Diamatic BDC-SLURRY PRO User manual

The Choice of Professionals

www.diamatic.usa info@diamatic.usa

Operating Instructions

BDC-SLURRY PRO

Original Operating Instructions

Version 1.0:

Diamatic

622 Grant Rd

Folcroft, PA 19032

Tel: +1 619-295-0893

The Choice of Professionals

www.diamatic.usa P a g e | 2 info@diamatic.usa

Table of Contents

Table of Contents-------------------------------------------------------------------------------------------------------------------2

1.

Introduction-----------------------------------------------------------------------------------------------------------------------3

2.

Machine Description------------------------------------------------------------------------------------------------------------4

3.

Safety-------------------------------------------------------------------------------------------------------------------------------5

3.1 Work Area Safety ----------------------------------------------------------------------------------------------------------5

3.2 Electrical Safety ------------------------------------------------------------------------------------------------------------5

3.3Personal Safety---------------------------------------------------------------------------------------------------------------6

3.4 Machine Safety General --------------------------------------------------------------------------------------------------6

3.5 Maintenance Safety --------------------------------------------------------------------------------------------------------6

3.6 Safety Regarding Slurry Vacuums -------------------------------------------------------------------------------------7

3.8 Transport Safety ------------------------------------------------------------------------------------------------------------7

4.

Start Up and Shut Down-------------------------------------------------------------------------------------------------------8

5.

Inspection and Maintenance --------------------------------------------------------------------------------------------------9

5.1. Emptying --------------------------------------------------------------------------------------------------------------------9

5.2. Pump Cleaning Instructions------------------------------------------------------------------------------------------- 10

5.3. Filter Inspection:--------------------------------------------------------------------------------------------------------- 11

5.4. Motor Cover Disassembly for Brush Inspection ----------------------------------------------------------------- 12

5.5. Ametek Motor Brush Inspection:------------------------------------------------------------------------------------ 13

5.6. Electro Motor Brush Inspection:------------------------------------------------------------------------------------- 14

6.

Troubleshooting --------------------------------------------------------------------------------------------------------------- 15

7.

Technical Information: ------------------------------------------------------------------------------------------------------- 16

8.

Slurry Vacuum Parts Breakout:-------------------------------------------------------------------------------------------- 17

9.

Slurry Vacuum Parts List:--------------------------------------------------------------------------------------------------- 18

10.

Filter Module Parks Breakout:------------------------------------------------------------------------------------------- 19

12.

Filter Module Parts List: --------------------------------------------------------------------------------------------------- 20

13.

Rear Stack Assembly Parts Breakout: ---------------------------------------------------------------------------------- 21

14.

Rear stack Assembly Parts list:------------------------------------------------------------------------------------------- 22

16.

Slurry Collection Assembly Parts Breakout:-------------------------------------------------------------------------- 23

17.

Slurry Collection Assembly Parts List:--------------------------------------------------------------------------------- 24

18.

Slurry Deck Motor Assembly Parts Breakout:----------------------------------------------------------------------- 25

19.

Slurry Deck Motor Assembly Parts List: ------------------------------------------------------------------------------ 26

20.

Floor Tool 32” Assembly Parts Breakout:----------------------------------------------------------------------------- 27

21.

Floor Tool 32” Assembly Parts List:------------------------------------------------------------------------------------ 28

22.

Double Stack Frame Assembly Parts Breakout: --------------------------------------------------------------------- 29

23.

Double Stack Frame Assembly Parts List: ---------------------------------------------------------------------------- 30

24.

Enclosure with Switch, PVC Parts Breakout:------------------------------------------------------------------------- 31

25.

Enclosure with Switch PVC Parts List: -------------------------------------------------------------------------------- 32

The Choice of Professionals

www.diamatic.usa P a g e | 3 info@diamatic.usa

1.

Introduction

Before use, operators must be provided with information, instruction and training for the use of the machine and the substances for

which it is to be used, including the safe method of removal and disposal of the material collected. All persons who are working

with or maintaining this machine must read the manual carefully and understand it fully. In case you sell the unit, hand it on to the

next owner.

Keep this manual always with the machine, to enable it to be referred to at any time. Any other work

not covered by this operating manual must not be carried out.

This machine is designed for industrial use by professionals. Only authorized and trained personnel may operate this machine.

This machine is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge. Diamatic BV offers a course on the use of the machine in order to make the operating and maintenance

personnel familiar with all elements of the machine.

The Choice of Professionals

www.diamatic.usa P a g e | 4 info@diamatic.usa

2.

Machine Description

The BDC-SLURRY PRO is an electrically powered slurry vacuum. This 120V single phase slurry vacuum comes with two

powerful 1200W motors and .5HP return pump enabling vacuuming and pumping simultaneously. The BDC-SLURRY PRO uses a

32” floor sweeper to vacuum slurry into its 32-gallon storage container. Designed to meet OSHA silica dust compliance standards,

while providing 44ft2 of hydrophobic filtration – 99% at 0.5 microns. The BDC-SLURRY PRO is designed to be the best solution

for all slurry control needs, with removal and disposal all in one unit. The BDC-SLURRY PRO produces up to 200 CFM, strong

enough to leave the floor clean of slurry in one pass. The BDC-SLURRY PRO will speed up production by having an easier and

more reliable way to remove slurry off of a concrete surface. It can be used for wet applications only.

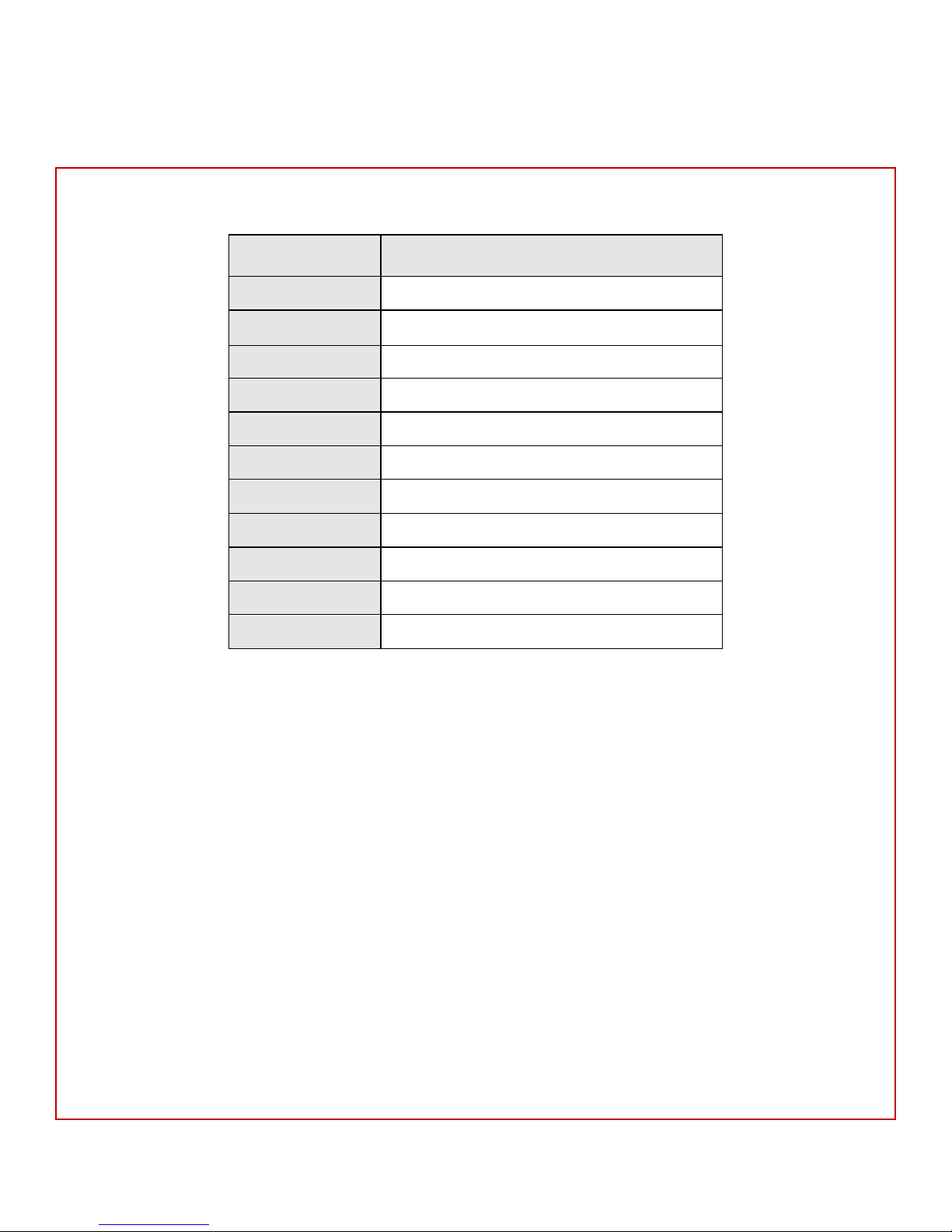

1

1200W Motor

4

Storage Container

7

32” Floor Sweeper

2

Return pump

5

Filter Housing

8

Blast Gate

3

Composite Modular Housing

6

Liquid fill shut off

9

Separate Slurry Collection Chamber

The Choice of Professionals

www.diamatic.usa P a g e | 5 info@diamatic.usa

3.

Safety

Read all safety warnings and all instructions. Failure to follow the warnings and instructions may

result in electric shock, fire, explosions and / or serious injuries.

3.1 Work Area Safety

a)

Do not use the machine in rain, damp or wet locations.

b)

Avoid dangerous environments: do not work in the presence of explosive atmospheres, in the presence of flammable liquids, gases or

dust. Remove materials or debris that may be ignited by sparks.

c)

The surface to be treated must be clean, make sure to remove all stones, screws etc..

Any stones, screws, bolts, pieces of wire etc. could cause serious damage if it gets inside the machine!

d)

Make sure there is enough ambient light on the work area. Cluttered or dark areas invite accidents.

e)

Do not use on wood.

f)

Keep children and bystanders away while operating the machine. They are likely not to foresee the potential dangers of the

machine. Distractions could cause you to lose control of the machine.

g)

Persons who are not operating the machine must not be permitted to stay in the surrounding area of at least 5 meters from the

machine.

h)

Never use the machine when the surface is not clear and if there is a risk of stumbling or tripping.

i)

Make sure that there are no cables or hoses in the driving direction of the machine.

j)

Make sure that there is nothing standing or situated on the surface to be treated.

k)

Make sure the machine can travel over all inequalities on the surface, small inequalities like weld seams or floor joints are no barriers

for the machine.

l)

Never stay in the rain with the machine.

m)

Check if there are any obstacles that can snag the cables when the machine is moving.

n)

Remove reinforcing steel or other objects protruding from the surface in order to prevent damage to the compounds or diamond discs.

o)

Warning!

Make sure that the surface to be treated does not contain dangerous materials such as:

-

combustible or explosive dusts or substances.

-

carcinogenic or pathogenic substances.

p)

Secure the work area around the machine in public areas providing an adequate safety distance from the machine. Use a red and

white safety chain and danger sign to enclose the work area.

3.2 Electrical Safety

a)

Use only extension cables for extending the main cable that are sized and marked in accordance with the overall power

consumption of the machine. Do not use damaged extension cables.

b)

Electrical cables must be rolled entirely off of the reels.

c)

Any damage to the electric cables and/or electrical components is not permitted.

d)

The voltage on the identification plate must comply with the power supply.

e)

Use an electrical power supply connection with earth connection and earth leakage circuit breaker.

f)

The circuit breaker of the power supply must have a ‘’D’’ characteristic. Circuit breakers with a “C” or “B” characteristic can give

problems when switching the motor on.

g)

Keep the machine original; The machine is always equipped with an earthed connection, do not change this and always use

earthed cables with an earthed plug.

h)

Inspect and test the electrical components regularly. The electrical components have to satisfy with the requirements set out in the

harmonised norm EN60204-1.

i)

Always call a skilled electrician or your distributor when you have questions about the safety of the electrical components.

j)

Work on electrical equipment or operating materials may only be undertaken by a skilled electrician or by trained persons under the

guidance and supervision of a skilled electrician as well as in accordance with the electrical engineering regulations.

k)

Always use tools that are insulated against voltages.

l)

Do not abuse the cables. Never use the cables for carrying, pulling or unplugging the machine. Keep cables away from heat, oil,

sharp edges or moving parts. Damaged or entangled cables increase the risk of electric shock.

m)

Be careful with water on the treated surface. Electrical cables must not come into contact with water.

The Choice of Professionals

www.diamatic.usa P a g e | 6 info@diamatic.usa

n)

The main power switch on the machine must be in the “Off” position before connecting to the power supply. (Only if there is a

main switch present on the electrobox.)

o)

During a long standstill of the machine, pull out the main plug and cover it with plastic foil.

p)

If the machine is to be operated using power from a generator, the generator must be operated in accordance with the current legal

regulations and directives in force. (this applies to the protective earth conductor in particular) in order to ensure that all safety

devices are functioning and to eliminate possible damage to electrical components.

3.3 Personal Safety

a)

Always wear Personal Protective Equipment while working with the machine.

-Dust mask class FFP2 or higher

-Ear protection

-Safety glasses with lateral protection

-Protecting gloves

-Safety shoes

b)

Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves away from moving parts.

c)

Stay alert, watch what you are doing and use common sense when operating the machine.

d)

All persons in the proximity of the machine, must wear ear protectors and safety shoes.

e)

Always seek professional medical attention immediately in case of injury.

3.4 Machine Safety General

a)

Safety functions and operating functions must work correct.

b)

No loose bolts and nuts permitted.

c)

Never operate machine without the guards and/or safety devices in place.

d)

Never change anything on the safety devices on the machine!

e)

The machine, specially the handle grips must be free of fats/oils and have to be dry.

f)

If the length of the brushes is, due to wear, less than 5mm or they are extremely deformed, the brushes have to be replaced.

Check the Service Manual for the order numbers.

g)

All repair work has to be done by qualified Diamatic personnel, this guarantees a safe and reliable machine.

The part numbers can be found in the Service Manual.

h)

If safety-critical changes occur to the machine or its working method, the machine must be shut down immediately! The cause

of the fault must be established, and rectified.

i)

In the event of operational malfunctions the machine must be shut down immediately and secured!

j)

Do not use the unit when it is damaged.

k)

Do not open or remove protective guards while driving gears are running.

3.5 Maintenance Safety

a)

Pull out the main plug before starting inspections and repairing on the machine.

b)

Wait for standstill of all drives before any inspections, adjustments and/or maintenance work is started.

c)

Block the machine in a stable position before doing any maintenance work.

d)

Failures due to inadequate or incorrect maintenance may generate very high repair costs and long standstill periods of the

machine. Regular maintenance therefore is imperative.

e)

Operational safety and service life of the machine depends, among other things, on proper maintenance.

f)

Prevent premature wear by keeping the machine as dust free as possible. Clean the machine for this reason regularly with a dust

collector and non-aggressive materials. Never use a high-pressure water cleaner to clean the machine.

g)

It is advisable to stock all spare parts or wear parts that cannot be supplied quickly. As a rule, production standstill periods are

more expensive than the cost for the corresponding spare part.

h)

Do not use any aggressive cleaning materials!

i)

Use lint-free cleaning cloths!

j)

For the electrical parts, use a tool that is insulated against voltages.

The Choice of Professionals

www.diamatic.usa P a g e | 7 info@diamatic.usa

3.6 Safety Regarding Slurry Vacuums

a)

The slurry container must be emptied regularly. Comply with the local waste treatment regulations considering the removed

material.

b)

The slurry hose must be connected properly with a hose clamp and industrial tape.

c)

The slurry hose must be undamaged and free of obstructions.

d)

Always switch on the dust collector first!

3.8 Transport Safety

a)

Be aware of your surroundings and machine operating level. Do not side hill, do not run on steep incline, this could cause

machine to tip over.

b)

The weight of the BDC-SLURRY PRO is 346 lbs. Use a crane or lift when transporting the machine, use the lifting eyes of the

machine.

c)

Before every use check the lifting eyes and welds for: deformation, damages, cracks, corrosion and wear.

d)

When lifting the machine from the ground, always use the lowest lifting speed. The cables must first be tensioned at this speed; they

must not be slack when the machine is lifted from the ground.

e)

During hoisting make sure to be at a safe distance from the machine with the most optimal view on the machine and working

environment.

f)

Never stand directly below the machine.

g)

When transporting the machine do so in such a manner that damage due to the effects of the use of force or incorrect loading and

unloading is avoided.

h)

The lifting eyes can also be used to fasten the machine on a pallet or during transport.

i)

Always drive backwards when driving up to a ramp or grade, and forwards when driving of the ramp.

j)

Chock wheels for transport and keep control handle in neutral position.

k)

Don’t leave the machine unsecured on jobsites.

l)

Park the machine always on a flat horizontal and levelled surface.

m)

Make sure the floating shroud is in transport mode when you transport the machine.

n)

Make sure the electrical cable and dust hose are disconnected.

o)

Store the cleaned and dry machine in a humid free room. Protect the electrical motor from moisture, heat dust and shocks.

p)

Never use the machine for lifting persons or items.

The Choice of Professionals

www.diamatic.usa P a g e | 8 info@diamatic.usa

4.

Start Up and Shut Down

Check that the slide valve

is closed.

Connect to proper power

source as indicated on the

serial tag.

Start machine using the ON /

OFF switch on the motor

domes.

Turn machine off using the

ON / OFF switch on the motor

domes.

It is critical that you

empty/clean the vacuum

after each use. If material

is allowed to “set up”

inside it will render the

vacuum inoperable. Please

refer to Section IV for

instructions.

Machine should be

emptied after every use.

1

2

3

4

Note: Electrical installation should be performed by a qualified electrician in accordance with

governing national and local electrical codes.

The Choice of Professionals

www.diamatic.usa P a g e | 9 info@diamatic.usa

5.

Inspection and Maintenance

5.1. Emptying

Collection vessel and pump must be cleaned after every single use. The pump may be used while the vacuum is

running, but if the pump needs to be cleaned you must turn the vacuum off.

Use the internal pump to

evacuate the water.

You

must hold the switch down

to operate the pump.

If pump becomes clogged,

refer to

the pump cleaning

instruction on the next page.

Once most of the water has

been pumped out of the

machine you can open the slide

gate at the bottom of the

collection unit. The solids can

be flushed

or scooped out. Close

slide gate when finished.

Check for carryover liquid

by opening the slide gate

under the filter housing.

Close slide gate when

finished.

1

2

3

4

Note: The emptying/cleaning instructions must be performed after each use. Do not

allow the material to set up inside.

The Choice of Professionals

www.diamatic.usa P a g e | 10 info@diamatic.usa

5.2. Pump Cleaning Instructions

Loosen hose cuff.

Disconnect clamps on

either side.

Remove motor deck.

Remove the pump

from the tank without

disconnecting the hose.

Place the pump in a 5-

gallon bucket and run the

clean water through the

pump.

1

2

3

4

5

Note: Pump should be cleaned daily to ensure material doesn’t build up and harden.

The Choice of Professionals

www.diamatic.usa P a g e | 11 info@diamatic.usa

5.3. Filter Inspection:

Disconnect the pump

from power if included.

Disconnect clamps on

either side.

Remove motordeck

and inspect filter. The

filter is used to stop

moisture from

entering the motor and

not for

filtering dust.

Loosen filter hold down

bracket bolts enough to

remove the filter.

Remove filter and

inspect. Replace filter as

needed to maintain

optimal performance

Open the slidegate under

the filters to empty any

liquid from the filter

chamber.

Close the slide gate before

using the unit.

5

Note: Inspection of the filter will vary with usage of the machine.

The Choice of Professionals

www.diamatic.usa P a g e | 12 info@diamatic.usa

5.4. Motor Cover Disassembly for Brush Inspection

Turn the machine off,

then disconnect the

power source.

Disconnect motor

terminal.

Loosen the motor

retaining knobs enough

to remove motor under

negative pressure.

Remove the 6 screws

attached to each motor

assembly.

Remove the plastic

motor cover to access

the top of the motor.

Remove the 2 metal

motor-cap-retaining

clips locating on each

motor (for Ametek

motors only)

1

2

3

4

6

5

The Choice of Professionals

www.diamatic.usa P a g e | 13 info@diamatic.usa

5.5. Ametek Motor Brush Inspection:

NOTE: A motor brush should be replaced if its length is less than 0.25 inches.

Remove motor fan

cover by pressing down

on clips located on each

side.

Remove the two

screws securing the

brush. Repeat the

process for the other

side.

Pull brush out from

wire clip.

Remove brush from wire

clip by sliding off

groove. If brush is worn

down to a length of

0.25” or less, replace

brush.

To replace or reinstall

brush, repeat process in

reverse.

1

2

3

4

The Choice of Professionals

www.diamatic.usa P a g e | 14 info@diamatic.usa

5.6. Electro Motor Brush Inspection:

NOTE: A motor brush should be replaced if its length is less than 0.25 inches.

Carefully dislodge the

plastic motor cap via the

built-in hooks on both

sides of motor brush.

(TIP: Dislodge

one side

of a cap first followed

by the other.)

With a flathead

screwdriver, flip brush

tab upward. Use pliers

to then pull the brush

out by the tab.

If the brush is worn

down to a length of

0.25” or less, replace

the brush. To replace

or reinstall brush, hold

down internal spring

using the tool supplied

with brush.

While holding spring

down, push the brush

back in. Remove the

brush tool once the

brush is in.

Push the motor brush

in until it’s flush.

1

2

3

4

5

The Choice of Professionals

www.diamatic.usa P a g e | 15 info@diamatic.usa

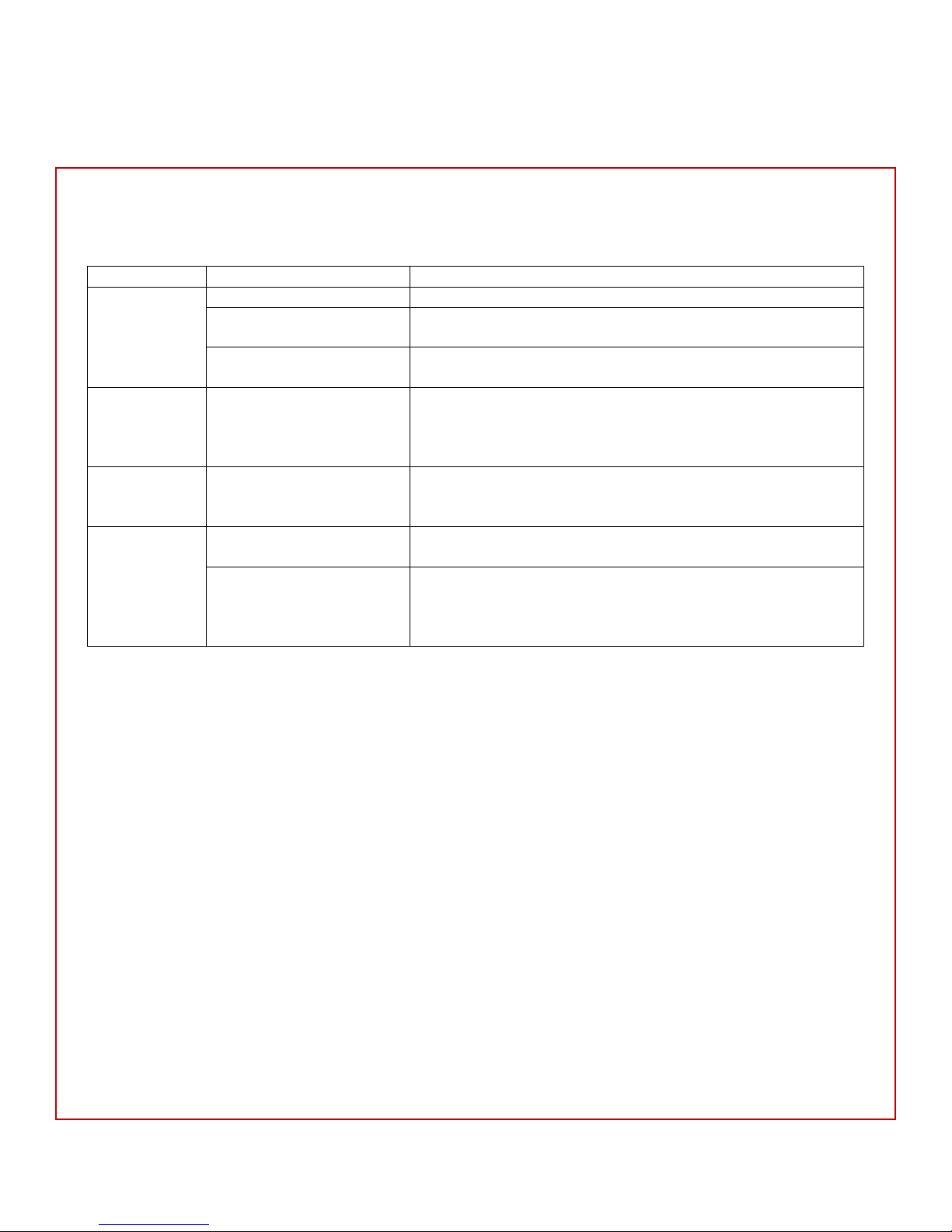

6.

Troubleshooting

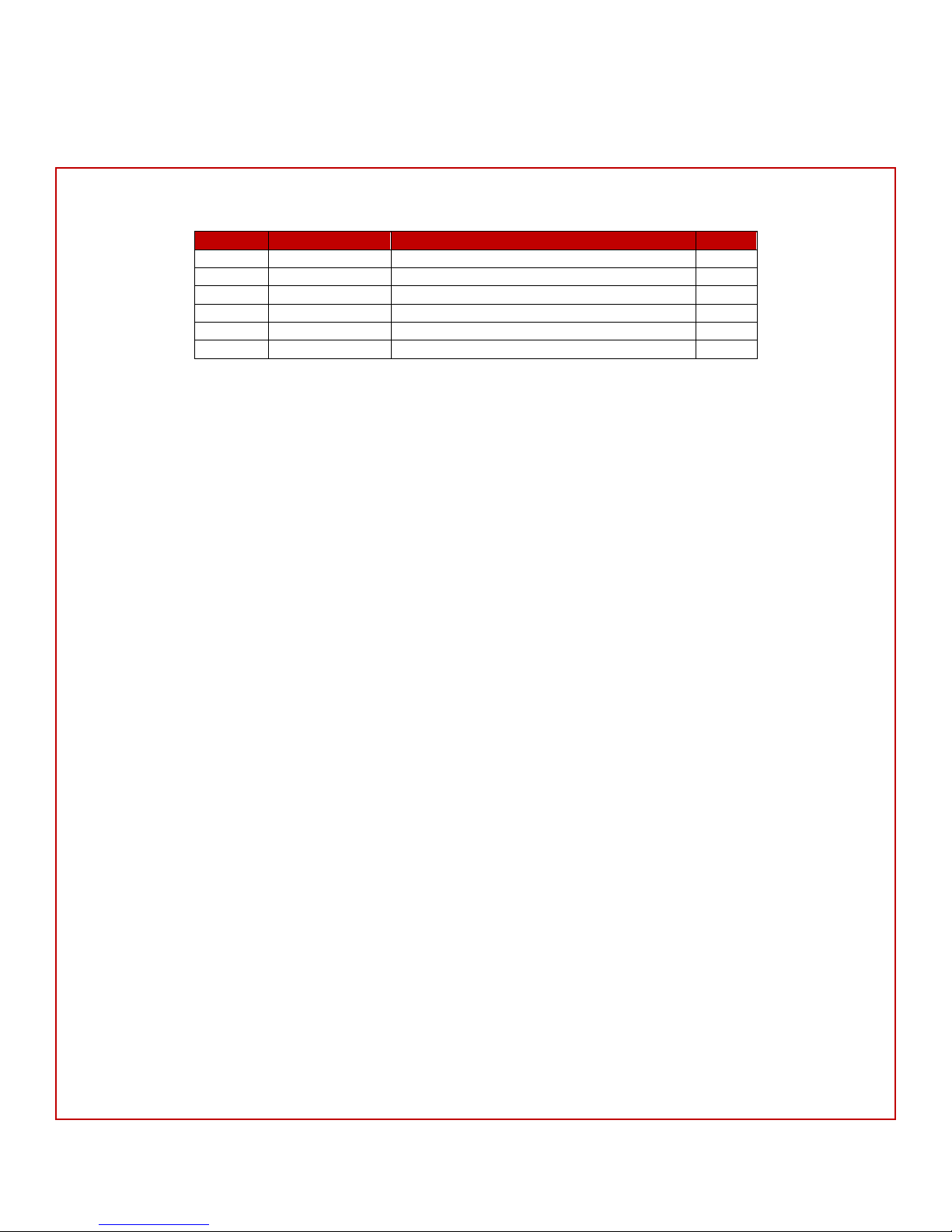

Problem

Possible Cause

Corrective Action

Insufficient

Vacuum

Hose Blocked

Unplug hose

Filter clogged or

improperly seated

Follow filter inspection procedure

Vacuum leak

Check that motor deck is properly seals and secured. Also,

check all hoses

Air Leaks

Worn or poorly seated

seals. Retainers improperly

installed

Block the inlet with a flat and rigid material to place the unit

under vacuum pressure then remove retainers and turn the unit

off. Inspect the seals for completeness, then reset and secure

components again under vacuum pressure

Unable to

control pump

manually

Incorrect setting

Remove the motor deck, then check that the internal sump

pump switch is set to the manual “HAND” position, i.e. the

switch is pushed up.

Unusual or

high pitched

Noises

Motor Bearings, turbine

bearing

Follow relevant motor / turbine inspection procedure. Check

motor bearings for noise by hand.

Worn or poorly seated

seals. Retainers improperly

installed

Block the inlet with a flat rigid material to place the unit under

vacuum pressure then remove retainers and turn the unit off.

Inspect the seals for damage. Then reseat and secure

Components under vacuum pressure.

The Choice of Professionals

www.diamatic.usa P a g e | 16 info@diamatic.usa

7.

Technical Information:

BDC-SLURRY PRO (110 Single Phase)

CFM

200

Electrical consumption

1x 120 Volt

Frequency

60 Hz

Amperage consumption

19 Ampere

Length

50.68 in

Width

31.5 in

Height

59.11 in

Weight machine

346 Lbs

Work width

32 in.

Length of Power Cord

25 ft.

Storage Capacity

32 Gal.

The Choice of Professionals

www.diamatic.usa P a g e | 17 info@diamatic.usa

8.

Slurry Vacuum Parts Breakout:

The Choice of Professionals

www.diamatic.usa P a g e | 18 info@diamatic.usa

9.

Slurry Vacuum Parts List:

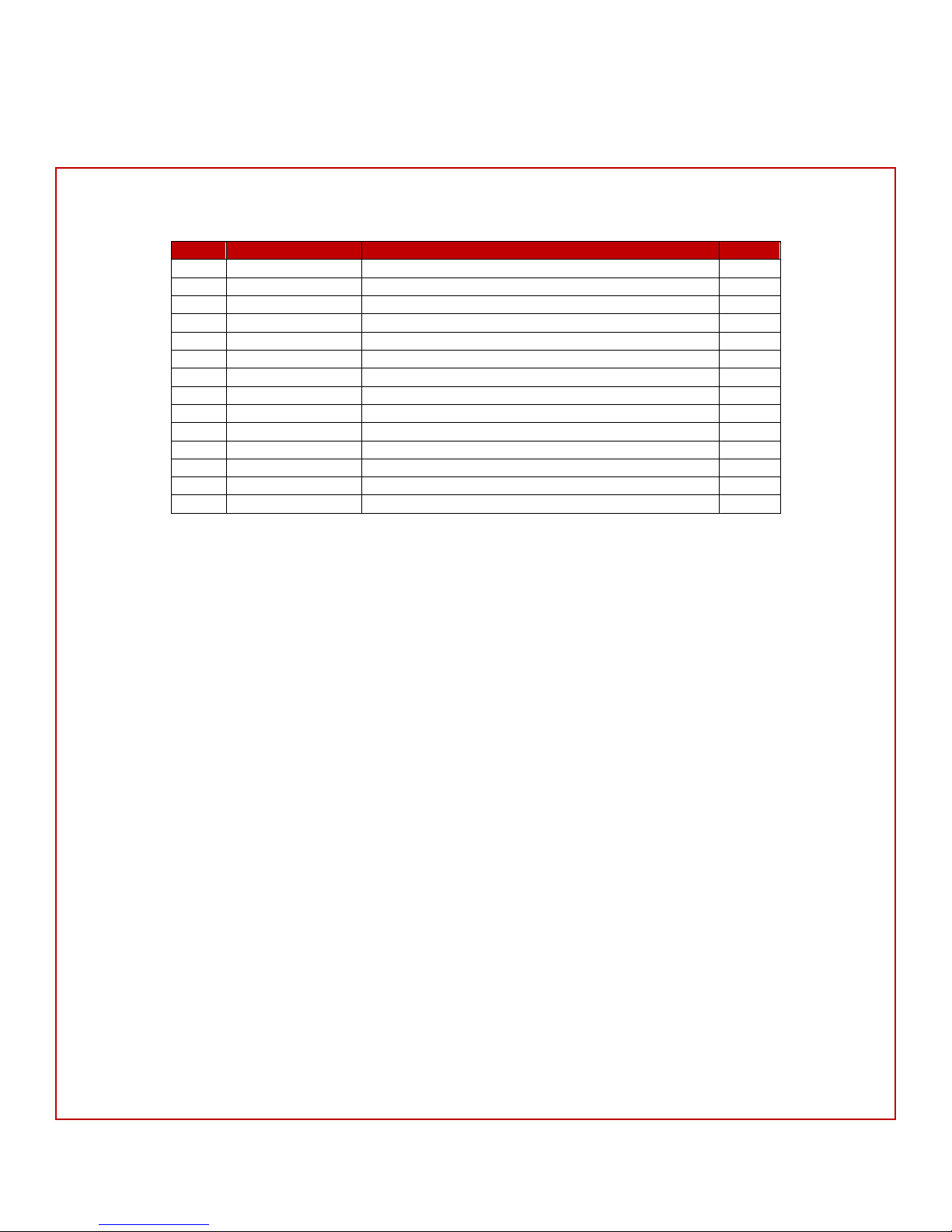

ITEM

NO.

PART NO.

DESCRIPTION

QTY.

1

93280500

DOUBLE STACK FRAME, SLURRY VAC, NON-EX

1

2

93280200

SLURRY COLLECTION ASM

1

3

93280100

FILTER MODULE, SLURRY VAC

1

4

90223WNSA001

SLURRY VAC MOTOR DECK ASSEMBLY, 110V

1

5

5018SLRY

FLOOR TOOL, 32IN, 2IN CONNECTION, SLURRY VAC

1

6

E989NNJ04

ENLCOSURE, W/SWITCH, PVC, SLURRY VAC

1

The Choice of Professionals

www.diamatic.usa P a g e | 19 info@diamatic.usa

10.

Filter Module Parks Breakout:

The Choice of Professionals

www.diamatic.usa P a g e | 20 info@diamatic.usa

12.

Filter Module Parts List:

ITEM

NO.

PART NO.

DESCRIPTION

QTY.

1

34823009

HOUSING SPACER, SMALL, RED, CLAMP PLATE HOLES

1

2

9675PLATE

NA CARTRIDGE FILTER PLATE

1

3

10007147

FILTER CARTRIDGE, 10.25 X 7.875

2

4

31406SA

LATCH PULL CLAMP LEVER ASM

2

5

10003683BRACKET

FILTER HOLD DOWN BRACKET, ALCOA

4

6

34812D

SPACER, 1/4" SCH40, 1/2" LONG

4

7

32861S

WASHER SPLIT LOCK M8 SS

4

8

200179

HEX BOLT 1/4-20 X 3/4" SS

1

9

328660

HEX BOLT M8 X 30 SS

4

10

34816S

HEX BOLT M6 X 30 SS

4

11

34876S

M6 LOCK NUT

4

12

200180

WASHER FLAT .25 (.688OD) SS

2

13

250025S

NUT LOCK .25-20, SS

1

14

565058A

REAR STACK ASM, DOUBLE STACK, RED, SLURRY VAC

1

Table of contents

Other Diamatic Vacuum Cleaner manuals