Digital Knight DK20SP User manual

Version 2-12

Digital Knight 16x20

Digital AUTOMATIC Swinger

Contents

Introduction

Congratulations on your purchase of the Air Operated Automatic

DK20SP 16x20 digital swinger! This heat press machine has many ex-

citing features, all of which are meant to help make your heat transfer

pressing endeavors as successful and easy as possible. Please take the

time now to thoroughly read through this manual to become acquaint-

ed with them. It will explain some key features, concepts and methods

that will save much time and effort in using this press and in your heat

pressing applications.

Throughout this manual, many areas and components of this ma-

chine will be referred to by specic names. Please refer to the illustra-

tions below in order to become familiar with some of the terminology

used in this manual.

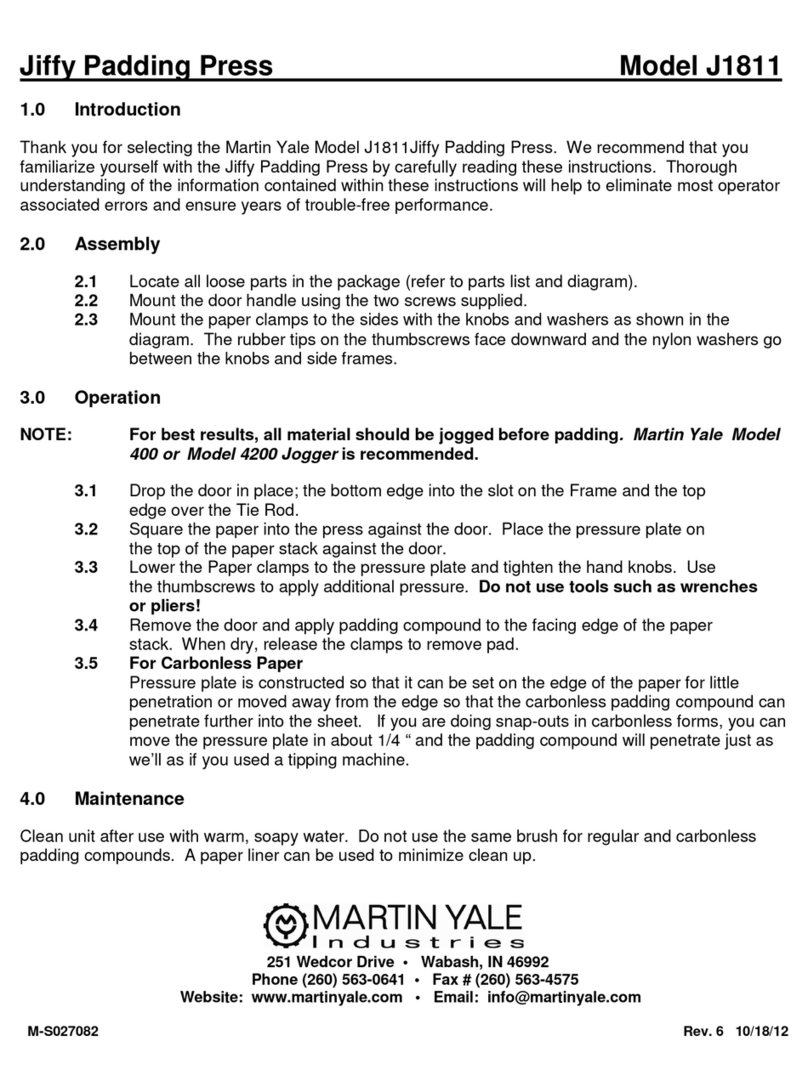

Temperature

°F/°C Indicator

Ready/Heating Indicator

Open/Timing/Done Ind.

Time

Pressure Bar Graph

TEMP key

PRG key

Up/Down Arrow keys

Default Operating Mode of Controller

Height Knob

Top Head

Power Inlet

E-Stop Button

Activate Button(s)

Heat Platen

Lower Table

Silicone Pad

Pressure Gauge

Air Inlet

Air Regulator

Setup & Suggestions

• Locate the press on a rm, sturdy work surface. It is recommended but

not necessary to bolt the press to a workbench using the rear mounting

holes on the base frame.

• A stand on lockable casters is available from Geo Knight & Co or your

distributor.

• The height of the bench/work space the press is located on would be

ideally 27” to 32” high.

• Attach the power cord from the rear to the underside of the top head.

There is a power inlet under the top head that the modular cord will

plug into.

• It is HIGHLY RECOMMENDED that the cord be strapped or tied to

the back white post of the press, so that the cord is not pulled on and

tugged out of the power inlet where it plugs into the press. TEST and

make sure the cord travels freely when swinging the press, and that

there is no tension or pulling on the inlet socket where the power cord

plugs into the head. Make sure the cord can not be pressed by the

heater.

• The top head should be swung over the pressing table when not in

use.

• The air attachment is a 1/4” or 3/8” female NPT pipe thread. A standard

1/4” or 3/8” threaded male NPT tting can be used. 3/8” or 1/4” ID

hose will provide enough air volume for this press.

• The speed in which the press opens can be adjusted. Underneath the

front skirt of the press, behind the air regulator and air gauge, a brass

ow control can be found. (Slide the press forward off your benchtop to

look underneath.) This is where the air exits the press when the time is

nished and the press releases. If the press is releasing TOO SLOWLY

- the ow control valve can be loosened so that the air releases faster,

and the press opens quicker. If the press is releasing TOO QUICKLY

(slamming/banging down upon completion) the ow control can be

tightened so that the air releases slower, and the bottom table drops

more smoothly. If the air supply is dirty/oily, this may become clogged,

resulting in a slower and slower release. Remove the ow control and

clean it thoroughly.

Normal Operation

Normal Operating Mode

The pressure bar graph is not used on this automatic press.

Setting Temperature

Setting Time

Pre-Press Timer

Setting Platen Height

The height adjustment knob on the DK20SP allows for thicker

items to be placed in the press. The factory set height of the press is

the proper platen height setting for most fabrics, and materials under

1/4” thick. Unlike manual presses, the actual amount of pressure on the

DK20SP is determined by the air regulator and air gauge, NOT by the

height of the heat platen. However, if the platen height does not provide

enough clearance for especially thick items, this can be adjusted. There

should normally be 1/2” to 3/4” gap between the heater and bottom pad

or workpiece.

• To raise the heat platen, turn

the pressure knob to the left,

counterclockwise. The top head will

rise away from the lower table.

• To lower the heat platen, turn

the pressure knob to the right,

clockwise. The top head will lower

toward the pressing table.

Activating the Press

To actuate the machine, simply

press both black buttons together.

This will cause the air bladder to

ll, the table to raise, and the work

to be pressed. The digital timer will

automatically begin cycling. At the

end of the timer cycle the press will

automatically release and the timer

will reset to the preset time. BOTH

black buttons must be pressed together, to insure that both operators hands

are clear of the pressing area, for safety purposes.

To interrupt the timing cycle, in order to do a quick pre-press or

press for a shorter period of time than is set, simply press both black

buttons together again. For emergency one-hand release of the air pres-

sure, press the middle button on the front panel. THE GREEN

LIGHT MUST BE ON IN ORDER TO OPERATE

THE PRESS.

Guidelines & Standard Settings

The following information covers some basic guidelines for press-

ing, as well as some generic parameters for basic heat transfer applica-

tions.

• When pressing shirts, it is often recommended that the shirts be quickly

pressed for 2 to 4 seconds before transferring to remove wrinkles and water

content.

• When pressing two sides of a garment, pull the garment over the table so

that the printed side drapes underneath the table. This will avoid reheating

previously transferred designs on opposite sides of garments. It will also

avoid any bleed-through of inks on lighter fabrics.

• Avoid laying collars, cuffs, zippers, and other bulky parts of garments

on the lower table, as these can adversely affect pressing conditions, and

reduce the life of the silicone pad.

• When pressing rigid substrates (plastics, metals, woods, etc.), be sure that

any protective lms or laminates are removed before heating.

• Always check that the transfer image is face down against the material, to

avoid sealing the image against the heat platen instead of the substrate.

Always follow the transfer media suppliers instructions when

pressing. The information below is for general reference only, and may

not be as accurate as the instructions provided by the transfer media &

imprintable substrate supplier.

• Hot Split Supplier Transfers 350-375°F, 8-10 secs

• Puff Transfers 350-375°, 5-7 secs (extra heavy pressure)

• Ink-Jet Transfer Papers 360°, 15-18 secs

• ColorCopy/Laser Transfer Papers 375°, 20-25 secs

• Sublimation Inks (Polyester Fabrics) 400°, 35 secs

• Sublimation Inks (Plastics) 400°, 1 min, 15 secs

• Sublimation Inks (Metals) 400°, 1 min

• Sublimation Inks (Woods) 400°, 1 min, 15 secs

• Sublimation Inks (Ceramics) 400°, 4 min

ERR Mode

Over-Temp Alarm

Loading a Preset

Programmable Presets

How Presets Work

Editing/Programming a Preset

A Walkthrough Tutorial for using Presets

Part 1:

Part 2:

User Menus

Entering the user menus & options

To access the user menus, simply press TEMP & PRG at the same

time from the normal operating mode and let go.

(Try to use two hands and press the keys at the exact same time. If one

key is pressed too early from the other, the temperature setting or preset

modes may be activated instead. Turn the press off and then on and try

again.)

Fahrenheit / Celsius

Timer Counter Units

Recorded Pressings (User Odometer)

Pressure Minimum

Pressure Maximum

Temperature Drop Sense

Keypad Beeper

Alarms

• denotes a short beep.

_ denotes a longer beep.

~ denotes innite loop.

Alarm # Alarm Pattern

Off No alarm

01 • • • _

02 • • • _ ~

03 • • _

04 • • _ ~

05 • • •

06 • • • ~

07 _ ~

08 _

09 •

10 • (shorter)

Finished Warning Beep

Prepress Timer

Prepress Alarms

• denotes a short beep.

_ denotes a longer beep.

~ denotes innite loop.

Alarm # Alarm Pattern

Off No alarm

01 • • • _

02 • • • _ ~

03 • • _

04 • • _ ~

05 • • •

06 • • • ~

07 _ ~

08 _

09 •

10 • (shorter)

Operator Lockout

Maintenance

• The Lifter Springs & Shoulder Bolts are the greatest area of wear and

friction on the press. However they rarely if at all need to be replaced. If

the press raises and lowers unevenly, carefully turn the press on its side

and inspect the 4 springs. Replace all 4 springs at the same time if one or

more are broken or not even.

• Lightly Lubricating the lifter springs with white lithium grease or similar

spray on lubricate will greatly reduce squeaking and noise from the

underside of the press

• The air regulator is the easiest component to clog and damage from

contaminated air. Make sure a water trap / lter is placed inline with the

air supply before the connection to the press. The cleaner and drier the air,

the longer the life of the air regulator and other pneumatic components.

• The black push-buttons and rear safety switch should last many tens of

thousands of pressings. If however activation of the press is sporadic,

replace the push buttons and rear safety switch.

• The silicone pad on the lower table can degrade after much use and over

an extended period of time. This pad is replaceable. If the pad becomes

dried out, cracked, or there are chunks removed from the silicone pad, this

can result in inconsistent and poor quality transfers.

Parts / Maintenance / Misc

Replacement Parts

DKP-ACTCVR ................DK20SP FRONT COVER W/SWITCHES/ASBLY

SHN-DKPHOOD .............DK20SP FRONT COVER PANEL ONLY

ELN-ABB1 ......................PUSH BUTTON PANEL MOUNT (BLACK)

ELN-110SP ......................SPST PUSH/ ON-OFF SWITCH (E-STOP)

ELN-8043X1 ....................PILOT LIGHT (GREEN) 120V SOLICO

ARN-AR20HZ .................¼ NPT SMC REGULATOR W/PANEL NUT

ARN-15UB8 ....................PANEL MOUNT 0-160 AIR GAUGE 1½ DIA

SHN-DKPSKT .................DK20SP BOTTOM PANEL SKIRT

DKP-PVSWBX................DK20SP REAR PIVOT SWITCH BOX

DKP-HDHNDL ...............DK20SP HANDLE BAR W/KNOB

ARN-7564 ........................STYLE 116 MEDIUM AIR BAG

ARN-35AAA120V ..........MINI-3 WAY MAC VALVE 120V 35A SERIES

ARN-4ZJ85 ......................¼” EXHAUST PORT FLOW CONTROL

MEN-M5 ..........................3/4 X 3/8 X 3” DIE SPRING

FAS-AB383 ......................3/8 X 3 SOCKET HD SHOULDER SCREW

DKA-CTRLC ...................DIGITAL KNIGHT PROCESSOR BOARD

DKA-CTRLP ...................DIGITAL KNIGHT POWER BOARD

ELN-KM0227A1 .............DIGITAL KNIGHT MEMBRANE KEYPAD

RPK-DKPWR ..................DK POWER INLET/SWITCH/CORD KIT

DK2S-HBA120 ................DK20S/SP 16X20 HEATER BLOCK ASBLY

CAN-DKKNOB ...............DK/DC BLACK KNOB

FAS-EM5818 ...................5/8-18 HEX ACORN NUT

MEN-DKPVBLT .............DK/DC PIVOT BOLT

FAS-NTA1018 .................THRUST BEARING (2 req)

MEN-TWB1018 ..............SMALL WASHER THRUST BEARING (4 req)

SRM-381620 ....................3/8 X 16 X 20 SILICON SPONGE

MEN-DKCLLR ...............DK20S/SP STOP COLLAR

SHN-DK2SCVR ..............DK20S/SP TOP CONTROL PANEL COVER

SHN-DK20SHBC ............DK20S/SP 16X20 HEATER BLOCK COVER

ELN-K26TC ....................K-26” THERMOCOUPLE

ELN-MSTB2.5.................OST 5MM TRMNL THERMOCOUPLE PLUG

Table of contents

Other Digital Knight Power Tools manuals