DISHWASHER INSTRUCTIONS MANUAL

MDIISY31-(r01) Page 1 of 21

INDEX

CAP 1

FOREWORD ...............................................................................................................2

CAP 2 HANDLING AND TRANSPORTING THE MACHINE ..................................................2

TRANSPORTATION AND PACKAGING ....................................................................................2

HANDLING.........................................................................................................................22.2

STORAGE .........................................................................................................................32.3

DIMENSIONS .....................................................................................................................32.4

CAP 3 INSTALLATION ..........................................................................................................3

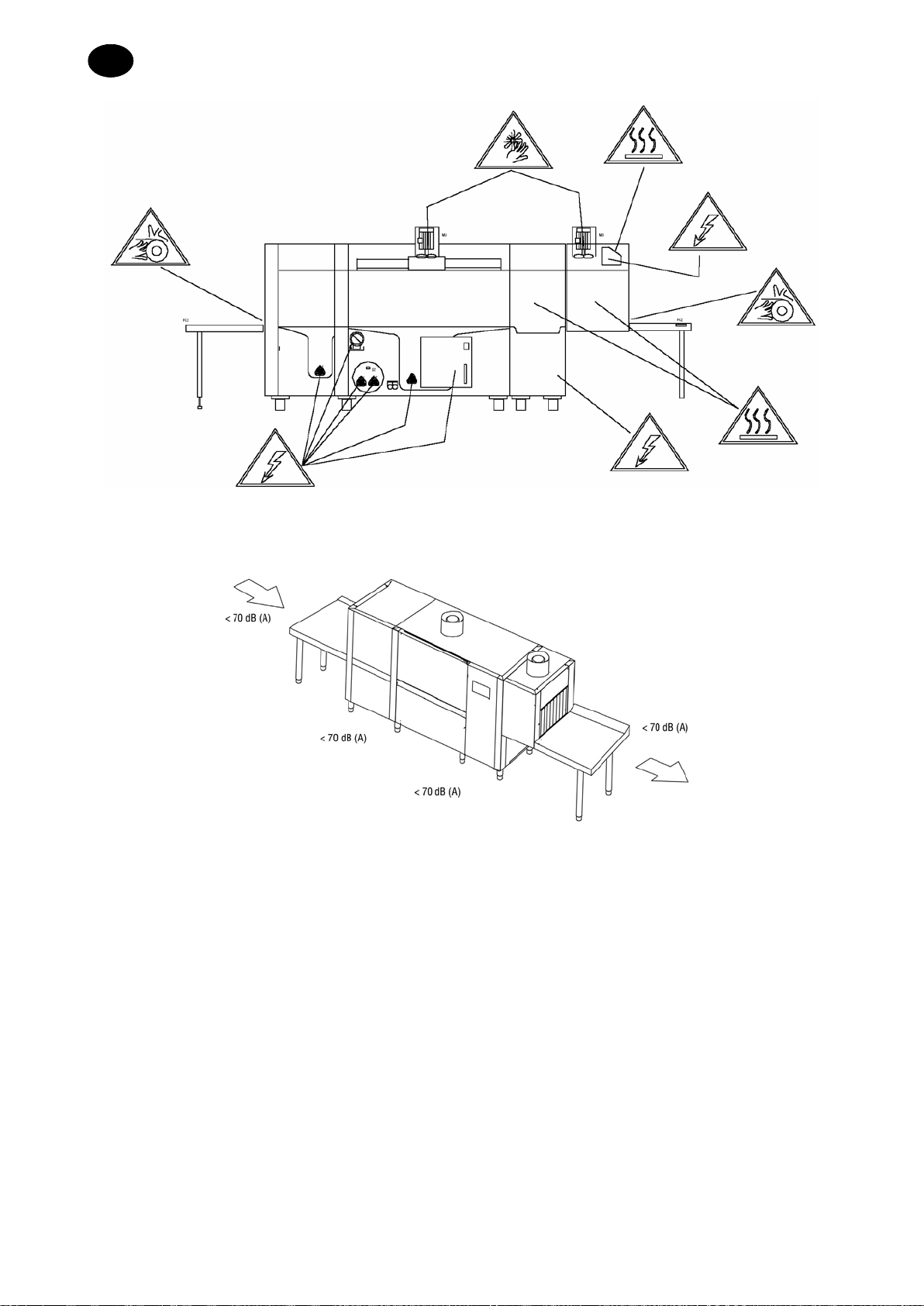

DANGER ZONES ................................................................................................................33.1

ACOUSTIC PRESSURE LEVEL ..............................................................................................43.2

UNPACKAGING AND POSITIONING........................................................................................53.3

ENVIRONMENTAL CONDITIONS............................................................................................53.4

CAP 4 INSTALLATION ..........................................................................................................5

ELECTRICAL CONNECTIONS................................................................................................54.1

HYDRAULIC CONNECTION...................................................................................................64.2

CONNECTION TO THE WATER DISCHARGE GRID....................................................................74.3

CONNECTING THE LIMIT SWITCH .........................................................................................74.4

INSTALLATION OF DISPENSERS...........................................................................................84.5

COMMISSIONING...........................................................................................................84.6 4.6.1 First boiler charging.....................................................................................................8

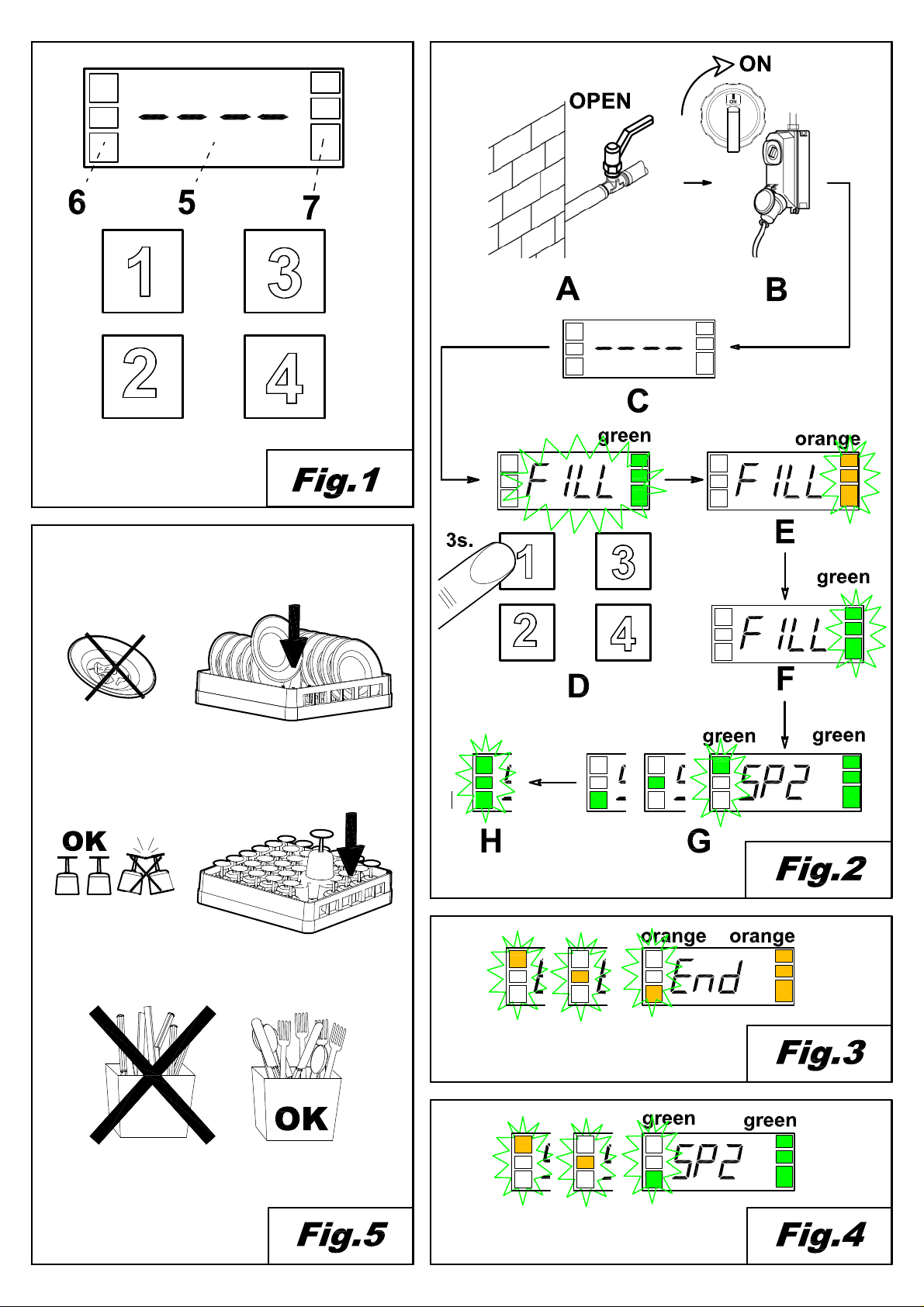

CONTROLS .......................................................................................................................84.7

RECOMMENDATIONS ON THE SAFETY REGULATIONS TO BE ADOPTED ..................................104.8

CAP 5 MACHINE DESCRIPTION.........................................................................................11

MACHINE DIAGRAM..........................................................................................................115.1

DANGEROUS POINTS .......................................................................................................125.2

SAFETY DEVICES.............................................................................................................125.3

USE ACCORDING TO THE REGULATIONS ............................................................................125.4

CAP 6 MACHINE USE .........................................................................................................13

COMMAND DESCRIPTION..................................................................................................136.1

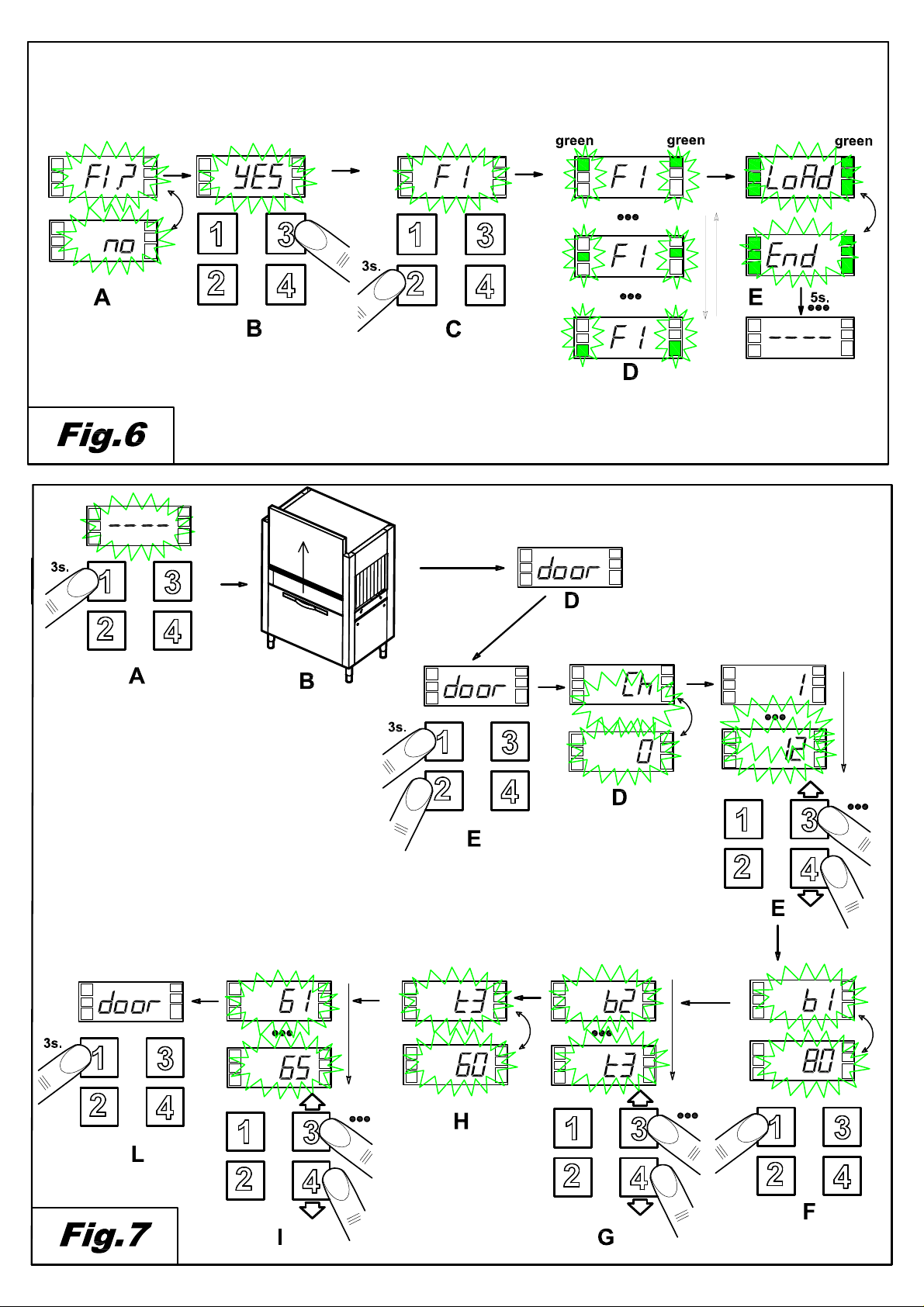

MACHINE START..............................................................................................................136.2

HEATING.........................................................................................................................136.3

WASHING........................................................................................................................136.4

WASHING PROGRAMME....................................................................................................136.5

STOP DEVICE ..................................................................................................................136.6

TEMPERATURE AND WORKING HOURS DISPLAY..................................................................146.7

LIMIT SWITCH DEVICE.......................................................................................................146.8

REGULATIONS.................................................................................................................146.9 6.9.1 temperatures .............................................................................................................14

6.9.2 dispensers.................................................................................................................15

USER MESSAGES.............................................................................................................166.10

FUNCTION AND STATUS BARS...........................................................................................166.11

SELF-DIAGNOSIS .............................................................................................................166.12

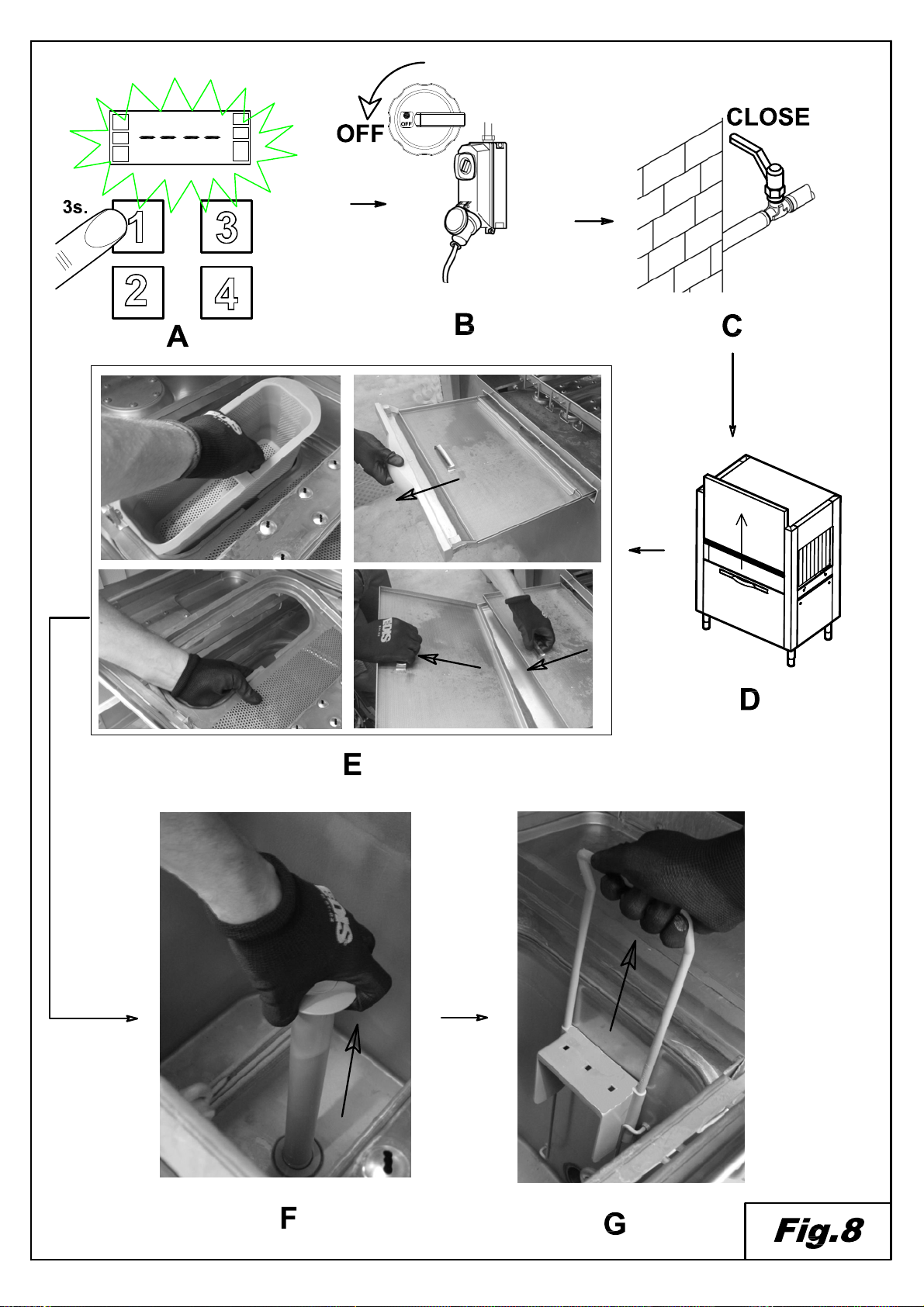

END OF WASHING OPERATIONS ........................................................................................186.13

POSITIONING THE DISHES.................................................................................................186.14

CAP 7 MAINTENANCE........................................................................................................19

GENERAL RULES .............................................................................................................197.1

PERIODICAL MAINTENANCE..............................................................................................207.2

CAP 8 DISPOSAL................................................................................................................21

CAP 9 ENVIRONMENT........................................................................................................21