Diamond Wire Technology CS400 User manual

INSTRUCTION MANUAL

Millennium Series Capstan Saws

Models CS400, CS410, CT400, CS810 and CT800

Diamond Wire Technology

1605 S. Murray Blvd.

Colorado Springs, CO 80916

(719) 570-1150

(719) 570-1176 (FAX)

Thank you for your purchase of this wire Saw.

This manual provides important information and instructions for the assembly, installation,

adjustment, operation and maintenance of your new wire Saw.

By carefully following these instructions, you are assured of obtaining the best results possible with

this equipment.

In the event you experience difficulty with the operation of your saw, or if you have special cutting

problems, please call us at (800) 237-6792 and ask for technical assistance. We are always at your

disposal for consultation and service.

CONTENTS

Introduction ___________________________________________________________________________________1

Mechanical Setup_______________________________________________________________________________1

Shipping Considerations_______________________________________________________________________1

Electrical and Pneumatic Connections ___________________________________________________________2

Drain Connection ____________________________________________________________________________2

Spray System (Optional) ______________________________________________________________________ 2

Wire Inspection ______________________________________________________________________________ 3

Guide Pulley Spacing _________________________________________________________________________3

Mounting the Part Specimen______________________________________________________________________4

Operator Interface ______________________________________________________________________________5

Power On _____________________________________________________________________________________6

Manual Mode__________________________________________________________________________________6

Jogging the Actuators_________________________________________________________________________7

Common Setup Actions ______________________________________________________________________10

Automatic Mode _______________________________________________________________________________10

Wiring the Saw________________________________________________________________________________18

Wire Break Detection ________________________________________________________________________ 18

Removing a Worn Wire ______________________________________________________________________18

Removing a Broken Wire _____________________________________________________________________19

Installing a New Wire ________________________________________________________________________19

Adjustment and Maintenance ____________________________________________________________________ 22

Leveling ___________________________________________________________________________________22

Bow Sensor Positioning ______________________________________________________________________ 22

Bow Sensor Calibration ______________________________________________________________________23

Wire Tensioner _____________________________________________________________________________24

Preventative Maintenance _______________________________________________________________________ 26

Daily ______________________________________________________________________________________ 26

Weekly ____________________________________________________________________________________26

Monthly ___________________________________________________________________________________26

1

Introduction

The Diamond Wire Technology Millennium Capstan Saws are designed to make a series of

programmed cuts in a variety of materials. Slicing saws are designed to allow you to make up to

100 cuts (50 cuts with the Dicing Option) from a single program. Furthermore, each cut can be

programmed to a different width if desired. With the Dicing option, you can make up to 24 cuts

each in up to 4 different rotational positions from a single program. Furthermore, each dicing cut

can be programmed to a different width if desired. This flexibility permits the operator to cut

consistent slices, squares, and even complex polygons.

The cutting action is similar to that of a coping saw. A diamond-impregnated wire is tensioned

between pulleys above the part to be cut. The wire moves down through the material at a velocity

specified by the operator, or at a velocity that is automatically calculated based on wire bow.

Due to the small diameter and flexibility of diamond wire, a small angle forms between the part

and the pulleys as cutting proceeds. It is, in fact, this wire bow that imparts the necessary force

upon the specimen and allows cutting to occur. The saws incorporate a Bow Sensor which

continuously monitors wire deflection and automatically adjusts the velocity of the yoke drive to

maintain a constant bow, and hence a constant cutting force.

Please read the entire manual prior to undertaking any cutting operation. The manual contains a

considerable amount of interrelated information. A thorough understanding will translate into better

results.

Mechanical Setup

Shipping Considerations

Remove the yoke support block. To do this, jog the yoke up

until the block can be easily removed. Refer to the section,

Jogging the Actuators on page 7.

Air pressure is required to maintain wire tension. Since the saw is pre-

wired, the tensioner pulleys have been held in their outward position

with packing material to provide wire tension during shipping. DO

NOT REMOVE THE PACKING MATERIAL HOLDING THE

TENSIONER PULLEYS UNTIL AFTER AIR AND POWER HAVE

BEEN APPLIED TO THE SAW.

2

Electrical and Pneumatic Connections

The Saw requires 115 volt 50/60 Hz, single-phase power. Plug the controller power cord into a 15

Amp grounded outlet.

Connect the saw to a source of dry, lubricated air delivering

at least 80psi.

Connect the STEPPERS, SENSORS, and CAPSTAN

cables to their corresponding connectors on the right side of

the saw. The black cable connects to the lower receptacle

with the rotating ring. The two gray cables connect to the

flange mount receptacles. Each of the three connectors is of

a different pin configuration to ensure a correct connection.

There is an auxiliary (AUX) output connector on the back of the controller that can be used to

signal or power a sprayer, slurry pump, or relay. The output signal is 120VAC at 1.5 Amps. The

output is active whenever the wire drive is in operation. The connector, AMP 206429-1, is

available from several electronic suppliers.

Drain Connection

The base of the saw is designed to contain cutting lubricant if your

application calls for it. Two 3/8” push-to-connect fittings, located

on the rear of the saw should be plumbed with a drain hose to

carry away excess fluids. An overflow slot is cut near and above

the drain. Do not block this overflow. If liquid is allowed to rise

above the overflow, it could flow into the table bearings or the

table drives motor and cause permanent damage to the machine.

Spray System (Optional)

Place the coolant pump pallet as close to

the saw as possible, preferably directly

underneath the saw. Follow the diagram

for making the proper connections for

water and air to the saw.

Item 1 - 3/8” tubes to connect to the lower

rear of saw. These are the coolant drain

lines.

Item 2 – 1/4” tubing to connect to the ¼”

Tee located on the rear of the Rocker

plate.

3

Item 3 - 1/4” line from factory air supply.

Item 4 – 3/8” tubing for coolant return to pump suction side

Item 5 - 1/4” tubing connecting supply air to pump.

Once the coolant pump pallet has been connected to the saw ensure that the WIRE/RUN switch is

toggled to the WIRE position. Turn the facilities air on and check to ensure that the regulator in

the saw is set to 60 psi and that the oilier is filled with light machine oil.

Attach the coolant container to the saw with 3/8” plastic tubing (provided). Fill the container with a

mixture of surfactant and plain water. The container has a capacity of 5 US gallons (18 liters).

Wire Inspection

Inspect the wire to ensure that the saw is properly strung.

Note that the end of the wire attached to the rear of the capstan nearest the drive motor extends

to the right over the right tension pulley. The end of the wire attached to the front of the capstan

farthest from the drive motor extends to the left over the left tension pulley.

Note the relative spacing of the wire on the capstan. Every wire on the capstan should rest in its

own groove. There should be no wire loops crossed over one another on the capstan.

Observe the wire on the capstan. There should be no more than one or two empty grooves on

the capstan below the wires entering and exiting the capstan.

The wire should be seated in the groove of each of the four pulleys. Note that the entire strung

wire extending from the capstan and over each pulley is in one plane. Misalignment causes

premature wear of pulleys or the capstan, or it causes premature breakage of the wire.

If the wiring conforms to the above four notes, you may wish to run the saw manually to see how

the wire travels.

If the wiring does not conform to the above four notes, the wire should be removed and the saw

restrung before startup is considered.

NOTE

A spool of plain wire is included with your saw to allow you to practice

stringing the saw with less expensive wire. It is highly recommended that

you practice wiring the saw several times with plain wire before you use

diamond wire, to avoid making a costly error.

Guide Pulley Spacing

In most cases, a more accurate cut is achieved by minimizing the spacing between the guide

4

pulleys. Begin with the saw in an un-wired condition. Loosen the four 5/32” cap screws on each

pulley arm and move equally so that they both remain equidistant from the center. Tighten all eight

screws snug but not excessively. Observe carefully, and jog the yoke if necessary to ensure that the

pulleys and the bow sensor will clear the specimen and fixture during a complete cut program.

Verify that if the table indexes in the course of a cut program, the specimen and fixture remain

clear of the pulleys and bow sensor.

If it is necessary to adjust the pulley spacing with the saw already strung with cutting wire, the

procedure is more difficult but still possible.

1. Run the wire drive to one end of its travel and then stop.

2. Rotate the capstan by hand the last few remaining turns until the wire exits directly from its

retaining hole.

3. Affix a piece of masking tape over the wire on the capstan to prevent it from coming loose in

the next step.

4. Reduce the wire tension pressure regulator to about 10psi and switch the Tensioner

RUN/WIRE switch to WIRE. The tension pulleys move inward and the wire-cutting loop

becomes slack.

5. Move the guide pulleys to their desired position as described in the fist paragraph of this

section. If you are moving the guide pulleys outward a significant distance and there is not

enough slack in the cutting wire, remove the end of the wire from the capstan, pull about 6” of

wire from the capstan, and reinsert the wire end back into the next retaining hole and secure it.

6. Making sure that the wire is strung over all four pulleys, loosen the wire end in its capstan-

retaining hole, pull through any excess slack, and retighten.

7. Turn down the air regulator to 2 or 3psi and switch the Tensioner RUN/WIRE switch to RUN.

8. Rotate the capstan clockwise so that the wire continues to travel over the top of the capstan.

Look closely to see that the wire comes from the retaining hole exactly parallel to the groove.

9. Continue to rotate the capstan by hand one or two revolutions. Observe that the wire is tightly

seated in the capstan spiral; there are no crossovers, nor does the wire skip a groove. There

should be no more than two grooves of capstan showing between the windings.

10. Turn up the air regulator to between 15 and 30psi.

Mounting the Part Specimen

To avoid cutting into the dicing table, the saw is constructed to limit the downward travel of the

yoke so that the wire does not quite reach the table surface. In order to cut completely through the

specimen, you should first mount a 1 ½ inch sacrificial substrate to the table surface, and then

mount the specimen to this substrate. The substrate can be made from any suitable material that is

softer than the specimen. Typical materials are smooth particleboard or PVC. Affix the substrate to

the table using double-sided tape, wax, or glue.

5

Securely attach the part specimen to the table substrate using whatever method is appropriate for

the material.

Operator Interface

This section describes the controller’s user interface, including each of the input switches and the

LCD display.

POWER rocker switch – Provides AC power to the

controller and the saw.

AUTO/MANUAL switch – Manual mode allows

manual jogging of the saws functions and is used to

perform the bow sensor calibration. Use Automatic

mode to program, store, and initiate an automatic cut

program.

RESET pushbutton with built in indicator light –

In Manual mode, this toggles operation of the wire

drive. In Automatic mode, this begins an automatic

cut program once you have been prompted through the necessary setup screens.

Controller Box

WIRE SPEED control – Controls the speed of the cutting wire. Typically, you will turn the wire

Speed control to near 20% to before motion begins. This is the minimal motor drive current

necessary to overcome initial stiction.

LCD display – the 20 character by 2 line alphanumeric display provides a means of prompting the

operator for necessary programming and operational information, as well as status information

during automatic operation.

Keypad – The function of the four arrow keys will vary slightly depending on the action that is

being prompted for on the display. Exceptions will be noted in each of the screen descriptions, but

in general, they behave as follows:

Left Arrow – Go back to the previous screen.

Down Arrow – Jog an axis, scroll down through the

available choices, or decrease a numeric value.

Up Arrow - Jog an axis, scroll up through the available

choices, or increase a numeric value.

6

Right Arrow – Accept the choice or value currently displayed and proceed to the next screen.

The up and down arrow keys have three modes of operation: single step, slow repeat, and fast

repeat. This behavior is in effect for jogging motion and data entry, allowing both precise and

efficient control/input. A quick tap (less than 1/2 second) on either key results in a single step or

value change. Hold the key for more than 1/2 second and the value begins to change continuously

at a slow rate of speed. Release the key very briefly and resume pressing it and the action

accelerates and continues at a higher rate. Release the key very

briefly; resume pressing it and the action reverts to the slower

rate. Release the key altogether and the action ceases.

Capstan RUN/WIRE Switch – Located on the back panel, this

switch should be in the RUN position for normal operation. Set

this switch to WIRE only when wiring the saw.

Control Box Rear

Tensioner RUN/WIRE Switch – Located adjacent to the air controls,

this switch should be in the RUN position for normal operation. Set this

switch to WIRE for wiring the saw or for adjusting the tensioner pulleys.

Power On

Apply power to the saw by flipping the Power switch upwards. A red section of the rocker appears.

When power is first applied, the LCD screen displays a welcome message, including the program

version number. Press any of the four arrow keys on the keypad beneath the display to proceed.

The screen that follows depends on whether the controller mode switch is set to MANUAL or

AUTOMATIC.

Manual Mode

The saw allows both manual and programmed control of the yoke, table, and wire drive. Manual

control (jogging) of the yoke and table is useful during setup and initial positioning of the wire

prior to beginning an automatic cut program. Running the wire drive in Manual mode is useful to

ensure the drive is running properly before automatic mode is begun, determining the optimum

cutting speed of the wire, and to wire the saw.

7

Startup Screen – Manual Mode

Manual operation of the wire drive:

Turn the wire Speed control on the front of the control box to the "0" setting. If the wire Speed

control is set at a setting other than "0", operation of the wire drive will commence immediately

once the RESET Button is pressed.

Ensure that the Capstan RUN/WIRE switch on the rear of the control box is in the RUN

position.

Press the RESET button on the control box. The button will light. The purpose of the RESET

button is to alert the operator one more time that wire drive operation is to commence. Take a

moment to check that the wire Speed control is set to zero or at a setting you desire, and that the

position of the cutting wire relative to the part to be cut is in a satisfactory position.

Once the RESET lamp is lit, slowly turn the wire Speed control up to a setting you desire.

Make note of the value indicated on the wire Speed control. You will want to set the wire

Speed control to this value prior to starting a cut program in Automatic mode.

To turn off the wire drive, press the RESET button, or turn the wire Speed control to "0". If you

have pressed the RESET button, the green button illumination will extinguish.

Jogging the Actuators

After mounting a part onto the table, it will most

likely be necessary to move the table in either

direction and to jog the yoke down so that the wire is

positioned just above the material in preparation for

the first cut. The main jog menu appears as follows.

Use the up and down arrows to select either “yoke” or “table” and then press the right arrow key.

Jog the yoke up or down:

The display indicates the current action and the absolute position of the yoke since power was

turned on. Each step of the stepper motor results in a movement of 0.00025 inches (or 0.00635 mm,

if configured for metric display).

8

Press the up arrow to move the yoke upward, and press the down arrow to move the yoke

downward. Note the position value moves in the opposite direction. This is because downward

yoke movement is considered positive since this is the direction of cut.

A quick tap on either the up or down arrow key results in a single step. Press and hold one of these

keys and the yoke moves continuously at a slow rate of speed. Release the key very briefly and

resume pressing it and the yoke accelerates and continues to move at a higher velocity as long as

the key is held down. Release the key and the yoke quickly decelerates to a stop.

Press the left arrow to select another axis to jog, or the right arrow to move to the Jog Table menu.

The display indicates the current action and the absolute position of the table since power was

turned on. Each step of the stepper motor results in a movement of 0.00025 inches (or 0.00635 mm,

if configured for metric display).

Press the up arrow to move the table forward in the positive direction, towards the stepper motor.

Press the down arrow to move the table backward in the negative direction, away from the stepper

motor.

A quick tap on either the up or down arrow key results in a single step. Press and hold one of these

keys and the table moves continuously at a slow rate of speed. Release the key very briefly and

resume pressing it and the table accelerates and continues to move at a higher velocity as long as

the key is held down. Release the key and the table quickly decelerates to a stop.

Press the left arrow to select another axis to jog, or the right arrow to move to the Jog Yoke menu.

Jog the table rotation (Dicing Option only):

The display indicates the current action and the absolute position of the table rotation since power

on. Each step of the stepper motor results in a movement of 0.02 degrees.

9

Press the up arrow to rotate the table in the positive direction, CCW. Press the down arrow to rotate

the table in the negative direction, CW. Note that while the table rotates CCW, the cutting wire

“rotates” CW relative to the table surface. Therefore, when programming an automatic cut

sequence, think of the cutting wire moving relative to the specimen.

A quick tap on either the up or down arrow key results in a single step. Press and hold one of these

keys and the table rotates continuously at a slow rate of speed. Release the key very briefly and

resume pressing it and the table accelerates and continues to rotate at a higher velocity as long as

the key is held down. Release the key and the table quickly decelerates to a stop.

Jog the rocker clockwise or counter-clockwise (Models CT400 and CT800 only):

The display shows which key is allocated to which action. It does not indicate the actual rock

position. Here, the user needs to observe the position of the rocker and adjust the keys to position

the rocker in its start position.

Press the up arrow to move the rocker in a clockwise (CW) direction. Press the down arrow to

move the rocker in a counter-clockwise (CCW) direction.

A quick tap on either the up or down arrow key results in a single step. Press and hold one of these

keys and the rocker moves continuously at a slow rate of speed. The jog rocker action has only one

speed.

Position recommendation:

As noted above the absolute position on all axes is set to zero at power on. Since zero, or home, is

arbitrary and varies with each new part mounted for cutting, we recommend that you jog the wire

into position prior to making the first cut, then turn power off briefly. When power to the controller

is restored, the position values are now set to zero. This allows you to make all further movements

relative to this known position.

Should power to the controller be lost during a cut program, once again the position values will be

set to zero when power is restored. You can jog the saw back to the physical “home”, make note of

the position values, turn power off momentarily, then manually jog the saw to position values that

are compliments of the values recorded in the previous step. Now, the absolute position values are

restored to their “correct” values as they were prior to the power failure.

The stepper motors controlling the linear translation stages have a back shaft equipped with a

10

knurled knob. You can rotate the lead screws manually if you wish, but be aware that such a

change in position is not reflected on the display.

Common Setup Actions

Two additional operations are accessed from the Select Action menu. Use the up and down arrows

to select either and then press the right arrow key.

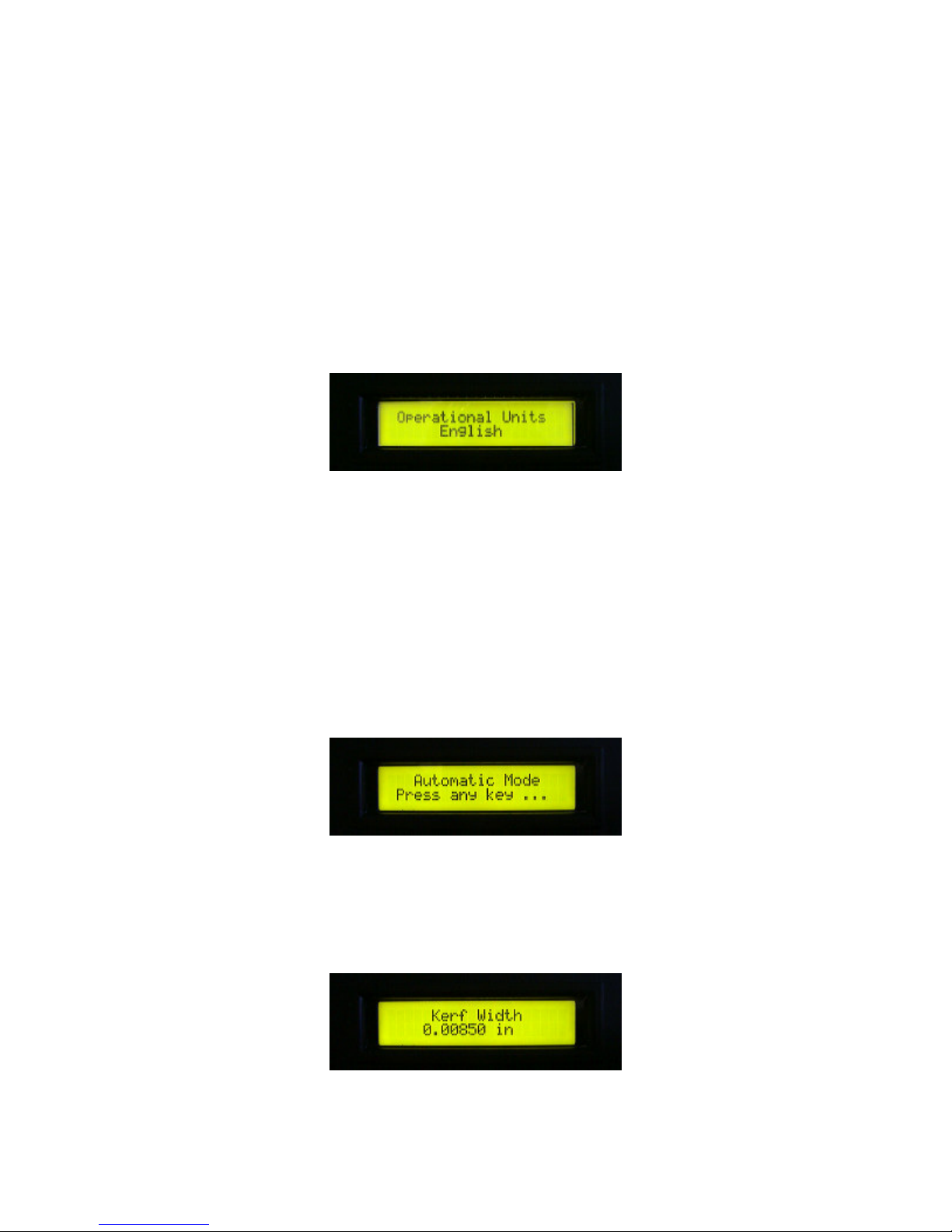

Set Operational Units:

The display indicates the currently configured display units.

Press the up arrow or down arrow to toggle your choice between English or metric. This parameter

affects display units only. Actual program parameters are stored internally in machine units.

Therefore, you can change the display units at any time and the stored program functions as

intended in either case.

Calibrate Bow Sensor

This function is explained under Bow Sensor Calibration in the Adjustment and Maintenance

section.

Automatic Mode

Automatic mode steps the operator through a series of menus that define the parameters of a cut

program. After all parameters have been defined, the operator initiates the cut program and

automatic cutting operation begins.

1. Use the up and down arrow keys to specify the kerf between each cut. This is typically set to the

11

diameter of the cutting wire, and the value is added to the slice thickness each time the table is

indexed into position for the next cut. Note that this addition is calculated and indexed

automatically. As a result, you specify the finished thickness of each cut and the kerf loss is

accounted for with this parameter.

2. Use the up and down arrow keys to indicate the number of cuts you wish to make.

3. Use the up and down arrow keys to specify yes or no, indicating whether each slice will be a

different width or if all slices in this program are to be the same thickness.

4. Use the up and down arrow keys to specify the slice thickness. If variable slice thickness was

selected in the previous step, then you are prompted to enter a thickness for each slice in turn.

The following steps 5 & 6 are for Dicing Saws only

5. Use the up and down arrow keys to specify an angle of rotation prior to the next cut sequence. If

you enter a non-zero value, the process continues with the next step. If you are performing only one

series of cuts, or if you are done programming all the rotational cut sequences desired, enter a value

of zero to indicate you are finished, and the process continues with Step 7.

6. Use the up and down arrow keys to specify an amount the table should linearly retract prior to

12

the next cut sequence. By default, this value is calculated to return the table to the same position it

was at the start of the previous cut sequence. This assumes you will be making symmetrical cuts for

each rotational cut sequence. You may enter a different value if your application requires it.

Programming Tip:

Even though the saw utilizes anti-backlash nuts, there is still the possibility of some backlash

in the table index stage. Machine tool operators eliminate the effect of backlash by over-

traveling in the negative direction and approaching all cuts from the same direction.

If you are programming more than one cut sequence and using this step to index the table

backwards between them, any backlash that does exist will cause the first cut of the second and

subsequent cut sequence to be inaccurate. One simple solution is to stop the program after

making cuts in a single axis, and reposition the specimen for the next axis manually. However,

there is a way to eliminate backlash within a multiple sequence program.

Enter an Index Table value greater than what is necessary to move the table back beyond the

specimen (and fixture). Enter a Number Of Cuts value one greater than what you actually

intend to cut. If you must over-index the table back more than one slice width, set the Variable

Width feature to yes and enter the over-index distance for Slice 1 Width. Enter the actual

desired slice width for the remaining cuts.

The first cut occurs out in the open and completes rather quickly since with no wire bow, the yoke

drive moves down at maximum speed. After the programmed dwell time, the yoke raises and the

table indexes forward, eliminating backlash, and the saw proceeds to make the first real cut in the

proper position.

7. Use the up and down arrow keys to specify the total downward motion of the yoke. You must

take into account the distance above the part that is the starting position of the wire, the thickness

of the part itself, and the amount of desired bow. We recommend you test this depth in jog mode to

ensure you are not cutting too deeply into the mounting platform, and that you do not encounter the

lower limit of yoke travel.

13

The following steps 8 & 9 are for Model CT400 and CT800 saws only

8. Use the up and down arrow keys to specify the rock angle. Select 0 if you do not wish to have

any rock action.

9. Use the up and down arrow keys to specify rock speed. You have three choices: slow, medium

and fast.

10. Use the up and down arrow keys to select between Bow Calculated or User Specified for the

Yoke Velocity Method:

Bow calculated You specify a target bow angle and the controller automatically adjusts

yoke velocity to maintain the desired wire bow. Proceed with Step 11.

User specified You specify fixed velocity values to control the downward motion of the

yoke. Skip to Step 12.

14

11. Use the up and down arrow keys to specify the desired wire bow. Allowed values range from

0.1 to 5.0 degrees. This is the angle made by the cutting wire, the right guide pulley, and the

horizontal. The angle is directly proportional to cutting force. The optimum angle varies depending

on the material to be cut and is usually determined through experience. After selection, press the

right arrow key to continue at Step 17.

12. Use the up and down arrow keys to specify an initial downward velocity of the yoke while

cutting.

13. Use the up and down arrow keys to specify a percentage of the total cut depth for which the

indicated velocity is in effect. The control program allows you to specify from one to three

different yoke velocities for a single cut. Through experimentation and experience, you can find a

velocity profile that results in the best possible cut in terms of quality and time.

One possible scenario would be to start relatively fast just to bring the wire down in contact with

the part, go very slowly for a few percent allowing the wire to etch a straight cut across the part

with very little bow, then speed up slightly to a constant cutting speed for the remainder of the cut

depth.

If the percentage specified is 100%, then the entire cut is performed at a constant velocity and

prompting skips to Step 17.

15

14. Use the up and down arrow keys to specify a new downward velocity of the yoke while cutting.

15. Use the up and down arrow keys to specify a percentage of the total cut depth at which the

indicated velocity is in effect. If the starting percentage plus the percentage specified here equals

100%, then the cut is performed with the two specified velocities and prompting skips to Step 17.

16. Use the up and down arrow keys to specify the downward velocity of the yoke for the

remainder of the cut.

17. Use the up and down arrow keys to specify the amount of time that the wire dwells at the

bottom of the cut before the cut is considered complete. Typically, the yoke moves ahead of the cut

to maintain a slight bow in the wire, which applies more downward force on the cutting surface

resulting in a faster cut. Dwell allows the wire to complete cutting at the center of the part even

though the edges may have already been cut through.

18. Use the up and down arrow keys to specify yes or no, indicating whether you want the wire

drive to remain on or be turned off while the yoke is retracting before indexing to the next cut

position. Your choice will depend on the material being cut. If the wire has a tendency to stick in

the part, then leaving the wire running will allow it to slip out more easily. Conversely, turning the

wire off when retracting might prevent small unwanted cut marks caused by a moving and

retracting wire.

16

19. This question is asked if any program parameters have changed. Answer “yes” if you want the

operating parameters just specified to be stored in non-volatile EEPROM memory so that they are

“remembered” even if power is turned off. Answer “no” if you want to perform a cut program

using the parameters you just specified without overwriting those stored in EEPROM.

20. In normal operation you will not see this screen and will go directly to Step 21. If however, you

interrupted a cut program in progress, or if there was a wire break during an automatic cut program,

you are asked if you want to resume the interrupted cut program or begin anew. If you jog the yoke

up or down before resuming an interrupted program, the control software compensates and still

considers your programmed cut depth as the end of cut indicator. This allows you to resume back at

the start of the current cut, exactly where it was interrupted, or anywhere in between.

21. This is a simple reminder to set the wire Speed control to the desired speed prior to beginning.

22. This screen appears if and only if the bow sensor is reading a value greater than zero. If you had

temporarily stopped a cut in progress and are now about to resume, the wire is likely already

embedded in the specimen and already bowed. In this case, the bow is appropriate and you should

skip the warning message by pressing the right arrow key to proceed. However, if the wire is not

currently engaged and is stretched straight between the guide pulleys, this warning indicates that

the bow sensor is in need of calibration. Switch to Manual mode and calibrate the bow sensor. See

Calibrate Bow Sensor in the Adjustment and Maintenance section for instructions.

17

23. As the display indicates, press the RESET button to begin the cut program. The RESET button

illuminates and the wire drive is operational. You can adjust the speed of the wire drive at any time.

The AUX output is active if you have employed it.

While cutting is in progress, the display indicates progress as follows:

Every 15 seconds, the display automatically changes to one of the three following informational

screens:

The first line indicates the current cut, and the total number of cuts that are to be made in the

program. The second line shows the current depth of cut.

This screen indicates the total amount of time elapsed since the program began.

This screen indicates the average linear speed of the cutting wire, calculated each time the capstan

changes direction.

You can manually toggle between each of these three screens at any time by pressing either the up

or down arrow key. When the yoke has reached the programmed cut depth, the display changes to

the dwell countdown timer.

This manual suits for next models

4

Table of contents