Diamond Products HCH50 User manual

DIAMOND

P R O D U C T S

HYDRAULIC CHAIN SAW

MODEL HCH50

OPERATOR MANUAL

September 2009

Part # 1801446

Operating instructions

10984695 en / 7.8.07

Manufacturer’s address:

TYROLIT Hydrostress AG

Witzbergstrasse 18

CH-8330 Pfäffikon

Switzerland

Telephone +41 (0) 44 / 952 18 18

Fax +41 (0) 44 / 952 18 00

TYROLIT Hydrostress AG reserves the right to make technical changes

without prior notice.

Copyright © 2003 TYROLIT Hydrostress AG, CH-8330 Pfäffikon ZH

All rights reserved, in particular copying and translation rights.

Reprinting of extracts from this safety manual is prohibited. No parts may

be reproduced or processed, copied or distributed using an electronic

system, in whatever form, without the written permission of TYROLIT

Hydrostress AG.

Operating instructions Overview

HCH5011 / 001 I (II)

Overview

Page

0 Introduction 1

0.1 Congratulations!- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

0.2 Validity of these Operating instructions- - - - - - - - - - - - - - - 2

0.3 Standards - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

0.4 Delimitation of the system- - - - - - - - - - - - - - - - - - - - - - - - 2

1 Product description 1

1.1 Important information on the Chain saw HCH5011 - - - - - - 1

1.2 Technical data - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

1.3 Accessories- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

1.4 Scope of supply- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

2 Safety instructions 1

2.1 General- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

2.2 Safety principles - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

2.3 General safety rules- - - - - - - - - - - - - - - - - - - - - - - - - - - - 3

2.4 Information and symbols- - - - - - - - - - - - - - - - - - - - - - - - - 5

2.5 Generally applicable warnings of residual dangers - - - - - - 6

2.6 Responsibility - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

3 Design and function 1

3.1 Design - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

3.2 Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

3.3 Component description- - - - - - - - - - - - - - - - - - - - - - - - - - 2

4 Controls and displays 1

4.1 Controls - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

4.2 Displays - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

5 Putting into operation 1

6Operation 1

6.1 General- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

6.2 System requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

6.3 Preparatory operations- - - - - - - - - - - - - - - - - - - - - - - - - - 5

6.4 Working with the Chain saw HCH5011- - - - - - - - - - - - - - - 10

6.5 After the work - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

7 Maintenance 1

7.1 General- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

7.2 Maintenance and servicing table - - - - - - - - - - - - - - - - - - - 3

8 Servicing 1

8.1 General- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

8.2 Tensioning the diamond chain- - - - - - - - - - - - - - - - - - - - - 3

8.3 Changing the diamond chain- - - - - - - - - - - - - - - - - - - - - - 4

8.4 Changing the bar - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

8.5 Changing the drive wheel - - - - - - - - - - - - - - - - - - - - - - - - 6

8.6 Troubleshooting- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

Overview Operating instructions

II (II) HCH5011 / 001

9 Taking out of service and storage 1

9.1 Taking out of service- - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

9.2 General - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

9.3 Storage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

10 Transport, Packing 1

10.1 Transport- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

10.2 Packing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

11 Disposal 1

11.1 General - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

11.2 Disposal regulations - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

11.3 Disposal of the Chain saw HCH5011 - - - - - - - - - - - - - - - - 2

Operating instructions Introduction

HCH5011 / 001 0-1

0 Introduction

0.1 Congratulations!

You have decided to buy an advanced, tried and tested Hydrostress

system and have thus acquired a highly sophisticated and reliable state-of-

the-art unit.

Thanks to the stress we place on quality assurance, your Hydrostress

system is another top-of-the-range Swiss product:

• High performance

• Reliable operation

• High portability

• Easy handling

• Low maintenance costs

Only original Hydrostress spare parts ensure quality and

interchangeability.

In the case of neglected or inappropriate maintenance, we refuse to accept

any warranty commitment as specified in our terms of delivery.

Any repair work is to be carried out by trained personnel only.

Should you need more details concerning your Hydrostress system in

order to keep it in perfect condition, please contact our after-sales service

for further information.

We hope that you will not experience any problems while working with your

Hydrostress system.

TYROLIT Hydrostress AG

Management

Copyright © Hydrostress, Jan. 2003

TYROLIT Hydrostress AG

Witzbergstrasse 18

CH-8330 Pfäffikon

Switzerland

Telephone +41 (0) 44 / 952 18 18

Fax +41 (0) 44 / 952 18 00

Introduction Operating instructions

0-2 HCH5011 / 001

0.2 Validity of these operating instructions

These operating instructions are only valid for the following system:

Chain saw HCH5011

0.3 Standards

These operating instructions have been prepared in accordance with

CE Machinery Directive Appendix I and with the relevant standards in force

at the time of printing.

0.4 Delimitation of the system

TheseoperatinginstructionsdescribetheuseoftheChain saw HCH5011.

Operating instructions Product description

HCH5011 / 001 1-1

1 Product description

1.1 Important information on the Chain saw

HCH5011

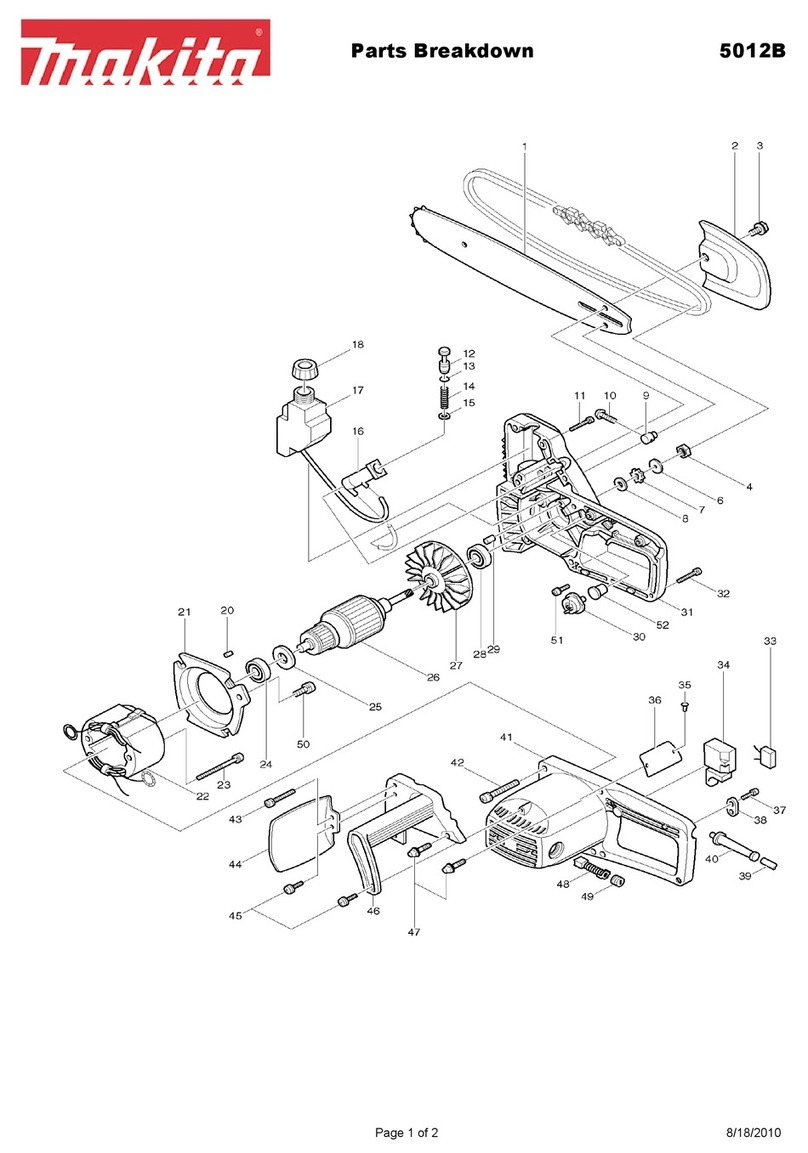

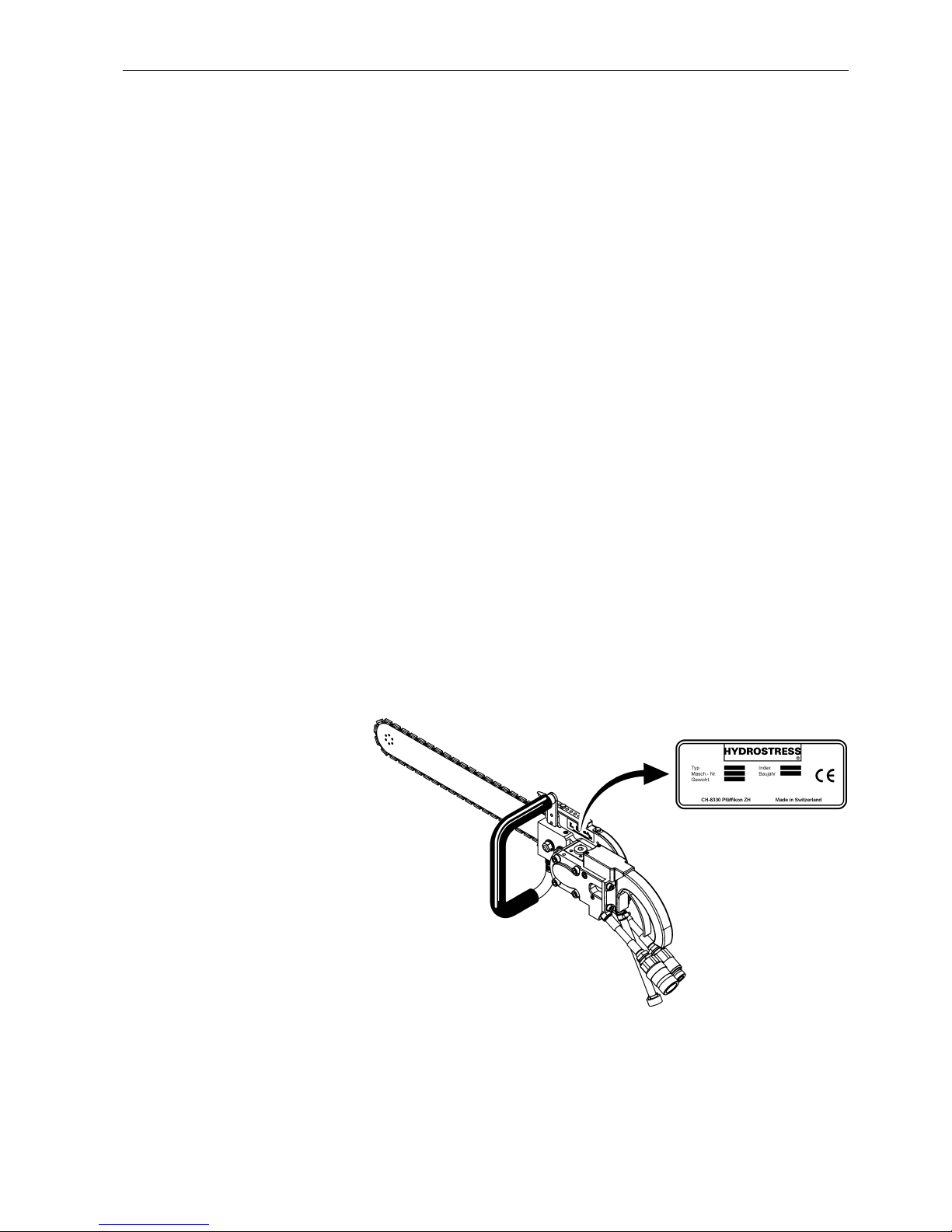

1.1.1 Main components

Fig. 1-1 Main components

1 Bar 7 Operating handle with manual starter

2 Chain 8 Coupling FD (flow)

3 T-handle 9 Hose stem (water)

4 Valve block 10 Nipple FD (return)

5 Cutting mandrel

6 Chain guard

1

2

3

5

4

6

7

8

9

10

Product description Operating instructions

1-2 HCH5011 / 001

1.1.2 Intended purpose

The Chain saw HCH5011 is designed and built for the following

application:

• Cutting of concrete (including reinforced), masonry and natural stone

• Cutting of severance cuts, flush cuts and cross-cuts in ceilings, floors

and walls

• Only original TYROLIT Hydrostress AG tools (chains) should be used

The information provided in Chapter 1 “Technical Data” 1.2, 1-4

represents the mandatory usage limits and rated data

1.1.2.1 Safety measures

Any use other than for the intended purpose (see Chapter 1.1.2, 1-2)

constitutes improper use or misuse.

Since improper use or misuse can sometimes results in considerable

danger, here details of what we believe constitutes improper use or

misuse.

The following applications are prohibited:

• Cutting without the safety devices provided

• Cutting wood, glass and plastics

• Cutting without system and tool cooling

• Cutting in explosion-protected areas

• Cutting loose parts

• Incorrect or absence of waste water disposal (saw sludge)

1.1.3 Workplace and danger areas

Allow enough room for manoeuvre to ensure danger-free working.

Make sure you have sufficient lighting at your workplace.

Clearly cordon off the danger area so that no person can enter the danger

area during sawing.

The front, underneath and rear of the sawing area must be protected so

that persons or equipment cannot be harmed by falling parts or sawing

sludge, or by the protruding cutting tool.

Secure lumps of concrete that have been loosened against falling.

Breathing in the water fog that is created is a health hazard. Ensure

adequate ventilation in sealed-off areas.

The sludge resulting from cutting is very greasy. Remove this or ensure

that you or other people do not slip on it.

Operating instructions Product description

HCH5011 / 001 1-3

1.1.4 EC statement of conformity

We declare under our own liability that this product complies with the

following directives and standards:

1.1.4.1 Directive applied:

European Machine Directives (Machinery Directive) 98/37/EC

1.1.4.2 Standards applied:

1.1.5 Name plate

Fig. 1-2 Name plate

Designation Hydraulic chain saw

Type designation Chain saw HCH5011

Year of construction 2007

EN 292-1

EN 292-2 Safety of Machines

Basic concepts, general design principles

EN 294 Safety of machines

Safety distances to prevent upper limbs reaching danger

areas

EN 349 Safety of machines

Safety distances to avoid crushing of body parts

EN 982 Safety of machines

Safety requirements of safety systems and their components

Hydraulics

Product description Operating instructions

1-4 HCH5011 / 001

1.2 Technical data

1.2.1 Chain saw HCH5011

• Can be used with any hydraulic actuator (use a flow divider with

pressure limiter >40 l/min or >140bar)

• Flush cutting possible without removing the protective cover

1.2.1.1 Hydraulic system

Hydraulic hose Length 2 m

1.2.1.2 Water

1.2.1.3 Weight

Chain saw HCH5011 incl. bar and chain 10.5 kg

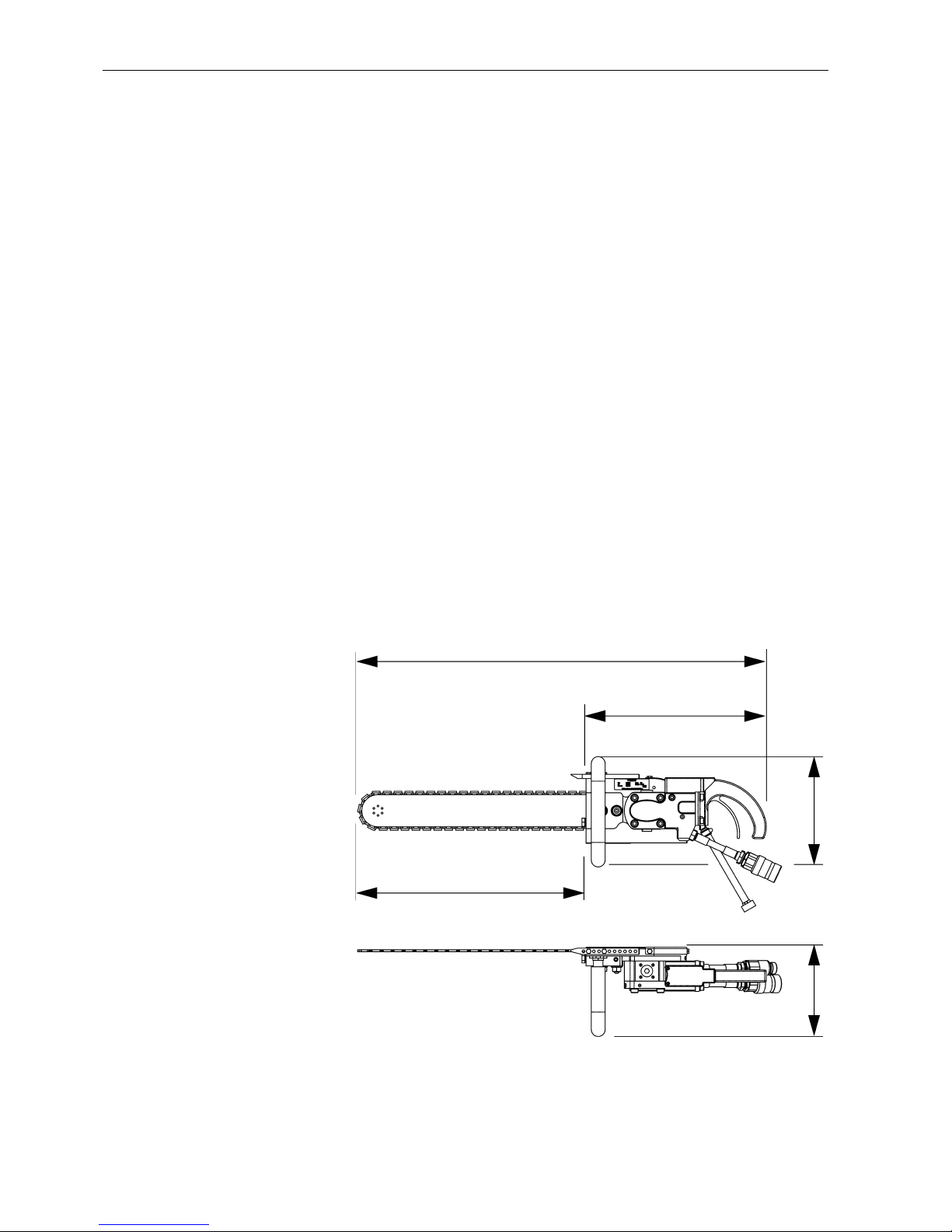

1.2.1.4 Dimensions Chain saw HCH5011

Fig. 1-3 Dimensions Chain saw HCH5011

Maximum pressure 140 bar

Maximum flow 45 l/min.

Minimum working pressure 2.5 bar

Minimum flow 7.5 l/min.

975 mm

415 mm

265 mm

230 mm

560 mm

Operating instructions Product description

HCH5011 / 001 1-5

1.2.2 Noise level

Depending on the working environment, the Chain saw HCH5011 can

cause excessive noise during operation.

The noise can permanently harm the hearing of operating personnel and

of other people nearby within a short time.

Ear protectors must therefore always be worn while working.

1.2.3 TYROLIT Hydrostress AG- Bar

1.2.3.1 Bar 20“ (Chain saw HCH5011)

1.2.3.2 Bar 16“

Danger

Noise danger

When using the Chain saw HCH5011 hearing protection must be

worn.

If this instruction is not followed irreparable hearing damage may

result.

Length / Cutting depth 20“ (approx. 50 cm) / 42 cm

Width 85 mm

(75 mm without chain)

Length / Cutting depth 16“ (approx. 40 cm) / 32 cm

Width 85 mm

(75 mm without chain)

Product description Operating instructions

1-6 HCH5011 / 001

1.2.4 Diamond chains

The Chain saw HCH5011 is fitted as standard with the Hydrostress

Universal O-Ring diamond chain 20“ with double pumper.

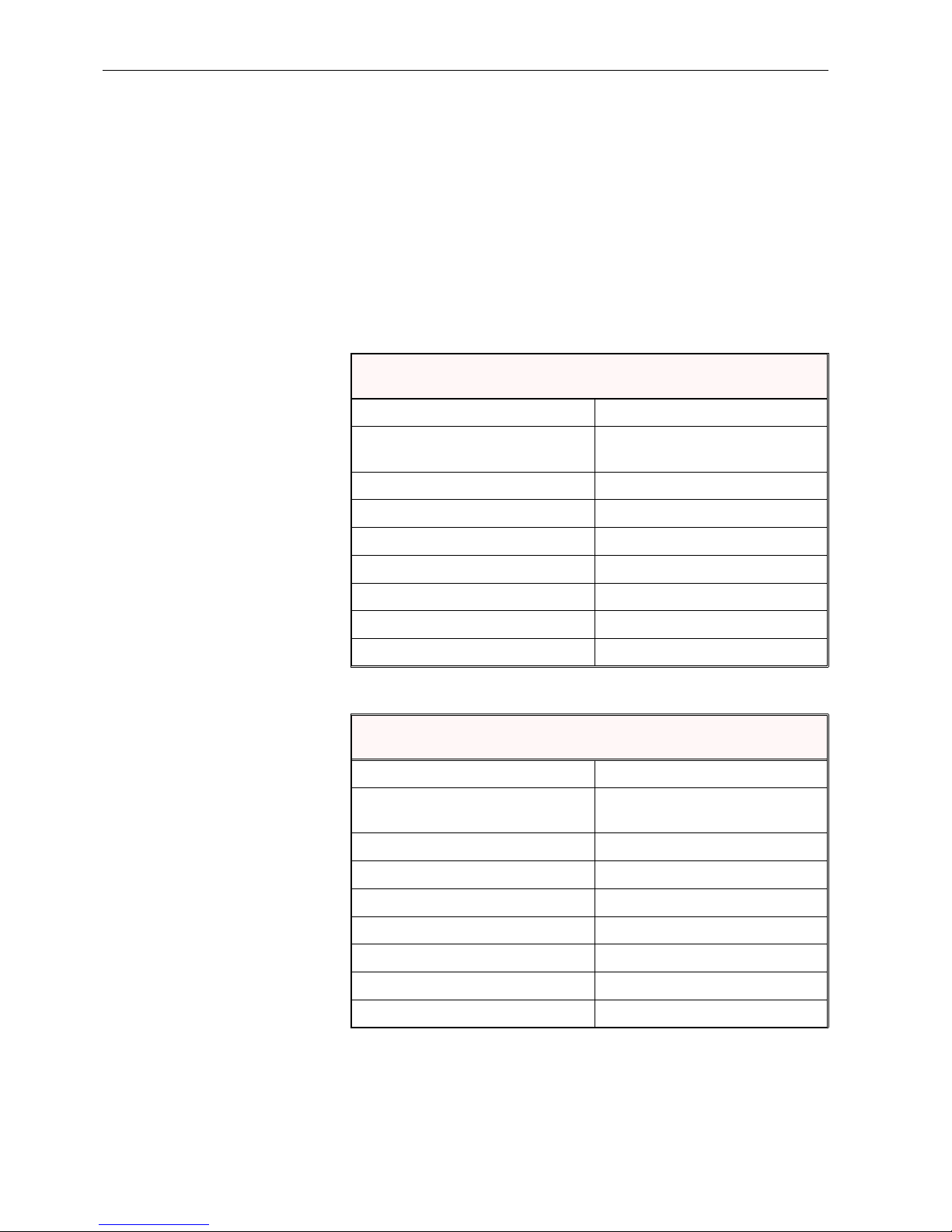

1.2.4.1 Hydrostress Universal O-Ring diamond chain with double pumper

Application:

– Concrete with a moderate degree of reinforcement (reinforcing irons

of up to dia. 12mm)

– Brick and limestone

– Hard and soft natural stone

Hydrostress Universal O-Ring diamond chain 20“ with double

pumper

Part No. 10978001

Type Diamond chain with double

pumper

Number of segments 43

Segment dimensions:

Height 5.8 mm

Width 5.7 mm

Length 14 mm

Diamond segments laser-welded

Cutting speed 24 m/s

Hydrostress Universal O-Ring diamond chain 16“ with double

pumper

Part No. 10978132

Type Diamond chain with double

pumper

Number of segments 37

Segment dimensions:

Height 5.8 mm

Width 5.7 mm

Length 14 mm

Diamond segments laser-welded

Cutting speed 24 m/s

Operating instructions Product description

HCH5011 / 001 1-7

1.2.4.2 Hydrostress concrete O-Ring diamond chains

The Hydrostress “concrete O-ring diamond chain” is characterised by a

long service life and high cutting power in highly reinforced concrete.

Application:

– Concrete with a high degree of reinforcement (reinforcing irons of up

to dia. 19mm)

– Brick and limestone

– Hard natural stone

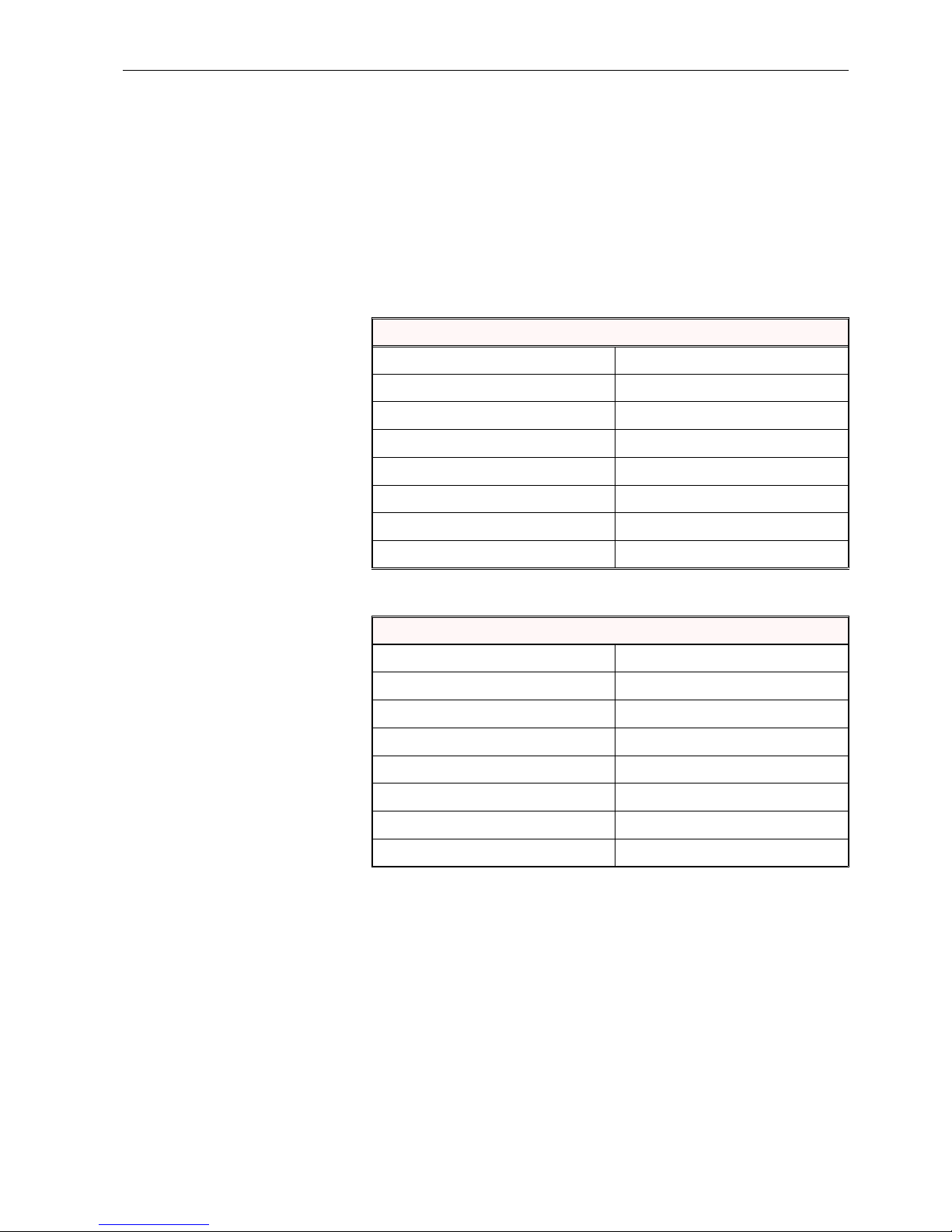

Hydrostress Concrete O-Ring diamond chain 20“

Part No. 10977642

Number of segments 43

Segment dimensions:

Height 5.8 mm

Width 5.7 mm

Length 15.2 mm

Diamond segments laser-welded

Cutting speed 24 m/s

Hydrostress Concrete O-Ring diamond chain 16“

Part No. 10978131

Number of segments 37

Segment dimensions:

Height 5.8 mm

Width 5.7 mm

Length 15.2 mm

Diamond segments laser-welded

Cutting speed 24 m/s

Product description Operating instructions

1-8 HCH5011 / 001

1.3 Accessories

• Flow divider / Pressure limiter 40 l/min, 140 bar

• Pressure control valve 140 bar

1.4 Scope of supply

Complete chain saw system HCH5011:

•Chain saw HCH5011

• Carrying case HCH5011

• Tool kit HCH5011

• Operating Instructions / Spare parts list

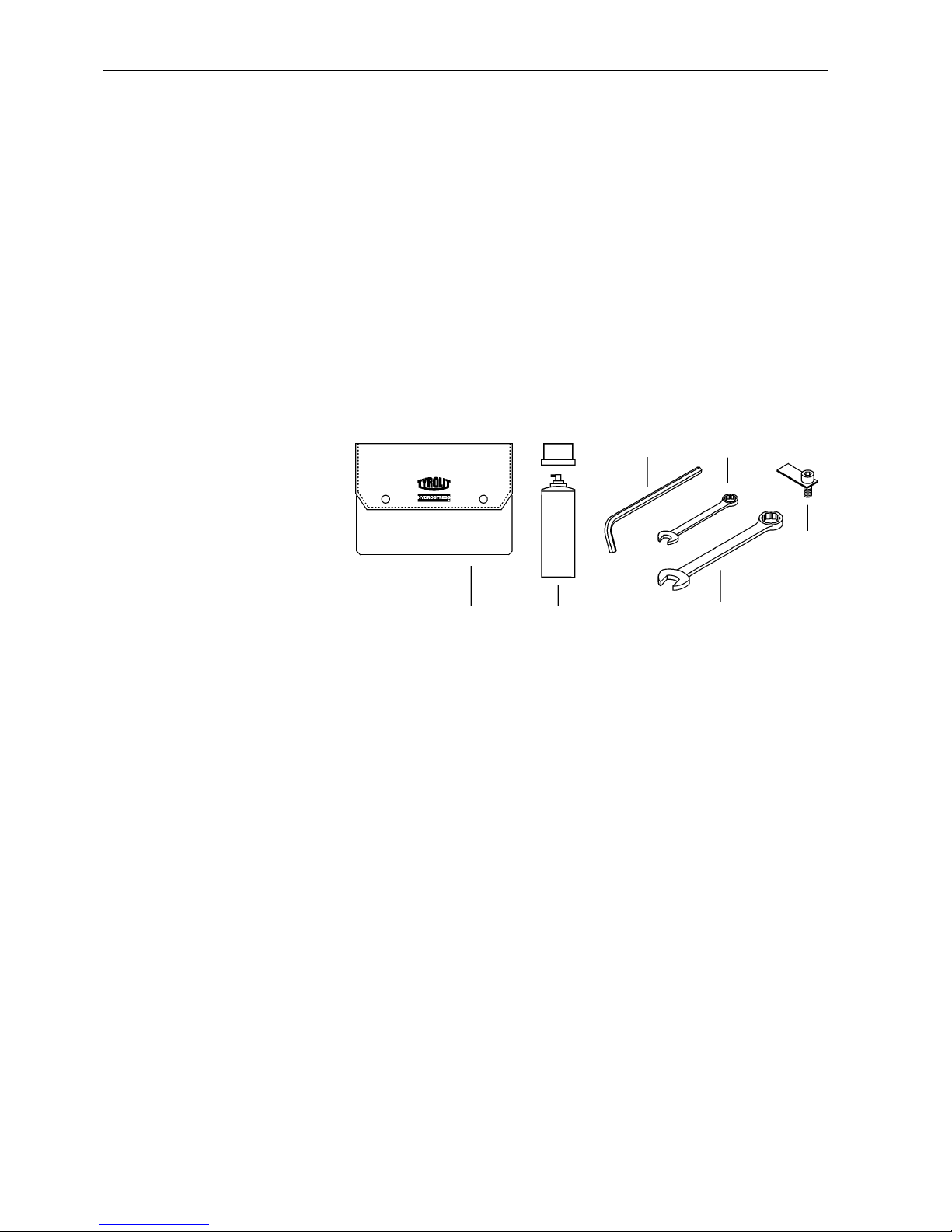

1.4.1 Tool kit comprises:

Fig. 1-4 Tool kit

1. Plastic tool bag Part No. 976497

2. Chain spray Part No. 975061

3. Allen key SW 5 Part No. 973791

4. Ring/open ended spanner SW 10 Part No. 973781

5. Ring/open ended spanner SW 19 Part No. 973784

6. Drive wheel assembly guide Part No. 962724

1

4

3

5

6

2

Operating instructions Safety instructions

HCH5011 / 001 2-1

2 Safety instructions

2.1 General

2.1.1 Target audience

This chapter describes the safety instructions that it is essential to follow

when using the Chain saw HCH5011.

All persons who work on and with the Chain saw HCH5011, have a duty

to read and understand the chapters of the Operating instructions relevant

to their particular activities.

This applies in particular to the “Safety instructions” chapter which is

mandatory for all persons and activities.

2.1.2 Observance of the safety instructions

No work must be performed on or with the Chain saw HCH5011 before the

safety instructions contained in the Operating instructions (Chapter 2) have

been read and understood. The Operating instructions are mandatory for

all work – abridged instructions should only be used in the form of

checklists.

The Chain saw HCH5011 has been inspected before being shipped and

is delivered in perfect condition. TYROLIT Hydrostress AG does not

accept any liability for damage caused by the failure to observe the

instructions and information provided in the Operating instructions. This

applies in particular to:

• Damage caused by improper use and operator error.

• Damage caused by failure to observe safety-related information in the

Operating instructions or shown on the warning signs fitted to the

machine.

• Damage caused by defective or absence of maintenance work.

Independently performed conversions and alterations may affect safety

and are not permitted.

2.1.3 Use for intended application

The intended application is described in “Chapter 1” under 1.1.2, 1-2.

2.1.4 Observance of the information on workplace safety and

danger area

The workplace and danger area are described in “Chapter 1” under

1.1.3, 1-2.

Safety instructions Operating instructions

2-2 HCH5011 / 001

2.2 Safety principles

2.2.1 Delimitation of the safety concept

The Chain saw HCH5011 has no effect on the safety concept of the

connected systems, apparatus and installations.

2.2.2 Safety elements

Protection from personal injury is based primarily on a safety concept and

design safety.

2.2.2.1 Passive safety elements

Protection from live parts

All functional units that contain parts which carry hazardous voltages, are

shock-protected by suitable covers.

2.2.3 Removing protective devices

Protective devices should only be removed when the device is turned off,

disconnected from the mains and at a standstill. Safety components in

particular should only be removed and refitted by authorised personnel,

see “Chapter 2”2.6.1, 2-7.

Before using the Chain saw HCH5011 again, the safety elements must be

checked for correct operation.

2.2.4 Safety measures (organisational)

2.2.4.1 Product monitoring obligation

Operating personnel must notify changes in the operational behaviour or

safety-related components to a responsible person or the manufacturer

immediately.

2.2.4.2 Location of Operating instructions

A copy of theOperating instructions must be available at all times to staff at

the place of use of the apparatus.

Operating instructions Safety instructions

HCH5011 / 001 2-3

2.3 General safety rules

2.3.1 Statutory provisions

The generally applicable national and local safety and accident prevention

provisions and the supplementary operator regulations must be followed

and complied with.

2.3.2 Inspection and maintenance obligation

The operator is under an obligation to only use the Chain saw HCH5011

when it is in a perfect and undamaged condition. The maintenance

intervals shown in the Operating instructions must be adhered to without

fail. Malfunctions and mechanical damage must be rectified without delay.

2.3.3 Spare parts

Only TYROLIT Hydrostress AG original spare parts should be used.

Otherwise damage may be caused to the Chain saw HCH5011 or to other

property and persons.

2.3.4 Power connections

The Chain saw HCH5011 must be connected and coupled to the drive

assembly used in accordance with the Operating instructions.

2.3.5 Modifications

No technical alterations should be made to the apparatus in the form of

additions or conversions without the written consent of TYROLIT

Hydrostress AG.

2.3.6 Safety instructions in the individual chapters

The chapters of these Operating instructions contain additional safety

instructions. These make reference to specific potential dangers (residual

dangers). The instructions must be followed closely and require that the

actions described are taken.

Safety instructions Operating instructions

2-4 HCH5011 / 001

2.3.7 Safety clothing

Fig. 2-1 Safety clothing

1. Helmet with ear protectors 5. Waterproof, sturdy,

2. Visor or goggles comfortable clothing

3. Breathing mask 6. Work boots with steel toecaps

4. Waterproof gloves and non-slip soles

Safety clothing must always be worn when drilling, sawing, nibbling or

compressing concrete or stone in order to protect against the following

dangers:

Sources of danger Safety clothing

Falling parts: Helmet, steel-capped safety shoes

Moving, sharp-edged parts: Safety gloves

Flying pieces of concrete and

stone, flying sparks: Goggle or helmet with visor

Slipping: Anti-slip shoes

Noise Ear protectors

Contamination of respiratory tracts Respiratory mask

1

2 / 3

4

5

6

Operating instructions Safety instructions

HCH5011 / 001 2-5

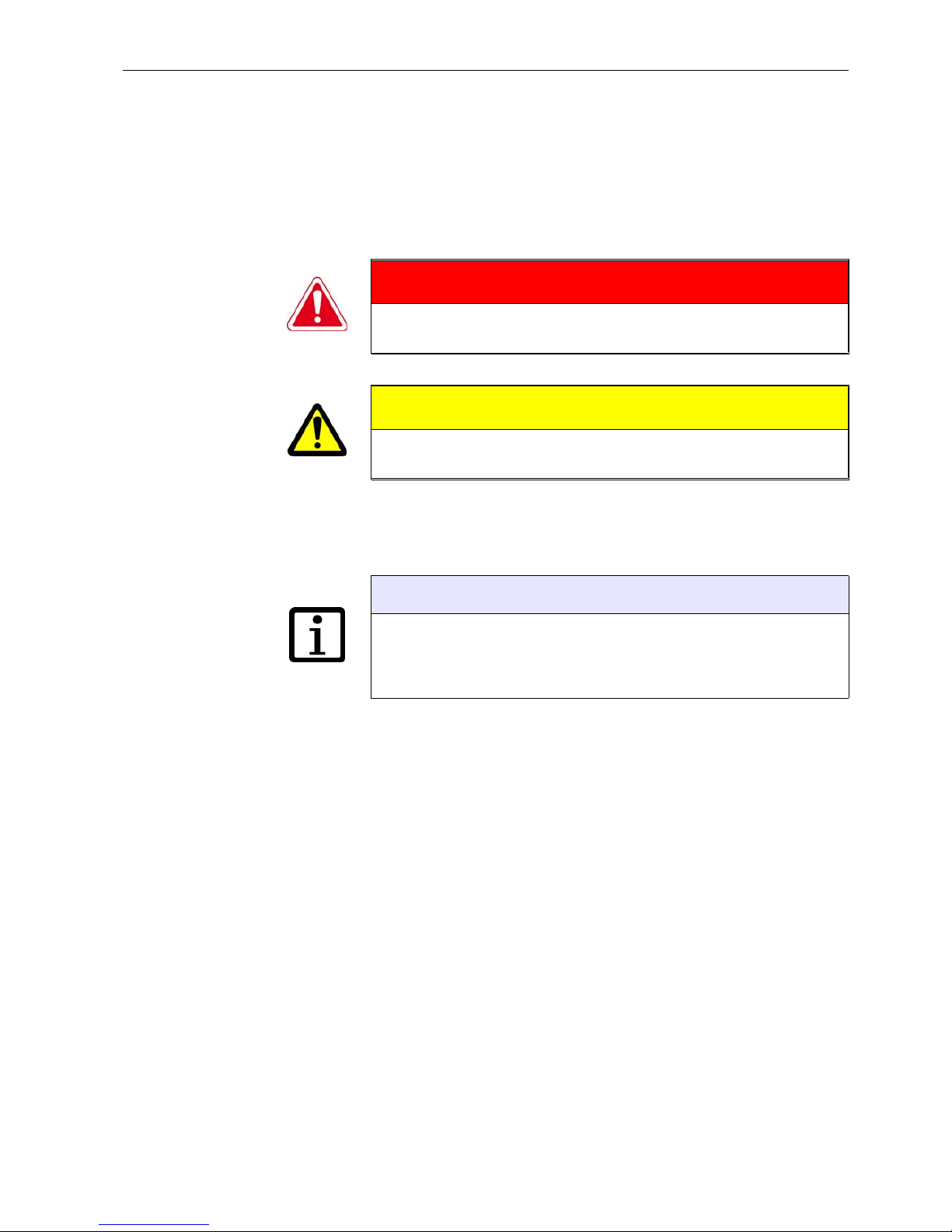

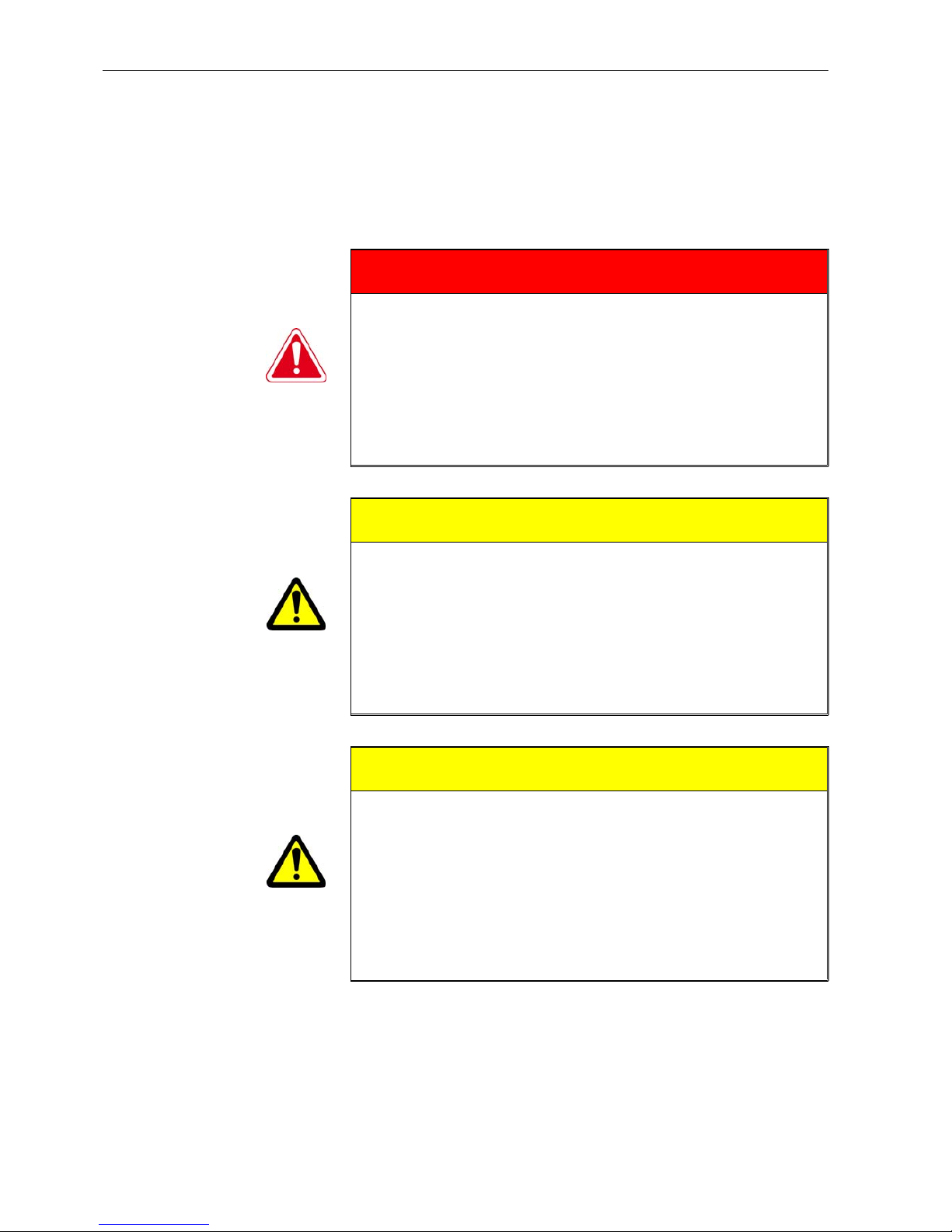

2.4 Information and symbols

In these Operating instructions information panels are used to draw

attention to residual dangers and to point out important technical

requirements.

2.4.1 Danger symbols in the Operating instructions

Fig. 2-2 Danger and warning notices

2.4.2 Information symbol

Fig. 2-3 Information notice

Danger

Warning of danger, where failure to comply could lead to death or

serious injury.

Warning

Warning of danger, where failure to comply could lead to injury or

damage to property.

Information

Text displayed in this way is practical information and is aimed at

achieving optimum use of the installation or apparatus. Failure to take

note of this information may mean that the performances shown in the

technical data can no longer be guaranteed.

Safety instructions Operating instructions

2-6 HCH5011 / 001

2.5 Generally applicable warnings of residual

dangers

In the following warnings of residual dangers are shown that are generally

applicable to all work (with and on the saw systems and during all phases

of the life of the systems).

Danger

Electric shock due to defective electronic equipment.

The electrotechnical equipment must be checked prior to each use

and from time to time during prolonged usage. Defective parts

such as cables and plugs must be exchanged by electrotechnically

trained personnel in the powered down state.

Failure to comply with this regulation may lead to serious physical

injury or death. Secondary damage such as fires may also occur.

Warning

Danger from sharp tool edges.

Touching a tool whilst it is still in motion is prohibited.

When touching tools at a standstill it is recommended that

protective gloves are worn.

Failure to adhere to this regulation may result in cut wounds to the

hands.

Warning

Danger of allergic reactions if skin comes into contact with

hydraulic oil.

Persons who have an allergic reaction to hydraulic oil must wear

protective gloves and goggles when carrying out work where they

come into contact with hydraulic oil. Any areas of the skin affected

must be rinsed immediately with copious amounts of water.

Failure to adhere to this regulation may result in allergic reactions

or injuries to the eyes.

Other manuals for HCH50

1

Table of contents

Other Diamond Products Chainsaw manuals