5

ŸA manufactured home (USA only) or mobile home OEM installation

must confirm with the Manufactured Home Construction and Safety

Standard, Title 24 CFR, Part 3280,or, when such standard is not

applicable, the Standards for Manufactured Home Installations, ANSI

A225.1/NFPA 501A, or Standard for Gas Equipped Recreational

Vehicles and Mobile Housing, CSA Z240.4

ŸToddlers, young children, and others may be susceptible to accidental

contact burns. A physical barrier is recommended if there are at risk

individuals in the house. To restrict access to a fireplace or stove,

install an adjustable safety gate to keep toddlers, young children and

other at risk individuals out of the room and away from hot surfaces

ŸClothing or other flammable material should not be placed on or near

the appliance

ŸAny safety screen, guard or barrier removed for servicing the

appliance must be replaced prior to usage

ŸLabel all wires prior to disconnecting when servicing controls. Wiring

errors can cause improper and dangerous operation after service.

Verify proper operation after service prior to firing.

ŸInstallation and repair should be done by a qualified service person.

The appliance should be inspected before use and at least annually

by a professional service person. More frequent cleaning might be

required due to excessive lint from carpeting, bedding material etc. It

is imperative that control compartments, burners and circulating air

passageways of the appliance be kept clean.

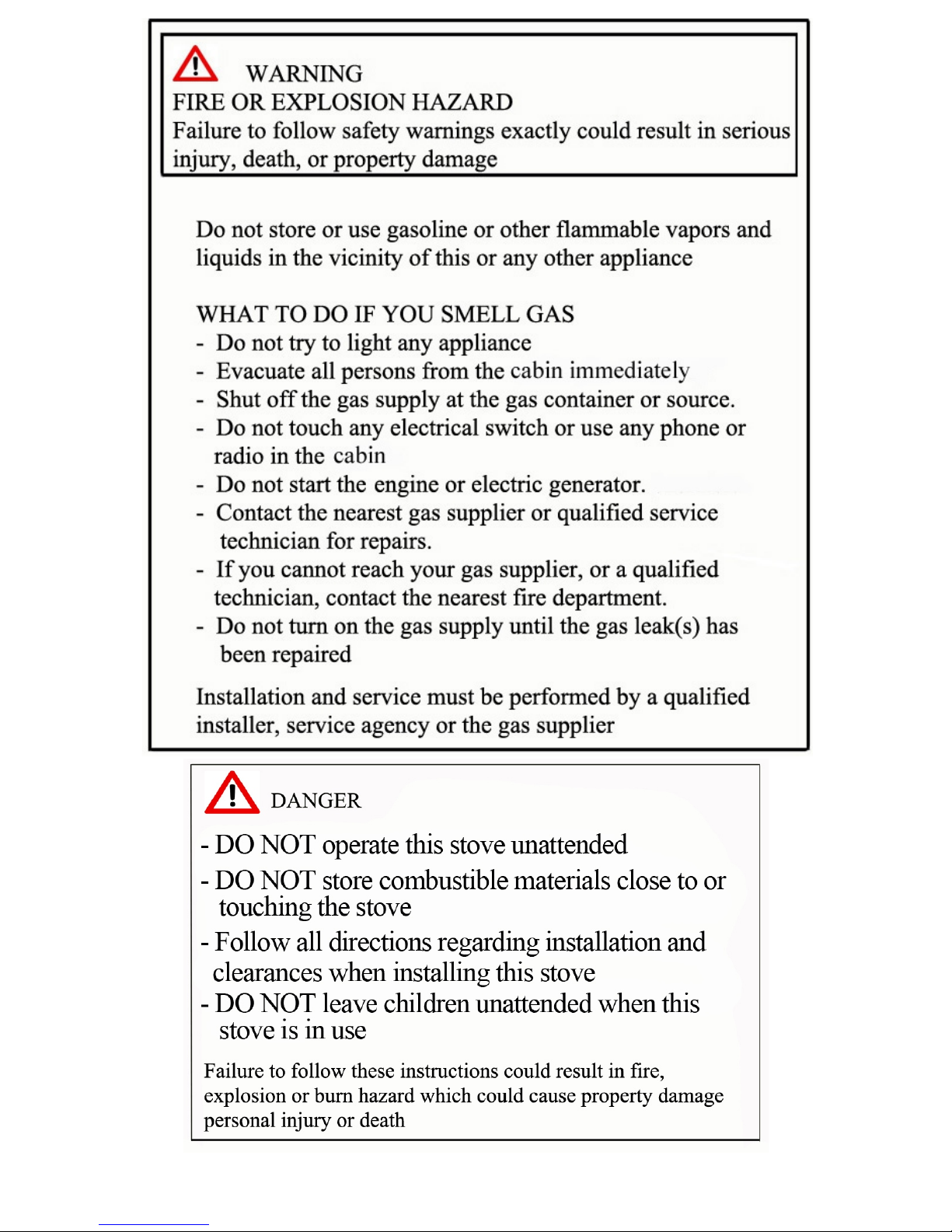

*** FAILURE TO ADHERE TO THE SAFETY WARNINGS LISTED IN

THIS MANUAL COULD RESULT IN DAMAGE TO PROPERTY OR

SEVERE PERSONAL INJURY***