Digital Knight DK14S User manual

Version 3-21

Digital Knight DK14S

12x14 Digital Swinger

Contents

Introduction

Congratulations on your purchase of the DK14S 12x14 swinger!

This heat press machine has many exciting features, all of which are

meant to help make your heat transfer pressing endeavors as successful

and easy as possible. Please take the time now to thoroughly read through

this manual to become acquainted with them. It will explain some key

features, concepts and methods that will save much time and eort in

using this press and in your heat pressing applications.

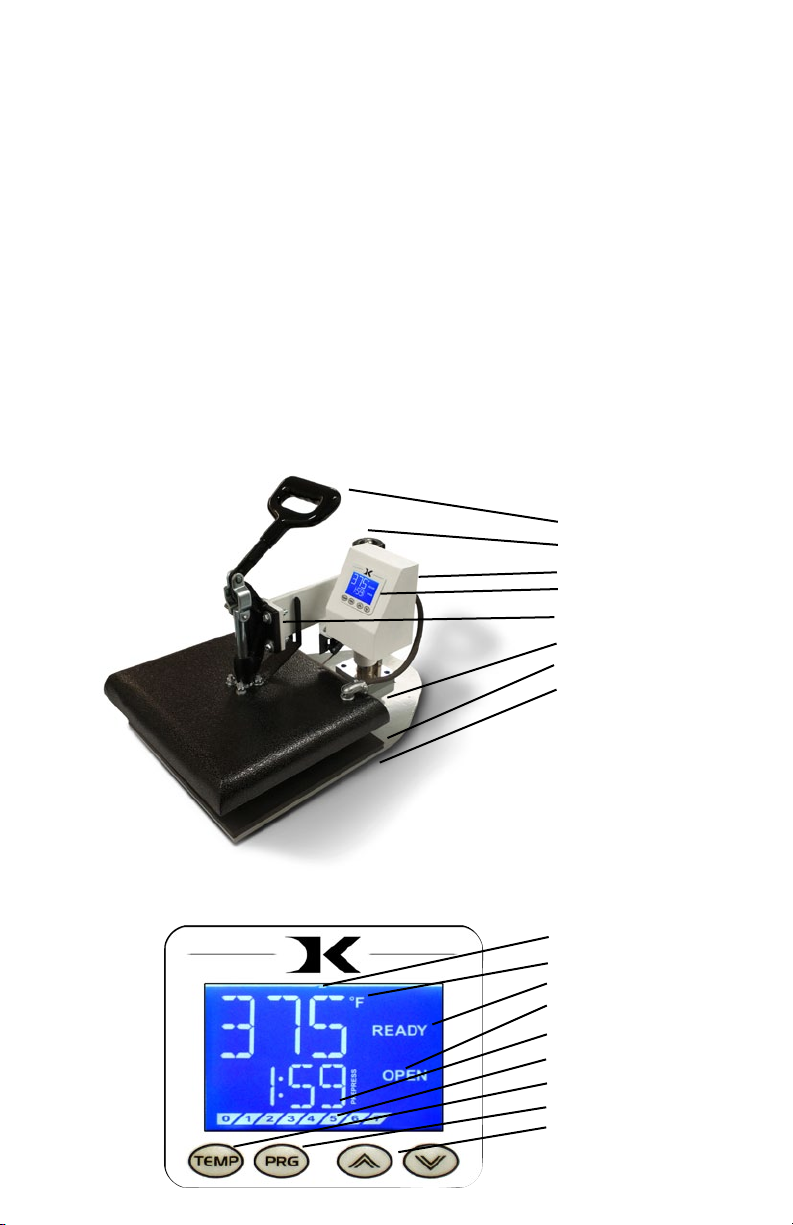

Throughout this manual, many areas and components of this machine

will be referred to by specic names. Please refer to the illustrations

below in order to become familiar with some of the terminology used

in this manual.

Handle

Pressure Knob

Pwr Inlet/On-O

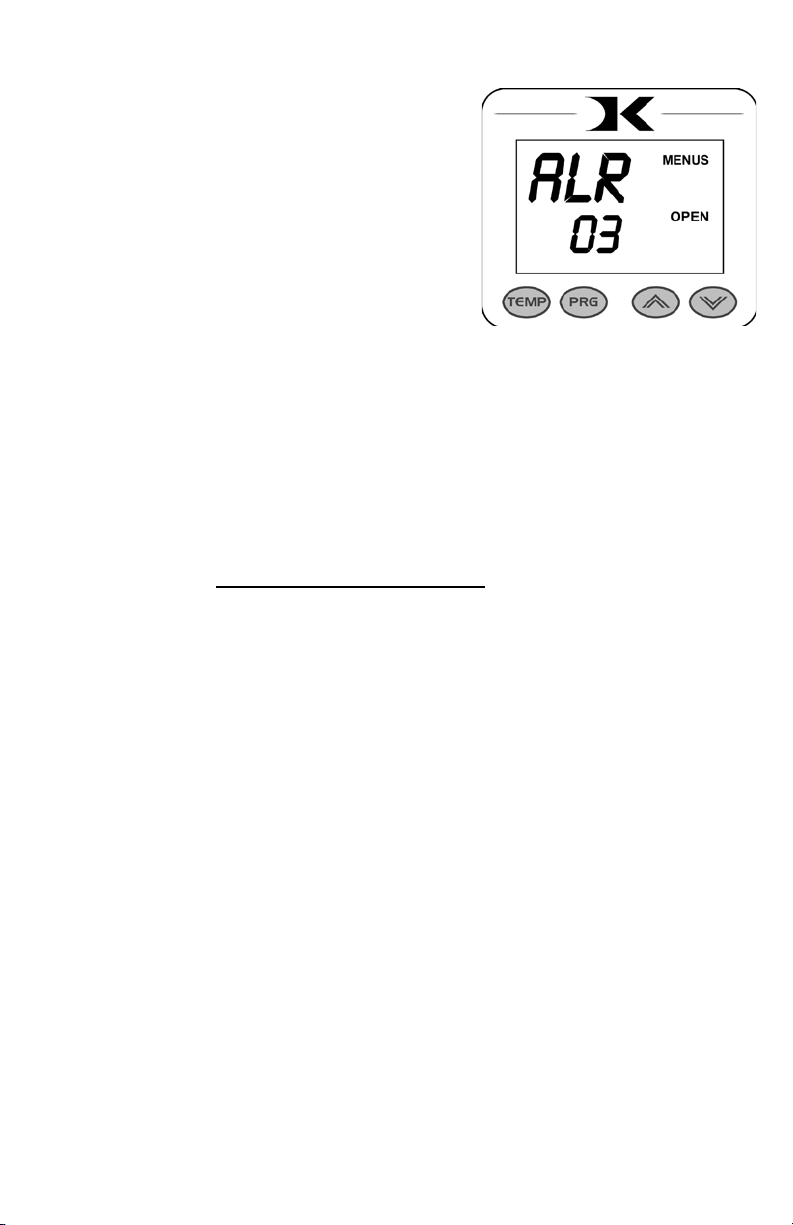

Digital Control

Clamp / Linkage

Heat Platen

Silicone Pad

Base Frame

Temperature

°F/°C Indicator

Ready/Heating Indicator

Open/Timing/Done Ind.

Time

Pressure Bar Graph

TEMP key

PRG key

Up/Down Arrow keys

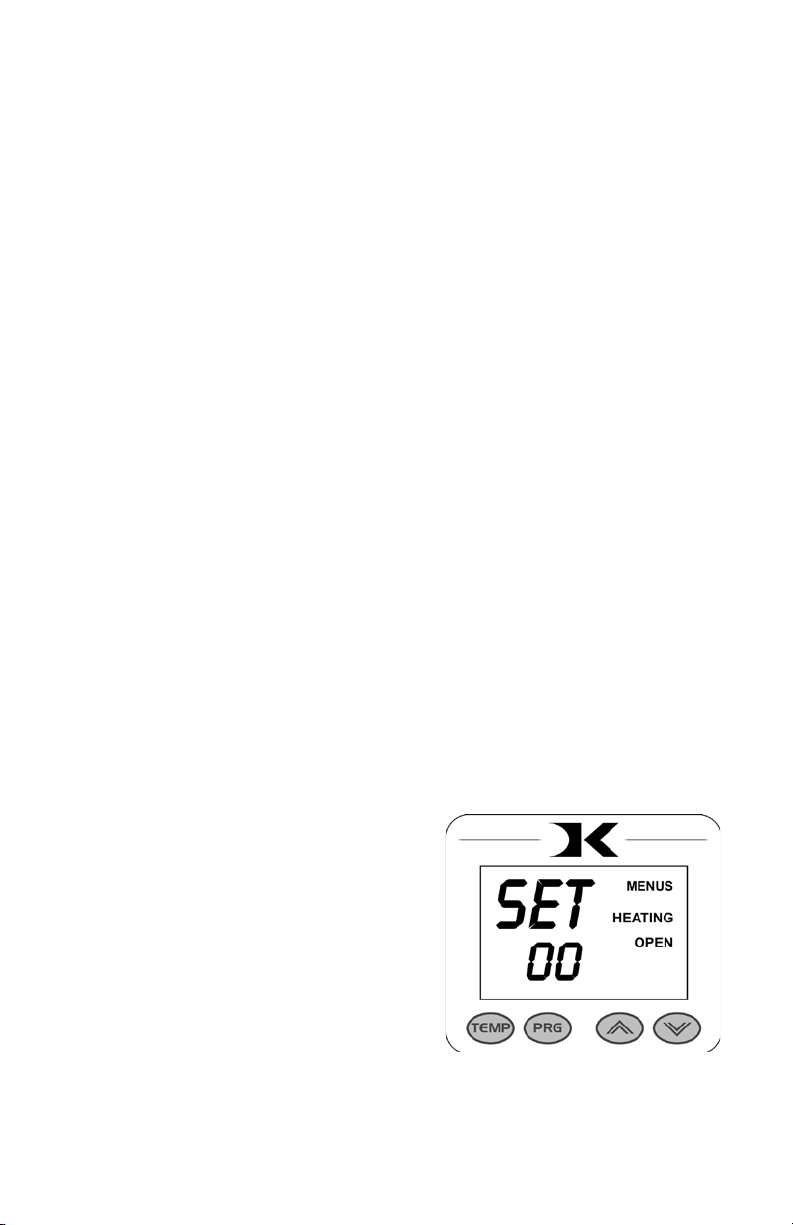

Default Operating Mode of Controller

Setup & Suggestions

• Locate the press on a rm, sturdy work surface. It is recommended but

not necessary to bolt the press to a workbench using the rear mounting

holes on the base frame.

• A stand on lockable casters is available from Geo Knight & Co or your

distributor.

• The height of the bench/work space the press is located on would be

ideally 27” to 32” high. The higher the press, the more dicult to

close/lock.

• Attach the power cord from the rear to the underside of the top head.

There is a power inlet under the top head that the modular cord will

plug into.

• It is HIGHLY RECOMMENDED that the cord be strapped or tied to

the back white post of the press, so that the cord is not pulled on and

tugged out of the power inlet where it plugs into the press. TEST and

make sure the cord travels freely when swinging the press, and that

there is no tension or pulling on the inlet socket where the power cord

plugs into the head. Make sure the cord can not be pressed by the

heater.

• The press should remain in the unclamped OPEN position when not in

use. Do not leave the heater block closed on the table when not using,

unless transporting.

• The top head should be swung over the pressing table when not in

use. Do not leave the platen down on the silicone pad when heating.

Always leave the heat platen in the UP position.

Normal Operation

Normal Operating Mode

Setting Temperature

Setting Time

Pre-Press Timer

Setting Pressure

Guidelines & Standard Settings

The following information covers some basic guidelines for press-

ing, as well as some generic parameters for basic heat transfer applica-

tions.

• When pressing shirts, it is often recommended that the shirts be quickly

pressed for 2 to 4 seconds before transferring to remove wrinkles and water

content.

• When pressing two sides of a garment, pull the garment over the table so

that the printed side drapes underneath the table. This will avoid reheating

previously transferred designs on opposite sides of garments. It will also

avoid any bleed-through of inks on lighter fabrics.

• Avoid laying collars, cus, zippers, and other bulky parts of garments

on the lower table, as these can adversely aect pressing conditions, and

reduce the life of the silicone pad.

• When pressing rigid substrates (plastics, metals, woods, etc.), be sure that

any protective lms or laminates are removed before heating.

• Always check that the transfer image is face down against the material, to

avoid sealing the image against the heat platen instead of the substrate.

Always follow the transfer media suppliers instructions when

pressing. The information below is for general reference only, and may

not be as accurate as the instructions provided by the transfer media &

imprintable substrate supplier.

• Hot Split Supplier Transfers 350-375°F, 8-10 secs

• Pu Transfers 350-375°, 5-7 secs (extra heavy pressure)

• Ink-Jet Transfer Papers 360°, 15-18 secs

• ColorCopy/Laser Transfer Papers 375°, 20-25 secs

• Sublimation Inks (Polyester Fabrics) 400°, 35 secs

• Sublimation Inks (Plastics) 400°, 1 min, 15 secs

• Sublimation Inks (Metals) 400°, 1 min

• Sublimation Inks (Woods) 400°, 1 min, 15 secs

• Sublimation Inks (Ceramics) 400°, 4 min

ERR Mode

Over-Temp Alarm

Loading a Preset

Programmable Presets

How Presets Work

Editing/Programming a Preset

A Walkthrough Tutorial for using Presets

Part 1:

Part 2:

User Menus

Entering the user menus & options

To access the user menus, simply press TEMP & PRG at the same

time from the normal operating mode and let go.

(Try to use two hands and press the keys at the exact same time. If one

key is pressed too early from the other, the temperature setting or preset

modes may be activated instead. Turn the press off and then on and try

again.)

Fahrenheit / Celsius

Timer Counter Units

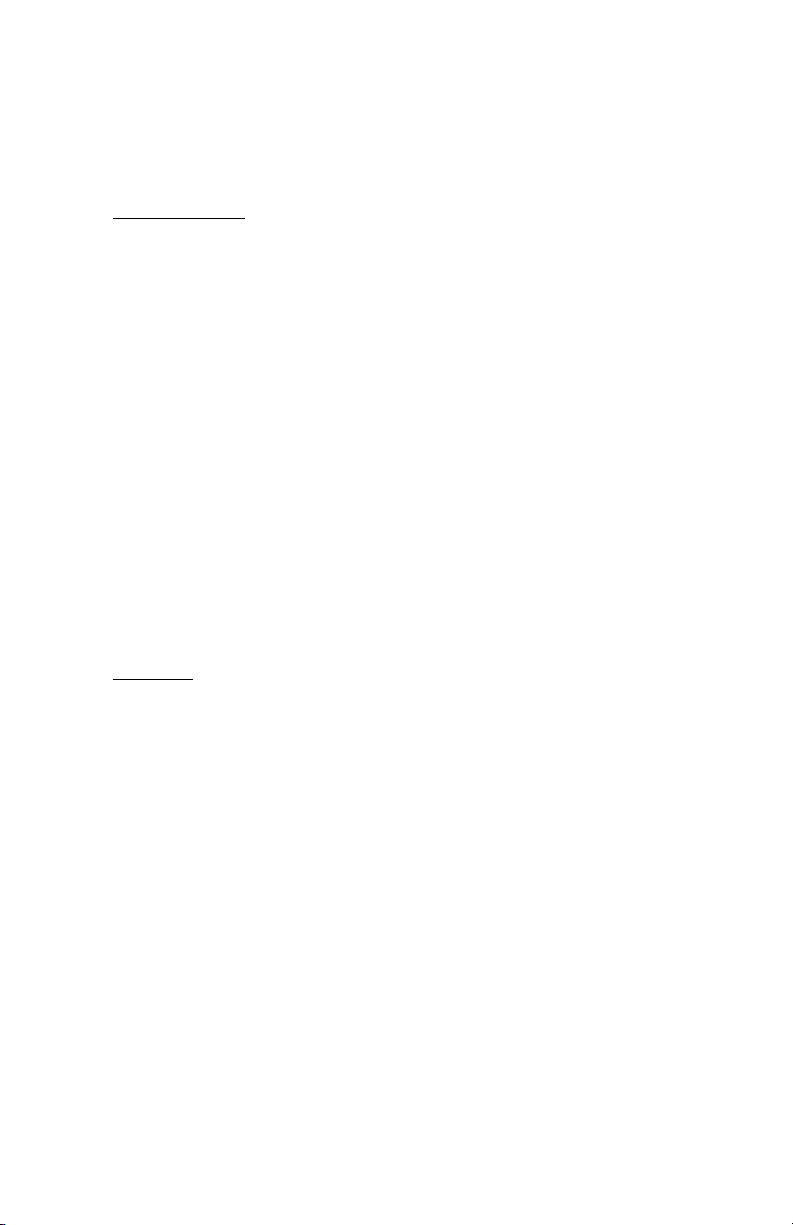

Recorded Pressings Odometer

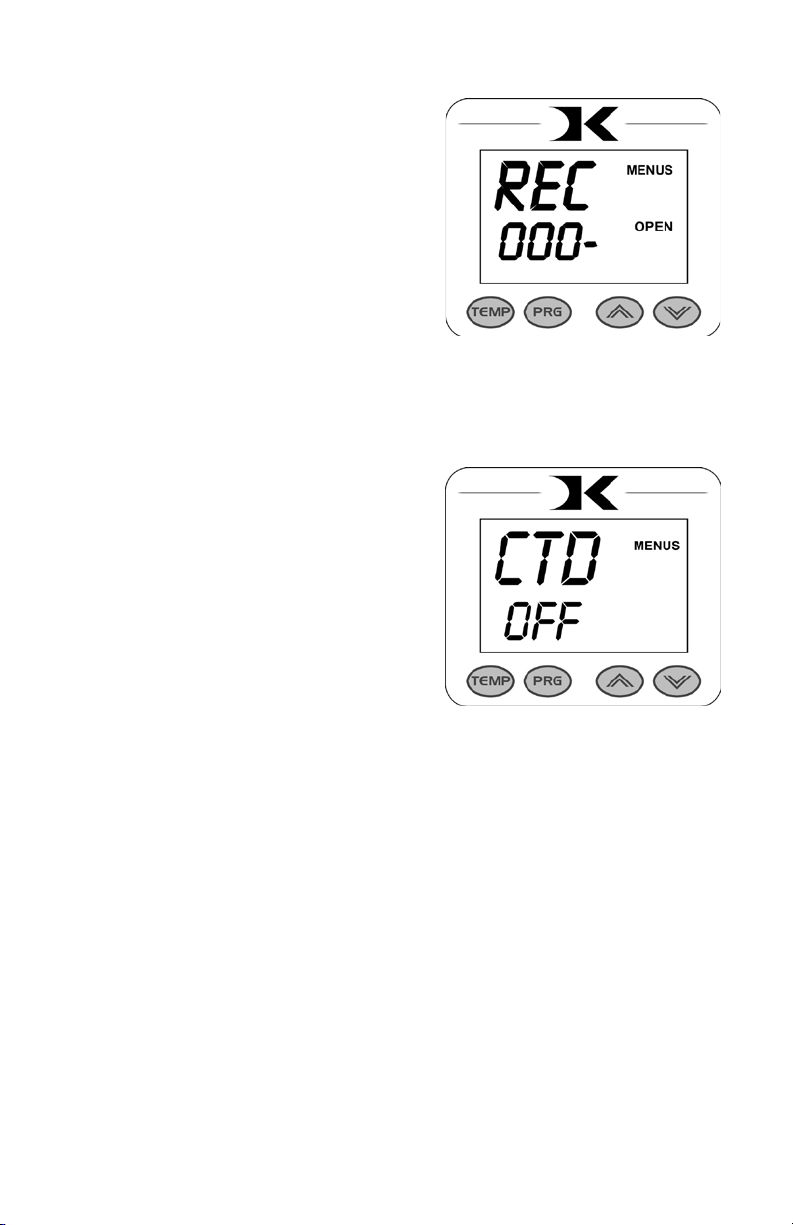

Pressings Countdown Odometer

Pressure Minimum

Pressure Maximum

Temperature Drop Sense

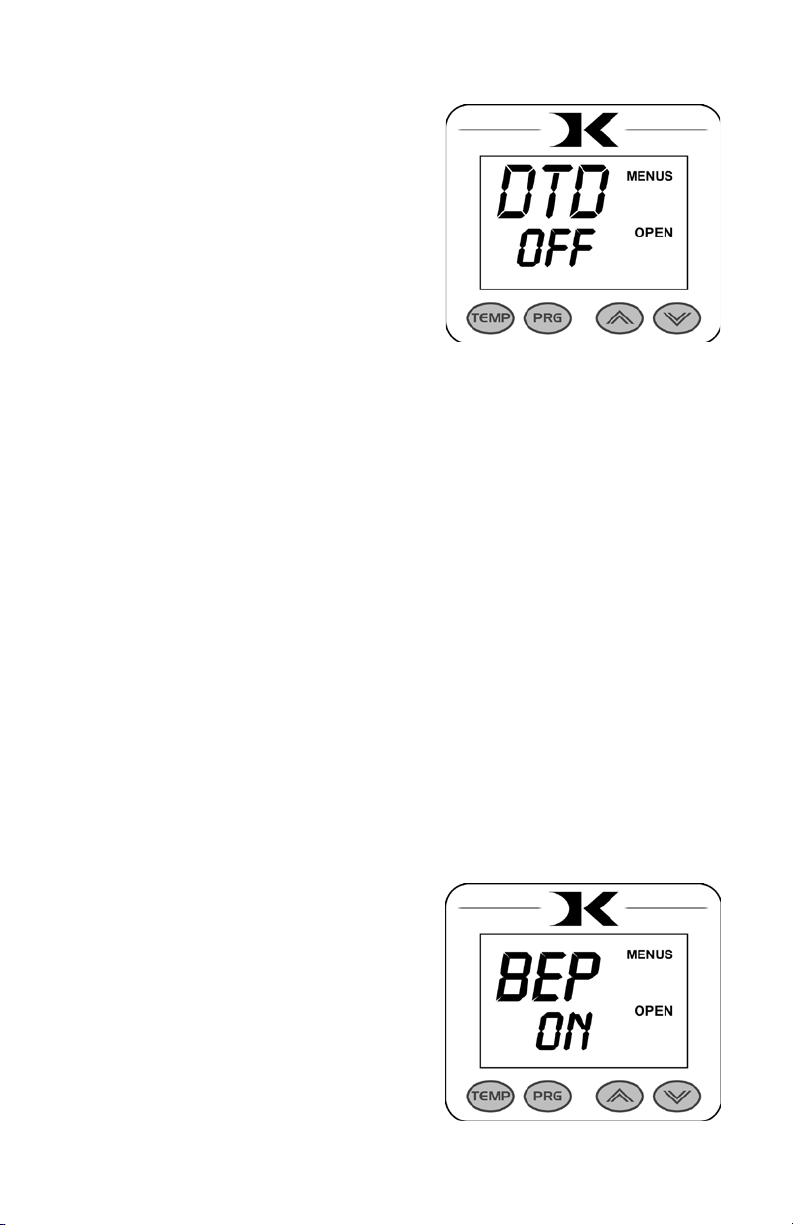

Keypad Beeper

Temperature Drop Sense Timer Disable

Alarms

• denotes a short beep.

_ denotes a longer beep.

~ denotes innite loop.

Alarm # Alarm Pattern

O No alarm

01 • • • _

02 • • • _ ~

03 • • _

04 • • _ ~

05 • • •

06 • • • ~

07 _ ~

08 _

09 •

10 • (shorter)

Finished Warning Beep

Prepress Timer

Prepress Alarms

• denotes a short beep.

_ denotes a longer beep.

~ denotes innite loop.

Alarm # Alarm Pattern

O No alarm

01 • • • _

02 • • • _ ~

03 • • _

04 • • _ ~

05 • • •

06 • • • ~

07 _ ~

08 _

09 •

10 • (shorter)

Operator Lockout

Replacement Parts

MEN-DCCLP ...................DC16 (DK14S) CLAMP LINK ASSEMBLY

DKA-CTRLC ...................DIGITAL KNIGHT PROCESSOR BOARD

DKA-CTRLP ...................DIGITAL KNIGHT POWER BOARD

ELN-KM0227A1 .............DIGITAL KNIGHT MEMBRANE KEYPAD

RPK-DKPWR ..................DK POWER INLET/SWITCH/CORD KIT

ELN-VS10N031C ............TIMER LEVER MICRO SWITCH

DK14-HBA120 ................DK14S 12X14 HEATER BLOCK ASBLY 120V

SRM-381214 ....................3/8 X 12 X 14 SILICON SPONGE

DK14-SVLARM ..............DK14S SILVER POST & WHITE ARM ASBLY

DK14-STLBASE .............DK14S COMPLETE STEEL BASE

SHN-DK14HBC ..............DK14S 12 X 14 HBA COVER

SHN-DK14GD .................DK14S BENT REAR HBA GUIDE

DCA-LRGPBSFT ............DC LARGE PRESSURE BLOCK & SHAFT ASBLY

ELN-K26TC ....................K-26” THERMOCOUPLE

ELN-MSTB2.5.................OST 5MM TRMNL THERMOCOUPLE PLUG

• The clamp/linkage assembly is the greatest area of wear and friction on the press.

The posts that connect to the heat platen should be lubricated with SuperLube - a

clear high-temperature lubricant.

• If the pins in the clamping mechanism wear, or the holes become elongated,

eventually the press will not lock properly. This can be very detrimental to pressing

results & quality! Contact the factory for very inexpensive clamp replacements to

get the clamps back to new condition.

• The silicone pad on the lower table can degrade after much use and over an extended

period of time. This pad is replaceable. If the pad becomes dried out, cracked, or

there are chunks removed from the silicone pad, this can result in inconsistent and

poor quality transfers.

Maintenance / Misc

Table of contents

Other Digital Knight Power Tools manuals