Diamond Products CP38KXL User manual

CORE POWER

OPERATOR’S MANUAL

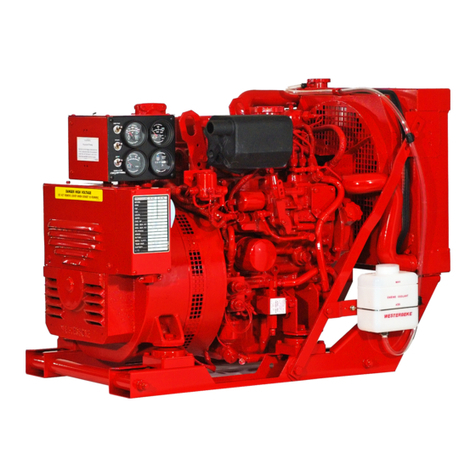

CP38KXL

HYDRAULIC POWER UNIT

July, 2023

Part #: 1802747-01

CP38KXL HYDRAULIC POWER UNIT OPERATOR’S MANUAL

Table of Contents

Introduction ............................................................................................................................................. 5

CP38KXL Controls .............................................................................................................................. 6

CP38KXL Dimensions ......................................................................................................................... 7

CP38KXL Specifications ..................................................................................................................... 8

Operating .............................................................................................................................................. 13

General Operating Precautions ......................................................................................................... 13

Emergency Stop ................................................................................................................................ 13

Activating the Emergency Stop ..................................................................................................... 13

Deactivating the Emergency Stop ................................................................................................. 13

Handlebars ........................................................................................................................................ 13

Adjusting the Handlebars .............................................................................................................. 13

Flow Control Valve ............................................................................................................................ 13

Pressure Relief Valve ........................................................................................................................ 13

Adjusting the Pressure Relief Valve .............................................................................................. 14

Hydraulic Oil Cooler .......................................................................................................................... 14

Air to Oil Cooler (Optional) ................................................................................................................ 14

Hoses ................................................................................................................................................ 15

Hose Connections ......................................................................................................................... 15

Fuel ................................................................................................................................................... 15

Adding Fuel ................................................................................................................................... 15

Engine ............................................................................................................................................... 15

Tasks Prior to Starting the Engine ................................................................................................. 15

Starting the Engine ........................................................................................................................ 15

Stopping the Engine ...................................................................................................................... 16

Heating Cold Oil ............................................................................................................................ 16

Maintaining Hydraulic Oil Temperature ......................................................................................... 16

Operating Driven Equipment ............................................................................................................. 16

Maintenance ......................................................................................................................................... 17

General ............................................................................................................................................. 17

Pre Maintenance Preparations .......................................................................................................... 17

General Cleaning .............................................................................................................................. 17

Cleaning Techniques ..................................................................................................................... 17

Service Schedule .................................................................................................................................. 18

Daily Service ......................................................................................................................................... 19

Check Engine Oil Level ..................................................................................................................... 19

Check Fuel Level .............................................................................................................................. 19

Check the Hydraulic Oil Level ........................................................................................................... 19

Check the Hydraulic Oil Filter ............................................................................................................ 20

Replacing the Hydraulic Oil Filter .................................................................................................. 20

Drain the Water from the Oil Cooler .................................................................................................. 20

25 Hour Service .................................................................................................................................... 20

Clean the Low Profile Pre-cleaner Filter ........................................................................................... 20

100 Hour Service .................................................................................................................................. 21

Change the Engine Oil and Filter ...................................................................................................... 21

150 Hour Service .................................................................................................................................. 22

Replace the Low Profile Air Cleaner Element ................................................................................... 22

Replace the fuel Filter ....................................................................................................................... 22

200 Hour Service .................................................................................................................................. 23

Replace Hydraulic Oil ........................................................................................................................ 23

500 Hour Service .................................................................................................................................. 23

Replace the Spark Plugs

................................................................................................................... 23

CP38KXL HYDRAULIC POWER UNIT OPERATOR’S MANUAL

Regular Maintenance ............................................................................................................................ 23

Engine ............................................................................................................................................... 23

Battery ............................................................................................................................................... 23

Battery Type .................................................................................................................................. 24

Servicing the Battery ..................................................................................................................... 24

Appendix A ........................................................................................................................................ 28

Troubleshooting ................................................................................................................................ 28

Appendix B ........................................................................................................................................ 29

Additional Resources..................................................................................................................... 29

Appendix C........................................................................................................................................ 30

Model and Serial Numbers ............................................................................................................ 30

CP38KXL HYDRAULIC POWER UNIT OPERATOR’S MANUAL

Introduction

Welcome to the Diamond Products family and thank you for choosing Diamond Products equipment.

At Diamond Products we are driven to ensure you are completely satisfied with your product and

continually strive to improve our product line so that we can offer you the best possible equipment in

the industry.

This operator’s manual is a critical document that provides pertinent information regarding the safety,

operation, maintenance, and care of your new equipment. Keep this manual available at all times.

Operate the equipment and all of its components according to this manual. Failure to comply with and

understand the following safety, operation and maintenance instructions can result in serious injuries

and/or death. All operators must be properly trained or supervised by experienced personnel prior to

using this equipment and should understand the risks and hazards involved. Diamond Products

discourages improper or unintended equipment usage and cannot be held liable for any resulting

damages.

Equipment modifications should be made by Diamond Products to ensure safety and design. Any

modifications made by the owner(s) are not the responsibility of Diamond Products and void all

equipment warranties if a problem arises as a result of the modification.

Refer to the Diamond Products Parts List for additional information and part diagrams. Refer to the

engine/motor manual and manufacturer as the primary source for all safety, operations, and

maintenance instructions regarding the engine/motor. Prior to operating, record the equipment’s serial

number, and the engine’s/motor’s model and serial numbers in Appendix C.

5

CP38KXL HYDRAULIC POWER UNIT OPERATOR’S MANUAL

CP38KXL Controls

1. Flow Control Valve – Allows the operator

the ability to increase or decrease flow from

the hydraulic tank to the tool(s).

2. Hydraulic Gauge – Provides visual

indication of hydraulic oil pressure.

3. Tach/Hour Meter - Provides visual

indication of engine speed and total

number of engine operating hours.

4. Emergency Stop Button – Stops the

engine

5. Inlet Water Connection – Allows cooling

water enter into the hydraulic oil cooler.

6. Outlet Water Connection – Allows cooling

water to discharge from the hydraulic oil

cooler.

7. Pressure Port Connection (1/2”) –

Attachment point for 1/2” hydraulic oil

supply hose.

8. Return port Connection (1/2”) –

Attachment point for 1/2" hydraulic oil

return hose.

9. Pressure Por Connection (3/4”) –

Attachment point for 3/4" hydraulic oil

supply hose.

10. Return Port Connection (3/4”) –

Attachment point for 3/4” hydraulic oil

return hose.

6

CP38KXL HYDRAULIC POWER UNIT OPERATOR’S MANUAL

CP38KXL Dimensions

CP38KXL Dimensions Inches Millimeters

A Unit Height 40 1016

B Unit Length 52-1/4 1327

C Unit Width 27 686

7

CP38KXL HYDRAULIC POWER UNIT OPERATOR’S MANUAL

CP38KXL Specifications

Engine Kohler PRO EFI ECH980

Emission Regulation US EPA & EU Stage V

Engine Type Kohler, 4-cycle, gasoline, OHV, cast iron cylinder liners,

aluminum block, electronic fuel injection

Engine Max Power 38 HP (28.3 kw) @3600 rpm (Kohler rating)

Peak Torque 58 lb.-ft (78.6 Nm) @ 3400 rpm

Engine Air Filtration Low profile paper element with pre-cleaner

Battery 12 Volt (300 CCA), Group U1

Starter 12 Volt solenoid shift starter

Fuel Type Gasoline, Unleaded, 87 Octane or higher

Fuel Tank 4.4 Gallon (16.7 Liter) with fuel gauge level indication

Engine Oil** 2 Qt. (1.9 Liter) 10W-30

Hydraulic Pump Casappa PLP20, 1.0 CI, 3.6 KSI

Hydraulic Fluid Mobile DTE10 EXCEL 46, 11 Gal. (41.6 Liter)

Max. GPM 16 GPM (60.6 L/M) @ no load, 3600 rpm

Hydraulic Relief 3000 psi (83 bar), factory set, adjustable

Lubrication Type NLGI #2 Lithium grease

Wheels 12” x 2-1/2” x 1” rubber tread x 2-3/4” steel hub

** See Kohler engine manual for additional oil specifications based on climate.

8

CP38KXL HYDRAULIC POWER UNIT OPERATOR’S MANUAL

Safety

Operate the equipment and all of its

components according to this manual. Failure

to comply with and understand the following

safety, operation and maintenance instructions

can result in serious injuries and/or death. All

operators must be properly trained or

supervised by experienced personnel prior to

using this power unit and should understand

the risks and hazards involved. Diamond

Products discourages improper or unintended

equipment usage and cannot be held liable for

any resulting damages.

Equipment modifications should be made by

Diamond Products to ensure safety and

design. Any modifications made by the

owner(s) are not the responsibility of Diamond

Products and void all equipment warranties if a

problem arises as a result of the modification.

Refer to the Diamond Products Parts List for

additional information and part diagrams. Refer

to the engine manual and manufacturer as the

primary source for all safety, operations, and

maintenance instructions regarding the engine.

Prior to operating, record the power unit’s

serial number, and the engine’s model and

serial numbers in Appendix C.

Notice: The information in this manual may

be updated at any time!

Safety Alerts

DANGER

Serious injuries and/or death will occur if

these instructions are not followed.

WARNING

Serious injuries and/or death could occur if

these instructions are not followed.

CAUTION

Mild and/or moderate injuries could occur if

these instructions are not followed.

Proposition 65

PROPOSITION 65

WARNING: This product

produces gasoline or diesel

engine exhaust, which is known

to the state of California to cause

cancer, birth defects or other

reproductive harm. For more

information go to:

WWW.P65WARNINGS.CA.GOV

Spark Arrester Requirement

WARNING

In the State of California it is a violation of

section 4442 or 4443 to use or operate the

engine on any forest-covered, brush-

covered, or grass-covered land unless

the engine is equipped with a spark arrester,

as defined in section 4442, maintained

in effective, working order or the engine

is constructed, equipped, and maintained

for the prevention of fire pursuant to

section 4443.

Respiratory Hazards

WARNING

Concrete cutting produces dust and fumes

known to cause illness, death, cancer,

respiratory disease, birth defects, and/or

other reproductive harm. Safety protection

techniques include, but are not limited to:

• Wearing gloves.

• Wearing safety goggles or a face

shield.

• Using approved respirators.

• Washing work clothes daily.

• Using water when wet cutting to

minimize dust.

• Washing the hands and face prior to

eating/drinking.

For additional safety and self-protection

information contact your employer, the

Occupational Safety and Health

Administration (OSHA), and/or The National

Institute for Occupational Safety and Health

(NIOSH).

9

CP38KXL HYDRAULIC POWER UNIT OPERATOR’S MANUAL

General Safety

• Read and understand all safety,

operations, and maintenance instructions

provided in this manual prior to operating or

servicing the power unit.

• Keep equipment components clean and

free of slurry, concrete dust, and debris.

• Inspect water hoses prior to operating the

equipment. Clean, repair, or replace

damaged components.

• Inspect hydraulic hoses prior to operating

the equipment. Clean, repair, or replace

damaged components.

• Raise the equipment to a proper height for

access when working underneath the

equipment. Use chocks to block the

wheels, and fit blocks or jacks under the

frame edges.

• Repair the equipment immediately when a

problem arises.

• Replace equipment decals if unreadable.

• Dispose of all hazardous waste materials

according to city, state, and federal

regulations.

• Always have a phone nearby, and locate

the nearest fire extinguisher and first aid kit

prior to operating the equipment.

• Operate the equipment wearing flame

resistant clothing.

• Underage or non-trained personnel should

not operate the equipment.

• Keep all body parts away from rotating

machinery.

• Replace all guards and access panels

(unless stated otherwise) prior to operating

the equipment.

DO NOT:

• Assume the equipment will remain still

when parking/stopping the equipment on a

slope. Chock the wheels to help prevent

unnecessary movement.

• Drop equipment, supplies, tools, etc., when

handling to help prevent injuries.

• Lift and carry equipment, supplies, tools,

etc., that are too heavy and/or cannot be

lifted easily.

• Operate the equipment without using the

appropriate safety equipment required

for the work task.

• Operate or service the equipment with any

clothing, hair, or accessories that can snag

in the machinery, which could lead to

serious injuries or death!

• Operate the equipment using attachments

not associated with or recommended for

the equipment.

• Operate the equipment around combustible

materials.

• Operate the equipment with anyone near

the work area.

• Operate the equipment until all

unnecessary materials have been removed

from the work area.

• Operate the equipment with loose nuts,

screws, and bolts.

• Operate the equipment when ill or fatigued.

• Operate the equipment under the influence

of drugs and/or alcohol.

• Operate the equipment on steep slopes.

• Touch hot components when operating the

equipment.

• Leave the equipment unattended until the

engine is off.

• Place the equipment into storage until it

has cooled down.

• Service the equipment until it has cooled

down.

• Service the equipment with the engine

running.

10

CP38KXL HYDRAULIC POWER UNIT OPERATOR’S MANUAL

Battery and Electrical Safety

• Ignitable explosive gases are

emitted from the battery. DO

NOT expose the battery to

sparks or open flames.

• Keep the area around the battery well-

ventilated.

• Keep the battery level when handling it.

• Use protective eyewear or a face shield,

and avoid contact with the skin when

handling/servicing the battery.

• Use a proper battery tester when testing

the battery strength.

• Always be sure to connect the battery

cables to the proper terminal when

reconnecting the cables.

• Occasionally inspect the battery, cables,

clamps, and terminals for damages.

Service components as necessary.

• Always keep the battery cable clamps

away from the battery terminals when the

battery is disconnected to avoid accidental

connections while servicing.

• Immediately rinse your clothing, skin, or

eyes with water if exposed to battery acid.

Seek medical attention immediately!

• Disconnect the battery prior to servicing all

equipment components (unless stated

otherwise).

• Remove the battery when storing the

equipment for longer periods.

• Always use the correct size fuses (amps) to

prevent fires.

Fuel Safety

• Always use caution when refueling.

• Store all fuel in appropriate safety

containers.

• DO NOT operate the equipment with a fuel

leak.

• DO NOT fuel the equipment with the

engine running.

• Let the engine cool prior to adding fuel.

• Refer to the engine manual for

recommended fuels.

• Always use appropriate fuels in cold

weather.

• Move the equipment away from the

refueling area prior to starting the engine.

•

DO NOT smoke or expose fuel

to open flames when filling the

fuel tank or working with fuel

.

• Clean up any spilled fuel prior to starting

the engine.

•

Drain the fuel tank and fuel lines when

storing the equipment for longer periods of

time. Refer to the engine manual for

additional recommendations.

Engine Safety

• Refer to the engine manual as the primary

source for engine safety.

• Always know how to turn off the engine

quickly for emergency purposes.

• Fill the fuel tank and check the oil level

prior to starting the engine.

•

Keep all body parts away from

rotating equipment parts with

the engine in operation.

• DO NOT start the engine without the air

filter(s) installed.

• DO NOT allow dust to enter the air intake

tube when cleaning/replacing air filter(s).

• Replace damaged components

immediately that may allow dust to enter

the engine.

• DO NOT leave the engine running

unattended.

•

Always operate the equipment in

well-ventilated areas.

Concentrated engine exhaust

can cause loss of consciousness and/or

death

.

• DO NOT touch the engine/muffler

assembly with the engine running, and

always let them cool down prior to touching

or servicing the equipment.

• Handle hot oil carefully when changing the

oil.

• Let the engine cool prior to removing

pressurized caps (applicable models).

•

DO NOT use any starter substances or

starter fluids (e.g., starter fluid sprayed into

the air filter) when starting the engine using

a glow plug (applicable models). These

materials are extremely flammable and

explosive, and can melt parts or possibly

explode when used to help start the

engine.

11

CP38KXL HYDRAULIC POWER UNIT OPERATOR’S MANUAL

Hydraulic Safety

• Turn off the engine prior to servicing

hydraulic components.

• Always make sure any hydraulic

components being serviced are not

supporting the weight of other equipment

components. If a particular component is

under pressure when connection points are

loosened, oil may spray out forcefully.

• Always place a piece of

cardboard or paper up against

hydraulic components, or use a

leak detection fluid to check for

hydraulic fluid leaks. Keep all body parts

away from leaks and/or areas that may

eject hydraulic fluid. Pressurized

hydraulic fluid can penetrate the skin,

causing serious injuries. Seek medical

attention immediately!

Transporting Safety

• Make sure the truck/trailer is in good,

working condition and sufficient to transport

the load. DO NOT tow the equipment

behind a vehicle.

• Close the fuel shutoff valve (applicable

models) when transporting.

• Drain the fuel tank when transporting long

distances.

• Use ramps that will support the weight of

the equipment and yourself when loading

or unloading.

• Chock the wheels and secure the power unit

in the truck/trailer prior to transporting.

• Refer to the Department of Transportation

(DOT) for additional transportation

recommendations.

Lifting Safety

• Move yourself and all others away

from the lifting area when hoisting

the power unit to prevent being

crushed.

• Secure the appropriate hoisting cables, straps,

and/or chains to the power unit’s designated lift

point prior to hoisting.

• Never use the tie-down brackets (applicable

models) to lift the power unit.

• DO NOT attempt to lift the power unit

irresponsibly and/or improperly.

12

CP38KXL HYDRAULIC POWER UNIT OPERATOR’S MANUAL

Operating

General Operating Precautions

•

Prior to operating the power unit, read the

operator’s manual thoroughly and ensure

that you understand the safe and proper

operation of the power unit.

•

Use approved personal protective

equipment at all times while operating the

power unit.

•

Ensure that there is firefighting equipment

and a first aid kit nearby while operating the

power unit.

•

Ensure the work area is free of

obstructions, people, and/or animals prior

to operating the power unit.

Emergency Stop

If an emergency condition should arise, the

power unit is equipped with an emergency stop

button located on the front of the control panel.

The emergency stop places the power unit into

safe mode allowing the operator to address the

emergency condition.

NOTE: Only use the emergency stop in an

emergency condition. Do not use it to stop the

power unit during normal operations.

Activating the Emergency Stop

To activate the emergency stop, press down

on the emergency stop button. The engine will

shut off.

Deactivating the Emergency Stop

Prior to deactivating the emergency stop,

ensure that the power unit is back into a safe

operating condition. Then turn the emergency

stop button clockwise until it springs back into

position. The power unit can now be restarted.

Emergency Stop Button

Handlebars

The handlebars help to guide and maneuver

the power unit. The handlebars have two

positions for operation, fully extended or

retracted for storage and transport. Both

positions can be locked in place using the

provided detent pins.

Handlebars

Adjusting the Handlebars

1. Remove the detent pin holding the

handlebar in the handlebar tube.

2. Move the handlebar to the desired position

by aligning the hole through the handlebar

with the corresponding hole in the

handlebar tube.

3. Reinsert the detent pin through the holes to

lock the handlebar in place.

4. Repeat for the second handlebar.

The pressure compensated flow control valve

allows full flow control while the gas engine

remains at its most efficient wide-open throttle.

This allows a higher operating pressure at all

flows.

The flow control valve is located on the upper

left of the control panel. When the valve is set

at the min gpm setting, all flow is directed to

the hydraulic tank. As the valve is rotated

clockwise, the flow to the tools will increase.

Flow Control Valve

Pressure Relief Valve

13

CP38KXL HYDRAULIC POWER UNIT OPERATOR’S MANUAL

Overpressure protection is provided by a

pressure relief valve located just below the left

side of the control panel. The valve is factory

set at 3000 psi (206.9 bar) which directs all

flow back to the tank. The valve can be

manually adjusted down to 1200 psi (83 bar).

CAUTION

When adjusting the pressure relief valve

DO NOT exceed 3000 psi.

Adjusting the Pressure Relief Valve

1. Ensure that there are no tools attached to

the power unit and start the engine.

2. Allow the hydraulic oil to warm up to

approximately 100°F (38°C).

3. Rotate the flow control valve clockwise to

allow maximum flow over the relief.

Pressure Relief Valve

4. Using a 1” wrench, loosen the lock nut

securing the adjusting bolt on the relief.

5. Using a 3/8” allen key, turn the adjusting

bolt counterclockwise to bring the relief

pressure down to the required setting.

6. When the required setting is achieved,

tighten the lock nut on the adjusting bolt to

secure.

7. Rotate the flow control valve back to the

min rpm setting and turn the engine off.

Hydraulic Oil Cooler

The power unit is equipped with a brazed plate

oil cooler. Water will pass through the cooler

and discharge to the driven tools for dust

suppression or blade and bit cooling. Some

tools will automatically shut the water off when

not actively cutting or drilling. This may result

in higher oil temperatures if the power unit

continues to run for long periods without

cooling water. Ideally the oil temperatures

need to stay below 120° F (49° C). In order to

avoid this situation, an optional oil to air cooler

is available.

NOTE: If temperatures are expected to drop

below 0°F (-18°C), drain the water from the

cooler.

Hydraulic Oil Cooler

Air to Oil Cooler (Optional)

A radiator/fan driven oil cooler is available to

provide an additional cooling source for the

hydraulic oil. The fan is set to turn on at

approximately 120°F (49°C) and continue to

run until the oil temperature drops below 120°F

(49°C). The fan will continue to run even if the

engine is turned off. However, the fan will stop

whenever the emergency stop button is

activated.

14

CP38KXL HYDRAULIC POWER UNIT OPERATOR’S MANUAL

Hoses

Large diameters and short lengths are

preferred and offer the highest system

efficiency. Particular attention must be paid to

the hose lengths. When using a 50 foot

(15.2 M) supply hose there is also a 50 foot

(15.2 M) return hose for a total of 100 feet

(30.5 M) of hose. At 15 GPM and oil

temperature at 100°F (37.8°C), this could

result in a 400 psi (27.5 bar) pressure loss

when using a 1/2” hose and a 140 psi (9.6 bar)

pressure loss when using a 5/8” hose. As oil

temperature changes, the pressure loss will

change dramatically.

Hose Connections

It is best to make all hose connections prior to

starting, as even the slightest pressure will

make hose connections difficult. Push the hose

couplings together until they click, then turn the

locking ring on the coupling to the secured

position.

Fuel

WARNING

Always use caution when refueling.

DO NOT operate the power unit with a fuel

leak.

DO NOT fuel the power unit with

the engine running.

DO NOT smoke or expose fuel to

open flames when filling the fuel

tank or working with fuel.

CAUTION

Clean up any spilled fuel prior to starting the

engine.

Adding Fuel

1. Turn off the engine and let the power unit

cool down.

2. Remove the fuel tank cap.

3. Fill the fuel tank with unleaded 87 octane or

higher only. DO NOT overfill the tank for

expansion purposes. Refer to the engine

manual for additional information.

4. Replace the fuel tank cap.

Fuel Tank Cap

Engine

WARNING

Operate the power unit in well-

ventilated areas. Concentrated

engine exhaust can cause loss

of consciousness and/or death.

DO NOT touch the engine/muffler with the

engine running, and always let them cool

down prior to touching or servicing the

power unit.

DO NOT leave the power unit unattended

while the engine is running

.

Tasks Prior to Starting the Engine

1. Check oil level and add as required. DO

NOT overfill.

2. Check fuel level and fill as required. DO

NOT overfill.

3. Pull up on the emergency stop button.

4. Ensure the fuel shutoff valve located under

the fuel tank is open.

5. Set the flow control valve to zero.

Starting the Engine

1. Set the throttle control midway between

fast and slow positions.

NOTE: If the fuel system is dry, turn the key

switch to ON position for one minute to prime

the system.

2. Turn the key switch to START and release

as soon as the engine starts.

NOTE: If the engine does not start within 10

seconds, turn the key switch to OFF position

and try again approximately 30 seconds later.

Refer to the engine manual if the condition

persists.

3. Set the throttle control to the fast position.

15

CP38KXL HYDRAULIC POWER UNIT OPERATOR’S MANUAL

Stopping the Engine

1. Rotate the flow control valve

counterclockwise to the min rpm setting.

2. Set the throttle control back to midway

between the fast and slow positions.

3. Turn the key switch to the off position.

4. Close the fuel shutoff valve located under

the fuel tank.

NOTE: If the hydraulic oil temperature is above

120°F (49°C) and the unit is equipped with the

oil to air cooler, the fan will continue to run

after the engine is turned off until the oil

temperature falls below 120°F (49°C).

Heating Cold Oil

Cold oil greatly increases pressure loss in

hoses and fittings and may affect tool

operation. Prior to operating tools, heat the oil

by forcing it over relief as follows:

1. Ensure no tools are connected to the

power unit.

2. Start the engine in accordance with the

starting instructions above.

3. Rotate the flow control valve clockwise

toward the max rpm setting.

4. Allow the hydraulic oil to warm up to

approximately 100°F (38°C).

5. Rotate the flow control valve to the min rpm

setting.

6. Turn off the engine.

7. The unit is now ready for operation.

Maintaining Hydraulic Oil Temperature

With an ample water supply and the oil to air

cooler, it is unlikely that overheating will be an

issue except in the most extreme ambient

temperatures. To lower high oil temperatures,

operate the unit with the flow control valve in

the min rpm setting. This will unload the unit

while circulating oil through the cooling system.

The rate of cooling will depend on the ambient

temperature and the amount of water being

circulated through the cooler.

NOTE: Monitor the thermometer on the top of

the hydraulic tank. Maximum recommended oil

temperature is 180°F (82°C).

Operating Driven Equipment

The operator must know the hydraulic

requirements and limitations of the driven

equipment and the appropriate adjustments

must be made on the controls. The introduction

of other devices may cause system heating or

may render the system inoperative.

CAUTION

The power unit is equipped with a positive

displacement gear pump. All tools must

be equipped with a control valve that

allows flow directly to return ports when

not in use. Blocking oil flow or abruptly

disconnecting the tool can send flow

over relief and potentially overheat the

system.

Instructions supplied with the driven equipment

must be followed to ensure correct connection

and operation of each individual piece of

equipment. Equipment supplied by Diamond

Products will be capable of being connected

correctly and will be compatible with this power

unit, providing neither has been modified from

original factory condition. With equipment from

other manufacturers, it will be necessary to

determine the following:

• Correct direction of flow through the

equipment.

• Correct pressure and flow required by the

equipment.

• Compatibility of any valves or circuitry and

quick disconnects. Some handheld

equipment uses a trigger control, which is

operated frequently. These valves must be

of the open center type for correct

operation.

CAUTION

The quick disconnects must be clean when

connecting hoses and devices. Failure to

thoroughly clean may result in

contamination and premature failure of

system or tool components.

16

CP38KXL HYDRAULIC POWER UNIT OPERATOR’S MANUAL

Maintenance

General

Failure to read and comply with the

maintenance instructions provided in this

manual prior to performing maintenance may

result in serious injuries and/or death, and may

harm the power unit. DO NOT attempt to

perform maintenance on the power unit if you

are not properly trained for it, or are not

supervised by an experienced person.

Refer to the CP38KXL Parts List for additional

information and part diagrams when

performing maintenance tasks. Refer to the

engine manual and manufacturer as the

primary source for all safety, operations, and

maintenance instructions for the engine.

Contact the power unit and/or engine

manufacturer with any additional questions.

Remove all necessary guards and access

panels prior to servicing the power unit.

Replace prior to operating.

Pre Maintenance Preparations

• Ensure the power unit is in a safe area to

conduct maintenance.

• Maintain proper cleanliness of the work

area to minimize personal injury or

equipment damage.

• Ensure the power unit is sufficiently cool to

conduct any maintenance.

• Place the power unit on a level surface with

the engine turned off and the emergency

stop activated.

• Ensure there is adequate lighting in the

work area to ensure safety.

• Ensure all equipment and tools required for

the maintenance task are staged and

available for use.

• Prior to any maintenance being performed,

know the locations of all safety equipment

such as fire extinguishers, first aid kits, etc.

• All maintenance shall be performed by

qualified personnel only.

General Cleaning

The power unit must be cleaned after each use

and prior to conducting any maintenance.

Ensure that the power unit is cool prior to

cleaning. Ensure affected electrical equipment

is properly covered or de-energized prior to

cleaning with water or air.

Cleaning Techniques

Various cleaning options can be utilized

depending on the type of cleaning required.

High pressure washers and a mild detergent

will work the best. Compressed air and low

pressure water can also be utilized where

required.

CAUTION

Care must be taken when using high

pressure water and compressed air to

conduct any maintenance or cleaning.

High pressure water and compressed air

can cause injury to personnel or damage

to equipment if not used properly.

Air to Oil Cooler

Ensure that the air to oil cooler is cool prior to

cleaning. Use compressed air or a power

washer, set at 25° or larger, to clean the cooler

fins being careful not to damage the fins. A

mild detergent with low pressure water can

also be used to clean or degrease the oil to air

cooler.

NOTE: Plugged or damaged radiator fins can

and will diminish the cooling capacity of the air

to oil cooler.

Control Panel

Do not spay water on the control panel to

clean. Use a damp cloth or compressed air to

clean electrical components. Dry the control

panel after cleaning.

Engine

Use a mild detergent and water to clean the

engine. Do not to spray water forcefully on the

engine to prevent damage to components.

NOTE: Do not spray water into the exhaust

pipe or air filter.

17

CP38KXL HYDRAULIC POWER UNIT OPERATOR’S MANUAL

Service Schedule

The service schedule is based primarily on the standard operating time of the machine. The

frequency of the maintenance tasks can be increased based on the working environments of the

machine. For additional recommended engine maintenance, refer to the engine owner’s manual.

18

CP38KXL HYDRAULIC POWER UNIT OPERATOR’S MANUAL

Daily Service

Check Engine Oil Level

1. Remove the engine oil dipstick from the left

side of the power unit.

En

g

ine Oil Dipstick

2. Check the oil level on the dipstick. The

level should be at the top of the FULL

indicating line.

Engine Oil Level Indicators

3. If the level is low, remove the engine oil fill

cap located next to the oil dipstick.

Oil Fill Cap (Top of Engine)

4. Add oil until the level is correct on the

dipstick.

5. Replace the engine oil fill cap.

Check Fuel Level

1. The fuel cap is equipped with a fuel level

gage for fuel level indication.

Fuel Tank with Level Indicating Cap

2. If the fuel level is low, remove the fuel tank

fill cap located on the top of the fuel tank.

3. Fill the tank with unleaded 87 octane or

higher only.

4. Replace the fuel tank fill cap.

Check the Hydraulic Oil Level

It is important to keep the hydraulic oil free of

contamination to avoid damage to system

components. There is a strainer in the fill cap

that must be checked for debris prior to every

use and must always be in place when filling

the tank with fresh hydraulic oil.

1. The hydraulic tank, located on the right

side of the power unit, has a liquid level

sight gage located on the side. The

hydraulic oil level should be at the upper

end of the sight glass.

Liquid Level Sight Gage

19

CP38KXL HYDRAULIC POWER UNIT OPERATOR’S MANUAL

2. If the oil level is low, remove the fill cap

from the top of the tank and fill the tank to

the upper end of the sight glass.

Hydraulic Oil Tank Fill Cap

3. Check for any contamination in the fill

strainer and remove as required.

4. Replace the fill cap onto the tank.

Check the Hydraulic Oil Filter

An oil filter with a differential pressure gage is

provided at the inlet of the hydraulic tank to aid

in minimizing contamination in the system.

When the gage indicates that the differential

pressure is in the red zone (25 -100 psi), the

filter should be replaced.

Hydraulic Oil Filter

Replacing the Hydraulic Oil Filter

1. Remove the four bolts securing the left side

panel to the frame.

2. Place an oil receptacle drain pan under the

hydraulic oil filter.

3. Loosen the fitting on the inlet hose to the

hydraulic oil filter.

4. Remove the hose and allow the fluid to

drain into the drain pan.

5. Remove the filter using a filter wrench.

6. Dispose of the oil and filter in accordance

with city, state and federal regulations.

7. Completely fill the new filter with Mobile

DTE10 EXCEL 46 oil and add a thin film of

oil to the gasket on the filter.

8. Screw the new filter into the filter head until

the gasket is seated. Then turn the filter 1/2

turn by hand to secure.

9. Reinstall the inlet hose to the filter head

and tighten the hose fitting securely.

10. Remove the reservoir tank cap.

11. Add Mobile DTE10 EXCEL 46 oil to the

reservoir tank up to the upper end of the

sight glass. DO NOT overfill as fluid will

leak out from the reservoir cap.

12. Replace the cap and tighten to secure.

Drain the Water from the Oil Cooler

When storing the unit for an extended period of

time or when operating in cold climate

conditions, it is important to drain the water

from the oil cooler to prevent it from freezing

and causing damage to the cooler.

1. Ensure that all hoses are disconnected

from the oil cooler water inlet and outlet

fittings.

2. Using low pressure air, blow out the water

tubes from the top fitting until there is little

to no water exiting the lower fitting.

25 Hour Service

Clean the Low Profile Pre-cleaner Filter

If the air to oil cooler option is installed, start at

step #1. If the tool tray option is installed, start

at step #5. If no air to oil cooler is installed start

at step #7.

20

Table of contents

Other Diamond Products Portable Generator manuals