Dimac R30 User manual

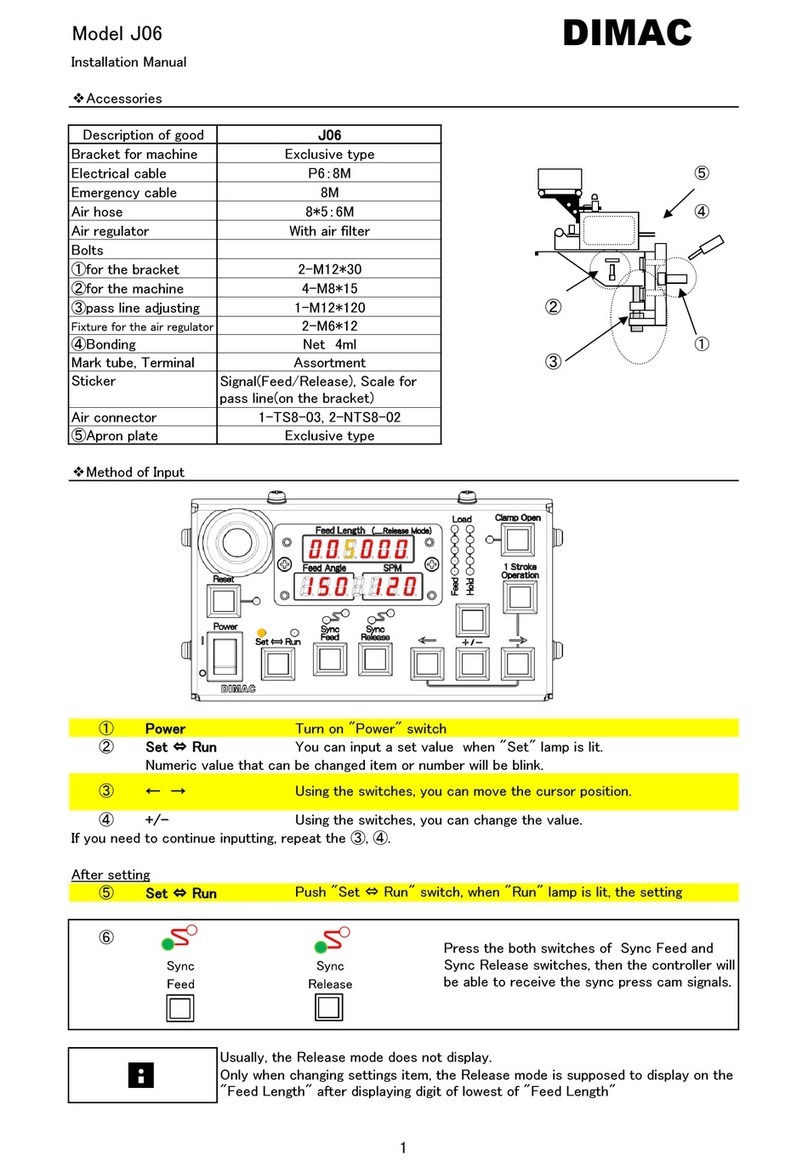

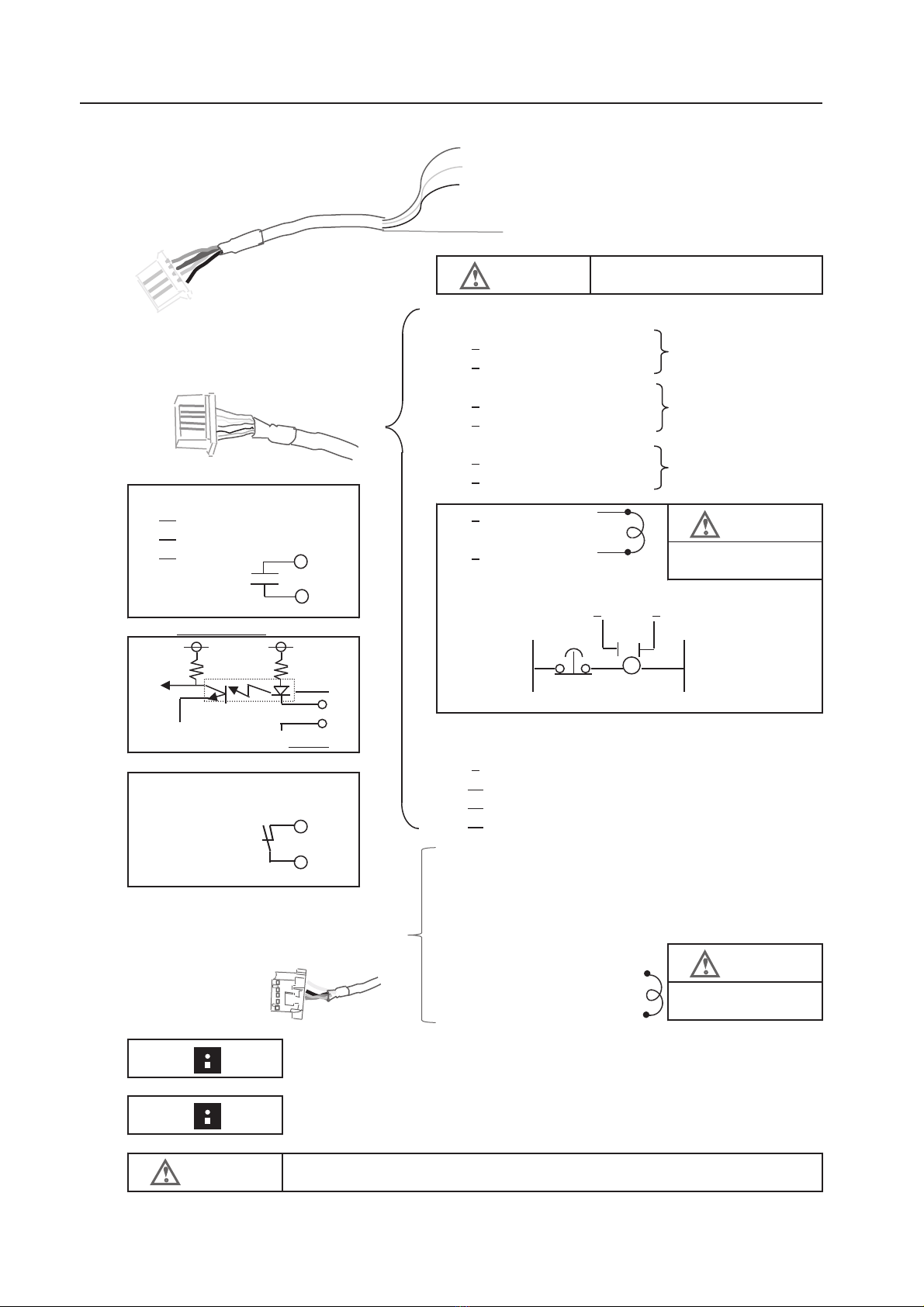

❖Accessories of Installation

Bracket for machine

Electrical cable ⑤

Emergency cable

Air hose ④

Air regulator

Bolts

①for the bracket

②for the machine

③pass line adjusting ②

④Bonding ①

Mark tube, Terminal ③

Sticker

Air connector

⑤Apron plate

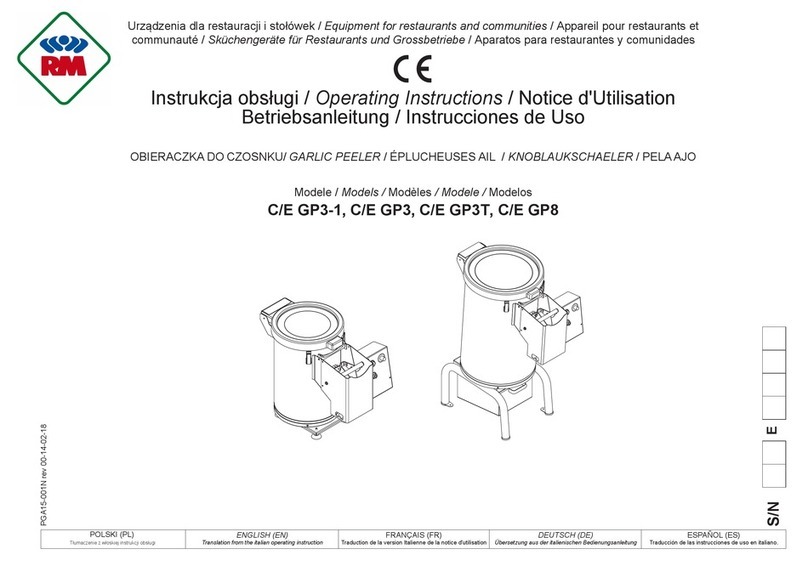

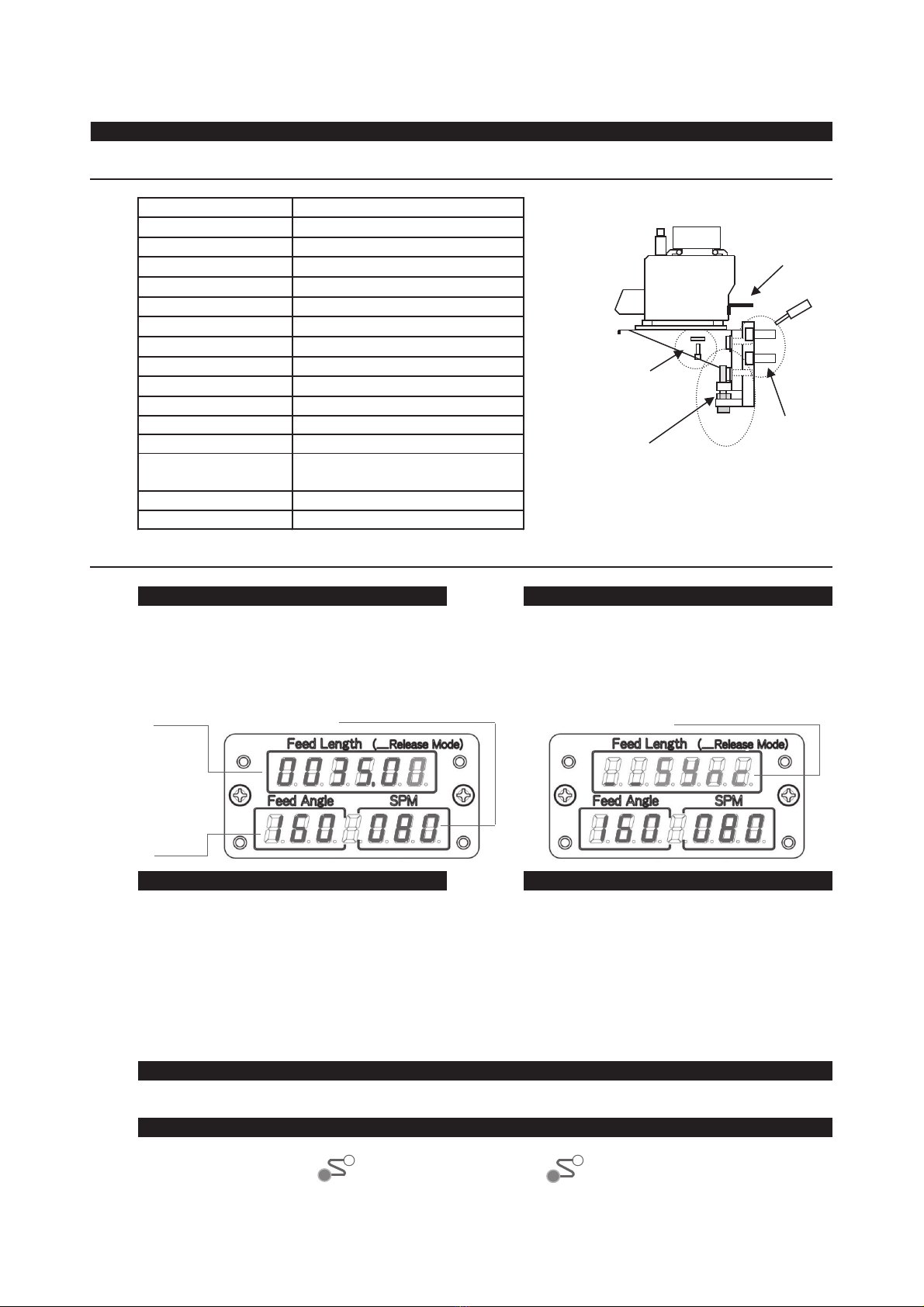

❖Setting Items

Feed Length, Feed Angle, SPM Release Mode

Changeable main screen in "Set" state.

Feed length Release Mode

Setting method of table screen Setting method of "Release Mode"

①Power ①Power

② ← → Setting items can be changed.

③ + / - The value can be Changed.

③ + / - The value can be Changed.

After setting

Synchronous operation

Model

R30 R40 R50

Installation Manual

To display "Release Mode", push on "Sync

Release" switch in "Set" state.

Turn ON "Power switch"

"Release Mode" is not displayed in "Set" state.

Exclusive type

Feed

Angle

R30, R40, R50

Exclusive type

P6:8M

8M

2-M6*12

4-M14*30

8*5:6M

With air filter

Numeric value that can be changed item or

number will be blink.

② First, push on "Sync Release" switch, keep

it.

When "Sync Release" is turned off, the

display returns the main screen.

Press rotation speed

DIMAC

Net 4ml

4-M8*25

1-M12*120

1-3/8B, 2-2/8B

Numeric value that can be changed item or

number will be blink.

If you need to continue inputting, repeat

②,③.

Turn ON "Power switch"

Assortment

Signal(Feed/Release), Scale for

pass line (on the plate)

Description of good

Fixture for the air regulator

⑤

Sync Feed

Sync Release

Press the both switches of Sync-

Feed, -Release switches, then the

feeder will be able to operate

automatically.

④

Set ⇔ Run

Push "Set ⇔ Run" switch, when "Run" lamp is lit, the setting

finishes.

1

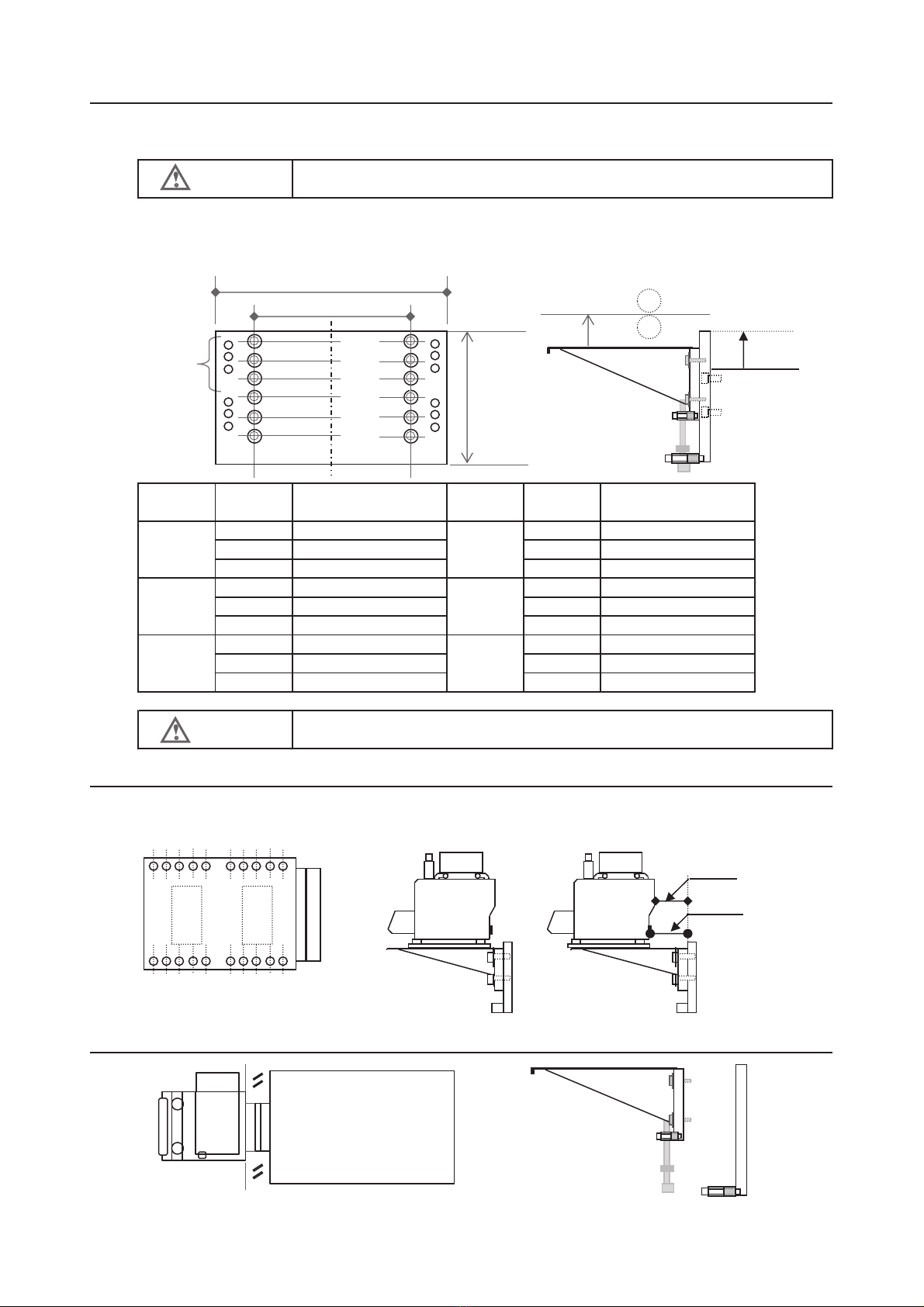

❖R30, R40, R50 Pass line

The pass line height is decided by combination a plate and a holder.

It is necessary to tighten 4 points with a bolt to fix the holder on the plate.

The plate has 4 bolts. The plate thickness: 22mm

Plate Holder

From top 20

A,B,C 30

30

30 250

30

30

Plate Hole Plate Hole

height position height position

A A

B B

C C

A A

B B

C C

A A

B B

C C

❖Mounting position

Main machine-Mounting position: 5

5 4 3 2 1 5 4 3 2 1 Using No.1 Using No.5

85

117

5 4 3 2 1 5 4 3 2 1

❖Confirmation of balance ❖Assembly drawing of the bracket

210~265

190~245

260~315

220~275

240~295

h=0

h=30

h=60

h=90

h=120

h=150

130~185

170~225

150~205

140~195

110~165

120~175

100~155

90~145

70~125

Bolster

h(mm)

95

CAUTION

The plate-center equals the feeding rolls -center.

Bolster

Pass line (mm)

Pass line (mm)

350

200

200~255

180~235

160~215

CAUTION

In case of the pass line over 285mm, Need to add processing holes for fixing bolts.

230~285

2

❖Wiring

Red R(200V 50/60Hz)

PC-A Power cable White S(200V 50/60Hz)

0.75mm2Black T(200V 50/60Hz)

Not wiring when single phase

Green/Yellow E(Earth)

1

PC-B Signal cable 2

0.5mm2Option

3

4

5

6

Wire #

1:2 1A at AC 250V or less 7

3:4 1A at DC 30V or less

5:6 8 24V GND

Example for circuit

78

Wire # 7:8 9:10 11:12 S5:S6 0V EMG 100V

5V 24V

R

CPU

7,9,11 ,S5

5V GND

8,10,12, S6

9 Feed input

Wire # 1A at AC 250V or less 10 24V GND

S1:S2 1A at DC 30V or less 11 Release input

S3:S4 12 24V GND

S1

S2

S3

PC-C S4

0.5mm2

S5

S6 Blown:24V GND

White:Emergency stop

To Emergency stop circuit

Emergency and press

processing select

Need to short the circuit of press processing select(S5, S6), if you don't use the

circuit.

DANGER

To cover each cable which is not using connection.

Green:Emergency stop

To Emergency stop circuit

Black:Emergency stop

Red:Emergency stop

Need to wire the release signal, Otherwise Not available in continuous feeding

because of checking the movement of the press using two cam signals.

CAUTION

Yellow:Press cont.

processing

Need to short, if not

using.

You can select which 3 phase or single phase. If it's single phase, you don't have to connect the black wire.

Press cam signal

DANGER

Connect to the primary side

Drive stop signal output

To the stop continuous

on the press circuit

Work shortage sensor

output

Input stop

of Feeder

Press cam signal

CAUTION

To the stop continuous

on the press circuit

Continuous stop signal

output

To the stop continuous

on the press circuit

Need to short, if not

using.

3

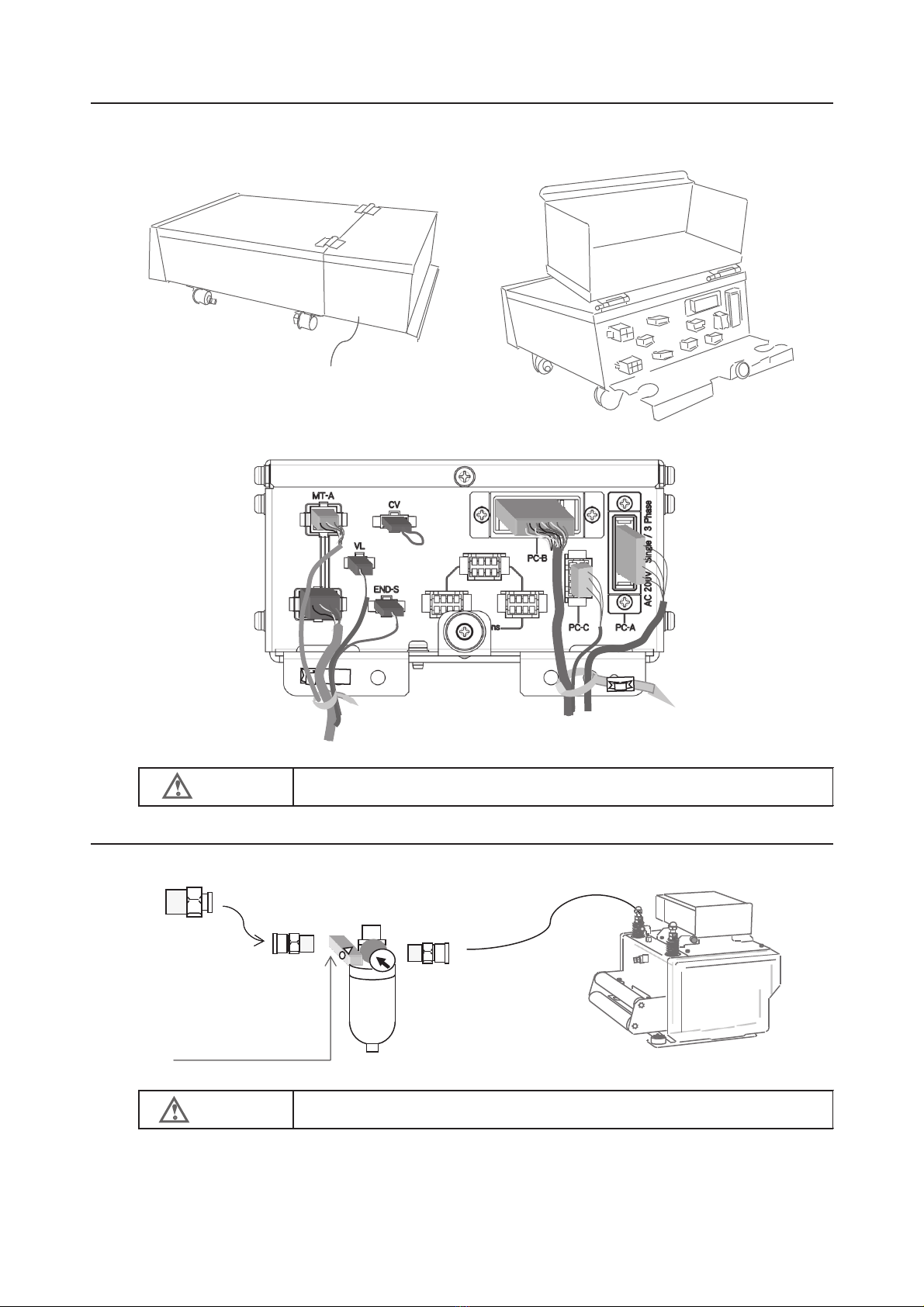

❖Cable connecting

The receptacles of PC-A, PC-B, PC-C are placed inside the connecting cover.

Connecting cover

❖Air piping

3/8B To Air connector

2/8B

*Approximate air pressure : 0.3~0.5 MPa

*Maximum air pressure: 0.5 MPa

CAUTION

2/8B

DANGER

Need to fix three external cables in prepared nylon band.

Air passes in specific

direction

4

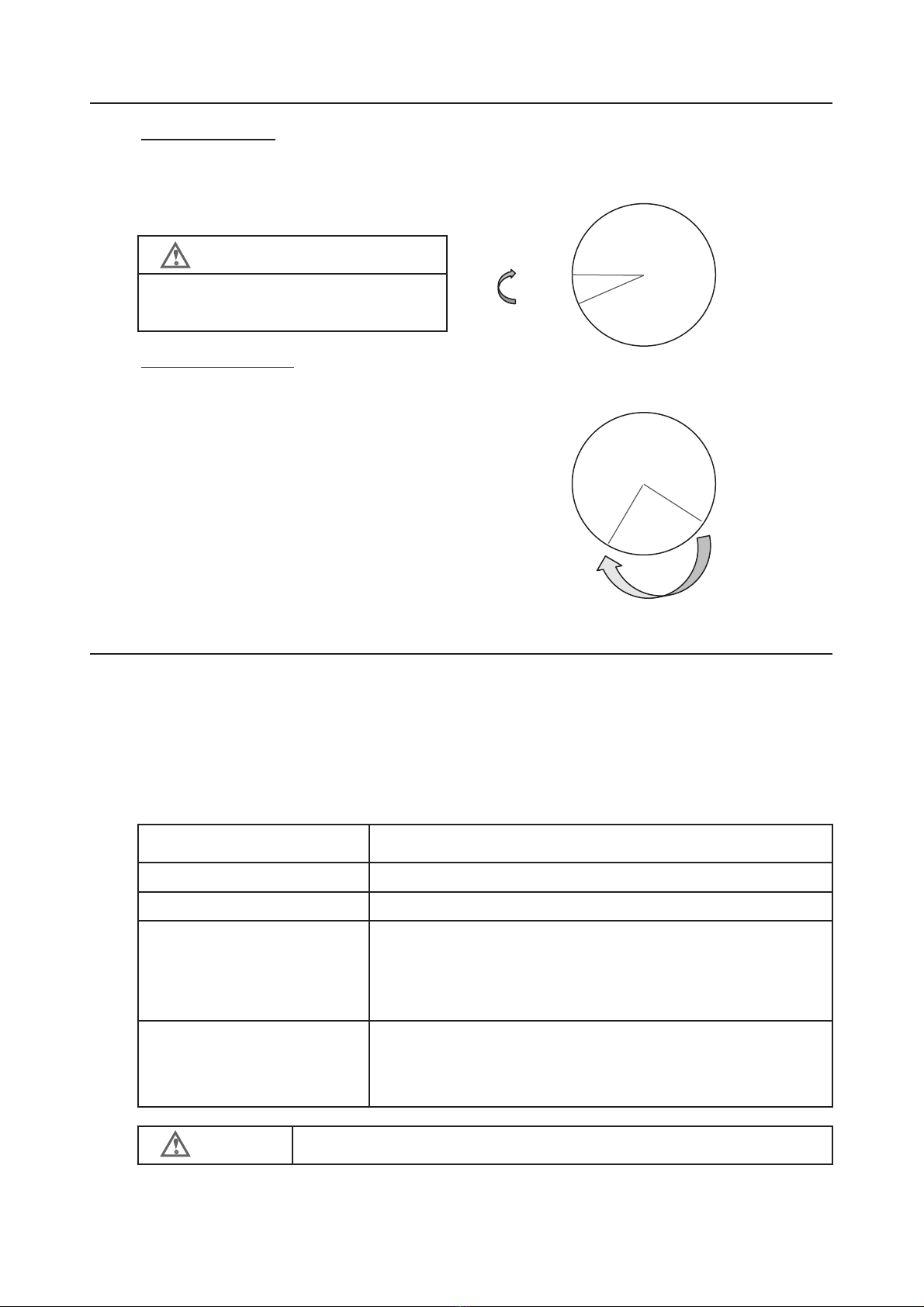

❖Adjusting Press cam signals

Feed signal adjusting

Set the feed start position to feed signal OFF position. Press cam signal

When you make the feed starts on 270°, 0°

Set the ON angle of feed to 240°, and set the OFF angle to 270°

270° 90°

ON

240°

Release signal adjusting 180°

0°

When the release angle is assumed to 200°from 200°, 60°

you turn on the press cam signal in 110 degrees,

and turn off in 200 degrees. 270° 90°

110°

200°

180°

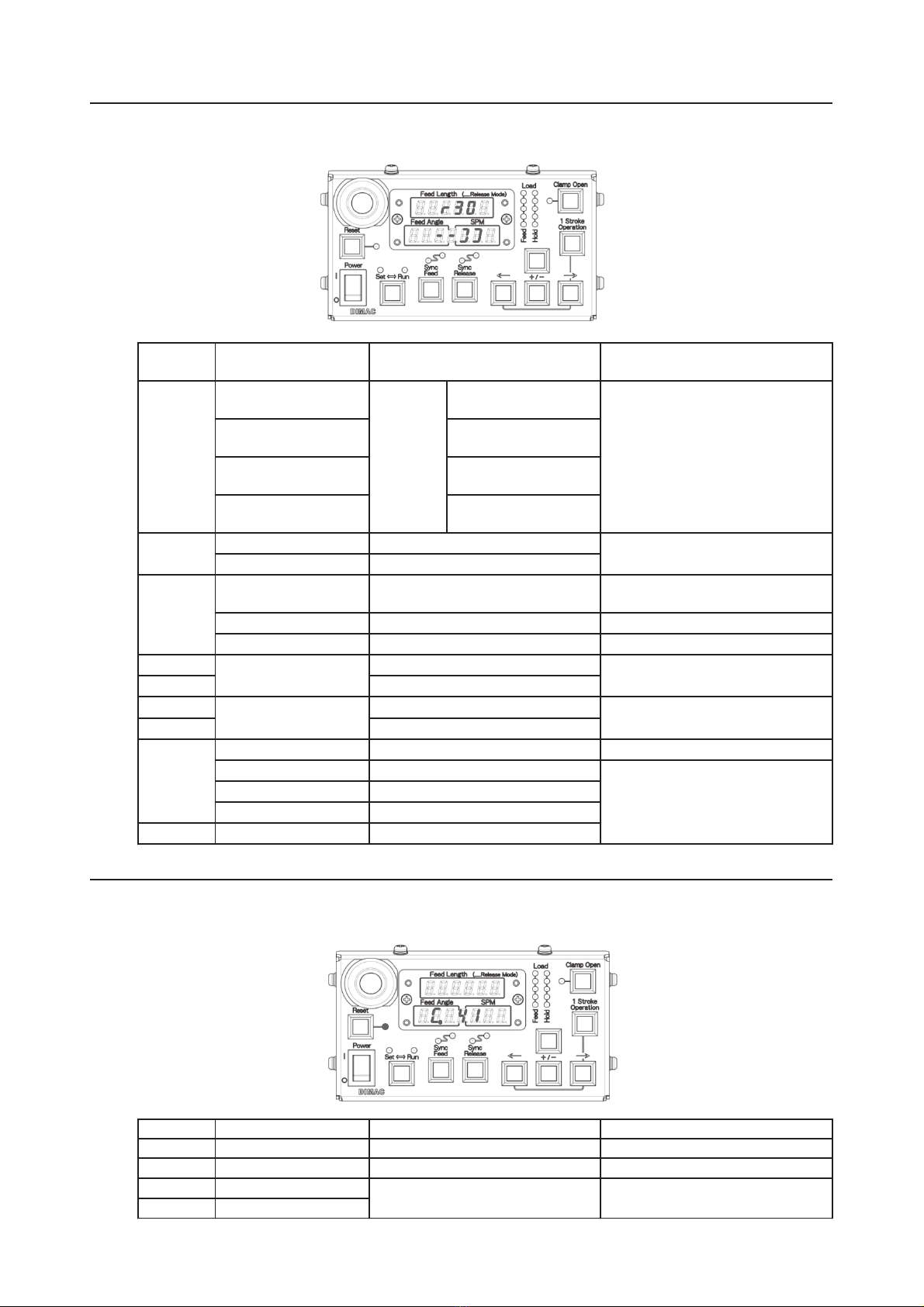

❖Release setting in the controller 【 (_Release Mode) 】

【 (_Release Mode) 】 the display is the back screen of 【 Feed Length 】.

Release Mode is not displayed in "Set" state only.

To display " Release Mode", Push on "Sync Release" switch in "Set" state.

To change the "Release Mode", Keep "Sync Release" switch ON, and using "+" or "-" switch,

You can change the release mode.

Display and contents

Invalid the release signal, Release off state.

Release angles setting. It can be input from 1°to 50°.

Input the release start using the press cam signal.

Release timer setting. It can be input from 0.001sec to 0.05 sec.

Input time period, the release carry out.

Input the release start using the press cam signal.

The delay time will vary depending in the springs pressure.

Set the ON to the release start angle, and set

the OFF to the finish.

NOTE

Need to set the ON of the feed signal to the

feed completed angles when using option

"Overrun-Function".

_ _ _ A50

Need to adjust the signal of the release

start even if the release system is used a

time setting of timer or angles.

The retention angles of the release ON must

be 25 degrees or more.

Feed Length (_Release Mode )

Contents

_ _ Sync

Synchronization press cam signal

_ _ _ OFF

_ _ _ A01

~

the control calculates the release time from the setting SPM and the

angles, the release will operate in the time range.

~

_ _ _ T50

NOTE

The release operation is delayed due to air cylinder.

_ _ _ T01

5

❖Code

Position: Left

Direction: L to R

Position: Right

Direction: L to R

Position: Left

Direction: R to L

Position: Right

Direction: R to L

Emergency stop switch ON

Emergency stop switch OFF

Input stop signal release Turn on Reset switch

Input stop signal Automatic reset after clear

EnD Work shortage sensor ON

EnD_2

EnD

EnD_2

Interfere releasing Turn on "Reset" switch

Input feed signal during feeding

Input feed signal during releasing

Input release signal during feeding

O_run Overrun

❖Caution display

This caution displays have a possibility which the feeder is reset. These displays are as the follows,

Reset : Blinking. Feed Angle SPM : C. Number

Code

C. 40 Open phase Confirmation of the power supply

C. 41 Low voltage detection Checking the voltage

C.

50 -1

C.

50 -2

Number

State / Content

Note

Motor connection anomaly

Contact failure

I - F

7.7.7.7.7.7.

666666

101010

Input stop signal during driving

press

1.0.1.0.1.0.

662662

663663

777777

1.1.1.1.1.1.

Another work shortage sensor ON

Work shortage sensor release

Another work shortage sensor release

Turn on "Sync Feed" and "Sync

Release" after turn on "Reset"

switch

664664

661661

After releasing the Emergency

stop switch, turn off the power

Turn on Reset switch after input

stop signal release

4.4.4.4.4.4.

444444

After setting a work pieces, turn

on "Reset" switch

Turning off "Sync Feed", the work

shortage sensor will disabled.

The code will display the operating state of the feeder to suit the operation state and setting

disabled state.

ENG

STOP

Contents

Method of reset

Model

number

When turning on power only, the

control panel displays the program

Feed Angle SPM

- - ] ]

-. -..].].

CC - -

C. C. -. -.

Feed Length

r30

6 CS-0173_1

This manual suits for next models

2

Other Dimac Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Wallenstein

Wallenstein CT162 Operator's manual

ProMinent

ProMinent CHLORINSITU IIa Series Maintenance instructions

SCHUNK

SCHUNK NSE mini 90 Assembly and operating manual

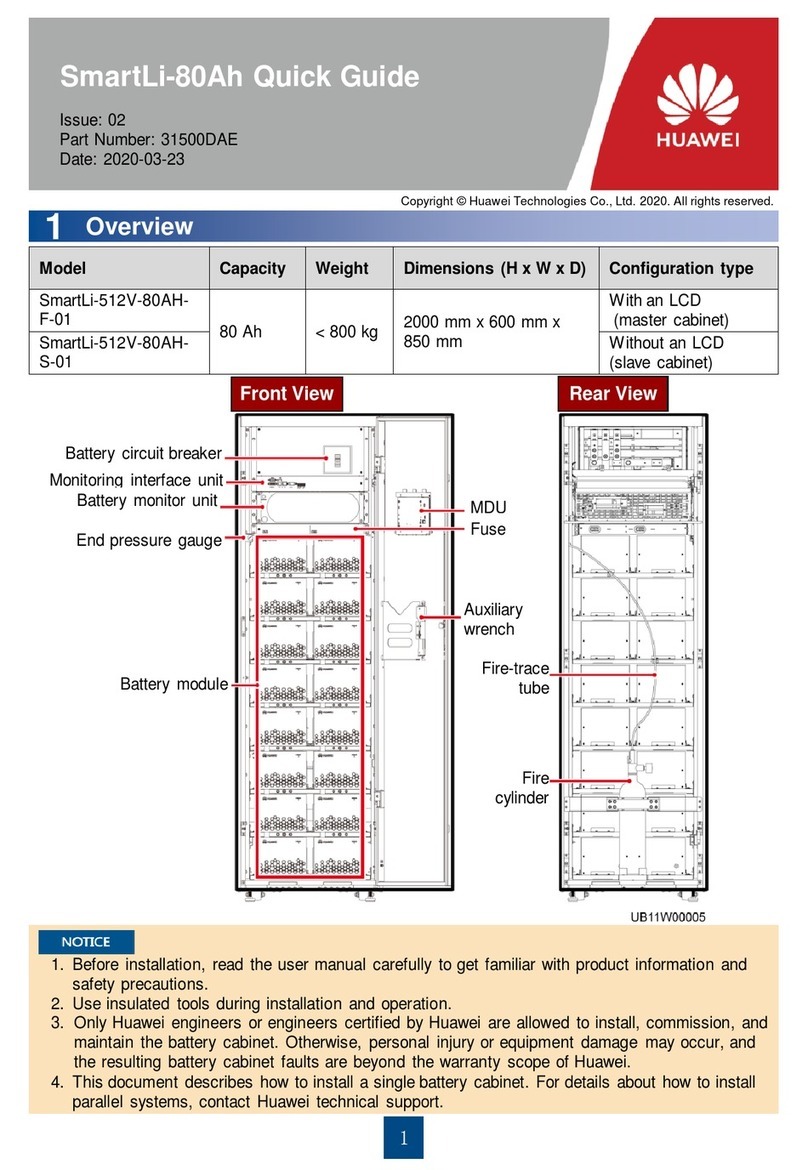

Huawei

Huawei SmartLi-512V-80AHF-01 quick guide

Spirax Sarco

Spirax Sarco FT 14 Installation and maintenance instructions

Cognex

Cognex DataMan 8072 Reference manual