2. Orientations

Read the information and instructions of this manual carefully, before using the

product. This ensures the correct use of the equipment and maximum use of its

technical features as well as a prolonged service life.

Keep this manual for future consultations.

Digicon reserves its right to alter its products at any moment to adapt them to more

recent technical advancements.

Digicon maintains its right to alter the information contained in this manual without

previous notice.

Digicon does not provide any contractual warranty concerning the information in

this manual, and cannot be held responsible for errors it may contain and problems

due to its use.

The information contained in this manual is exclusive property of Digicon and is

protected by copyright laws.

This manual cannot be reproduced, photocopied or translated, in its entirety or in

part, into any kind of medium, without Digicon's written consent.

3. Introduction

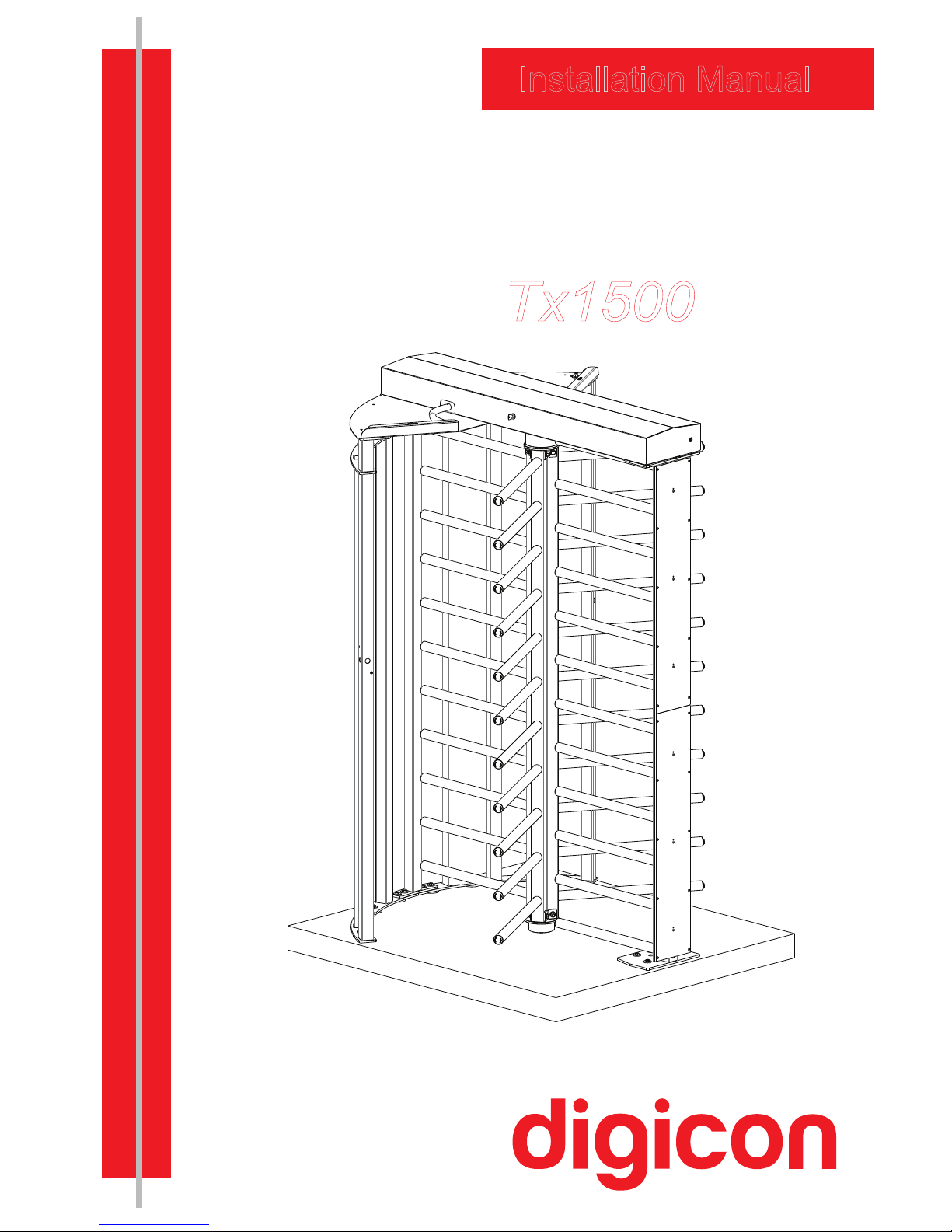

The Full-height is a bidirectional access control equipment forTurnstile Tx1500

entrance and exit of pedestrians. Highly resistant, both indoors and outdoors, it is

sturdy, safe, and firmly fixated to the floor. It is completely integrated to access

controllers. This manual presents a detailed description the installation of Tx1500

and of the components that accompany it.

To see our complete catalogue, visit www.digicon.com.br.

Torniquete

Tx1500

06