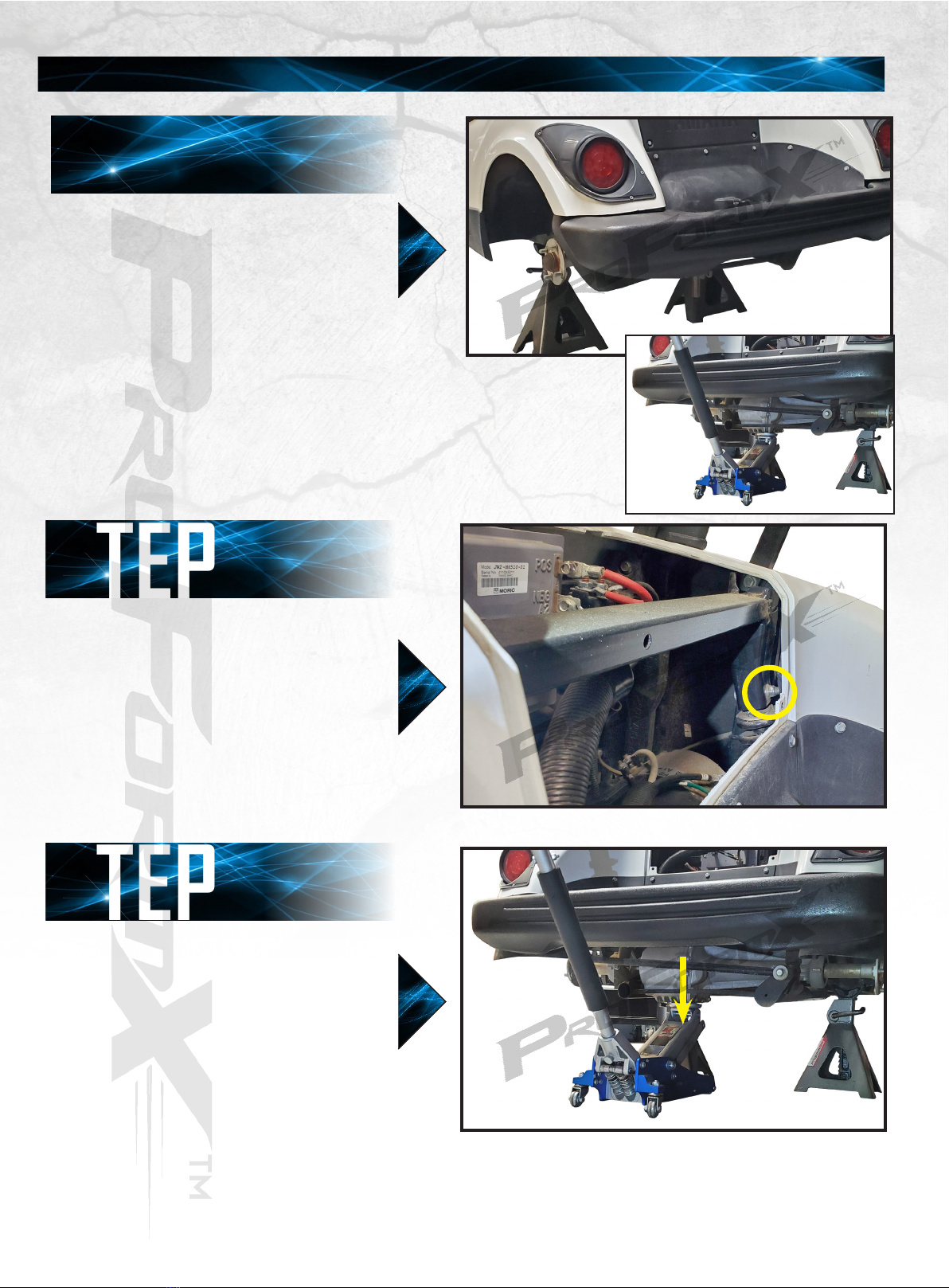

After installing this lift, the front wheels must be properly aligned. Failure to properly align the front

wheels may result in decreased ability to control the golf cart which may result in a rollover or crash.

IMPORTANT: Camber and toe must be adjusted for proper operation.

CAMBER ADJUSTMENT

TOE ADJUSTMENT

To adjust for proper camber, use a framing square

or level to verify the tire is resting at a 90° angle

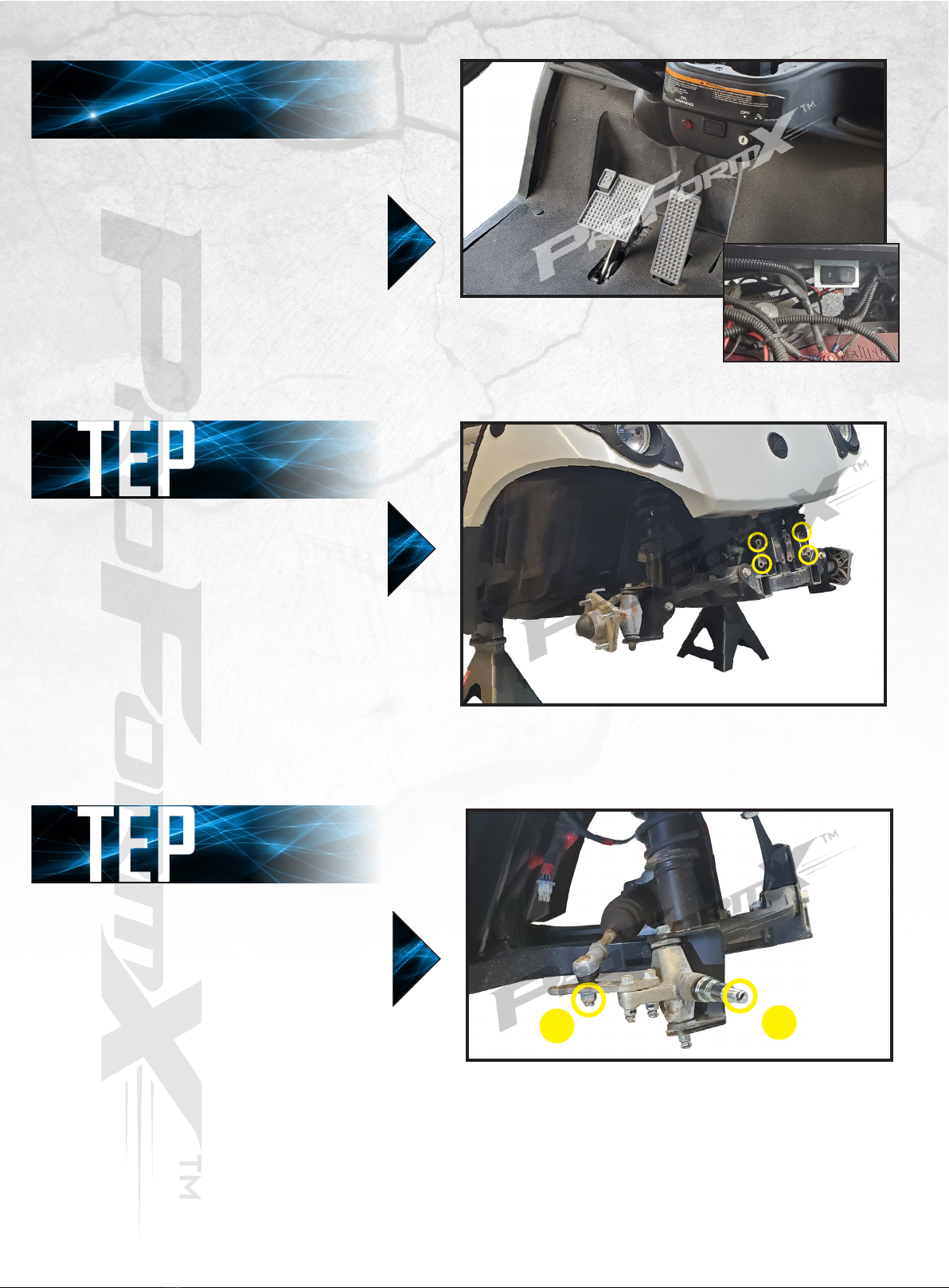

to the ground. Lift front of cart with a oor jack.

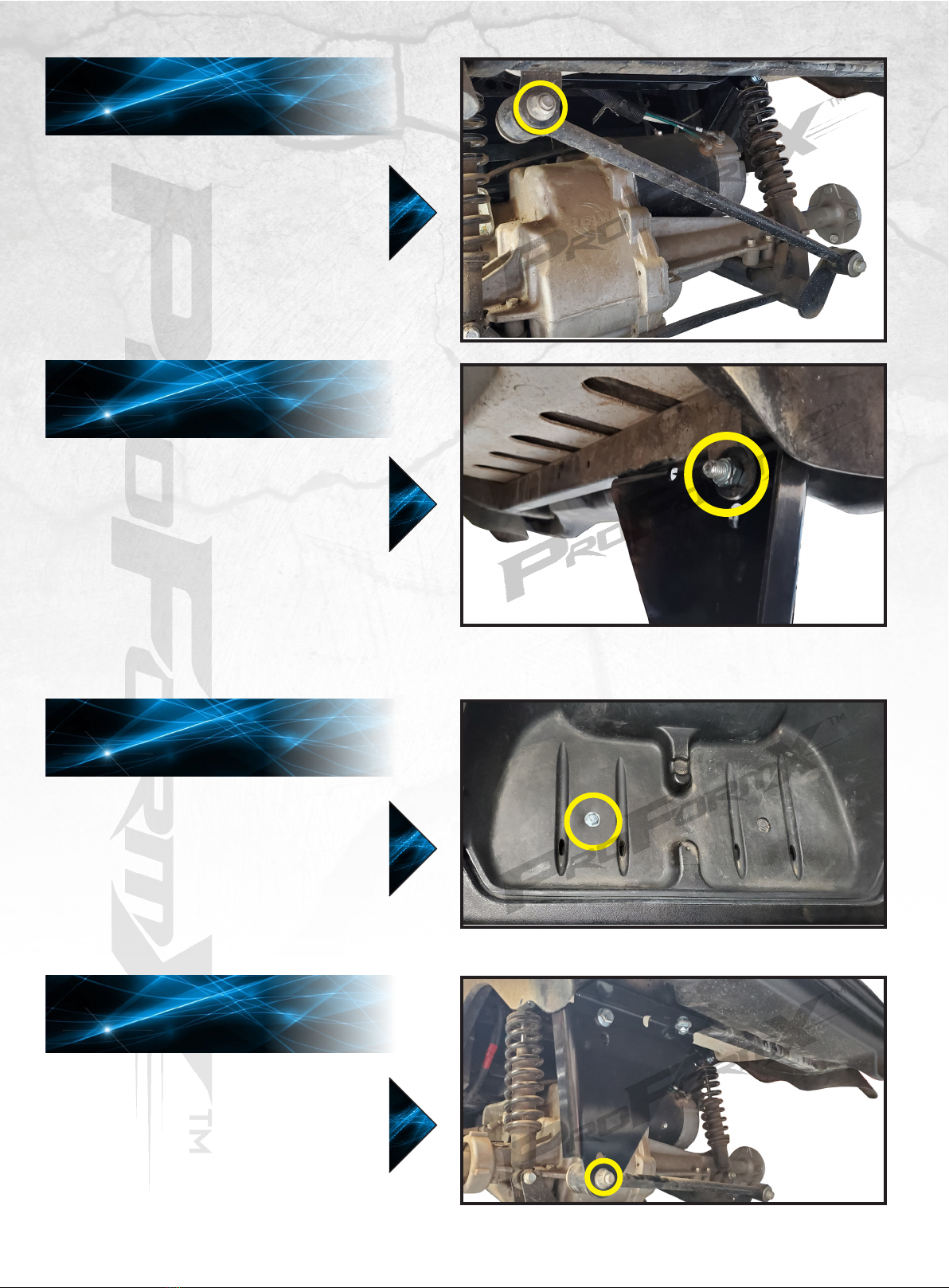

First adjustment will be at the lower A-Arm (A).

Using a adjustable wrench, adjust the lower heim

joint in or out as needed to achieve proper 90°.

If further adjustment is still needed, remove the

front tire and temporarily remove the spindle bolt

(B) to free heim joint. Loosen heim joint nut with

a adjustable wrench and screw in/out heim joint

as needed.

Re-tighten nut, reattach spindle, and front tire.

Check camber again, if further adjustment is

needed, repeat process above.

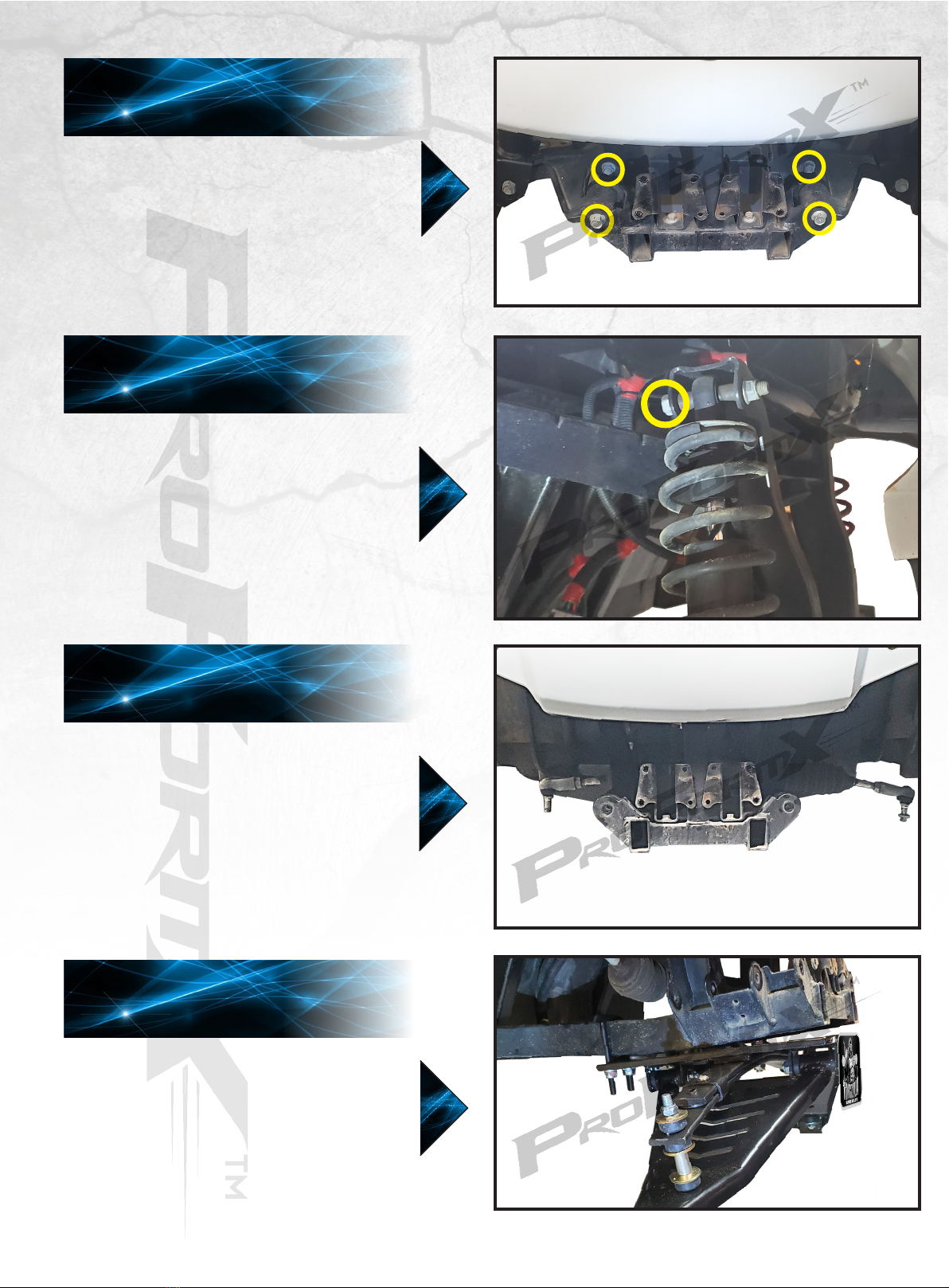

Ensure tires are pointing as straight as possible

and steering wheel is in the centered position.

First, nd a common point to measure from on

the inside front and inside rear of tires. You will

need to adjust the steering arms until the front

measurement is 1/4” greater than the rear

measurement. Tires should toe OUT in the front.

To adjust steering rack, loosen nut on tie rod end

(C) with a 17mm wrench and adjust tires in or out

using a 12mm wrench on the steering rack (D).

Tighten nut on tie rod end

when complete.

Drive the cart around and then recheck your

alignment. Readjust if necessary

A)

B)

C)

D)

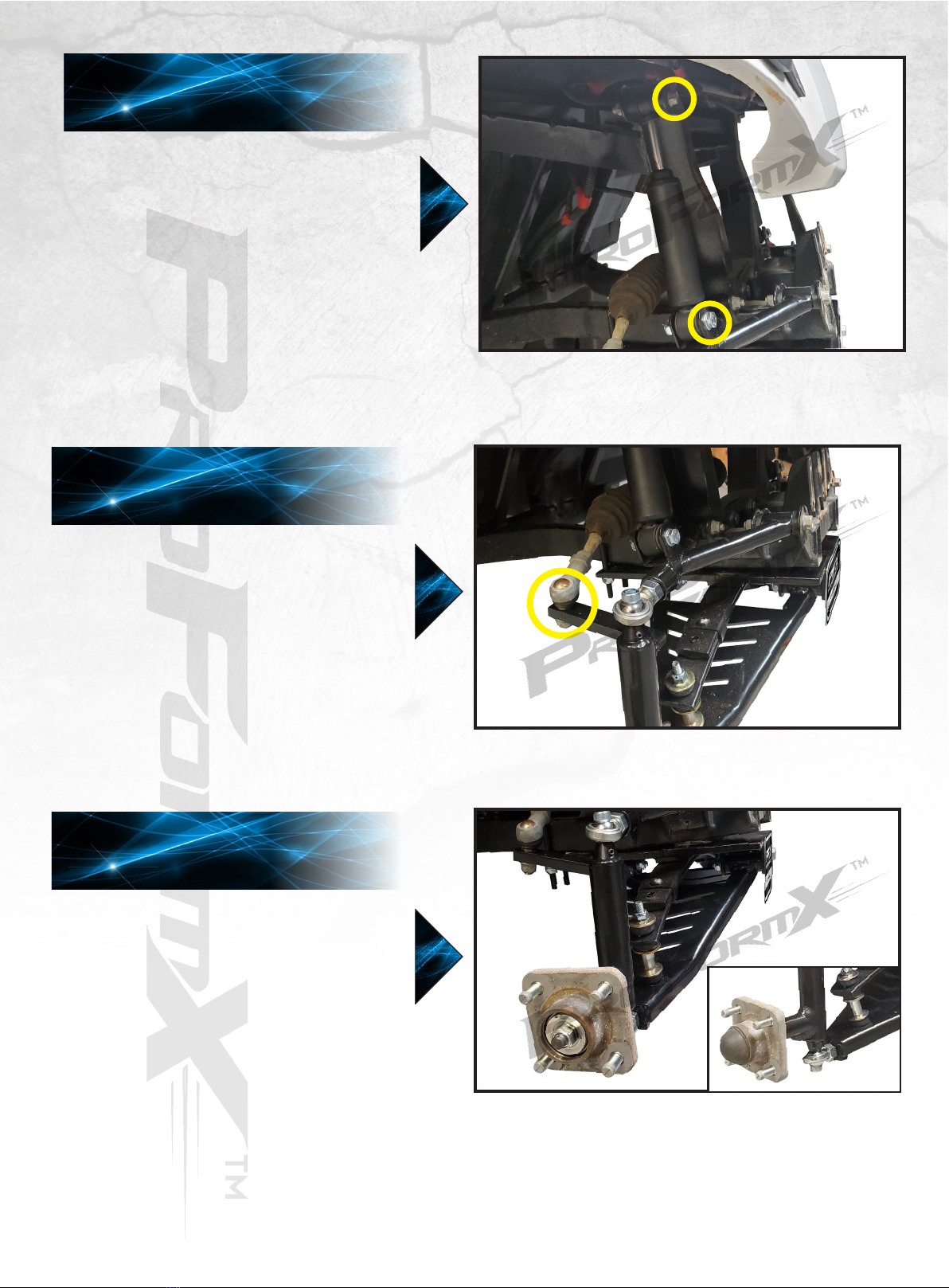

Be sure to use threadlock adhesive on spindle

bolts and retighten set screws in spindles.

STEP 25 WARNING

ALIGNMENT INSTRUCTIONS