DiamaPro Systems HGX-5 User manual

HGX-5

5” Hand Grinder

INSTRUCTION MANUAL

READ BEFORE OPERATING

www.DiamaProSystems.com

470-977-2323

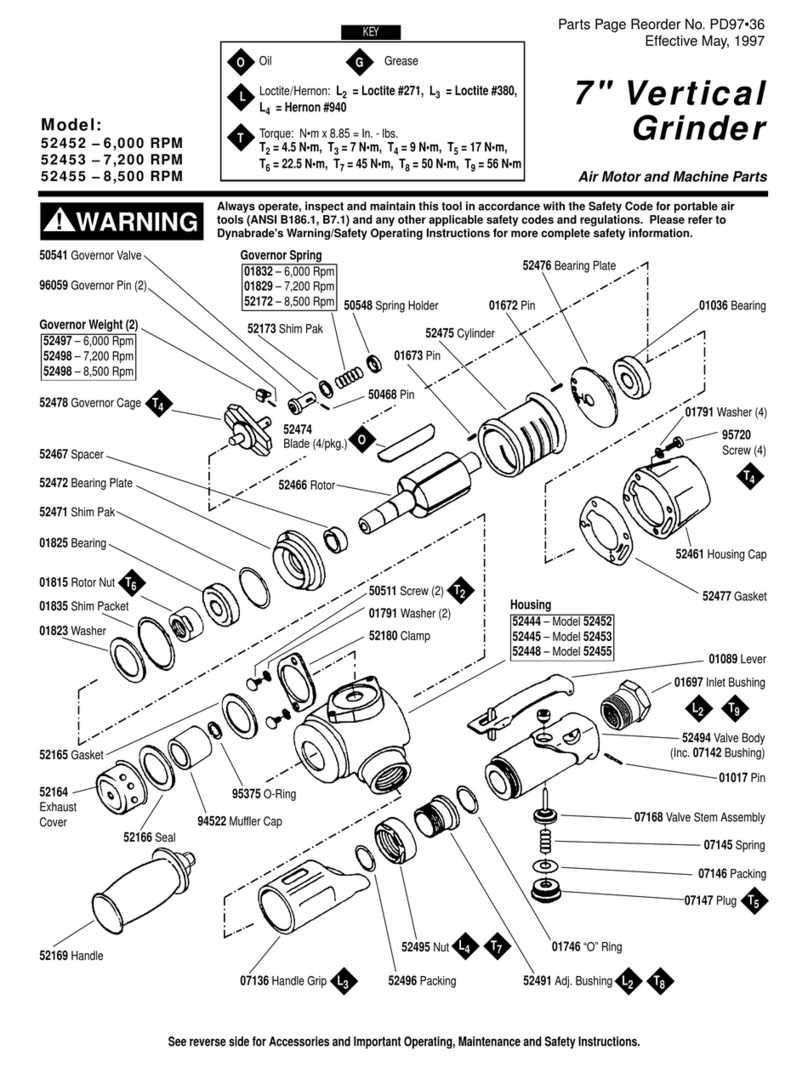

ASSEMBLY VIEW PARTS LIST

Part1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

Description

Top Pressing Plate

Grinding Wheel

Nether Pressing Plate

Wheel Guard

Cross Groove Hexagon Head Screw M6x18

Dust Cap

Cross Slotted Head Set Screw M4x14

Front Cover

Bearing 6201-2RST

Front Cover Bearing Pressing Plate

Cross Slotted Head Set Screw M4x10

Output Shaft

Woodru Key 2.5x3.7xΦ10

Big Bevel Gear

Circlip for Shaft

Bearing 606-2Z

Head

Cross Groove Disc Head Self Tapping Thread ST4.2x22

Self-Lock Pin with Cap

Self-Lock Spring

Steel Cable Bae Ring

Hexagon Nut M6

Bevel Pinion

Bearing PT629-2RST

Head Bearing gland

Cross Recessed Countersunk Head Screw M4x12

Seal Ring

Rotor Assembly

Dustband

Bearing PT608-2RST

Bearing Sleeve

Break Wind Ring

Cross Groove Disc Head Self Tapping Thread ST3.9x70

Stator Assembly

Casing

Carbon Brush

Coil Spring

Cross Groove Disc Head Self Tapping Thread ST2.9x10

Carbon Brush Holder

Capacitor 0.22uf

Cross Groove Disc Head Self Tapping Thread ST4.2x14

Cable Pressing Plate

Back Cover

Switch Push Rod

Push Rod Spring

Switch Block

Switch

Speed Controller

Cable Sleeve

Plug

Side Handle

Wrench

Part1No.

HGX500100

HGX500101

HGX500102

HGX500103

HGX500104

HGX500105

HGX500106

HGX500107

HGX500108

HGX500109

HGX500110

HGX500111

HGX500112

HGX500113

HGX500114

HGX500115

HGX500116

HGX500117

HGX500118

HGX500119

HGX500120

HGX500121

HGX500122

HGX500123

HGX500124

HGX500125

HGX500126

HGX500127

HGX500128

HGX500129

HGX500130

HGX500131

HGX500132

HGX500133

HGX500134

HGX500135

HGX500136

HGX500137

HGX500138

HGX500139

HGX500140

HGX500141

HGX500142

HGX500143

HGX500144

HGX500145

HGX500146

HGX500147

HGX500148

HGX500149

HGX500150

HGX500151

12. Remove adjusting keys or

wrenches before turning the tool

on. A wrench or a key that is left at-

tached to a rotating part of the tool

may result in personal injury.

13. Do not overreach. Keep proper

footing and balance at all times.

Proper footing and balance enables

better control of the tool in unex-

pected situations.

14. Use safety equipment. Always

wear eye protection. Dust mask,

non-skid safety shoes, hard hat,

and hearing protection must be

used for appropriate conditions.

Ordinary eye or sun glasses are

NOT eye protection.

TOOL USE AND CARE

15. Use clamps or other practical

ways to secure and support the

workplace to a stable platform.

Holding the workpiece by hand or

against your body is unstable and

may lead to loss of control.

16. Do not force tool. Use the cor-

rect tool for your application. The

correct tool will do the job better

and safer at the rate for which it is

designed.

17. Do not use tool if switch does

not turn it on or o. Any tool that

cannot be controlled with the switch

is dangerous and must be repaired.

18. Disconnect the plug from the

power source before making any

adjustments, changing acces-

sories, or storing the tool. Such

preventative safety measures

reduce the risk of starting the tool

accidentally.

19. Store idle tools out of the reach

of children and other untrained

persons. Tools are dangerous in

the hands of untrained users.

20. Maintain tools with care. Keep

cutting tools sharp and clean.

Properly maintained tools with

sharp cutting edges are less likely

to bind and are easier to control.

21. Check for misalignment or bind-

ing of moving parts, breakage of

parts, and any other condition

that may aect the tool’s opera-

tion. If damaged, have the tool ser-

viced before using. Many accidents

are caused by poorly maintained

tools.

22. Use only proper 5” DiamaPro

Systems tools with this model.

Accessories that may be suitable

for one tool, may become hazard-

ous when used on another tool.

23. Tool service must be performed

only by qualied repair person-

nel. Service or maintenance per-

formed by unqualied personnel

could result in a risk of injury.

24. When servicing a tool, use only

identical replacement parts.

Follow instructions in the Mainte-

nance section of the manual. Use

of unauthorized parts or failure to

follow maintenance instructions

may create a risk of electric shock

or injury.

25. Always use with a DiamaPro

Systems dust shroud.

26. Failure to follow proper use guide-

lines will result in void of

warranty.

GENERAL SAFETY TOOLS

(For All Tools)

WARNING: Read and understand all instructions. Failure to follow

all instructions listed below may result in electric shock, re and/or

serious personal injury.

Warning: The body of the machine may get warm after extended

use. If this occurs, turn o the machine and let it cool down to

avoid risk of damaging the unit, or personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

1. Keep your work area clean and

well lit. Cluttered benches and dark

areas invite accidents.

2. Do not operate power tools in

explosive atmospheres, such as

in the presence of ammable liq-

uids, gases or dust. Power tools

create sparks which may ignite the

dust or fumes.

3. Keep bystanders, children, and

visitors away while operating a

power tool. Distractions can cause

loss of control.

ELECTRICAL SAFETY

4. Power tool plugs must match

the outlet. Never modify the

plugs in any way. Do not use any

adapter plugs with grounded

power tools. Unmodied plugs

and matching outlets will reduce

risk of electric shock. Do not

change the plug in any way. Dou-

ble insulation eliminates the need

for the three wire grounded power

cord and grounded power supply

system.

5. Avoid body contact with ground-

ed surfaces such as pipes, radi-

ators, ranges and refrigerators.

There is an increased risk of elec-

tric shock if your body is grounded.

6. Do not expose power tools to rain

or wet conditions. Water entering

a power tool will increase the risk of

electric shock.

7. Do not abuse the cord. Never use

the cord to carry the tool or pull

the plug from an outlet. Keep

cord away from heat, oil, sharp

edges or moving parts. Replace

damaged cords immediately.

Damaged cords increase the risk of

electric shock.

8. When operating a power tool

outside, use an outdoor exten-

sion cord marked “W-A” or “W.”

These cords are rated for outdoor

use and reduce the risk of electric

shock.

PERSONAL SAFETY

9. Stay alert, watch what you are

doing and use common sense

when operating a power tool. Do

not use tool while tired or under

the inuence of drugs, alcohol, or

medication. A moment of inattention

while operating power tools may

result in serious personal injury.

10. Dress properly. Do not wear

loose clothing or jewelry. Con-

tain long hair. Keep your hair,

clothing, and gloves away from

moving parts. Loose clothes, jew-

elry, or long hair can be caught in

moving parts.

11. Avoid accidental starting. Be

sure switch is o before plug-

ging in. Carrying tools with your

nger on the switch or plugging in

tools that have the switch on invites

accidents.

SPECIFIC SAFETY RULES

1. Always use a DiamaPro Systems

dust shroud. Shrouds protect opera-

tor from broken wheel fragments.

2. Accessories must be rated for at

least the speed recommended on

the tool warning label. Wheels and

other accessories running over rated

speed can y apart and cause injury.

3. Do not let the tool come in con-

tact with live wire. Contact with a

“live” wire will make exposed metal

parts of the tool “live” and shock the

operator.

4. Always use safety glasses or gog-

gles. Ordinary eye or sun glasses

are NOT safety glasses.

5. Check the wheel carefully for

cracks or damages before opera-

tion. Replace cracked or damaged

wheel immediately. Run the tool (with

guard) at no load for about a minute,

holding tool away from others. If

wheel is awed, it will likely separate

during this test.

6. Only use with DiamaPro Systems

5” cup wheels and abrasives.

7. Be careful not to damage the

spindle, the ange (especially the

installing surface) or the outer

ange. Damage to these parts could

result in wheel breakage.

8. NEVER use tool with wood cutting

blades or other saw blades. Such

blades when used on a grinder fre-

quently kick and cause loss of control

leading to personal injury.

9. Hold the tool rmly.

10. Keep hands away from rotating

parts.

11. Make sure cord is clear of wheel.

Do not wrap cord around your arm

or wrist. If control of tool is lost, cord

may become wrapped around you

and cause personal injury.

12. Make sure the wheel is not con-

tacting the workpiece before the

switch is turned on.

13. Before using the tool on an

actual workpiece, let it run for

a while. Watch for vibration or

wobbling that could indicate poor

installation or a poorly balanced

wheel.

14. Use the specied surface of the

wheel to perform the grinding.

15. Watch out for ying sparks. Hold

the tool so that sparks y away from

you and other persons or amma-

ble materials.

16. Do not leave the tool running.

Operate the tool only when hand-

held.

17. Do not touch the workpiece im-

mediately after operation; it may

be extremely hot and could burn

your skin.

18. ALWAYS wear proper apparel

including long sleeve shirts.

Leather gloves and shop aprons

to protect skin from contact with

hot grindings.

19. Use of this tool to grind or

sand some products. Paints and

wood could expose user to dust

containing hazardous substanc-

es. Use appropriate respiratory

protection.

20. Must use with DiamaPro Hepa

Filtered Dust Collector

DO NOT let comfort or familiarity with product (gained from repeated use)

replace strict adherence to grinder safety rules. If you use this tool unsafely or

incorrectly, you can suer serious personal injury.

SAVE THESE INSTRUCTIONS

WARNING: MISUSE or failure to follow the safety rules stated in this

instruction manual may cause serious personal injury.

nMaintenance & Daily Care.

CAUTION:

Always be sure that the tool is

switched o and unplugged before

attempting to perform inspection and

maintenance.

1. The tool and its air vents have to

be kept clean. Regularly clean the

tool’s air vents, or whenever the

vents start to become obstructed.

2. Make sure all screws are properly

tightened.

3. Regularly check if the cord insula-

tion is broken.

n Eective and safe grinding &

sanding operation.

• Always hold the tool rmly with

one hand on housing and the

other on the side handle. Turn the

tool on and then apply the wheel

or disc to the workpiece.

• Operating the tool while removing

the wheel guard is forbidden.

1. Do not place too much pressure on

the tool. Excessive strength could

damage the tool engine and abra-

sive wheel due to overload.

nReplacing carbon brushes.

1. Remove and check the carbon

brushes regularly. Replace when

the tool sparks or wears down with

5-7mm left.

2. Both carbon brushes should be re-

placed at the same time. Use only

DiamaPro Systems brushes.

3. Please send this tool to DiamaPro

Systems’ authorized service center

to replace or be repaired by an

experienced technician.

CAUTION:

Be sure to reinstall the knob after

inserting new carbon brush.

After replacing brushes, plug in the

tool and break in brushes by running

tool with no load for ~10min. If the

tool is not working well, ask your local

DiamaPro Systems service center for

repair.

To maintain product SAFETY &

RELIABILITY, repairs and other

maintenance or adjustment should

be performed by DiamaPro Systems

Authorized or Factory service cen-

ters, always using DiamaPro Systems

replacement parts.

FUNCTIONAL DESCRIPTION

nOperation Instructions:

Wheel Guard

Aim the convex end of the wheel

guard to the slot mouth of the

front cover, and then rotate the

guard body to 180°, finally tighten

the fastening screw (Fig1 & Fig2).

Side grip (Fig 5)

CAUTION:

Always be sure that the side grip

is installed securely before oper-

ation.

Screw the side grip securely on

the position of the tool as shown

in Fig5.

Hold the side grip rmly by hand to

better control the tool.

Fig5

Installing or removing

grinding wheel

CAUTION:

• When using an abrasive cut-

o wheel, be sure to use only

the supplied wheel guard,

inner ange, and outer ange

designed for use with cut-o

wheels.

1. Mount the inner ange onto the

spindle. Fit the wheel/disc on

the inner ange and screw the

outer ange onto the spindle

(Fig 3).

2. To tighten the outer ange,

press the shaft lock rmly

so that the spindle cannot

revolve, then use the lock nut

wrench and securely tighten

clockwise (Fig 4).

3. To remove the wheel, follow

the installation procedure in

reverse.

NOTICE:

The groove of INNER

FLANGE must align the

atness of spindle when you

install the wheel and tighten

enough.

Fig1

Fig2

Fig3

Table of contents

Other DiamaPro Systems Grinder manuals