

NC, N/A, N/F Strainer

Page 2 of 9 Bopp & Reuther Messtechnik GmbH

Table of Contents

1 IDENTIFICATION.........................................................................................................3

1.1 Supplier/Manufacturer...........................................................................................................................................3

1.2 Type of Product.....................................................................................................................................................3

1.3 Name of Product....................................................................................................................................................3

1.4 Date of Release......................................................................................................................................................3

1.5 Version No..............................................................................................................................................................3

2 AREA OF APPLICATION............................................................................................3

3 SYSTEM DESIGN........................................................................................................3

4. TECHNICAL DATA.....................................................................................................3

4.1 Operating Temperature.........................................................................................................................................3

4.2 Nominal Pressure:.................................................................................................................................................3

4.3 Pressure Drop........................................................................................................................................................4

5. CONSTRUCTIVE DESIGN..........................................................................................5

5.1 Model/Dimensions.................................................................................................................................................5

5.2 Weights...................................................................................................................................................................6

5.3 Materials.................................................................................................................................................................6

5.4 Filter Element Mesh Size.......................................................................................................................................7

6 ORDER INFORMATION ..............................................................................................7

7 STANDARDS AND DIRECTIVES................................................................................7

8 COMMISSIONING AND OPERATION.........................................................................7

9 SAFETY INFORMATION.............................................................................................7

11 MAINTENANCE.........................................................................................................9

12 REPAIRS....................................................................................................................9

13 SERVICE ADDRESSES.............................................................................................9

NC, N/A, N/F Strainer

Bopp & Reuther Messtechnik GmbH Page 3 of 9

1 Identification

1.1 Supplier/Manufacturer

Bopp & Reuther Messtechnik GmbH

1.2 Type of Product

Strainer, series N and NC

1.3 Name of Product

Strainer, series N and NC

1.4 Date of Release

30/10/03

Letzte Revision August 2008

1.5 Version No.

A-EN-03551-00Rev.C

2 Area of Application

The strainer is used to prevent measuring errors and

damages caused by impurities contained in liquids.

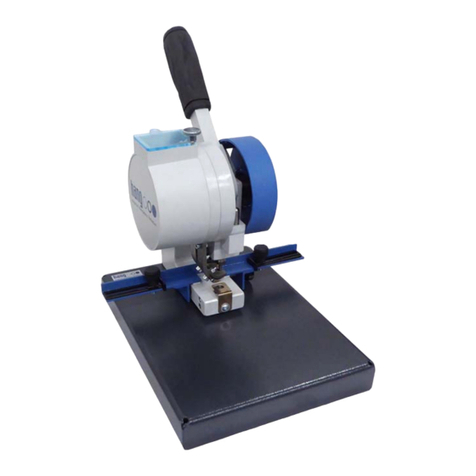

3 System Design

Strainers are made of a cast (NC models) or a welded

(N models) housing and a filter element with a metallic

fabric liner. The liquid flows from the top down through

the filter element in which the impurities are captured

by the fine-meshed metallic fabric. The filter element

can be removed for cleaning after opening the cover.

The NC strainer has conical internal surfaces and

highly radiused edges. These design features

guarantee that the strainer and the connected

pipework are drained completely after opening the

drain plug installed at the lowest position. There is

absolutely no liquid left in the strainer after drainage.

The strainer can be aerated or deaerated via a vent

plug installed at the highest position.

The N/A and N/F models also have a drain plug at the

bottom and a vent plug on the cover. The drained off

liquid will probably contain product residue.

4. Technical Data

4.1 Operating Temperature

NC model -10 to max. +300 °C

(up to –200°C on request)

N model -10 to max. +100 °C

Please pay attention to the material yield point drop

for temperatures above +100°C.

4.2 Nominal Pressure:

NC model PN 40

(Class 150 RF and 300 RF)

N model PN 16, 40, 100

(Class 150 RF, 300 RF

and 600 RF)

NC, N/A, N/F Strainer

Page 4 of 9 Bopp & Reuther Messtechnik GmbH

4.3 Pressure Drop

NC strainer

N strainer

Strainer pressure drops depending

on the flow rate and on the liquid

viscosity with unsoiled filter

elements.

The highest permissible

differential pressure with soiling is

3 bar.

NC, N/A, N/F Strainer

Bopp & Reuther Messtechnik GmbH Page 5 of 9

5. Constructive Design

5.1 Model/Dimensions

NC strainer N strainer

NC strainer

Dimensions for housing with DIN and ANSI flanges in mm

DN Type PN Qmax

[ℓ/min]

Capacity

[litre]

L H D a c L1 L2 B

15 NCR 40 35 0.5 210 236 132 70 166 105 105 180

25 NCR 40 120 0.6 220 246 132 70 176 110 110 180

50 NCS 40 350 3 300 363 190 101 262 154 146 260

80 NCS 40 1250 8.5 400 496 255 125 371 207 193 370

100 NCS 40 3330 23 470 721 320 150 571 240 230 600

N strainer material A and F

DN PN

Qmax

[m³/h]

Capacity

[litre]

L D A B H d

100

4”

16 / Class 150

220

50

550 465 370

270

740 324

40 / Class 300 600 750

100 / Class 600 700 480 390 800 368

150

6”

16 / Class 150

300

600 420

372 740 324

40 / Class 300 650 465 750

100 / Class 600 750 480 390 800 368

150

6”

16 / Class 150

420

110

700 530 485

395

1010

420

40 / Class 300 750 550 500 1025

100 / Class 600 800 520 1060

200

8”

10

520 750

530 485 1010

16 / Class 150

25

550 1025

40 / Class 300 500

100 / Class 600 850 520 1060

NC, N/A, N/F Strainer

Page 6 of 9 Bopp & Reuther Messtechnik GmbH

5.2 Weights

DN PN Capacity

[litre]

NC strainer

[kg]

N/A strainer

[kg]

N/F strainer

[kg]

15 40 0.5 8 --- ---

25 40 0.6 9,5 --- ---

50 40 3 25 --- ---

80 40 8.5 52 --- ---

100 40 23 130 --- ---

100

4”

16 / Class 150 50 --- 130 130

40 / Class 300 50 --- 220 220

100 / Class 600 50 --- 390 390

150

6”

16 / Class 150 50 --- 140 140

40 / Class 300 50 --- 230 230

100 / Class 600 50 --- 400 400

150

6”

16 / Class 150 110 --- 230 230

40 / Class 300 110 --- 360 360

100 / Class 600 110 --- 630 630

200

8”

10 110 --- 240 240

16 / Class 150 110 --- 250 250

25 110 --- 300 300

40 / Class 300 110 --- 380 380

100 / Class 600 110 --- 640 640

5.3 Materials

Model NC/A2

Cast steel

NC/F

Special cast steel

N/A

Steel plate

(welded)

N/F

Special sheet

steel (welded)

Housing GS-C25N 1.0619.01 1.4405 P265GH (HII) 1.4571

Cover P265GH (HII) (HII) 1.4408 P265GH (HII) 1.4571

Flange GS-C25N 1.0619.01 1.4405 P265GH (HII) (welding flange) 1.4571

C22.8 (connection flange DIN)

C21 (connection flange ANSI)

Strainer 1.4571 1.4571 1.4571 1.4571

Nuts and bolts CK 35 / C 35 A4-70 C35E A4-70

Gaskets Centellen

C WS3844

Sigraflex (cover)

Teflon with

25% glass fibre

(deaeration)

PTFE (draining)

Novapress Multi and

Centellen C WS3844

PTFE

NC, N/A, N/F Strainer

Bopp & Reuther Messtechnik GmbH Page 7 of 9

5.4 Filter Element Mesh Size

NC: Standard 0.25 mm

Optional 0.025/0.04/0.063/0.1/0.5/0.8/1.0/2.0

N: Standard 0.25 mm

Optional 0.1/0.5/0.8/1.0/2.0

(All sizes in mm)

6 Order Information

When ordering please state:

The product data, especially weight, temperature,

pressure, viscosity, material, connection sizes,

measuring range, desired accessories, required

approvals, certificates and material certificates.

7 Standards and Directives

Explosion protection directive 94/9/EC:

The device complies with standards EN1127-1 and

EN13463-1 in accordance with ATEX100a. The

operator should always observe respective

regulations when installing and connecting the device

in explosive areas.

Pressure equipment directive 97/23/EC

The NC strainers are suitable for group 1 liquids

- Classification depends on the product’s pressure

stage and capacity acc. to Article 3, §3 (designed and

produced according to excellent engineering

techniques) or acc. to Category III, Module B and C1.

The N/A or N/F strainers are suitable for group 1

liquids

- Classification generally within Category IV, with

individual acceptance acc. to Module G of the

pressure equipment directive for N/A or N/F welded

strainers.

8 Commissioning and Operation

The strainer should be connected to the process via

the flanges. (Please observe the direction of flow!!).

The operator has to ensure that the strainer cannot be

electrostatically charged. For this purpose, an

earthing strap has to be fixed to a screw on the cover

and connected to earth. This ensures that the strainer

is included in the system’s equipotential bonding.

9 Safety Information

The strainer should only be used for its intended area

of application (see 2). Always observe the pressure

and temperature limits stated on the type plate as well

as all other technical data and safety information

during device installation, commissioning and

operation.

Always observe national and international regulations

concerning the operation of devices and systems

under pressure.

Prior to installation, the operator has to ensure that

the pressure bearing parts have not been damaged

during transportation.

The devices have to be installed, operated and

serviced by qualified personnel. The operator has the

responsibility to ensure that the personnel have

received sufficient and appropriate training. In cause

of doubt, please contact the manufacturer.

NC, N/A, N/F Strainer

Page 8 of 9 Bopp & Reuther Messtechnik GmbH

Only measure liquids to which the materials of the

pressure bearing elements are resistant.

Only release flanges or connections for deaeration or

draining purposes when the devices are

depressurised.

Only use the original spare parts specified by the

manufacturer when replacing components. In the

case of non-compliance, warranty shall not apply.

Carefully select gaskets or sealing elements

according to the operating instruction specifications

(see 5.3).

Type Plates

The used abbreviations have the following meaning:

Serial number: Clear identification no.

Year: Year of construction

PT: Achieved test pressure, and test date

DN: Nominal width

Capacity: Strainer capacity in litres

TS: Permissible operating temperature

PS: Permissible operating pressure

Mesh size: Mesh size of the inserted strainer

Type plate for N/A, N/F, and NC DN 80 to DN 100 strainers

Messtechnik

Bopp & Reuther

D-67346 Speyer

0036

NC, N/A, N/F Strainer

Type plate for NC DN 15 to DN 50 strainers

Additional plate NC DN 50 strainers

Messtechnik

Bopp & Reuther

PT bar

0036

1-40-70288-550/a

D - 67346 Speyer

10 Disposal and

Decommissioning

Disposal or decommissioning should only be carried

out by qualified personnel. Product residue has to be

disposed of in accordance with legal regulations.

11 Maintenance

Depending on the degree of liquid soiling, the strainer

has to be changed at regular intervals. In order to

achieve this, open the drain plug and drain off the

liquid. Subsequently open the plugs at the cover and

remove the strainer. Retighten the vent plug together

with a new gasket. Insert the new strainer. Place a

new gasket in the cover and retighten.

12 Repairs

This device has been designed, produced and tested

with the utmost care. In the unlikely event that a fault

should occur, please contact our service department.

P 401.003 rus

ПО ВОПРОСАМ ПРОДАЖ И ПОДДЕРЖКИ ОБРАЩАЙТЕСЬ:

Архангельск (8182)63-90-72

Астана +7(7172)727-132

Белгород (4722)40-23-64

Брянск (4832)59-03-52

Владивосток (423)249-28-31

Волгоград (844)278-03-48

Вологда (8172)26-41-59

Воронеж (473)204-51-73

Екатеринбург (343)384-55-89

Иваново (4932)77-34-06

Ижевск (3412)26-03-58

Казань (843)206-01-48

Калининград (4012)72-03-81

Калуга (4842)92-23-67

Кемерово (3842)65-04-62

Киров (8332)68-02-04

Краснодар (861)203-40-90

Красноярск (391)204-63-61

Курск (4712)77-13-04

Липецк (4742)52-20-81

Магнитогорск (3519)55-03-13

Москва (495)268-04-70

Мурманск (8152)59-64-93

Набережные Челны (8552)20-53-41

Нижний Новгород (831)429-08-12

Новокузнецк (3843)20-46-81

Новосибирск (383)227-86-73

Орел (4862)44-53-42

Оренбург (3532)37-68-04

Пенза (8412)22-31-16

Пермь (342)205-81-47

Ростов-на-Дону (863)308-18-15

Рязань (4912)46-61-64

Самара (846)206-03-16

Санкт-Петербург (812)309-46-40

Саратов (845)249-38-78

Смоленск (4812)29-41-54

Сочи (862)225-72-31

Ставрополь (8652)20-65-13

Тверь (4822)63-31-35

Томск (3822)98-41-53

Тула (4872)74-02-29

Тюмень (3452)66-21-18

Ульяновск (8422)24-23-59

Уфа (347)229-48-12

Челябинск (351)202-03-61

Череповец (8202)49-02-64

Ярославль (4852)69-52-93

сайт: www.boppreuther.nt-rt.ru || единый адрес: brp@nt-rt.ru

This manual suits for next models

2

Table of contents