© Martin Engineering GmbH 1 M3814UK-03/16

Contents

1 Contents

1 Contents ............................................................................ 1

2 Introduction ...................................................................... 3

2.1 About this Installation Manual............................................ 3

2.1.1 Scope ............................................................................ 3

2.1.2 Copyright ....................................................................... 3

2.1.3 Disclaimer ...................................................................... 3

2.1.4 Reference to additional documentation ......................... 4

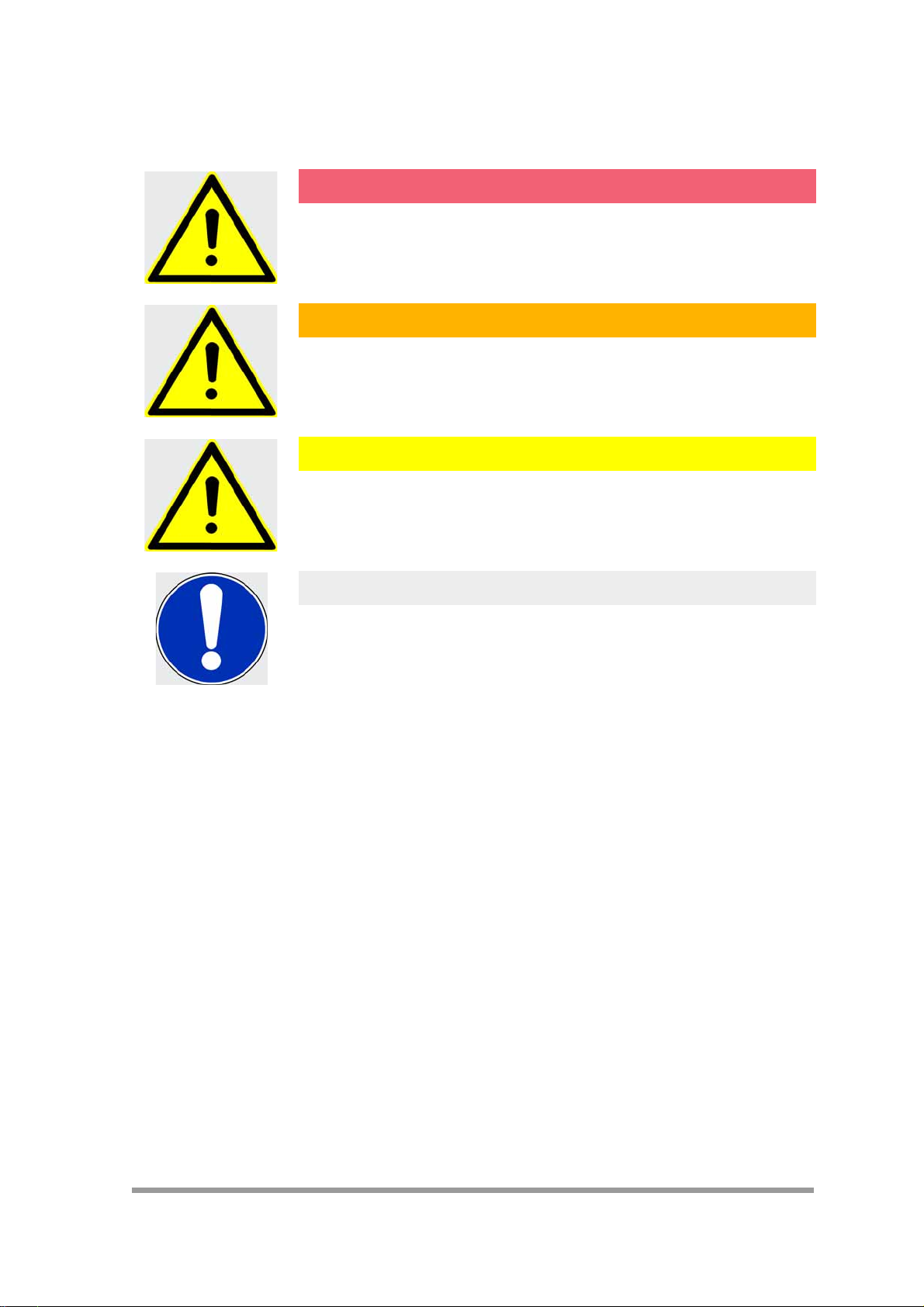

2.1.5 Classification of hazards................................................ 5

2.2 Appropriate Use................................................................. 6

2.2.1 Conveyor belt systems with open transfer systems ...... 6

2.2.2 Use in EX-protection areas ............................................ 6

2.2.3 Operating limits of this product...................................... 7

2.3 Safety in the Workplace ..................................................... 7

2.3.1 Safety instructions, safety in the workplace ................... 7

2.3.2 Obligations of the operator............................................ 8

2.3.3 Authorised personnel ..................................................... 8

3 Product Description ......................................................... 9

3.1 Design and Function.......................................................... 9

3.2 Tensioners ......................................................................... 9

3.3 Type explanation.............................................................. 10

4 Installation Preparation ................................................. 11

4.1 Prior to Installation ........................................................... 11

4.1.1 Materials and tools required ........................................ 11

4.1.2 Preparatory measures ................................................. 11

5 Installation ...................................................................... 13

5.1 Safety Instructions............................................................ 13

5.2 Installation procedure....................................................... 14

5.2.1 Determining the installation position ............................ 14

5.2.2 Installing the tensioner ................................................. 17

5.2.3 Installing the primary cleaner....................................... 18

5.2.4 Centre the mainframe below the conveyor belt........... 20

5.2.5 Aligning the mainframe parallel to the conveyor belt ... 20

5.2.6 Aligning the mainframe horizontally ............................. 21

5.2.7 Install locking sleeve.................................................... 22

5.2.8 Tensioning the primary cleaner blade ......................... 22

5.3 Operation with load.......................................................... 23

5.4 Installation - Check-list..................................................... 24

5.5 Attaching the warning label or the warning tag................ 25

6 Maintenance ................................................................... 26

6.1 Safety Instructions............................................................ 26

6.2 Weekly maintenance........................................................ 26

6.3 Replacing the cleaner blades........................................... 28

7 Troubleshooting ............................................................. 30

7.1 Safety Instructions............................................................ 30

7.2 Troubleshooting ............................................................... 30