Diamond Products CSE12 User manual

CORE CUT

OPERATOR’S MANUAL

CSE12

ELECTRIC CHAINSAW

Rev.: 21-01

EQUIPMENT DESIGNATION OPERATOR’S MANUAL

Table of Contents

Introduction..........................................................................................................................................4

Overview..........................................................................................................................................5

Equipment Specifications.................................................................................................................6

Safety Precautions ..............................................................................................................................7

Proposition 65..................................................................................................................................7

Spark Arrester Requirement.............................................................................................................7

Respiratory Hazards ........................................................................................................................7

General Safety.................................................................................................................................8

Chain Saw Safety ............................................................................................................................9

Transporting Safety..........................................................................................................................9

Lifting Safety....................................................................................................................................9

Operation...........................................................................................................................................10

Starting and Stopping Saw.............................................................................................................10

Starting ...................................................................................................................................10

Stopping..................................................................................................................................10

Overload and Overheat Protection.................................................................................................10

Making a Cut..................................................................................................................................10

Checklist.................................................................................................................................10

Beginning the Cut ...................................................................................................................10

Square Cut-outs......................................................................................................................11

Pipe Cutting ............................................................................................................................11

Water Supply ..........................................................................................................................11

Maintenance......................................................................................................................................12

General Maintenance.....................................................................................................................12

Sharpening a New or Glazed Chain...............................................................................................12

Choosing a Chain ...................................................................................................................12

Installing Guide Bar and Chain.......................................................................................................12

Tensioning the Chain..............................................................................................................12

Wearing Parts.........................................................................................................................14

Replacing the Drive Sprocket..................................................................................................14

Replacing Carbon Brushes .....................................................................................................14

Reference..........................................................................................................................................15

Appendix A ....................................................................................................................................15

Serial Number.........................................................................................................................15

EQUIPMENT DESIGNATION OPERATOR’S MANUAL

Introduction

Welcome to the Diamond Products family and thank you for choosing Diamond Products equipment.

At Diamond Products we are driven to ensure you are completely satisfied with your product and

continually strive to improve our product line so that we can offer you the best possible equipment in

the industry.

This operator’s manual is a critical document that provides pertinent information regarding the safety,

operation, maintenance, and care of your new equipment. Keep this manual available at all times.

Operate the equipment and all of its components according to this manual. Failure to comply with and

understand the following safety, operation and maintenance instructions can result in serious injuries

and/or death. All operators must be properly trained or supervised by experienced personnel prior to

using this equipment and should understand the risks and hazards involved. Diamond Products

discourages improper or unintended equipment usage and cannot be held liable for any resulting

damages.

Equipment modifications should be made by Diamond Products to ensure safety and design. Any

modifications made by the owner(s) are not the responsibility of Diamond Products and void all

equipment warranties if a problem arises as a result of the modification.

Refer to the Diamond Products Parts List for additional information and part diagrams. Refer to the

engine/motor manual and manufacturer as the primary source for all safety, operations, and

maintenance instructions regarding the engine/motor. Prior to operating, record the equipment’s serial

number, and the engine’s/motor’s model and serial numbers in Appendix A.

4

EQUIPMENT DESIGNATION OPERATOR’S MANUAL

Overview

5

EQUIPMENT DESIGNATION OPERATOR’S MANUAL

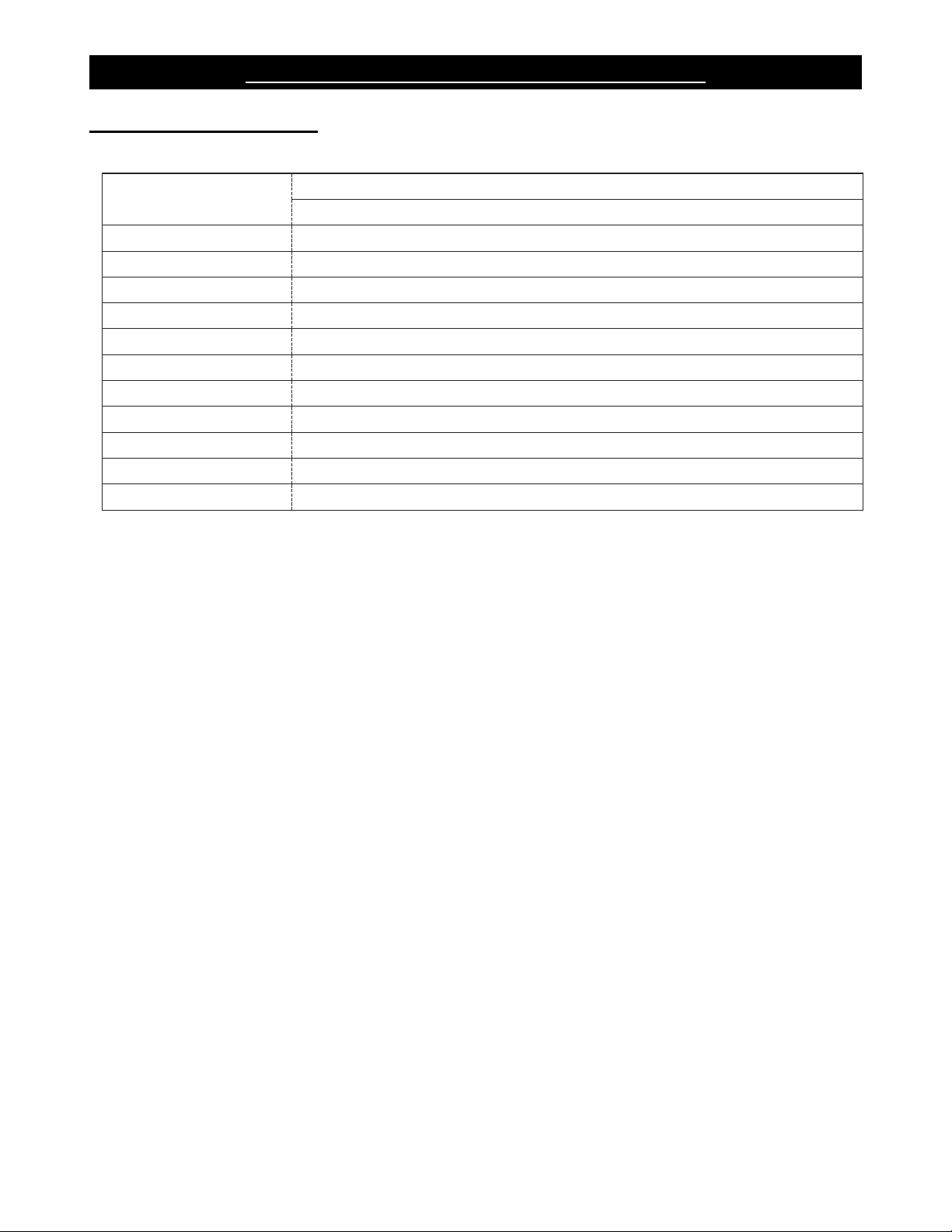

Equipment Specifications

Power Input

220 V: 3200 W

110 V: 3000 W

Voltage

220-240V~ 50/60Hz or 110-120V~ 50/60Hz (see machine nameplate)

No Load Speed min -1

10000

Max. Linear speed

20.65 m/s

Diamond Chain

25 links

Sprocket Pitch

3/8"

Guide Bar Nominal Size

330 mm (13")

Guide Bar Overall Length

382 mm (15")

Max. Depth of Cut

300 mm (11.8")

Protection Class

Class I

Dimensions (L x W x H)

630mm (930mm with guide bar) x 215mm x 280mm

Weight

8.0 kg (17.6 Lbs.), (8.94 kg (19.7 Lbs.) with guide bar & chain)

6

EQUIPMENT DESIGNATION OPERATOR’S MANUAL

Safety Precautions

Operate the equipment and all of its

components according to this manual. Failure

to comply with and understand the following

safety, operation and maintenance instructions

can result in serious injuries and/or death. All

operators must be properly trained or

supervised by experienced personnel prior to

using this saw and should understand the risks

and hazards involved. Diamond Products

discourages improper or unintended

equipment usage and cannot be held liable for

any resulting damages.

Equipment modifications should be made by

Diamond Products to ensure safety and

design. Any modifications made by the

owner(s) are not the responsibility of Diamond

Products and void all equipment warranties if a

problem arises as a result of the modification.

Refer to the Diamond Products Parts List for

additional information and part diagrams. Refer

to the engine manual and manufacturer as the

primary source for all safety, operations, and

maintenance instructions regarding the engine.

Prior to operating, record the saw’s serial

number, and the engine’s model and serial

numbers.

Notice: The information in this manual may

be updated at any time!

Safety Alerts

DANGER

Serious injuries and/or death will occur if

these instructions are not followed.

WARNING

Serious injuries and/or death could occur if

these instructions are not followed.

CAUTION

Mild and/or moderate injuries could occur if

these instructions are not followed.

Proposition 65

WARNING

Engine exhaust and some of its

constituents are known to the

State of California to cause

cancer, birth defects, and/or other

reproductive harm.

Spark Arrester Requirement

WARNING

In the State of California it is a violation of

section 4442 or 4443 to use or operate the

engine on any forest-covered, brush-

covered, or grass-covered land unless the

engine is equipped with a spark arrester, as

defined in section 4442, maintained in

effective, working order or the engine is

constructed, equipped, and maintained for

the prevention of fire pursuant to section

4443.

Respiratory Hazards

WARNING

Concrete cutting produces dust and fumes

known to cause illness, death, cancer,

respiratory disease, birth defects, and/or

other reproductive harm. Safety protection

techniques include, but are not limited to:

•Wearing gloves.

•Wearing safety goggles or a face

shield.

•Using approved respirators.

•Washing work clothes daily.

•Using water when wet cutting to

minimize dust.

•Washing the hands and face prior to

eating/drinking.

For additional safety and self-protection

information contact your employer, the

Occupational Safety and Health

Administration (OSHA), and/or The

National Institute for Occupational Safety

and Health (NIOSH).

7

EQUIPMENT DESIGNATION OPERATOR’S MANUAL

General Safety

•Read and understand all safety,

operations, and maintenance instructions

provided in this manual prior to operating or

servicing the saw.

•Keep equipment components clean and

free of slurry, concrete dust, and debris.

•Inspect water hoses prior to operating the

equipment. Clean, repair, or replace

damaged components.

•Raise the equipment to a proper height for

access when working underneath the

equipment. Use chocks to block the

wheels, and fit blocks or jacks under the

frame edges.

•When using a jack to raise the equipment,

place the jack against a solid, flat area

under the frame base to properly support

the equipment.

•Repair the equipment immediately when a

problem arises.

•Replace equipment decals if unreadable.

•Dispose of all hazardous waste materials

according to city, state, and federal

regulations.

•Always have a phone nearby, and locate

the nearest fire extinguisher and first aid kit

prior to operating the equipment.

•Operate the equipment wearing flame

resistant clothing.

•Always wear safety glasses when removing

retaining rings.

•Persons under the statutory age limit

should not operate the equipment.

•Keep all body parts away from rotating

machinery.

•Replace all guards and access panels

(unless stated otherwise) prior to operating

the equipment.

•Chock the wheels to help prevent

unnecessary movement.

DO NOT:

•Drop equipment, supplies, tools, etc., when

handling to help prevent injuries.

•Lift and carry equipment, supplies, tools,

etc., that are too heavy and/or cannot be

lifted easily.

•Operate the equipment without using the

appropriate safety equipment required for

the work task.

•Operate or service the equipment with any

clothing, hair, or accessories that can snag

in the machinery, which could lead to

serious injuries or death!

•Operate the equipment using attachments

not associated with or recommended for

the equipment.

•Operate the equipment around combustible

materials or fumes to prevent

fires/explosions.

•Operate the equipment with anyone near

the work area or within the direct line of the

blade.

•Operate the equipment until all

unnecessary materials have been removed

from the work area.

•Operate the equipment with loose nuts,

screws, and bolts.

•Operate the equipment when ill or fatigued.

•Operate the equipment under the influence

of drugs and/or alcohol.

•Operate the equipment on steep slopes.

•Cut concrete with guards and access

panels removed.

•Grease the equipment with the engine

running.

•Touch hot components when operating the

equipment.

•Leave the equipment unattended until the

engine is off and the blade has stopped

spinning.

•Place the equipment into storage until it

has cooled down.

•Service the equipment until it has cooled

down.

•Service the equipment with the engine

running.

8

EQUIPMENT DESIGNATION OPERATOR’S MANUAL

Chain Saw Safety

•Operate the equipment without using the

appropriate safety equipment required for

the work task.

•Always hold the chain saw with your right

hand on the rear handle and your left hand

on the front handle. Holding the chain saw

with a reversed hand configuration

increases the risk of personal injury and

should never be done.

•Hold the chain saw by insulated gripping

surfaces only, because the saw chain may

contact hidden wiring or its own cord. Saw

chains contacting a "live" wire may make

exposed metal parts of the chain saw "live"

and could give the operator an electric

shock.

•Wear eye protection. Further protective

equipment for hearing, head, hands, legs

and feet is recommended. Adequate

protective equipment will reduce personal

injury from flying debris or accidental

contact with the saw chain.

•Do not operate a chain saw in a tree, on a

ladder, from a rooftop, or any unstable

support. Operation of a chain saw in this

manner could result in serious personal

injury.

•Always keep proper footing and operate

the chain saw only when standing on fixed,

secure and level surface. Slippery or

unstable surfaces may cause a loss of

balance or control of the chain saw.

•Carry the chain saw by the front handle

with the chain saw switched off and away

from your body. When transporting or

storing the chain saw, always fit the guide

bar cover. Proper handling of the chain saw

will reduce the likelihood of accidental

contact with the moving saw chain.

•Follow instructions for lubricating, chain

tensioning and changing the bar and chain.

•Improperly tensioned or lubricated chain

may either break or increase the chance for

kickback.

•Cut concrete, masonry, and similar

materials only. Do not use chain saw for

purposes not intended. For example: do

not use chain saw for cutting wood, metal,

or plastic materials. Use of the chain saw

for operations different than intended could

result in a hazardous situation.

Transporting Safety

•Remove the blade prior to transporting the

equipment.

•Make sure the truck/trailer is in good,

working condition and sufficient to transport

•Raise the equipment to avoid damaging

components while moving up and down

ramps.

•Use extreme caution when guiding

the equipment up and down

ramps. Slowly drive the equipment

forward down the ramp. Slowly

back the equipment in reverse up the ramp.

Avoid standing directly downhill from the

equipment to prevent machine rollover.

•Place the equipment in neutral and turn off

the engine once the equipment is loaded in

the truck/trailer.

•Chock the wheels and secure the saw in the

truck/trailer prior to transporting.

•Refer to the Department of Transportation

(DOT) for additional transportation

recommendations.

•DO NOT tow the equipment behind a

vehicle.

•Close the fuel shutoff valve (applicable

models) when transporting.

•Drain the fuel tank when transporting long

distances.

•Use heavy-duty ramps that will support the

weight of the equipment and yourself when

loading or unloading.

Lifting Safety

•Move yourself and all others away from

the lifting area when hoisting the saw to

prevent being crushed.

•Secure the appropriate hoisting cables, straps,

and/or chains to the saw’s designated lift points

prior to hoisting.

•Never use the tie-down brackets (applicable

models) to lift the saw.

•DO NOT attempt to lift the saw irresponsibly.

9

EQUIPMENT DESIGNATION OPERATOR’S MANUAL

Operation

Starting and Stopping Saw

Starting

•This machine has a lock-off type switch.

First press the trigger release, then

squeeze the trigger switch to switch on. For

safety reasons, the switch is not possible to

lock on.

Stopping

•Release the trigger switch to stop the

machine. After the machine has been

switched off, the chain will still rotate for a

few seconds, take care that parts of your

body do not come into contact with the

chain while it is still rotating!

WARNING: Do not set the machine down until

the chain has stopped turning.

Overload and Overheat Protection

•When the tool is operating within its normal

load range, the LED load indicator will glow

green.

•When full load is reached, the load

indicator will flash red. If full load is

exceeded and sustained for too long, the

motor will shut down and the load indicator

will glow solid red. In this case, the motor

must be first shut off and then restarted.

•If the temperature of the motor gets

too high, the thermal protection will

shut the motor down. The switch must

be first shut off and then restarted.

When this happens, do not

immediately start cutting after

restarting the motor. Always run the

machine at no load for a few minutes

to return to a normal operating

temperature before continuing.

Making a Cut

Checklist

•Proper chain tension and ensure guide bar

nuts are tight

•Good condition of the chain, guide bar, and

drive sprocket

•Connect the water supply, check for leaks

and for proper water flow to the chain

•Ensure all safety equipment is in place and

functioning normally

•Mark the line of cut before beginning.

WARNING: A new operator should perform

some practice cuts under controlled conditions

to become familiarized with concrete chain saw

techniques. Experience with a wood cutting

chain saw does NOT qualify an operator to use

a concrete chain saw.

WARNING: Position the power supply cord so

that it will not become caught on worksite

obstacles.

CAUTION: Do not attempt to enter a kerf which

is narrower than the chain. This will damage

the diamond segments.

CAUTION: Avoid the chain being pinched in

the kerf. Plan the cut, and support the

workpiece if necessary, to avoid the kept

closing down on the chain as cutting

progresses.

NOTE: When cutting concrete with embedded

rebar, always cut in such a way that the chain

is cutting both concrete and rebar at the same

time. The concrete will help to keep the

diamond segments sharp.

Beginning the Cut

•With the chain running at full speed,

slowly approach the workpiece with

the nose of the guide bar and plunge

in. Hold the saw as straight as

possible.

•Start by making a shallow, 10 to 20mm

outline cut along the entire cutting line

with the nose of the guide bar. Then

plunge in deeper and complete the cut.

•While cutting, keep steady feed

pressure on the tool to prevent the

chain from chattering and bouncing.

Use enough pressure so that the

10

EQUIPMENT DESIGNATION OPERATOR’S MANUAL

motor audibly slows by about 20-30%.

This will keep the diamonds sharp.

Use the bumper spike for leverage to

assist in keeping pressure on the

cutting face.

Square Cut-outs

•When the tool is operating within its normal

load range, the LED load indicator will glow

green.

•When performing large square cut-

outs, after the initial shallow outline

cut, carefully hold the saw as squarely

as possible and plunge cut each of the

corners all of the way through.

•Make the bottom horizontal cut first,

then drive some wedges into kerf of

the bottom if the cut section is large

and heavy. Next, perform the 2 side

vertical cuts. Make the top horizontal

cut last.

•This cutting sequence will avoid the chain

being pinched by the workpiece.

WARNING: Ensure that appropriate

bracing is in place to controlfalling of the

concrete as the final cut is completed.

Concrete is extremely heavy and could

lead to severe injury if it falls in an

uncontrolled manner.

Pipe Cutting

•When cutting a concrete pipe,

support the pipe so that it will not

pinch the chain. Plunge straight

through the pipe, leaving a tab of

uncut material at the very top, which

will keep the pipe stable while cutting.

Cut this tab last to complete the cut.

Water Supply

•This tool must always be used with a

supply of clean water at a minimum

pressure of at least 1.5bar (20 psi). The

water serves as a coolant to avoid the

working surface of the diamond segments

from overheating and since it is not

possible to use oil, the water also serves as

the only lubricant available for the chain

and guide bar. Sufficient water pressure

will maximize chain life.

•To connect the water supply, attach the

quick-release water coupling to a water

hose and regulate the water flow by

adjusting the water feed valve.

CAUTION: Never use this tool without water,

the diamonds will overheat and the O-rings in

the chain will fail from the excessive heat.

WARNING: Check all connections of the water

feed system to

ensure there are no leaks. Inspect hoses and

other critical parts which could deteriorate.

WARNING: The maximum water pressure

should not exceed 70 psi (4 bar).

WARNING: Never allow water to enter the

motor.

NOTE: Contaminants in the water supply can

easily plug up the water nozzles in the water

feed system. Ensure that the supply water is

clean. If you find that there is no water flow to

the chain, then clean out the water feed

system on the machine.

NOTE: Use a wet vacuum to collect cooling

water if nearby objects could be damaged by

water.

11

EQUIPMENT DESIGNATION OPERATOR’S MANUAL

Maintenance

General Maintenance

•This machine operates in a harsh

environment with water and slurry. At the

end of each work day, thoroughly clean the

machine with water, then oil the bar and

chain with a water displacing spray such as

WD-40 to prevent rust. Ensure that the

water feed ports are clear. Chain tension

should be checked frequently and

readjusted immediately when necessary.

Inspect all parts of the saw for proper

function before each use. Pay special

attention to the condition of the chain,

inspecting each diamond segment for wear

or damage.

Sharpening a New or Glazed Chain

•If the chain is new, or if the chain’s

diamond segments become glazed,

sharpen by making a few cuts into an

appropriate alumina oxide or silicon carbide

dressing stone. Simply make shallow

plunge cuts into the stone as many times

as necessary to restore its cutting

performance. If a dressing stone is not

available, cutting into a highly abrasive

work material, such as cinder block will

also work.

Choosing a Chain

This chain saw uses a 25-link diamond

chain and a 13” guide bar. Chains with

different types of diamond segments are

available for different applications.

•Choose a chain with soft bond

segments for hard materials, such as

reinforced concrete. Trying to use a

chain with hard bond segments to cut

hard materials will lead to

unsatisfactorily slow cutting and the

chain will need to be sharpened many

times.

•Choose a chain with a hard bond

segments for softer, more abrasive

materials. Using a chain with soft

bond segments to cut soft materials

will lead to unnecessarily shorter

segment life. By choosing the correct

chain for the application, cutting will

be more effective and economical.

Installing Guide Bar and Chain

1. With the 2 side cover nuts removed and

the side cover removed, slacken the tension

adjustor by turning anticlockwise.

2. Slip the guide bar into position over the

studs with the hole engaged with the adjustor

pin. (the bar is symmetrical and may be

installed with either side up)

3. Place the chain around the drive

sprocket first, ensuring that the drive links

engage the sprocket teeth.

4. Starting from the drive sprocket end,

loop the chain around the guide bar nose

sprocket, ensuring that the drive links engage

with the guide bar groove and remain engaged

with the sprockets.

5. Place the side cover in position and

thread on the 2 side cover nuts, leaving them

finger tight only (to allow the tension adjustor to

be adjusted). They will be tightened fully after

tensioning according to the instructions below.

Tensioning the Chain

Note: Proper chain tension with a concrete

chain saw is much looser than with a wood

chain saw. It must be loose enough to run

freely with only water as its lubrication.

•An over tensioned chain will give

unnecessary load to the motor and will lead

to premature chain stretch, sprocket

damage, and spindle bearing damage.

•An overly slack chain could fly off the guide

bar and could also jump teeth on the drive

sprocket, leading to premature wear of the

sprocket and the chain’s drive links.

•In use, the chain must be readjusted if it

hangs below the guide bar 10mm or more

•To tension the chain, first loosen the 2 side

cover nuts and leave them finger tight.

CAUTION: attempting to turn the adjustor

12

EQUIPMENT DESIGNATION OPERATOR’S MANUAL

without loosening the side cover nuts could

result in damage to the adjustor mechanism.

•While holding the guide bar upward from

the nose end, turn the tension adjustor

clockwise to tighten.

•Rotate the chain by hand, grabbing the

chain by its diamond segments, to ensure

the chain rotates freely.

•WARNING: Wear gloves when handling

the chain and bar. Keep fingers away from

the edges of the guide bar rails. When

worn, they will have a very sharp edge.

•When the associated parts have some

wear, there will be some positions where

the chain is looser and other positions

where it is tighter. Find the tightest point,

and make the final adjustment at that

position.

•Tension is correct when the chain is free to

run around the guide bar, and the chain

will hang with the drive links just barely

engaging the guide bar groove at the

bottom center position.

•Once adjustment is satisfactory, the 2 side

cover nuts may be tightened. While still

holding guide bar upward, tighten the 2

side cover nuts firmly.

•CAUTION: Running the saw with the side

cover nuts loose will cause a hazardous

situation and could lead to damage to the

tension adjustor mechanism.

13

EQUIPMENT DESIGNATION OPERATOR’S MANUAL

Wearing Parts

1. Diamond Chain

The diamond segments will wear away with

normal use. In addition, the chain itself will

stretch due to accumulated wear of each joint

of the chain. Inspect each segment of the

chain before each use, noting any segment

damage or undue wear.

2. Guide Bar

The guide bar rails will wear from abrasion with

the chain. If the saw tends to cut to one side,

the rails have worn unevenly. The guide bar

rails can be re-squared by carefully sanding on

a bench mounted belt sander. If the chain’s

drive links are touching the bottom of the guide

bar grooves, the guide bar must be replaced.

Running a good chain on worn out guide bar

will prematurely wear out its drive links and the

motor will overload easily from the excessive

friction.

Extra life can be had from the guide bar by

flipping it over to the other side, since the

bottom wears faster than the top. It is a good

practice to flip the guide bar each time you

replace a chain. Generally, the guide bar will

need to be replaced after about 3 chains.

3. Drive Sprocket

Running a good chain on a worn-out sprocket

will prematurely wear out its drive links. After

about 3 chains, the drive sprocket will wear

away and need replacement.

Replacing the Drive Sprocket

To change the drive sprocket, first remove the

side cover, chain, and guide bar. Using circlip

pliers, remove the circlip, then the washer

which retain the drive sprocket, then lift the

sprocket off the splines. Replacement is the

reverse of removal.

Replacing Carbon Brushes

The carbon brushes are a normal wearing part

and must be replaced when they reach their

wear limit. This machine is equipped with auto-

stop carbon brush holders. If the machine

comes to a stop unexpectedly, the brushes

should be checked. The auto-stop brush

design protects the motor by stopping the

machine before the carbon brushes are

completely worn out.

Caution: Always replace the brushes as a pair.

1. Remove the screw and remove the

brush cover.

2. Using pliers rotate the brush spring out

of the way and slide the old carbon brush out

of the brush holder.

3. Unscrew the screw to remove the brush

lead. The old carbon brush may now be lifted

away.

4. Install a new brush. Installation is the

reverse of removal.

5. Replace the brush cover.

14

EQUIPMENT DESIGNATION OPERATOR’S MANUAL

Reference

Appendix A

Serial Number

Record the CSE12’s serial number below for future reference and customer service purposes.

Serial Number

15

NOTES

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

16

NOTES

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

NOTES

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

333 Prospect Street, Elyria, Ohio 44035

(440) 323-4616 •(800) 321-5336 •Fax (800) 634-4035

www.diamondproducts.com

Printed in U.S.A.

EQUIPMENT AND PARTS

WARRANTY

Diamond Products warrants all equipment manufactured by it against defects

in workmanship or materials for a period of one (1) year from the date of

shipment to Customer.

The responsibility of Diamond Products under this Warranty is limited to

replacement or repair of defective parts at Diamond Products’ Elyria, Ohio

factory, or at a point designated by it, of such parts as shall appear to us upon

inspection at such parts, to have been defective in material or workmanship,

with expense for transportation and labor borne by Customer.

In no event shall Diamond Products be liable for consequential or

incidental damages arising out of the failure of any Product to operate properly.

Integral units such as engines, electric motors, batteries, transmissions,

etc., are excluded from this Warranty and are subject to the prime

manufacturer’s warranty.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED

OR IMPLIED, AND ALL SUCH OTHER WARRANTIES ARE HEREBY

DISCLAIMED.

Other manuals for CSE12

1

Table of contents

Other Diamond Products Chainsaw manuals