5

The clear tube of the water bubbler may become coated

with mineral deposits after a period of time. These deposits

can be removed by adding a cup of vinegar to the water

in the bubbler and cleaning the clear tube through the top

plastic fitting with the supplied brush. A water conditioning

filter housing and cartridge are available for abnormally

hard water.

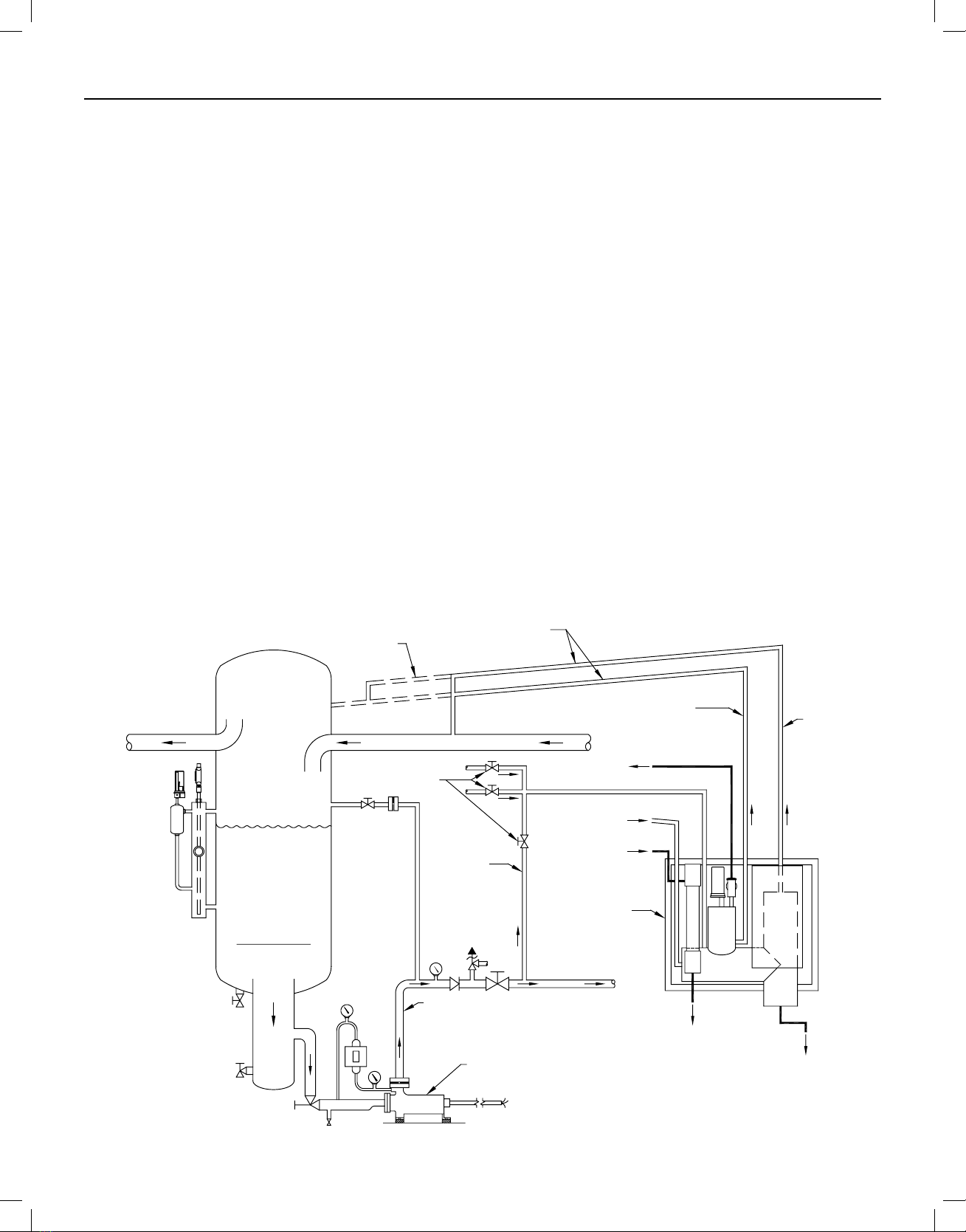

WATER BUBBLER DRAIN LINE

A 1” (25 mm) PVC socket/1” FPT water drain connection

is located at the bottom of the bubbler. The water bubbler

drain line should flow to a suitable drain or container, see

Figure 6. If the drain line is run overhead, the fitting on the

top of the water bubbler must be sealed, including the ¼”

NPT vent connection in the fitting, and a protective mesh

installed around the clear tube. Do not run the line more

than 10’ (3 m) above the height of the bubbler because

the pressure on the water bubbler could be excessive.

Support the drain line to prevent undue stress on the water

bubbler. Also, do not install a shutoff valve in this line.

Initially, fill the water bubbler with water through the 3”

(80 mm) plug located on top of the tube. Keep the plug

lubricated and hand tight. Check for leaks at the hose

fittings.

WATER PURGE LINE

Water removed from the refrigeration system by the

AUTO-PURGER Plus flows out the water purge line. This

line should be directed to a customer supplied container,

such as a 55 gallon drum for example, see Figure 6. It is

recommended to use rigid metal tubing or to secure the

line. Commonly, when draining water, initially all the water

is released, then any oil is released, and then a small

quantity of ammonia vapor may be released. A loose hose

may whip around when the last of the liquid slugs come

out of the hose and is therefore not recommended. The

customer supplied container may be partially filled with

water, and the end of the water purge line submerged in

this water so that any small amount of ammonia vapor

that may be released is dissolved in this water.

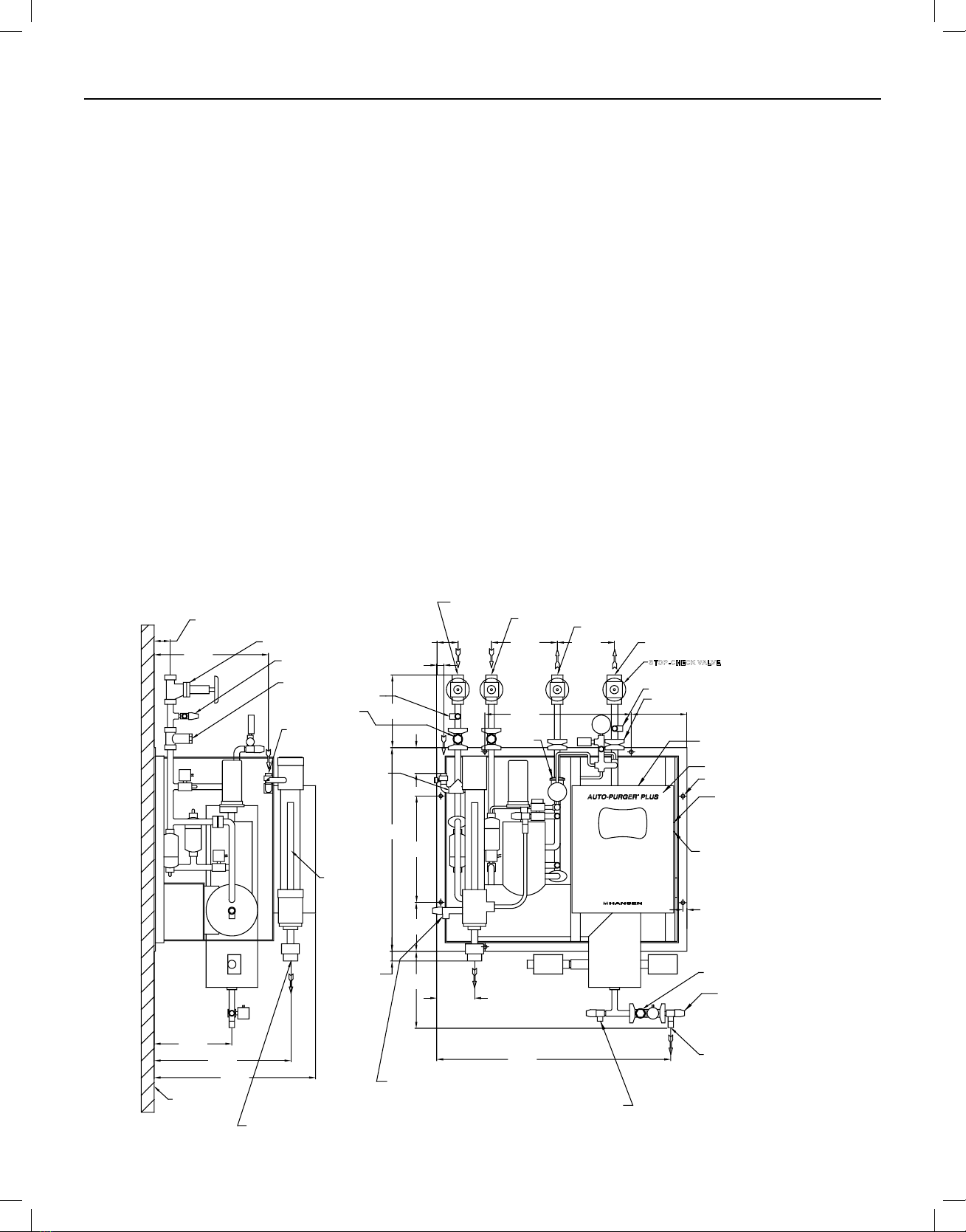

OIL DRAINS

Excess oil can reduce the purger capacity by lowering

the evaporating or condensing rate. Oil is not typically

a problem. Oil in the evaporator chamber is typically

released with the water that is released out the water purge

line. However, any oil that may collect in the purger can

be drained off through the two capped ¼” valves on the

purger, see Figure 1. Before draining oil, close the purge

gas gauge valve to the water bubbler, the low-pressure

pumped-liquid line shut-off valve, the foul gas line shut-

off valve, and the water bubbler fill line valve. Allow the

purger to pump out, then close the low-pressure liquid

return and suction line valves. Use normal oil draining

precautions to prevent injury or property damage.

ELECTRICAL CONNECTIONS

The standard AUTO-PURGER Plus requires a 115V 50/60Hz

17 amp electrical supply on a 20 amp circuit breaker;

models for 220V 50/60Hz, 11 amps electrical supply on

a 15 amp circuit breaker are available. All models have a

½” (13 mm) knockout on the side of the control cabinet to

access the power connection terminal strip.

AUTO-PURGER Plus models APPT08, APPT16, and APPT24

have an additional ¾” (20 mm) knockout for individual

purge point solenoid valves. Wires from each purge point

solenoid valve should be brought to the purger control

cabinet. Any additional access holes should be made on

the side of the control cabinet. All access holes into the

control cabinet must be sealed to prevent moisture, dust,

and debris entering the cabinet.

From each purge point solenoid, one wire is connected

to the corresponding screw terminal for the purge point

inside the control cabinet on the terminal strip. For 115V

models, the other wire from the purge point solenoid is

connected together for all the purge points and tied to

the available neutral position on the top terminal strip.

For the 220V models, the other wire from the purge point

solenoid is connected together for all the purge points

and tied to the top terminal strip labeled PP_COM. Both

115V and 220V models APPT08, APPT16, and APPT24

supply 115V to the purge points.

All APPT models have a relay available which energizes

whenever action is required by plant personnel. The

normally open contacts will close when action is required.

If desired, the contacts may be connected to a light, an

audible alarm, or to a plant computer, to notify plant

personnel to attend to the purger. The contacts are rated

for 10 amps. Connection to the relay is made at the top

terminal strip labeled REMOTE RELAY.

The purger should not be operated when the refrigeration

compressors are stopped. It is recommended to install

a customer supplied, externally mounted, power relay to

de-energize the purger when the refrigeration compressors

are stopped.

After completing all electrical connections inside the

cabinet, connect the cable from the Touchscreen to the

PLC. Connect the cable plug to the socket and tighten the

hand screws. Refer to the wiring tag inside unit.

LEAK TEST

Use standard refrigeration procedures to check the

AUTO-PURGER Plus for leaks before placing it in service.

To confirm a leak-free AUTO-PURGER Plus, manually

open one remote purge point solenoid valve, if there is

one. Manually open the foul gas shut-off valve and allow

pressure inside the purger to build to condensing pressure,

as shown on the high side pressure gauge. Then, manually

open the high side to low side bypass valve to pressurize

the evaporator section of the purger, as shown on the low

side pressure gauge, see Figure 6. Check for leaks. Close

the high side to low side bypass valve.

SECTION 2 INSTALLATION