1970 DODGE SUPER BEE WIRE SPLICING INSTALLATION

WIRE SPLICING INSTALLATION

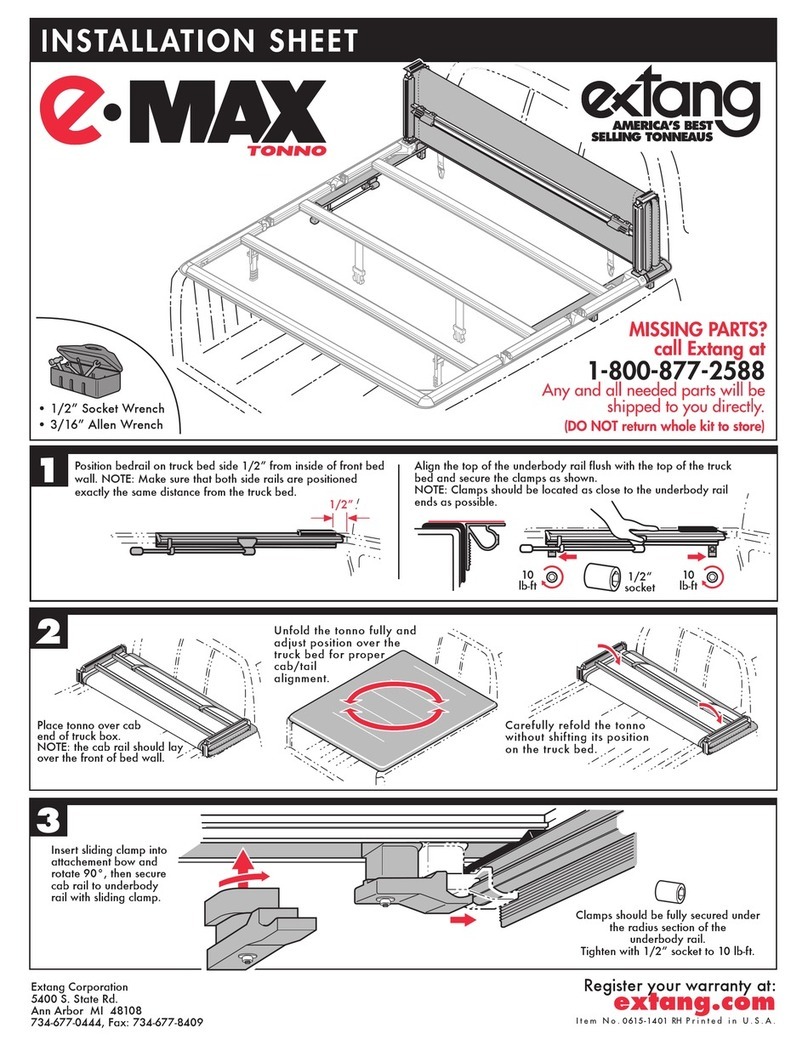

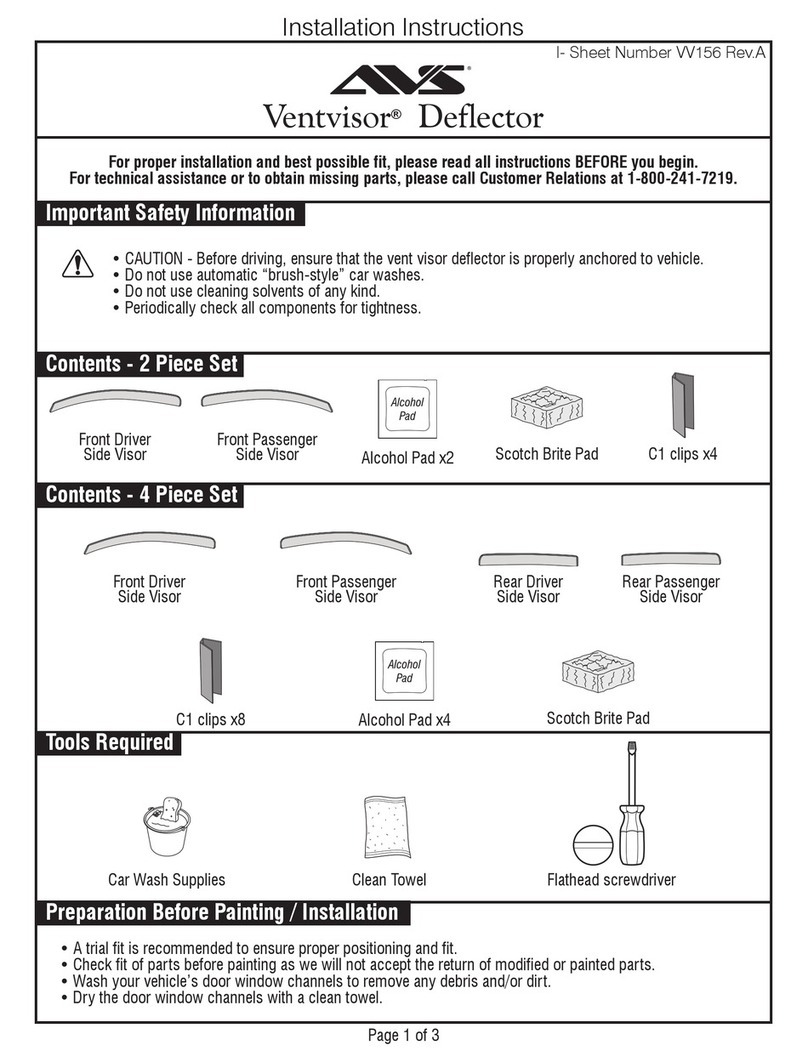

1. Find and access the tail light wires.

tail light housing assembly and remove the cloth tape to expose the taillight wires.

2. Splice the LED panel wires into the original wires.

3. Connect all the ground wires.

Connect all the ground wires together. Bolt them to the trunk latch support along with the original

rear body harness ground. The ground connection must be good in order to the operate the LED

tail lights.

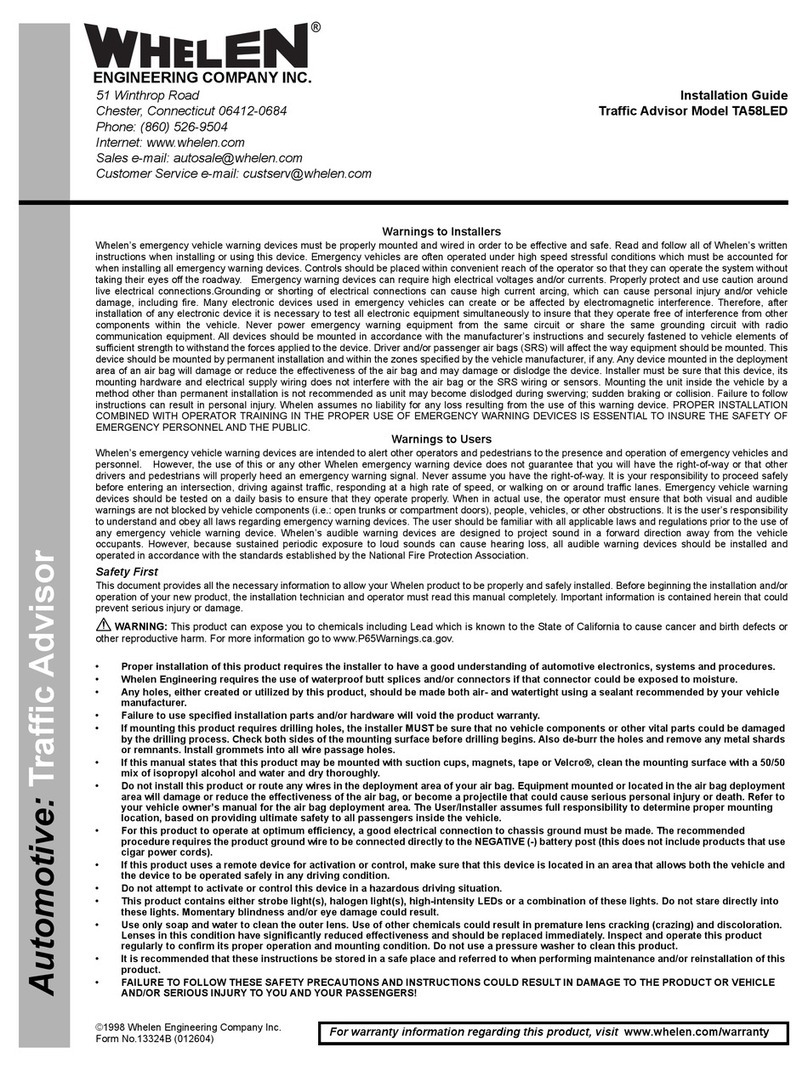

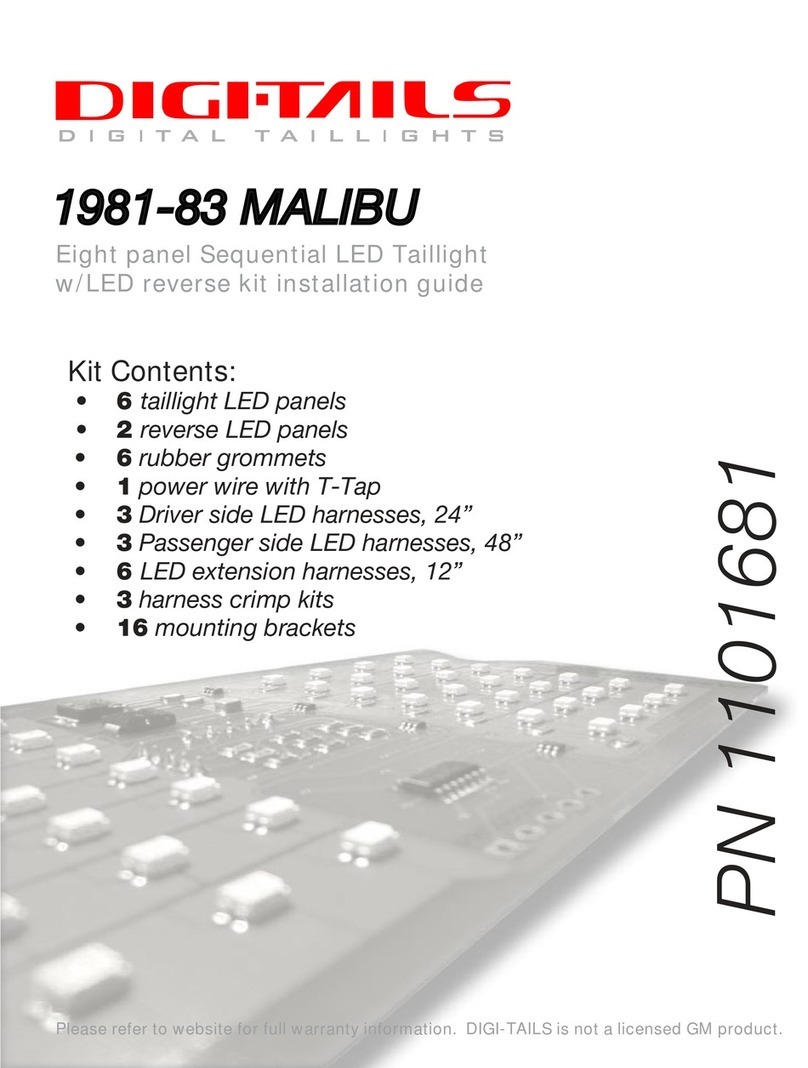

4. Splice the Orange constant power wire into the T-Tap

and the LED panel Orange wire.

An Orange power wire is supplied along with a T-Tap. The

orange power wire must be supplied with a constant 12 volt

battery supply for the LED circuitry to operate properly. The

T-Tap connector is used to splice to the constant power

source, like the dome light wire.

Spice the T-Tap connector into the constant power wire,

then plug the orange wire into the T-Tap. The other end of

the orange wire is spliced into the LED panel Orange wires.

!

Wire splicing installation

Pick a point in the rear body harness between the driver’s side quarter panel and

the driver’s side tail light housing assembly and remove the cloth tape to

Take the LED harness DARK GREEN wires and splice it with the original

Take the LED harness BROWN wires and splice it with the original

The light socket ends on the car harness are no longer needed.

Take the LED harness YELLOW wires and splice them in with the original

light wires. The ends going to the side marker lights must be included in the splice for

the side markers to remain functional.

Take the ground wires and connect them all together. Bolt them to the trunk latch

support along with the original rear body harness ground.

Note: A good ground connection is essential to the operation of the LED tail lights.

An ORANGE power wire is supplied along with a T-Tap. The orange power wire must be

supplied with a constant 12 volt battery supply for the LED circuitry to operate properly.

The T-Tap connector is used to splice to the constant power source, like the dome light wire.

Spice the T-Tap connector into the constant power wire, then plug the orange wire into

the T-Tap. The other end of the orange wire is spliced into the LED harness Orange wires.

The last page is a wire diagram of how the LED harness splices into the car’s original harness.

Insert wire onto T-Tap Crimp with pliers

Wires spliced together. Fold wires over to a side.

To keep the wires neatly tucked and in line, take the spliced sections and fold

them over to one side and tape them in place. This will allow you to place the

wiring into loom or have the ability to wrap the LED harness wiring tightly away.

Wire splicing installation

Pick a point in the rear body harness between the driver’s side quarter panel and

the driver’s side tail light housing assembly and remove the cloth tape to

expose the tail light wires.

Take the LED harness DARK GREEN wires and splice it with the original DARK

Take the LED harness BROWN wires and splice it with the original BROWN

The light socket ends on the car harness are no longer needed.

Take the LED harness YELLOW wires and splice them in with the original

light wires. The ends going to the side marker lights must be included in the splice for

the side markers to remain functional.

Take the ground wires and connect them all together. Bolt them to the trunk latch

support along with the original rear body harness ground.

Note: A good ground connection is essential to the operation of the LED tail lights.

An ORANGE power wire is supplied along with a T-Tap. The orange power wire must be

supplied with a constant 12 volt battery supply for the LED circuitry to operate properly.

The T-Tap connector is used to splice to the constant power source, like the dome light wire.

Spice the T-Tap connector into the constant power wire, then plug the orange wire into

the T-Tap. The other end of the orange wire is spliced into the LED harness Orange wires.

The last page is a wire diagram of how the LED harness splices into the car’s original harness.

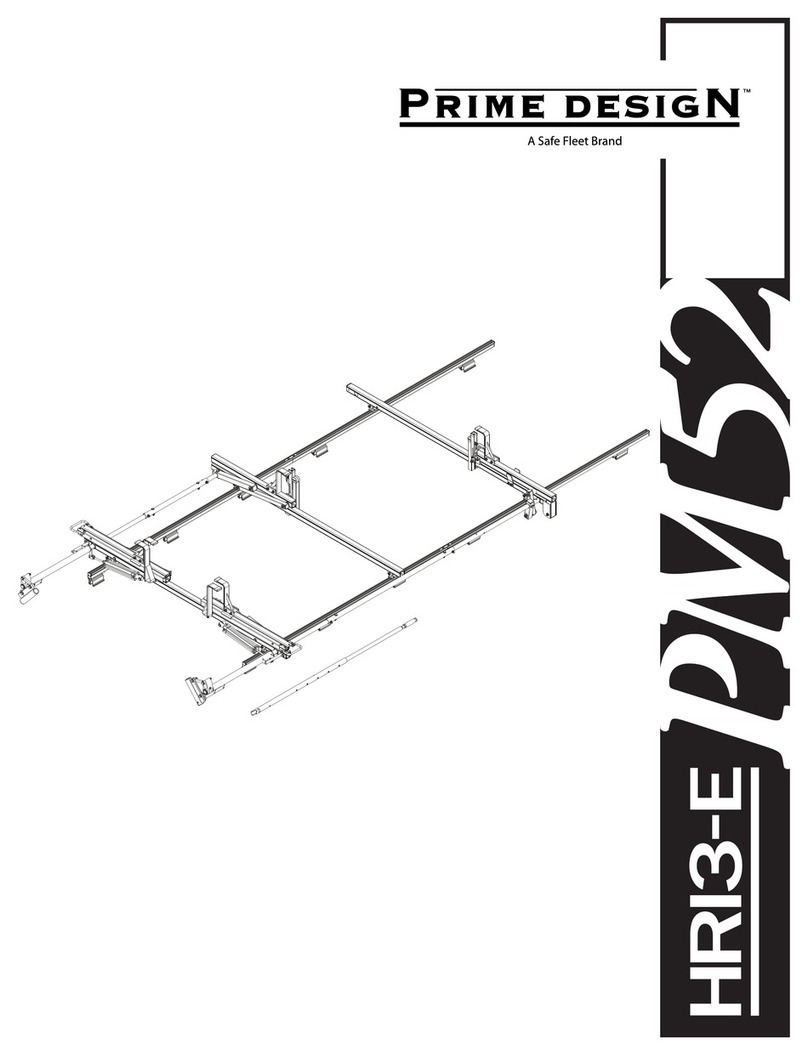

Insert wire onto T-Tap Crimp with pliers Plug connector

To keep the wires neatly tucked and in line, take the spliced sections and fold

them over to one side and tape them in place. This will allow you to place the

wiring into loom or have the ability to wrap the LED harness wiring tightly away.

1. Insert wire

onto T-Tap

2. Crimp with

pliers

3. Plug connector

into T-Tap

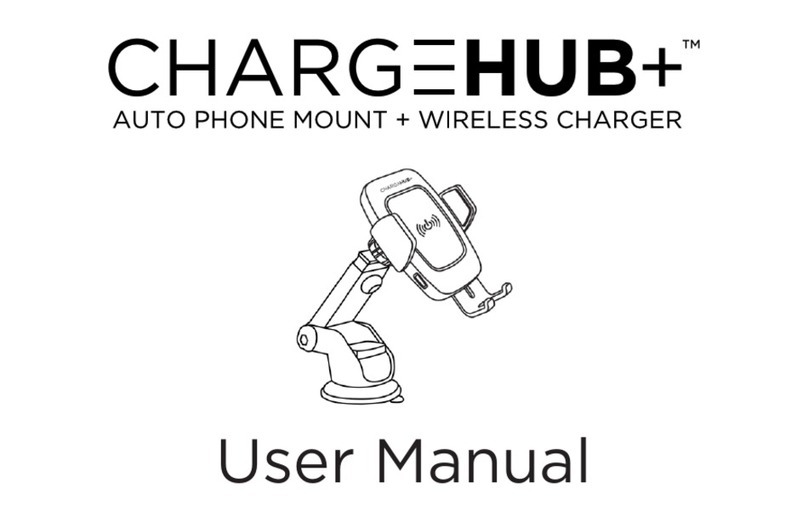

original harness is on the last page.

Note

5

LED Panel

Notes

Dark Green Dark Green

Brown Brown The light socket ends on the car harness

can be discarded.

Yellow Black

The ends going to the side marker lights

must be included in the splice for the

side markers to remain functional.