Diamond Products CSH24 User manual

CHAIN SAW

OPERATOR'S

MANUAL

MODEL

CSH24

March 2020

Part# 1801446

Table of Contents

Description Page No.

1. Product description

Main Components...........................................................................4

Usage Information ..........................................................................5

Technical Data ................................................................................6

2. Safety Instructions

General............................................................................................8

Safety Principles .............................................................................9

General Safety Rules.......................................................................10

Personal Protective Equipment.......................................................11

Information and Symbols................................................................12

General Warnings ...........................................................................13

Responsibility .................................................................................14

3. Design and Function

Overview.........................................................................................16

Chain Saw Unit...............................................................................16

Chain Saw Bar ................................................................................17

Diamond Chain...............................................................................19

4. Controls and Display

Controls...........................................................................................21

Displays...........................................................................................21

5. Operation

General............................................................................................22

System Requirements......................................................................26

Preparatory Operations ..................................................................26

Working with the CSH24 Chain Saw ............................................31

After Use ........................................................................................33

6. Maintenance

General............................................................................................34

Maintenance and Service Table......................................................36

7. Servicing

General............................................................................................38

Tensioning the Diamond Chain......................................................40

Changing the Diamond chain..........................................................41

Changing the Bar ...........................................................................42

Changing the Drive ........................................................................43

Troubleshooting..............................................................................44

8. Taking out of service and storage

General............................................................................................46

Storage ............................................................................................47

9. Transport

Transporting the CSH24.................................................................48

Product description

1 Product description

The CSH Chain Saw

Main Components

Fig. 1-1 Main components

7 Rear Handle

8 Coupling FD (flow)

9 Water Hose Assembly

10 Nipple FD (return)

1 Bar

2 Chain

3 Front handle

4 Valve block

5 Cutting mandrel

6 Chain guard

1

2

3

5

4

6

7

8

9

10

4

Product description

Intended purpose

The CSH24 Chain Saw is designed and built for the following

applications:

• Cutting of concrete (including reinforced), masonry and natural stone

• Cutting of severance cuts, flush cuts and cross-cuts in ceilings, floors

and walls

•Only original Diamond Products Chain should be used

Safety measures

Any use other than for the intended purpose constitutes improper use or

misuse.

Since improper use or misuse can result in considerable danger,

here are some examples of what we believe constitute improper

use or misuse.

The following applications are prohibited:

• Cutting without the safety devices provided

• Cutting wood, glass and plastics

• Cutting without system and tool cooling

• Cutting in explosion-protected areas

• Cutting loose parts

• Incorrect or absence of waste water disposal (saw sludge)

Workplace Safety

Allow enough room for maneuvering toensure danger-free working.

Make sure you have sufficient lighting at your workplace.

Clearly cordon off the danger area so that no person can enter the danger

area during sawing.

The front, underneath and rearof the sawing area must be protected so

that persons or equipment cannot be harmed by falling objects,

concrete slurry, or by the protruding cutting tool.

Secure pieces of concrete that have been loosened to prevent falling.

Breathing in the water vapor that is created is a health hazard.

Ensure adequate ventilation in sealed-off areas.

The slurry resulting from cutting is slippery. Remove the slurry orensure

that you orother people donot slip on it.

Usage Information

5

Product description

Technical data

CSH24 Chain Saw

•Can be used with any hydraulic actuator (use a flow divider with

pressure limiter > 11 gpm or> 2000 psi

• Flush cutting possible without removing the protective cover

Hydraulic system

Length 6.5ft

Hydraulic hose

Weight

CSH24 Chain Saw with bar and chain 23 pounds

Dimensions of the CSH24 Chain Saw

Fig. 1-3 Dimensions of CSH24 Chain Saw

Maximum pressure 2,000 psi

Maximum flow 12 gpm

Minimum working pressure 36 psi

Minimum flow 2 gpm

38-3/8"

16-5/16"

10-7/16"

9"

22"

Water

6

Product description

Noise level

Depending on the working environment, the CSH24 Chain Saw can

cause excessive noise during operation.

The noise can permanently harm the hearing of operating personnel and

of other people nearby within a short time.

Ear protection must therefore always be worn while working.

Danger

Noise danger

When using the CSH24 Chain Saw hearing protection must be

worn.

If this instruction is not followed irreparable hearing damage may

result.

7

Safety instructions

2 Safety instructions

General

Target audience

This chapter describes the safety instructions that are essential to

follow when using the CSH24 Chain Saw

All persons who work on and with the CSH24 Chain Saw, have a duty to

read and understand the chapters of the Operating instructions relevant to

their particular activities.

This applies in particular to the “Safety instructions” chapter which is

mandatory for all persons and activities.

Observance of the safety instructions

No work must be performed on or with the CSH24 Chain Saw before the

safety instructions contained in the Operating instructions have been read

and understood. The Operating instructions are mandatory for all work

– abridged instructions should only be used in the form of

checklists.

The CSH24 Chain Saw has been inspected before being shipped and is

delivered in perfect condition. Diamond Products does not accept

any liability for damage caused by the failure to observe the

instructions and information provided in the Operating instructions. This

applies in particular to:

• Damage caused by improper use and operator error.

• Damage caused by failure to observe safety-related information in the

Operating instructions or shown on the warning signs fitted to the

machine.

• Damage caused by defective or absence of maintenance work.

Independently performed conversions and alterations may affect safety

and are not permitted.

Use for intended application

The intended application is described in chapter one.

Observance of workplace safety and the danger area

The workplace and danger area are described in chapter one.

8

Safety instructions

Safety principles

Safety Boundaries

The CSH24 Chain Saw has no effect on the safety concept of the

connected systems, apparatus and installations.

Safety elements

Protection from personal injury is based primarily on a safety concept and

design safety.

Passive safety elements

Protection from live parts

All functional units that contain parts which carry hazardous voltages, are

shock-protected by suitable covers.

Removing protective devices

Protective devices should only be removed when the device is turned off,

disconnected from the mains and at a standstill. Safety components in

particular should only be removed and refitted by authorised personnel.

Before using the CSH24 Chain Saw again, the safety elements must be

checked for correct operation.

Safety measures (organisational)

Product monitoring obligation

Operating personnel must notify changes in the operational behaviour or

safety-related components to a responsible person or the manufacturer

immediately.

Location of Operating instructions

A copy of the Operating instructions must be available at all timesto

staff where the CSH24 is in use.

9

Safety instructions

General safety rules

Statutory provisions

The generally applicable national and local safety and accident prevention

provisions and the supplementary operator regulations must be followed

and complied with.

Inspection and maintenance obligation

The operator is under an obligation to only use the CSH24 Chain Saw

when it is in a perfect and undamaged condition. The maintenance

intervals shown in the Operating instructions must be adhered to without

fail. Malfunctions and mechanical damage must be rectified without delay.

Spare parts

Only Diamond Products original spare parts should be used.

Otherwise damage may be caused to the CSH24 Chain Saw or to other

property and persons.

Power connections

The CSH24 Chain Saw must be connected and coupled to the drive

assembly used in accordance with the Operating instructions.

Modifications

No technical alterations should be made to the apparatus in the form of

additions or conversions without the written consent of Diamond

Products

Safety instructions in the individual chapters

The chapters of these Operating instructions contain additional safety

instructions. These make reference to specific potential dangers (residual

dangers). The instructions must be followed closely and require that the

actions described are taken.

10

Safety instructions

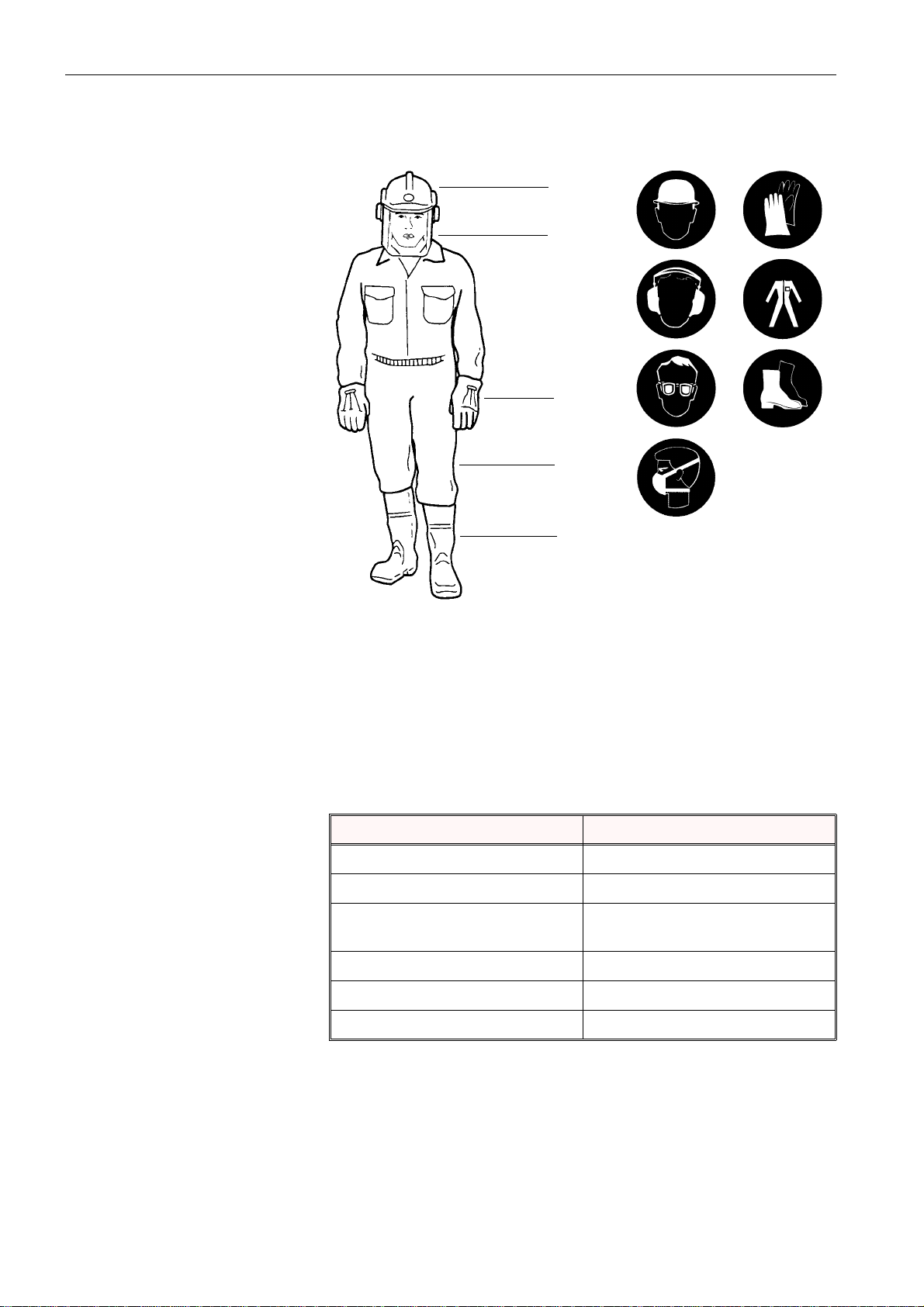

Personal Protective Equipment

Fig. 2-1 Personal Protective Equipment

1. Helmet with ear protectors 5. Waterproof, sturdy,

2. Visor or goggles comfortable clothing

3. Breathing mask 6. Work boots with steel toecaps

4. Waterproof gloves and non-slip soles

Personal Protective equipment must always be worn when drilling,

sawing, hammering or compressing concrete or stone in order to

protect against the following dangers:

Sources of danger Safety clothing

Falling parts: Helmet, steel-capped safety shoes

Moving, sharp-edged parts: Safety gloves

Flying pieces of concrete and

stone, flying sparks: Goggle or helmet with visor

Slipping: Anti-slip shoes

Noise Ear protectors

Contamination of respiratory tracts Respiratory mask

1

2 / 3

4

5

6

11

Safety instructions

Information and symbols

In these Operating instructions information panels are used to draw

attention to residual dangers and to point out important technical

requirements.

Danger symbols in the Operating instructions

Fig. 2-2 Danger and warning notices

Information symbol

Fig. 2-3 Information notice

Danger

Warning of danger, where failure to comply could lead to death or

serious injury.

Warning

Warning of danger, where failure to comply could lead to injury or

damage to property.

Information

Text displayed in this way is practical information and is aimed at

achieving optimum use of the installation or apparatus. Failure to take

note of this information may mean that the performances shown in the

technical data can no longer be guaranteed.

12

Safety instructions

General Warnings

The following warnings shown are generally applicable to all work (with

and on the saw systems and during all phases of the life of the systems).

Danger

Electric shock due to defective electronic equipment.

The electrotechnical equipment must be checked prior to each use

and from time to time during prolonged usage. Defective parts

such as cables and plugs must be exchanged by electrotechnically

trained personnel in the powered down state.

Failure to comply with this regulation may lead to serious physical

injury or death. Secondary damage such as fires may also occur.

Warning

Danger from sharp tool edges.

Touching a tool whileit is still in motion is prohibited.

When touching tools at astandstill it is recommended that

protective gloves are worn.

Failure to adhere to this regulation may result in personal

injury.

Warning

Danger of allergic reactions if skin comes into contact with

hydraulic oil.

Persons who have an allergic reaction to hydraulic oil must wear

protective gloves and goggles when carrying out work where they

come into contact with hydraulic oil. Any areas of the skin affected

must be rinsed immediately with copious amounts of water.

Failure to adhere to this regulation may result in allergic reactions

or injuries.

13

Safety instructions

Responsibility

Authorised personnel

Work on or with Diamond Products machines or systems should only

be performed by authorised personnel. Personnel are considered by

Diamond Products to be authorised if they meet the necessary

training and know-how requirements and they have been assigned a

precise functional role.

The personnel qualifications for the corresponding work are contained in

the introduction under “General” of the respective chapters.

The manufacturer

Diamond Products or a company expressly nominated by Diamond

Products is deemed to be the manufacturer of the products supplied

by Diamond Products. Within the context of an integrated quality and

safety control system the manufacturer is entitled to request from the

operator information on the products.

Operator

The operator named by Diamond Products is the primary, legal entity

responsible for the correct use of the product and for the training and use

of the authorised personnel. The operator sets out the mandatory skills and

level of training of the authorised personnel for his company.

Operative (user)

User is the term employed by Diamond Products to designate a person

who independently performs the following work:

•Setup Diamond Products machines or systems for tasks according

to the intended purpose.

• Performs tasks independently and monitors these.

• Locates malfunctions and initiates or performs troubleshooting.

• Carries out servicing and simple maintenance.

• Observes the correction functioning of the safety devices.

Service engineers

Service engineer is aterm used by Diamond Products to

designate a person who independently performs the following work:

•Installs Diamond Products machines and systems and controls their

correct application.

• Makes adjustments to machines and system for which special access

rights are required.

• Performs repairs, complex service work and corrective work.

14

Safety instructions

Qualification and training

Operator

• A technical trained person in a specialist role.

• Has extensive experience in personnel training and danger assessment.

• Has read and understood the “Safety instructions” chapter.

User

• Has completed concrete expert training or has professional experience.

•Has received an introduction (basic training) to operation of the

CSH24 Chain Saw froma service engineer.

• Has read and understood chapter 2 “Safety instructions”.

Service engineers

• Specialist professional training (mechanical / electrotechnical).

•Has attended specialist courses at Diamond Products.

• Has read and understood the “Safety instructions” chapter.

15

Design and function

3 Design and function

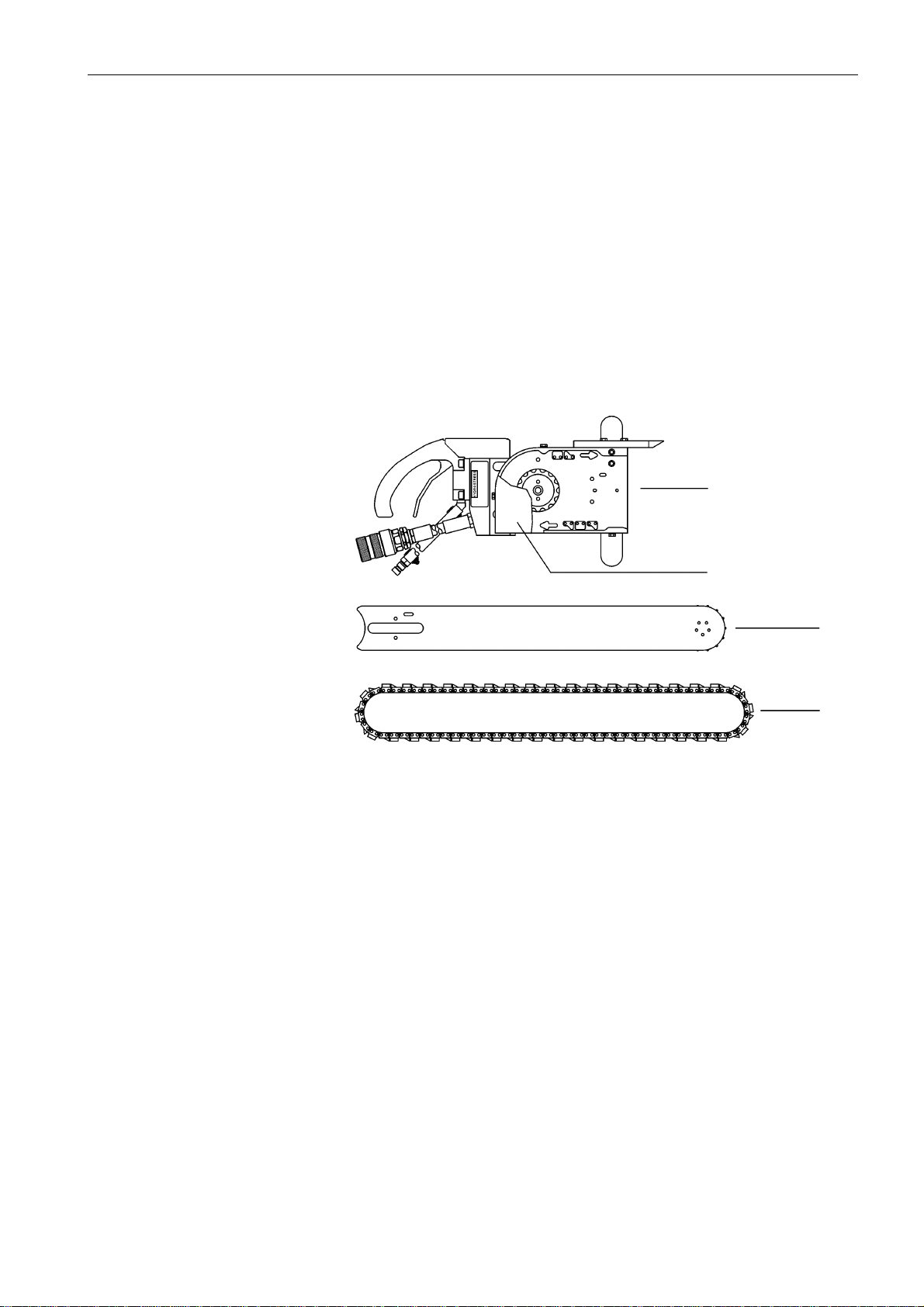

Overview

The CSH24 Chain Saw is comprised the following components.

•Chain Saw unit

•Chain Saw Bar

•Diamond chain

•Chain guard (Safety component)

Fig. 3-1 CSH24 Chain Saw design

1. Chain saw unit

2. Bar

3. Diamond chain

4. Chain guard

Function

The overall function of the CSH24 Chain Saw remains exactly the same.

The CSH24 Chain Saw is powered by a hydraulic drive assembly. The

chain is driven by the hydraulic motor incorporated into the chain saw unit.

The driven chain is inserted into the material to be cut.

1

2

3

4

16

Design and function

Component description

Chain saw unit

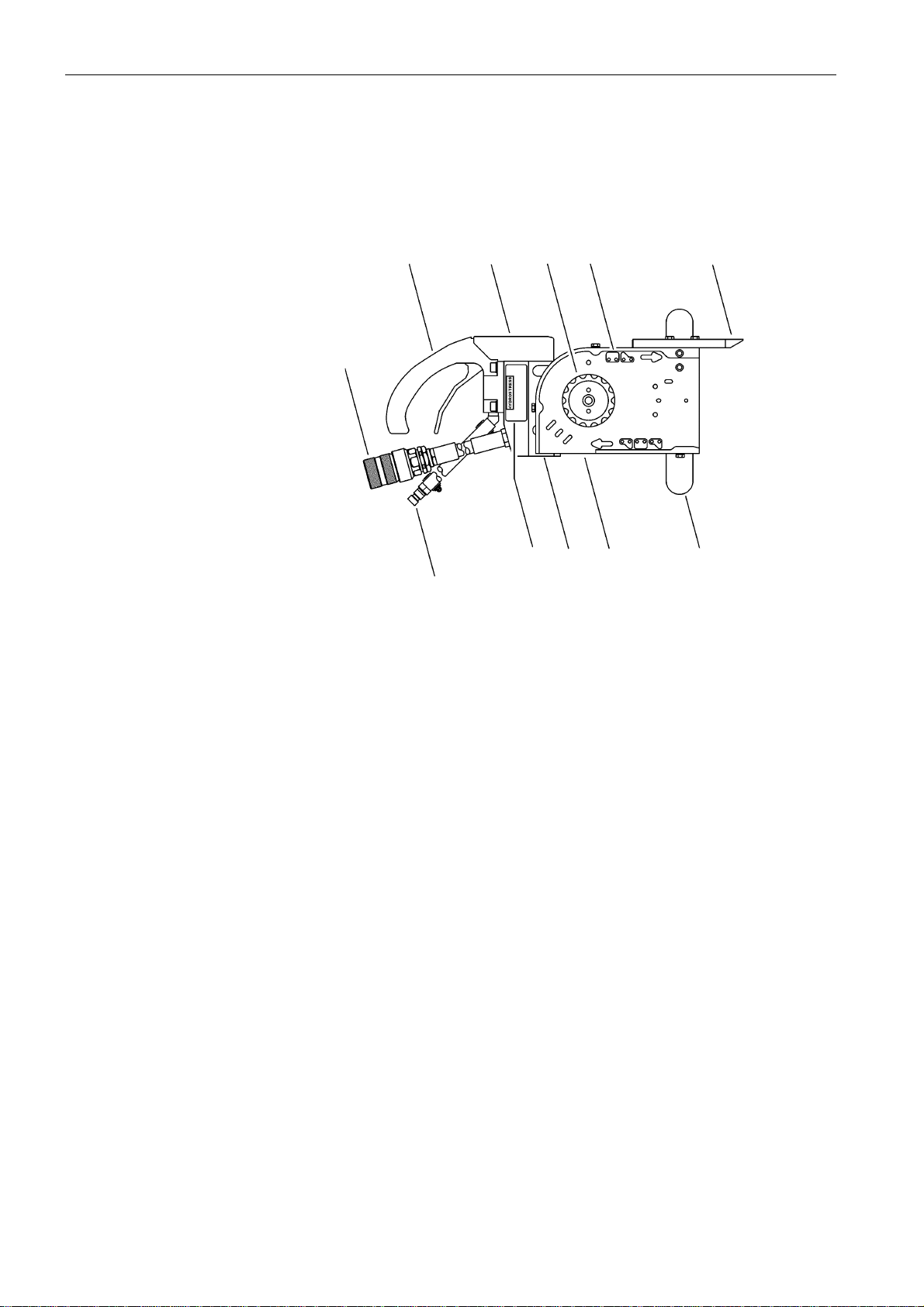

Fig. 3-2 Chain saw unit

1. Operating handle with manual starter 7. Water connection

2. Water level housing 8. Name plate

3. Drive wheel 9. Valve block

4. Fitting aid (chain-engraving) 10.Chain guard

5. Cutting mandrel 11.Front handle

6. Hydraulic connection

Function

The chain saw unit is the central component of the CSH24 Chain Saw.

The chain saw unit incorporates the drive motor and the operating handle

and front handle for using the CSH24. The unit along with its valve block

and the hydraulic and water connections also constitutes the interface with

the power source (drive assembly).

12345

78910 11

6

17

Design and function

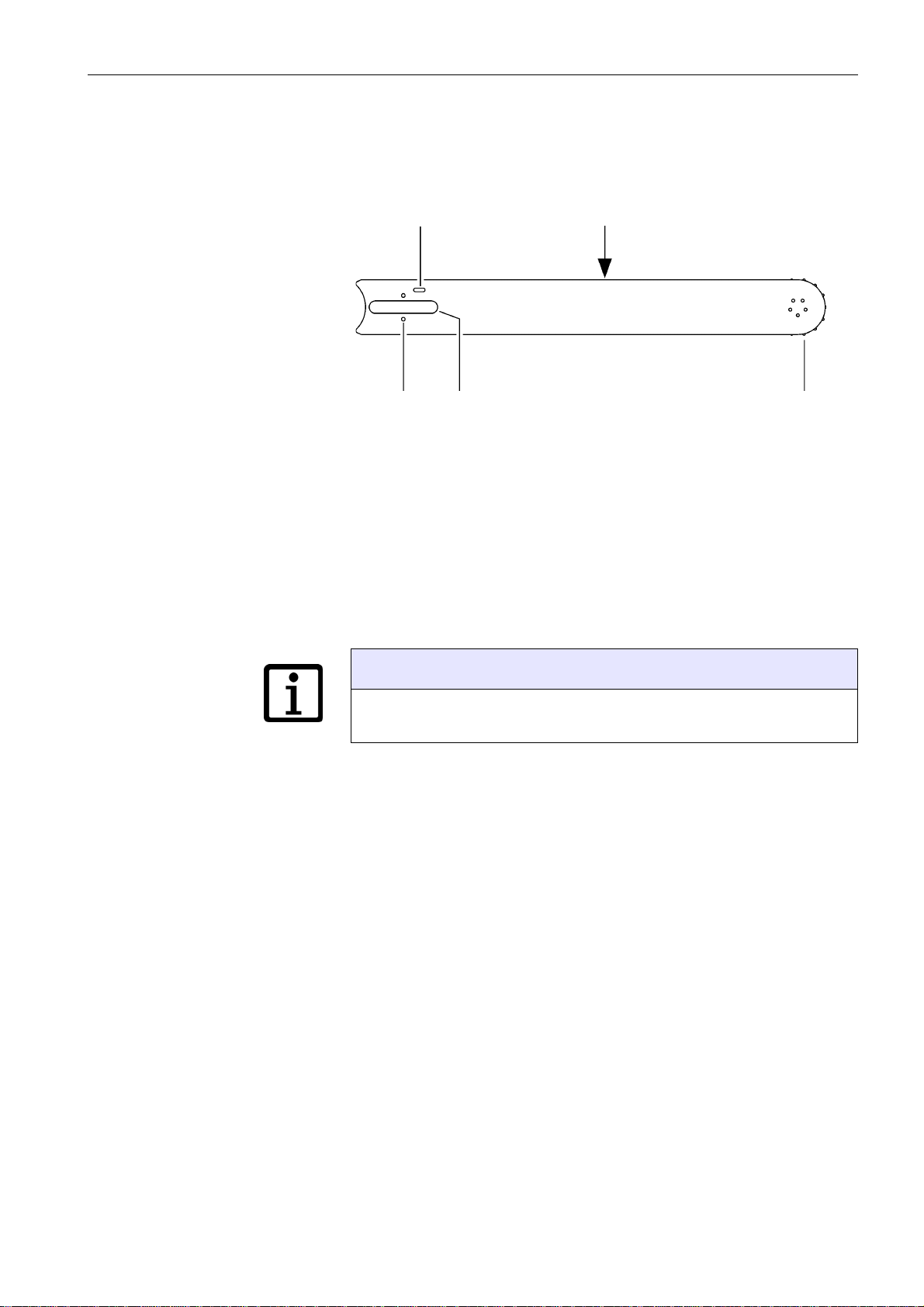

Chain Saw Bar

Fig. 3-3 Bar

1. Water inlet 4. Assembly opening

2. Chain guide 5. Reversing wheel

3. Assembly bore hole

for chain tensioner

Function

The bar is securely fixed to the chain saw unit. The chain runs andis guided

on the bar. The bar provides lateral support for the chain. The cutting

pressure is absorbed via the bar.

Information

The bar serves solely to guide the diamond chain. Never use the bar as

a lifting tool or a crow bar.

12

34 5

18

Design and function

Diamond chain

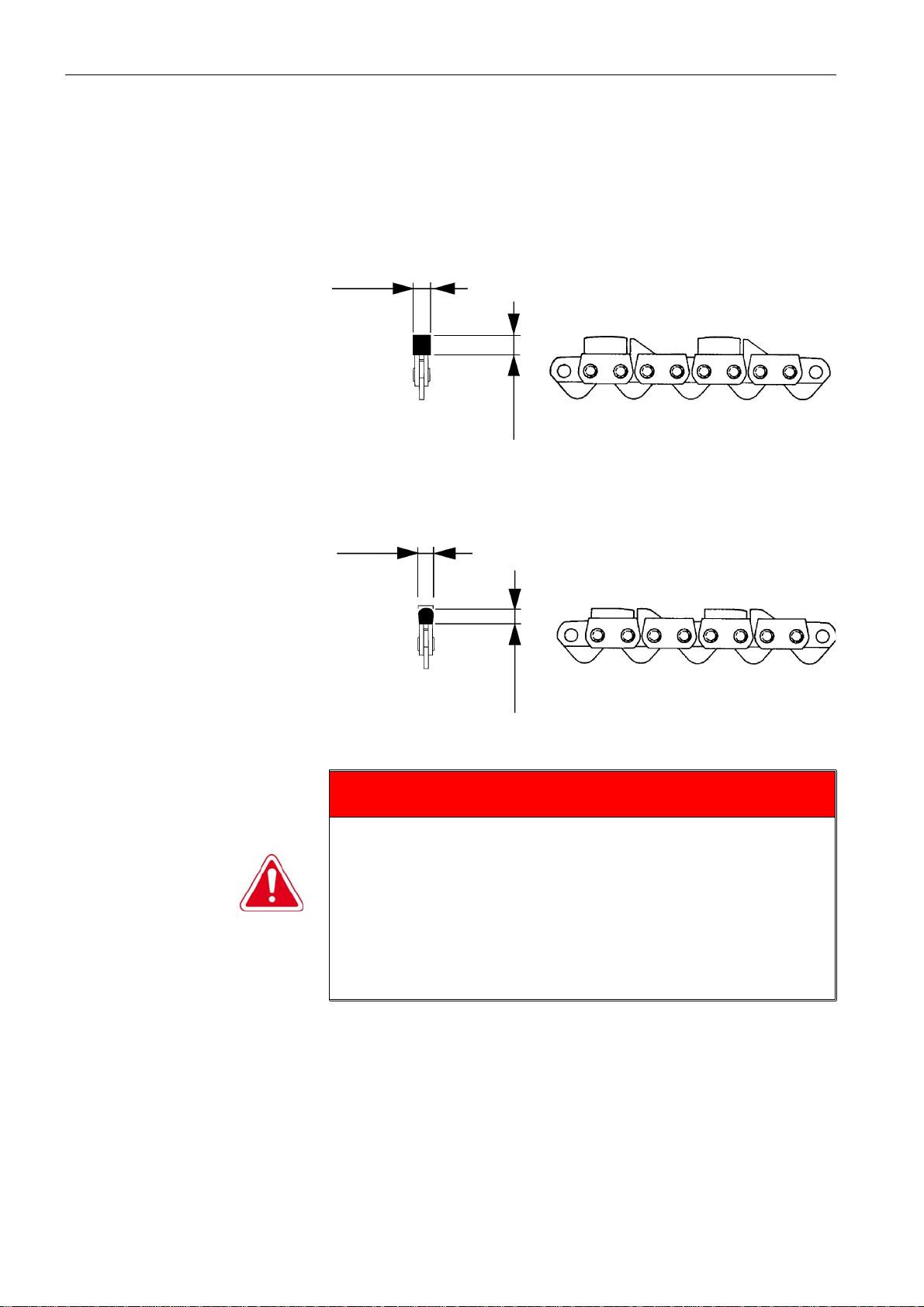

Dimensions of a new chain

Fig. 3-4 Dimensions of new chain

Dimensions of a worn chain

Fig. 3-5 Dimensions of worn chain

Danger

When working with a worn chain there is a danger of the chain

breaking.

A worn chain must be replaced by a new chain.

Do not take any notice of the fact that some segments are not

completely worn.

Failure to comply with this regulation may lead to serious physical

injury or death.

7/32"

15/64"

3/16"

1/16"

19

Design and function

Direction of travel and position of diamond chain

Ensure the correct position and direction of travel when fitting a chain.

The engraved mark on the chain saw unit is intended as a fitting aid.

Fig. 3-6 Diamond chain position and direction of travel

1. Fitting aid (engraving)

2. Chain direction of travel

Function

The diamond chain constitutes the tool for the CSH24 Chain Saw. It is

with the help of the chain that the cut is performed.

Danger

Working with an incorrectly fitted chain will reduce the lifetime of

the chain and there is a danger of the chain breaking.

Insert the chain correctly according to the engraved mark.

Failure to comply with this regulation may lead to serious physical

injury or death.

1

2

20

Table of contents

Other Diamond Products Chainsaw manuals