Dimac J06 User manual

Installation Manual

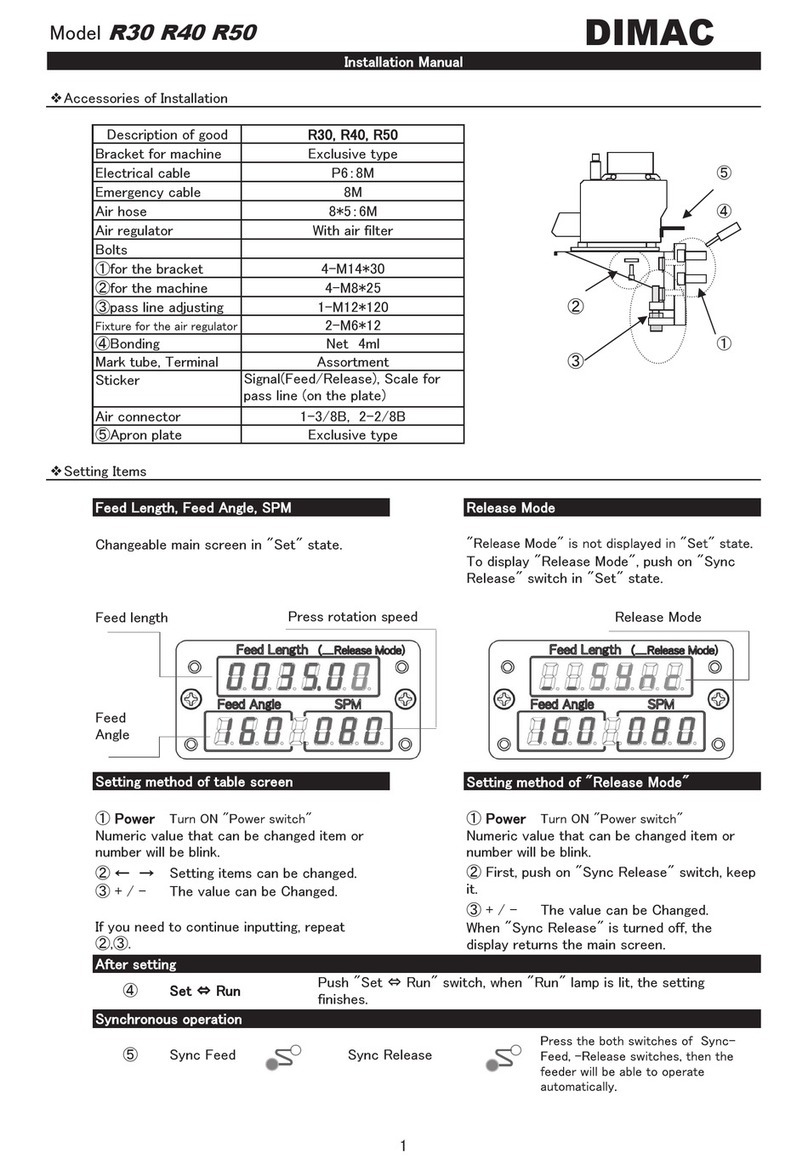

❖Accessories

Bracket for machine

Electrical cable ⑤

Emergency cable

Air hose ④

Air regulator

Bolts

①for the bracket

②for the machine

③pass line adjusting ②

④Bonding ①

Mark tube, Terminal ③

Sticker

Air connector

⑤Apron plate

❖Method of Input

①

Power Turn on "Power" switch

②Set ⇔ Run You can input a set value when "Set" lamp is lit.

Numeric value that can be changed item or number will be blink.

④+/- Using the switches, you can change the value.

If you need to continue inputting, repeat the ③, ④.

After setting

⑤Set ⇔ Run

Sync Sync

Feed Release

Usually, the Release mode does not display.

Press the both switches of Sync Feed and

Sync Release switches, then the controller will

be able to receive the sync press cam signals.

Signal(Feed/Release), Scale for

pass line(on the bracket)

1-TS8-03, 2-NTS8-02

Only when changing settings item, the Release mode is supposed to display on the

"Feed Length" after displaying digit of lowest of "Feed Length"

③

← →

Using the switches, you can move the cursor position.

Push "Set ⇔ Run" switch, when "Run" lamp is lit, the setting

finishes.

⑥

Exclusive type

DIMAC

Model J06

8*5:6M

2-M12*30

Exclusive type

Description of good

J06

4-M8*15

1-M12*120

Net 4ml

Assortment

P6:8M

8M

Fixture for the air regulator

With air filter

2-M6*12

1

❖J06 Pass line

The pass line height is decided by combination a plate and a holder.

It is necessary to tighten 4 points with a bolt to fix the holder on the plate.

Plate Holder

From top

A,B,C,D

210

Plate Hole Plate Hole

height position height position

A A

B B

C C

D D

A A

B B

C C

D D

A A

B B

C C

D D

❖Mounting position

Top view Mounting position 2&6, 3&7, 4&8, 5&9 1: not use (a~h:for J15)

h g f

e d c

b a

J06

70

❖Balance of confirmation ❖Assembly drawing of the bracket

88~138

100

h

Bolster

153~203

173~223

58~108

128~178

63~113

48~98

78~128

Bolster

9 8 7 6 5 4 3 2 1

h=75

h=100

178~228

108~158

73~123

98~148

133~183

158~208

h=0

h=25

h=50

113~163

188~238

138~188

123~173

148~198

h=125

33~83

203~253

163~213

CAUTION

180

Pass line (mm)

83~133

103~153

The plate-center equals the feeding rolls -center.

Pass line (mm)

70

2

❖Wiring

Red R(200V 50/60Hz)

PC-A Power cable White S(200V 50/60Hz)

0.75mm2Black T(200V 50/60Hz)

Not wiring when single phase

Green/Yellow E(Earth)

1

PC-B Signal cable 2

0.5mm2Option

3

4

5

6

Wire #

1:2 1A at AC 250V or less 7

3:4 1A at DC 30V or less

5:6 8 24V GND

Example for circuit

78

Wire # 7:8 9:10 11:12 S5:S6 0V EMG 100V

5V 24V

R

CPU

7,9,11 ,S5

5V GND

8,10,12, S6

9 Feed input

Wire # 1A at AC 250V or less 10 24V GND

S1:S2 1A at DC 30V or less 11 Release input

S3:S4 12 24V GND

S1

S2

S3

PC-C S4

0.5mm2

Option

S5

S6 Blown:24V GND

Need to short, if not

using.

Black:Emergency stop

DANGER

To cover each cable which is not using connection.

CAUTION

Yellow:Press cont.

processing

Need to short, if not

using.

Need to short the circuit of press processing select(S5, S6), if you don't use the

circuit.

To the stop continuous

on the press circuit

Work shortage sensor

output

To the stop continuous

on the press circuit

Continuous stop signal

output

To the stop continuous

on the press circuit

Red:Emergency stop

To Emergency stop circuit

Input stop

of Feeder

Press cam signal

CAUTION

You can select which 3 phase or single phase. If it's single phase, you don't have to connect the black wire.

Press cam signal

White:Emergency stop

To Emergency stop circuit

DANGER

Connect to the primary side

Emergency and press

processing select

Green:Emergency stop

Drive stop signal output

3

❖Cable connecting

The receptacles of PC-A, PC-B, PC-C are placed inside the connecting cover.

Connecting cover

❖Air piping

TS8-03

NTS8-02

To solenoid valve

*Approximate air pressure : 0.3~0.5 MPa

*Maximum air pressure: 0.5 MPa

NTS8-02

Air passes in specific

direction

CAUTION

DANGER

Need to fix three external cables in prepared nylon band.

4

❖Adjusting Press cam signals

Feed signal adjusting

Set the feed start position to feed signal OFF position. Press cam signal

When you make the feed starts on 270°, 0°

Set the ON angle of feed to 240°, and set the OFF angle to 270°

270° 90°

ON

240°

Release signal adjusting 180°

0°

When the release angle is assumed to 200°from 200°, 60°

you turn on the press cam signal in 110 degress,

and turn off in 200 degress. 270° 90°

110°

200°

180°

❖Release setting in the controller 【 (_Release Mode) 】

【 (_Release Mode) 】 The display is the back screen of 【 Feed Length 】.

Using "+" or "-" switch, Set the release mode.

The Release mode are as follows, Release OFF, Synchronization press cam signal, Timer finish.

Display and contents

Invalid the release signal, Release off state.

Release angles setting. It can be input from 1°to 50°.

Input the release strat using the press cam signal.

Release timer setting. It can be input from 0.001sec to 0.05 sec.

Input time period, the release carry out.

Input the release strat using the press cam signal.

The delay time will vary depending in the springs pressure.

NOTE

Need to set the ON of the feed signal to the

feed completed angles when using option

"Overrun-Function".

Set the ON to the release start angle, and set

the OFF to the finish.

The retention angles of the release ON must

be 25 degrees or more.

Need to adjust the signal of the release

start even if the release system is used a

time setting of timer or angles.

The Release mode is supposed to display on the "Feed Length" after displaying digit of lowest of "Feed

Length"

the control calculates the release time from the setting SPM and the

anggles, the release will operate in the time range.

~

Feed Length (_Release Mode )

Contents

_ _ Sync

Synchronization press cam signal

_ _ _ OFF

_ _ _ A01

NOTE

The release operation is delayed due to air cylinder.

_ _ _ A50

_ _ _ T01

~

_ _ _ T50

Other Dimac Industrial Equipment manuals