SSM 2 pro User manual

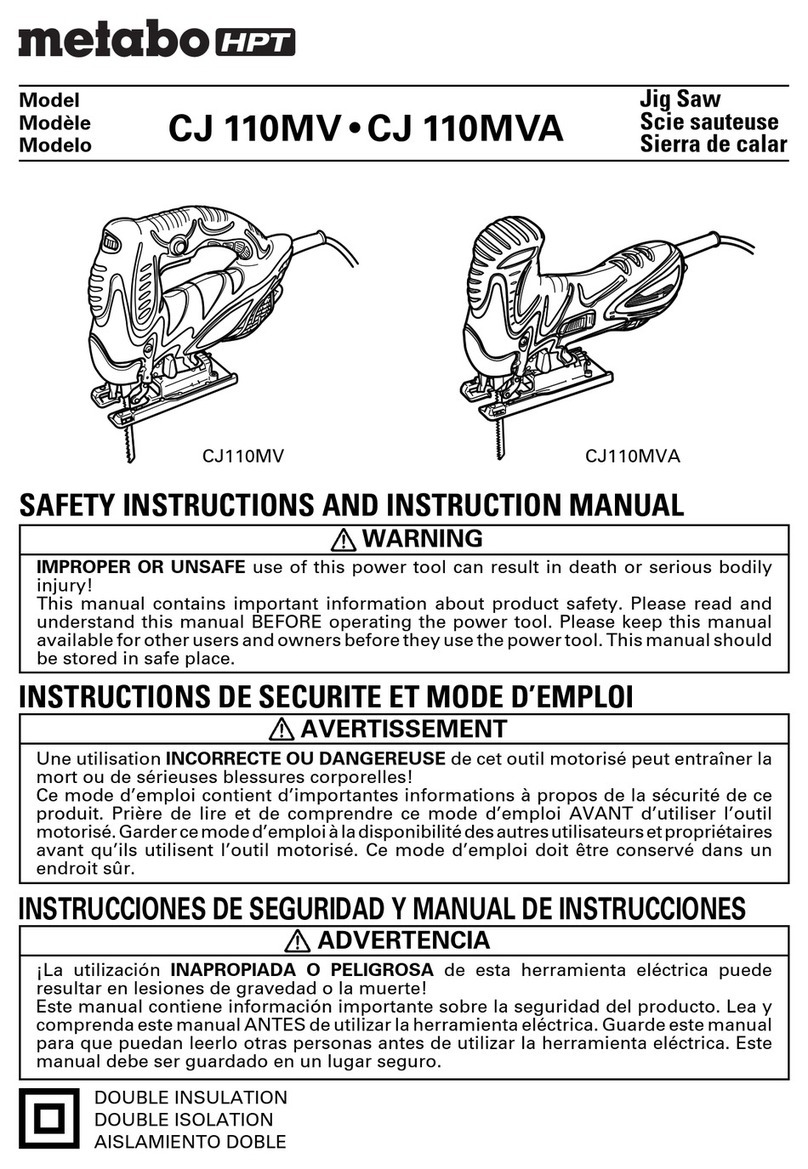

INSTRUCTION MANUAL

WARNING!

TO REDUCE THE RISK OF INJURY, USER MUST READ

AND

UNDERSTAND THIS INSTRUCTION MANUAL.

ORIGINAL

INSTRUCTIONS

Date

of

purchase: ....................................

SSM-2 PRO manual.en ©

05/2015

SSM

ProduktAB

SSM-2 PRO skate

sharpening

machine

Congratulations

on

your

purchase

of

a SSM-2

PRO

skate

sharpening

machine.

We

sincerely

thank

you

for

selecting

a

product

from

SSM

Produkt

AB.

To

obtain

an

additional

copy

of

this

manual, please

contact

SSM

at:

TABLE

OF

CONTENTS

SSM

PRODUKT

AB

Vaksala-Eke

SE-755 94 Uppsala, Sweden

Tel: +46 (0)18 500840

E-mail: [email protected]

Internet:

www.ssmprodukt.com

Limited Warranty.......................................................................

...

...............

..

..

...............

..

...........2

General Safety Rules.....

....

...............

..

...............

..

..

...............

..

.................

..

.................

..

............3-4

Specific Safety Rules and Symbols.......

..

...............

...

.................................................................5

Functional Description.

..

.................

..

...............

..

..

...............

..

...............

....

...............

..

.................6-7

Assembly

...

...................

...

...............

..

..

...............

..

...............

...

................

...

.................................. 8

Operation.........

..

...............

....

...............

..

.................

..

.................

..

.................

..

...............

....

......

9-11

Maintenance..................................

...

...............

..

..

...............

..

...............

...

.................................12-13

Technical Specifications and Dimensions.....

..

.................

..

.................

..

.................

..

...............

..

.13

Accessories................................................................

...

...............

..

...............

..

..

...............

...

....14-15

LIMITED WARRANTY

Scope

of

warranty

This warranty covers any defects

in

materials and workmanship under normal use.

Period

of

coverage

This warranty runs for two (2) years from the date

of

purchase. Please save your receipt or invoice.

Limitations

Failures due to abuse, misuse or

an

event or effect that cannot

be

reasonably anticipated or controlled (such as

flood, earthquake, act

of

God etc.) are not covered by this warranty. Surface coating problems caused by excessive

humidity, in-use scratches or abrasions, and direct exposure to the elements are also not covered.

Repair or replacement is the only option available under this warranty. SSM Produkt

AB

(SSM)

is

not responsible

for damages

of

any kind, including incidental and consequential damages.

Incidental damages include but are not limited to such damages as loss of time and loss of use. Consequential

damages include but are not limited to the cost

of

repairing or replacing property that was damaged ifthe product

from SSM does not work properly.

Correction

of

details

If your product cannot

be

repaired, we will replace your product free of charge.

How

to

get

service

Please return the defective product together with the purchase receipt or the invoice.

You

can obtain service by

contacting a dealer of SSM products or SSM directly. At our discretion, the dealer or SSM will either repair or replace

your product.

How

country

and state laws relates

to

the

warranty

This warranty gives you specific legal rights.

You

may also have other rights that vary from country to country and

from state to state.

SSM

PRODUKT

AB

RESERVES THE RIGHT TO

MAKE

IMPROVEMENTS

AND

MODIFICATIONS TO DESIGN

WITHOUT

PRIOR NOTICE.

SSM

PRODUKT

AB

VAKSALA-EKE,

SE-75594,

UPPSALA,

SWEDEN

GENERAL SAFETY RULES

IAI

WARNING!

When using electric tools basic safety precautions should always

be

followed to

reduce the risk of fire, electric shock and personal injury including the following.

Read all these instructions before attempting to operate this product and save these instructions.

Safe Operation

Keep your work area clear.

-Cluttered areas and benches invite injuries.

Consider work area environment.

-

Do

not expose tools to rain.

-

Do

not use tools

in

damp or wet locations.

-Keep work area well lit.

-

Do

not use tools

in

the presence

of

flammable liquids or gases.

Guard against electric shock.

-Avoid body contact with earthed or grounded surfaces (i.e. pipes, radiators, ranges, refrigerators).

Keep otherpersons away.

-

Do

not let persons, especially children, not involved

in

the work touch the tool or the extension cord and keep them

away from the work area.

Store idle tools.

-When not

in

use, tools should be stored

in

a dry locked-up place, out

of

reach

of

children.

00

not force the tool.

-It will do the job better and safer at the rate for which it was intended.

Use the right tool.

-

Do

not force small tools to do the job of a heavy duty tool.

-

Do

not use tools for purposes not intended; for example do not use circular saws to cut tree limbs or logs.

Dress properly.

-

Do

not wear loose clothing or jewelry; they can be caught

in

moving parts.

-Non-skid footwear

is

recommended when working outdoors.

-Wear protective hair covering to contain long hair.

Use protective equipment.

-Use safety glasses and hearing protection.

-Use face or dust mask ifworking operations create dust.

Connect dust extraction equipment.

-If the tool

is

provided for the connection of dust extraction and collecting equipment, ensure these are connected and

properly used.

00

not abuse the cord.

-Never yank the cord to disconnect

it

from the socket. Keep the cord away from heat, oil and sharp edges.

Secure work.

-Where possible use clamps or a vice to hold the work. It

is

safer than using your hand.

00

not overreach.

-Keep proper footing and balance at all times.

GENERAL SAFETY RULES (continued)

Maintain tools with care.

-Keep cutting tools sharp and clean for better and safer performance.

-Follow instruction for lubricating and changing accessories.

-Inspect tool cords periodically and ifdamaged have them repaired by

an

authorized service facility.

-Inspect extension cords periodically and replace if damaged.

-Keep handles dry, clean and free from oil and grease.

Disconnect tools.

-When not

in

use, before servicing and when changing accessories such as blades, bits and cutters, disconnect tools

from the power supply.

Remove adjusting keys and wrenches.

-Form the habit of checking to see that keys and adjusting wrenches are removed from the tool before turning

it

on.

Avoid unintentional starting.

-Ensure switch

is

in

"off' position when plugging

in

.

Use outdoor extension leads.

-When the tool

is

used outdoors, use only extension cords intended for outdoor use and so marked.

Stay alert.

-Watch what you are doing, use common sense and do not operate the tool when you are tired.

Check damaged parts.

-Before further use of tool,

it

should be carefully checked to determine that it will operate properly and perform its

intended function.

-Check for alignment of moving parts, binding of moving parts, breakage

of

parts, mounting and any other conditions

that may affect its operation.

- A guard or other part that

is

damaged should

be

properly repaired or replaced by

an

authorized service center unless

otherwise indicated

in

this instruction manual.

-Have defective switches replaced by

an

authorized service center.

-Do not use the tool ifthe switch does not turn it

on

and off.

Warning.

-The use

of

any accessory or attachment or performance of any operation with this tool other than those recommended

in

this instruction manual may present a risk

of

personal injury.

Have your tool repaired

by

a qualified person.

-This electric tool complies with the relevant safety rules. Repairs should only be carried out by qualified persons using

original spare parts; otherwise this may result

in

considerable danger to the user.

Noise

-The typical A-weighted noise levels determined according to

EN

61029-1 :2009 :

Sound pressure level

(L

pA

) : 80 dB

Sound power level

(L

WA

):

93 dB

Uncertainty (K): 2,5 dB

EC-DECLARATION OF CONFORMITY

We, SSM PRODUKT AB, Vaksala-Eke, SE-755

94

, Uppsala, Sweden declare that the product SSM-2 to which this

declaration relates

is

in

conformity with the following standards:

EN

61029-1 :2009

EN

55014-1 :2006

EN

61000-3-2:2006

EN

61000-3-3:2008

EN

55014-2:1997+A1:2001+A2:2008 Uppsala, November

21,2014

Stefan Gustavsson

(place, date) (signature, name)

following the provisions of 2004/1 08/EC, 2006/42/EC and 2006/95/EC directives.

SPECIFIC SAFETY RULES AND SYMBOLS

WARNING! READ OPERATOR'S

MANUAL BEFORE USING

THE MACHINE

The machine must be used only for the purpose

of

grinding skate blades.

EYE AND HEARING

PROTECTION REQUIRED

Always fasten the skate in the skate holder. NEVER hold skate being sharpened only by your hands.

It

is important

to

support the work properly

to

get the best result possible, minimize body exposure and loss

of

control.

Check grinding wheel protective cover for proper fit before using the machine to minimize the risk

of

flying debris.

Keep hands and body away from the rotating grinding wheel.

Contact with a rotating grinding wheel

or

parts from an exploding grinding wheel can result

in

serious injury.

Only use grinding wheels approved by SSM Produkt AB. Use grinding wheels with correct size and shape.

Unauthorized grinding wheels may be dangerous!

Keep grinding wheel securely fastened.

When fastening grinding wheel, never use damaged or incorrect flange, flange washer or nut.

The flange and flange washer were specially designed for the machine, for optimum performance and safety

of

operation.

Safety Warnings Specific for Grinding:

Use only wheel types that are recommended for your power tool and the specific guard designed for the

selected wheel. Wheels for which the power tool was not designed cannot be adequatelyguarded and are unsafe.

The guard must be securely attached to the power tool and positioned for maximum safety, so the least amount

of

wheel is exposed towards the operator.

The guard helps

to

protect operator from broken wheel fragments and accidental contact with wheel.

Wheels must be used only for recommended applications. For example: do not grind with the side

of

cut-off

wheel. Abrasive cut-offwheels are intended for peripheral grinding, side forces applied

to

these wheels may cause

them

to

shatter.

Always use undamaged wheel flanges that are

of

correct size and shape for your selected wheel.

Proper wheel flanges support the wheel thus reducing the possibility

of

wheel breakage. Flanges for cut-offwheels

may be different from grinding wheel flanges.

Do not use worn down wheels from larger power tools.

Wheel intended for larger power tool

is

not suitable for the higherspeed

of

a smaller tool and may burst.

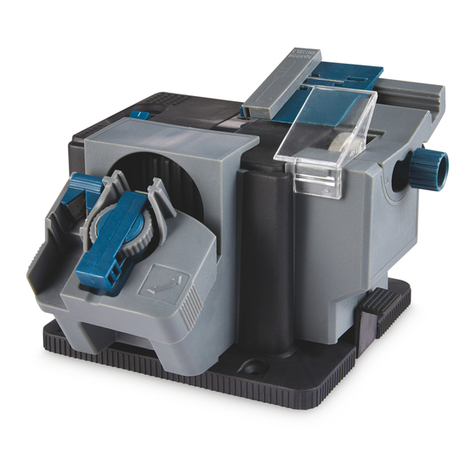

FUNCTIONAL DESCRIPTION

1.

Hole

for

fastening

the

machine

2a. Guide arm

2b. Where

to

put

the

skate

holder

3.

Extractor

tube

4a. Blade

support

device

4b. Scale wheel

for

adjusting

roller

5.

Power

switch

6.

Grinding

wheel

7.

Protective

cover

8a.

Pivot

device

8b. Diamond

for

hollow

shape

8c. Ruler

8d.

Adjusting

screw

9a. Flat

surface

device

9b. Diamond

for

plane shape

FUNCTIONAL DESCRIPTION (continued)

The machine

is

intended to do the finishing sharpening

on

skate blades (flat or hollow).

This

is

done by manually moving the skate blade (mounted

in

a holder) against a suitably dressed, rotating grinding

wheel. The open construction of the machine allows for a constant and easy supervision of the sharpening process.

The machine

is

built around a modified electric grinding machine with a guide arm attached to

it.

The electric motor

is

attached to a bottom plate. It

is

intended that the bottom plate should

be

kept horizontal. The axle of the electric

mo

tor will then

be

vertical.

On

the axle the following items are mounted

in

this order: a flange, a grinding wheel,

a flange washer, a balancing ring and a fastening nut. This

is

all partially covered by a protective cover.

1.

The Hole

for

fastening the machine can be used to attach the machine to the surface where it's placed.

Use a screw to attach it if necessary.

2a. The Guide arm

is

a flexible, horizontal arm which directs the skate holder.

2b.

You

put a skate holder

in

the plastic bushing

on

the front arm. Fasten your skate

in

that skate holder.

3.

The Extractor tube

is

intended to collect sparks and other debris created when grinding and dressing.

Fasten

it

onto the bottom plate with the wing nut

in

the angle you prefer; then attach a suitable dust extracto

r.

4a. The Blade support device

is

used to get the hollowness

on

your skate centered by controlling the vertical position

of the skate holder. When sharpening a skate hollow, put the skate blade

on

top

of

the roller.

4b. The Scale wheel ranges from 2.5 to 4.2

mm;

turn it to the skate blade thickness to get hollowness exactly centered.

5.

The Power switch

is

used to turn the machine

on

and off.

6.

The Grinding wheel rotates counter clockwise and

is

used to sharpen the skate blade.

Use grinding wheel S-2/HP70, S-2/ME60,

S-2/KBSO,

S-2/KB60 or S-2/60.

7.

The Protective cover

is

a guard that protects if a grinding wheel would break. It also prevents sparks from

spreading. The protective cover

is

fastened by three top nuts.

Sa.

The Pivot device

is

used with a diamond to dress the grinding wheel for hollow sharpening.

Use the nut to fasten the diamond.

Sb.

Use diamond

O-SO

or

SO-SO

.

Sc.

The Ruler (scale

in

mm/inch.)

is

used when measuring

on

the pivot device. Measure from the head of the

diamond to the pivot; the distance gives the hollowness obtained

on

your skate. See "AOJUSTMENTS".

Sd.

The Adjusting screw

is

used to move the pivot device inwards or outwards.

This

is

done by screwing

it

clockwise (outwards) or counter clockwise (inwards).

Scale 2

:1

GRINDING

WHEEL)

L-

__

-.--

__

--'

Dressed

by

pivot device.

Scale

1:1

Hollowness 13 mm

(Oeep Hollowness)

Skate

Blade

Hollowness

20

mm

(Shallow Hollowness)

9a. The Flat surface device

is

used with a diamond to dress the grinding wheel for flat sharpening.

9b. Use diamond SO-50,

SO-SO

or

O-SO.

Scale 2

:1

GRINOING WHEEL

Dressed

by

flat surface device.

ASSEMBLY

Your skate sharpening machine SSM-2 PRO

is

delivered complete (and the skate holder that you

ordered with the machine) and protected inside its delivery box. Remove all contents from the box

and inspect to ensure no damage was incurred during shipping.

Your SSM-2 PRO package should also include the following:

DESCRIPTION PART #QTY

Instruction manual

Exhaust tube

Allen screw driver

Allen screw driver

Double ended wrench

Skate holder

Getting

started:

SSM-2 PRO manual.en

UT

AS

2.5

mm

AS4mm

DEW 8,10

mm

H-5, H-8, H-10, H-10 S or H-10 P

I

A.

ICAUTION!

(the one you ordered)

IF

POSSIBLE, ALWAYS DISCONNECT THE SKATE SHARPENING

MACHINE FROM THE POWER SOURCE BEFORE MAKING ADJUSTMENTS.

Place the machine on a stable, level surface.

You

can fasten the machine with a screw through the hole (1)

in

the bottom plate.

The machine comes with a grinding wheel mounted and balanced.

Refer to MAINTENANCE:

HOW

TO CHANGE AND BALANCE THE GRINDING WHEEL (on page

12)

if

you want to replace or balance the grinding wheel.

The grinding wheel and the diamond are adjusted for a hollow radius

of

20 mm when delivered

from SSM Produkt AB. Refer to OPERATION:ADJUSTMENTS (on page 9) when you want to

change the radius.

MAKE SURE THAT NO DIAMOND IS TOUCHING THE GRINDING WHEEL WHEN YOU START

THE MACHINE. If necessary, reposition the diamonds outwards. For diamond (9b),screw it

directly. For diamond (8b), screw on the adjusting screw (8d).

MAKE SURE THAT THE BLADE SUPPORT DEVICE

IS

NOT TOUCHING THE GRINDING

WHEEL WHEN YOU START THE MACHINE. Follow the instructions under OPERATION:

ADJUSTMENTS (on page 9) to reposition the blade support device if necessary.

Mount the extractor tube (3) and attach a proper dust extractor. This will reduce the amount

of

sparks and debris. For more complete protection, wear a suitable face mask covering mouth and

nose.

Make sure you wear protection glasses and hearing protection when you use the machine.

OPERATION

ADJUSTMENTS before sharpening

Balancing grinding wheel

If necessary, exchange the grinding wheel.

Balance

it

if needed. (See MAINTENANCE: HOW TO

CHANGE AND BALANCE THE GRINDING WHEEL.)

Adjusting location of the blade support device

If necessary, adjust the position of the blade support

device (4a). It should

be

as close to the grinding

wheel as possible without touching

it.

Therefore, as the grinding wheel gets smaller with

time after repeated dressing (or gets bigger through

exchange to a new wheel) you have to reposition

the roller.

To

do this, first loosen the nut

(M)

on

the

right side

of

the roller's holder. (Avoid the nut

on

the

left side.)

You

can now move the roller's holder by

pushing or gently tapping

on

it.

When

in

a good

position, fasten the nut again. (Make sure that the

roller doesn't touch the grinding wheel.)

Adjusting the height

of

the blade support device

When sharpening hollow, you must make sure that the hollowness will

be

centered

in

the skate blade.

An

adjustment

will

be

necessary if the thickness

of

the skate blade has changed. Turn the scale wheel (4b) to the same number as

your skate blade thickness (4b shows a setting

of

2.B

mm).

Dressing the grinding wheel

To

dress for hollowness, use diamond

(Bb)

in

the pivot device

(Ba)

.

You

adjust the hollowness by screwing the

diamond

in

or out until you reach the correct position.

You

use the ruler

(Be)

to measure from inside the head of the

diamond screw (must

be

a

0-80

or a SD-80) to the pivot device (see Fig.A). The usable limits are 8 to

38

mm.

Secure the diamond

in

place by tightening the nut

on

the diamond screw.

As you dress the grinding wheel, it

is

consumed and gets smaller. Use the adjusting screw

(Bd)

to move the whole

assembly with the pivot device. Move

in

small amounts, at the same time turning the pivot device

up

and down until a

few times when dressing occurs. The dressing should

be

performed gently, so as not to damage diamond or grinding

wheel.

To

dress flat, use diamond (9b). Screw the diamond inwards

in

small amounts, at the same time turning the flat

surface device (9a), so that its diamond moves

up

and down past the grinding wheel. The last few movements should

give dressing. Dress gently.

Here the hollowness

is

set

at

25

mm.

OPERATION (continued)

HOW TO CHECK

IF

THE HOLLOWNESS

IS

CENTERED

It

is

important that you get the hollowness centered

on

the blade. With the SRK PRO blade support device the

hollowness will always

be

centered if you turn it to the same number

as

the skate blade width.

However, if something would malfunction you can check the centering by dressing the grinding wheel

properly, then put the skate

in

the holder with e.g. the front part to the left. Move the blade a few times forwards and

backwards

in

contact with the rotating grinding wheel. Remove the skate and put

it

back

in

the holder with the front

part to the right (the blade

is

now upside down). Slightly let the blade touch the grinding wheel to get a small

grinding mark (witness mark). If the mark fits into the hollow

(mark

C), then the SRK PRO

is

correctly adjusted. If the

mark covers the lower part

of

the blade

(mark

L1

or

L2), the supporting roller

is

too high. If the mark covers the upper

part

(mark

R1

or

R2) the supporting roller is too

low.

If SRK PRO needs

to

be

adjusted, check the separate SRK PRO

instruction paper how its done.

Another easy way of checking if the sharpening

is

centered

is

to

use the BEC, Blade Edge

Checker

(check the

separate BEC instruction paper how its done).

HOW TO ADJUST THE FLAT SURFACE DEVICE

The flat surface device comes with correct

setting from the factory. If necessary,

it

can

be

adjusted by loosening the lock screw and

correcting the angle using the adjustment

screw.

You obtain the correct angle as follows:

Dress the grinding wheel. Sharpen a skate,

then turn

it

in

the holder and let the blade

touch the grinding wheel to make a small

witness mark.

Compare to HOW TO CHECK

IF

THE

HOLLOWNESS

IS

CENTERED above.

If

you

get a mark that

is

not perfect, then

the angle

is

wrong. Adjust and try again.

(You

can also use the BEC here for

checking if the angle is correct.)

OPERATION (continued)

SHARPENING THE SKATE (advice)

Dress grinding wheel

Connect the machine to the power source and start it (using the powerswitch 5). Use the diamond (8b or 9b) to dress

the grinding wheel

so

that it will give the desired shape to the blade (flat or with desired hollowness).

If the grinding wheel feels blunt, you should dress it even if the shape does not have

to

be changed.

Hollow sharpening: Ice hockey skates and Figure skates

Correct any damage

on

the skate blade

Check the skate blade for damage. If massive damage is found,

use a whetstone to get the blade even

on

the sides.

Then fasten the skate

in

the skate holder.

Sharpen it at least twice with constant pressure applied

against the grinding wheel, see figure: p

When sharpening, keep the skate blade directed along a

straight line (PQ

in

the figure). Move the blade forwards and

backwards

in

the same direction as the arrows indicate.

Flat sharpening: Bandy skates and Touring skates

x

The two "X" points

in

the figure marks where the blade starts

to

turn away from the

Q

grinding wheel. Start the sharpening movement

"in

the air" outside an X-point. Then make a smooth contact with the

grinding wheel.

At

the otherX-point the skate will turn away from the grinding wheel. Continue the movement a bit

without having contact with the grinding wheel but the skate blade still on the support roller, before turning back and

doing the movement

in

the otherdirection.

Check for any remaining damage. If damage is found, repeat the sharpening until all damage or wear is gone.

Final sharpening

When no damage remains

on

the skate blade, sharpen the whole blade including the round ends slowly and smoothly.

Use light pressure to get a better micro finish and to avoid removing too much material from the round edges. Perform

the movement as shown below

in

one continuous sequence A+B+C or C+B+A. Remember to keep the B movement

straight.

A

Finish

Use a flat whetstone approximately twice

on

each side of the blade to remove any abrasive wounds.

ATTENTION!

When sharpening hollow, make sure that the skate blade always has contact with the blade support roller (4a).

00

not move the skate too slowly against the grinding wheel and do not apply too much pressure against

it.

The

skate blade may be "burnt" because too much heat

is

generated locally!

When sharpening, keep your hands on the skate and not on the skate holder.

00

not let the skate carry too

much weight

of

yourhands. Otherwise the skate blade will tilt from the horizontal plane.

MAINTENANCE

HOW TO CHANGE AND BALANCE THE GRINDING WHEEL

A

1 4 1. Grinding wheel

2. Flange washer

2 3. Balancing ring (eccentric ring)

4. Mark point on balancing ring

5. Nut

3 5

B C D E

1. First test the grinding wheel for cracks. Hold the wheel

on

a finger (through the center hole) and gently tap

on

it.

By listening

to

the sound you can check whether the wheel contains cracks.

Remove the protective cover, the nut, the balancing ring , the flange washer and the

old

grinding wheel.

(To

avoid wobbling of the grinding wheel, remember to thoroughly clean flange, flange washer and grinding wheel

mounting surface before mounting.)

Then put the new grinding wheel

on

top of the flange. Put the flange washer and then the balancing ring

on

top

(in

the neutral position, i.e. centered with the mark point

in

the

12

o'clock direction).

Fasten the nut with the grinding wheel having some selected mark (selected by you)

in

the 12 o'clock direction.

Start the engine and dress the grinding wheel with one of the diamonds.

Don't forget to have the protective cover on! If the grinding wheel vibrates, adjust using the following scheme.

(The grinding wheel will impart vibrations to the whole machine. They are most easily felt at the end of the guide

arm at the skate holder.)

2. Stop the engine and direct the grinding wheel

in

the 12 o'clock direction. Loosen the nut and move the balancing

ring somewhat

in

the 6 o'clock direction (i.e.

an

eccentric position).

Fasten the nut and restart the engine. Remember how much the grinding wheel vibrates (Fig.

B).

3. Do as

in

step 2, but with the mark point

in

the 9 o'clock, 6 o'clock and 3 o'clock directions.

The amount of eccentricity of the balancing ring should

be

kept the same (Figs.

C,

0, E).

4.

If there are fewer vibrations

in

some direction, turn the balancing ring

so

that its mark point has that direction.

If two directions give fewer vibrations than the others, put the mark point direction between the two.

Then fasten the grinding wheel with the balancing ring adjusted. Start the engine and dress the grinding wheel.

If the grinding wheel still vibrates, make a precision adjustment.

5.

If a precision adjustment

is

needed, move the balancing ring

in

small amounts to be more centered or more

eccentric or change the direction of its mark point slightly. Start the engine, dress the grinding wheel and test

if the vibrations lessen. This

is

an

iterative procedure.

It

should

be

possible to adjust until the vibrations practically disappear.

MAINTENANCE (continued)

SERVICE

If the machine is used correctly and only for sharpening skates then service is seldom needed. However, the grinding

wheel and diamonds should regularly be replaced. The grinding wheel should be replaced when the distance between

its outer diameter and the front edge of the protective cover has decreased to approximately 10 mm. (When the

diameter

of

the grinding wheel goes below 120 mm, the grinding wheel should be replaced

to

give a good result.)

To

retain the capacity of the machine and to continue to get a good result, always keep the machine clean.

Clean the outside. Remove dust with a soft brush if needed.

WARNING! A complete service should always be performed by a qualified technician. When performing maintenance

yourself (e.g. replacing grinding wheel or diamonds) ensure that the electric plug is disconnected.

To

avoid danger,

work

on

electrical parts should always be done by a qualified technician.

For power tools with type Y attachment: if the replacement of the supply cord is necessary, this has

to

be done by the

manufacturer or his agent

in

order

to

avoid a safety hazard.

TECHNICAL SPECIFICATIONS AND DIMENSIONS

HEIGHT (without holder and extractor tube): 320

mm

WIDTH (without holder and extractor tube): 250

mm

LENGTH (without holder and extractor tube): 350

mm

WEIGHT (without holder and extractor tube): 14.8

kg

POWER:

250W

VOLTAGE: 220-240 V

FREQUENCY: a.c. (1-phase) 50-60 Hz

MAXIMUM RPM: 2800-3400 RPM

GRINDING WHEEL TYPE:

GRINDING WHEEL DIMENSIONS:

(Diameter * Thickness * Arbor)

DIAMOND:

Type 5-2 from SSM

150 * 6 * 38

mm

For flat sharpening: SO-50,

50-80

or 0-80

For hollow sharpening:

50-80

or 0-80

THE MACHINE

IS

INTENDED FOR INTERMITTENT USAGE (on 60s I off 60s).

It

is

also available

in

a

c

~u

s

approved

110-120 V version.

Intertek

Your SSM Produkt AB distributor:

ACCESSORIES

--------------------------------------- G

RI

N

DIN

G WHEELS ---------------------------------------

5-2/60

Pink

Grit size 60

Standard wheel

S-2/HP70

Yellow

Grit size 70: special

For professional teams

S-2/ME60

Pink/purple

Grit size 60: ceramic

Excellent

on

all steels

S-2/KSO

Light blue

Grit size 80: ceramic

For professional teams

-------------------------------------- DIAMOND DRESSE

RS

--------------------------------------

o-SO

Natural diamond

For:

Pivot device &

Flat surface device

so-so

Synthetic diamond

For:

Pivot device &

Flat surface device

SO-50

Synthetic diamond

For:

Flat surface device

------------------------------ WHETSTONES OR HAND HONES ------------------------------

B-SSM

From silicon carbide

One fine grit size

Size: 75x18x10 mm

BB-SSM

From silicon carbide

Same mixture as 8-SSM

Size: 75x25x10 mm

CB-SSM

From aluminum oxide

Two different grit sizes

Size: 75x18x10 mm

OB-SSM

Diamond hand hone

Precision tool

Handle with care!

Size: 75x25x5.5 mm

---------------------------------------

E>CHAlJST

S~STEMS

---------------------------------------

U-S40

Welding fume exhaust

Very high quality

_

®®

til,

Uses the U-324 filter

(

14

))

~

NQS500

Dust extractor

Very powerful and quiet motor

Uses a cyclone intake

ACCESSORIES

---------------------------------------------

E:CllJIJlnnE:~lr

---------------------------------------------

V-2

Transport case for SSM-2

Size: 420x330x360 mm

Very durable to thrusts

BEC

Blade Edge Checker:

Controls that a sharpening is

centered

on

the skate blade.

SKR

Blade Straightener:

Used to straighten a

bent skate blade.

-----------------------------------------

~~lrE:

~()L.[)E:Ft~

-----------------------------------------

H-5

Original skate holder

For:

Ice hockey and Bandy

(not small childrens skates)

Universal s

For:

All skates (except some figure

skates and large goalie skates)

H-7

Goalie skate holder

For:

All goalie skates

Figure skates and special ones

like Matrix and Paramount)

H-8

Universal skate holder

For:

All skates (except some figure

skates and

tour

skates)

H-10 P

Figure skate h

For:

Figure skates and special ones

like revolution, parabolic, tapered

,

®S}ill

,

(

15

))

~