Diamond DCS9 User manual

Other Diamond Dishwasher manuals

Diamond

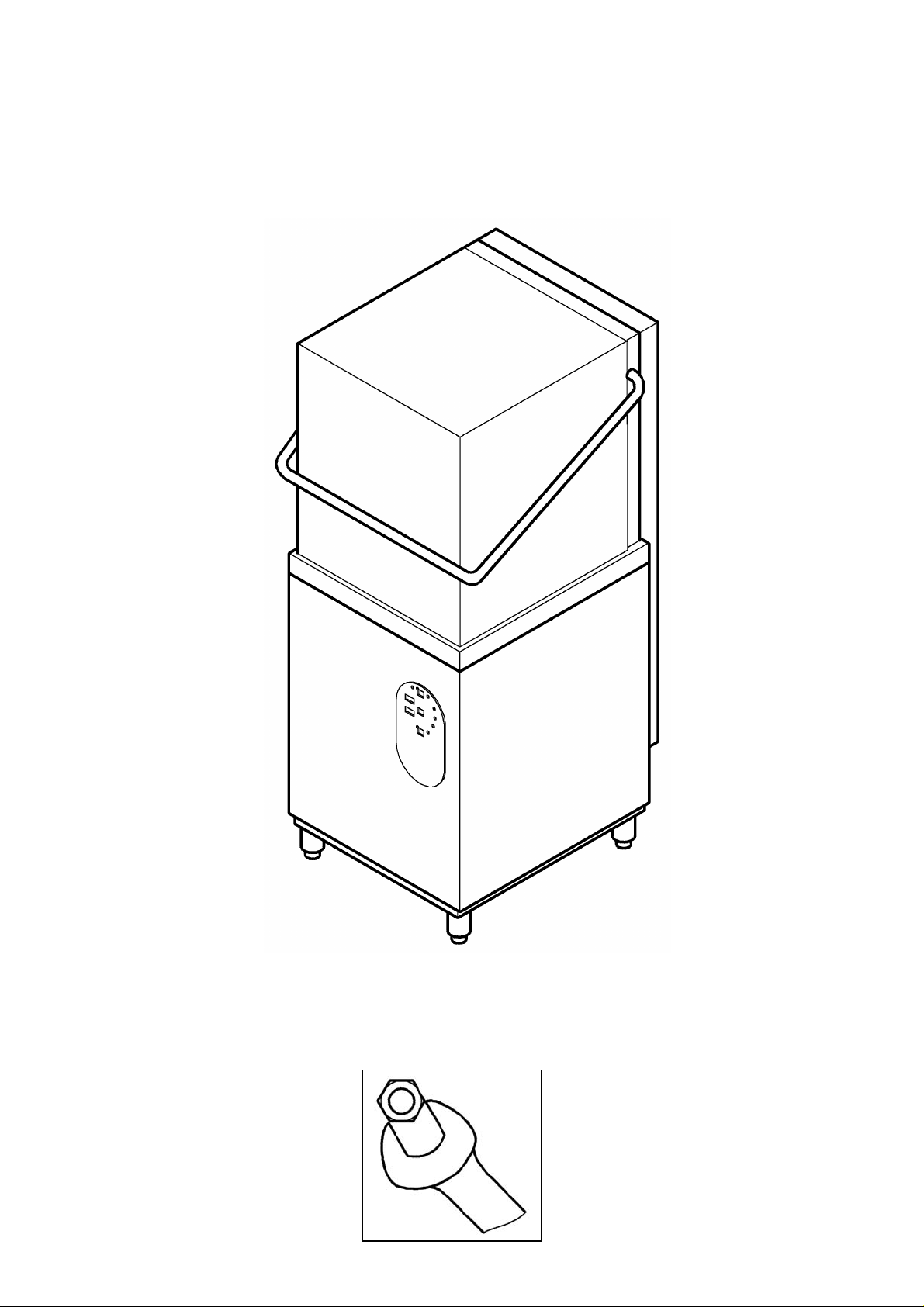

Diamond DC502/6M-PS User manual

Diamond

Diamond 046D/6 User manual

Diamond

Diamond 051D/6M-PS User manual

Diamond

Diamond T101BE23DN User manual

Diamond

Diamond D117E/7 User manual

Diamond

Diamond DC402/6-PS User manual

Diamond

Diamond DK7/2-NP User manual

Diamond

Diamond DC402/6 Assembly instructions

Diamond

Diamond DC202/6R User manual

Diamond

Diamond Diverso WR-LB40-MPSC User manual