Direct Color Systems 1024uvmvp User manual

DCS_Direct_Jet_1024UVMVP

_Getting_Started_Guide_1.2_030314

Getting

Started

Guide

DCS_Direct_Jet_1024UVMVP

_Getting_Started_Guide_1.2_030314

Notices The infor ation in this docu ent is subject to change without notice.

NO WARRANTY OF ANY KIND IS MADE WITH REGARD TO THIS MATERIAL, INCLUDING,

BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE.

No liability is assu ed for errors contained herein or for incidental da ages in connection

with the furnishing, perfor ance, or use of this aterial.

This docu ent contains proprietary infor ation which is protected by copyright. All rights

are reserved. No part of this docu ent ay be photocopied, reproduced, or translated into

another language without prior written consent.

Trademark IBM is a registered trade ark of International Business Machines

Acknowledge- Corporation. Windows is a trade ark of Microsoft Corporation. All other

ments product and co pany na es entioned herein are the trade arks of their respective

owners.

Technical If you require technical assistance, contact a technical representative at 860-829-1027

Support or e ail techsupport@directcolorsyste s.co

Technical infor ation and downloads are available on our FTP site:

ftp://ftp.directcolorsyste s.co /.

The FTP site requires a Login and password.

You will be pro pted to put in a user na e and password. (If you are not pro pted then

double click on a file)

Passwords are as follows and are case sensitive:

Login: dcs

Password: dcsftp

Corporate Direct Color Syste s®

99 Ha er Mill Rd

Rocky Hill, CT 06067

T: 860-829-2244

F: 860-829-2255

E ail: info@directcolorsyste s.co

Web Site: www.directcolorsyste s.co

EAA Rua do Alto Das Torres, 942

4430-009 Vila Nova De Gaia, Portugal

E ail: EAAinfo@directcolorsyste s.co

DCS_Direct_Jet_1024UVMVP

_Getting_Started_Guide_1.2_030314

Equipment

Certificate of

Compliance

Printing Edition 1.2 – March 2014

Histor Driver installation instructions updated

Printed in the USA

© Copyright 2014, Direct Color, LLC. All rights reserved.

Go to table of contents

DCS_Direct_Jet_1024UVMVP

_Getting_Started_Guide_1.2_030314

4 | P a g e

Table of Contents

Safet and Precautions 6

Getting Started with the Hardware 7

Choosing a Location 10

Turning the Printer on for the First Ti e 10

LCD Touch Screen 12

Control Screen 13

Main Menu Screen 15

Infor ation Screen 16

Using the 1024UVMVP 18

Understanding Functionality 19

Preparing the Media Table 19

Loading Substrates onto the Media Table 19

Filling the Bulk Ink S stem 21

Filling or Refilling 22

Pri ing the Syste 23

Difficult to Print to Substrates 25

Printing onto Reflective, Shiny, and/or Mirrored Surfaces 26

Printing onto Thin or Low- elt Point Plastics (e.g. PVC) 28

Go to table of contents

DCS_Direct_Jet_1024UVMVP

_Getting_Started_Guide_1.2_030314

5 | P a g e

Thank You

Thank ou for choosing the Direct Color Syste s

®

Direct Jet 1024UVMVP printer. Your printer is

designed to provide you with exceptional output quality on a variety of substrates. The Direct Jet's

ability to print to any different aterials without the need for surface pre-coating or

undercoating represents a sound invest ent in ti e and productivity that will put you ahead of

your co petition.

Direct Jet printers have any distinct advantages that will help you produce high quality graphics

in record ti e.

•The Direct Jet 1024UVMVP accepts aterial up to 6" (152 ) thick. Optional heights fully

adjustable to 10" (254 ) or 15" (381 ).

•The Direct Jet 1024UVMVP odel accepts substrates up to 13" (330 ) x 24" (610 ) in

size and has a printable area of 10" (254 ) x 24" (610 ).

•Innovative Multisolve™ UV-LED inks print and bond to plastic, wood, stone, etc. Using our

adhesion pro oter, the inks will bind to any difficult surfaces, such as glass or stainless

steel.*

•Prints white ink.

•Prints clear ink.

•A print speed of 1:10 inutes to print an 8" x 10" i age bi-directionally at 1440 x 720 dpi /

High Speed.

•Exceptional print resolution of up to 5760 dpi.

•Direct Jet UV printers print fro any IBM-PC

®

or co patible co puter running Windows

®

7

or 8, 32- and 64-bit versions using Direct Color Syste s' exclusive Color Byte RIP (Raster

I age Processing) software.

* All substrates should be tested for i age receptivity, adhesion and durability with final acceptance and

suitability deter ined by the custo er. Direct Color Syste s® akes no warranty, expressed or i plied.

Go to table of contents

DCS_Direct_Jet_1024UVMVP

_Getting_Started_Guide_1.2_030314

6 | P a g e

Safet and Precautions

•Please read these guidelines before operating your Direct Jet printer.

•Keep all inks, solvents and lubricants out of the reach of children.

•Use only approved cleaning agents and solvents and then only for the purposes specified in

this guide.

•Use only genuine Multisolve™ UV-LED inks.

•Keep inks in a cool, dark and dry location.

•Inks ust be used in opaque containers only.

•This printer produces potentially har ful UV light. Protect eyes and skin fro exposure.

•Avoid physical contact with the printer's table and print head while the printer is in

operation.

•Avoid dropping ite s or spilling liquids in or on the printer.

•Keep hair, jewelry or loose clothing away fro the oving parts of the printer.

•Lifting this printer by hand requires a ini u of two people.

•Do not atte pt to repair this achine without prior DCS authorization. Unless specified in

this guide, only qualified service personnel should atte pt any disasse bly, repair or access

to internal co ponents. If you need to ake echanical adjust ents, turn off your printer

and disconnect it fro all power and data sources.

•Safety Glasses and gloves should be used whenever filling or draining ink

tanks, or anually cleaning the print head. These sy bols will be used

throughout this anual as a re inder to use safety glasses and gloves.

Wear protective gear whenever there is exposure to the inks, regardless

of whether a sy bol is displayed.

For prolonged exposure, DCS reco ends Butyl Black or Ethylene Vinyl

Alcohol Copoly er la inated gloves.

•The Adhesion Pro oter should not be used in an enclosed area without adequate

ventilation. RESPIRATORY PROTECTION: If exposure can exceed the PEL/TLV,

use only NIOSH/MSHA approved air-purifying or supplied air respirator

operated in a positive pressure ode per the NIOSH/OSHA 1981 occupational

health guidelines for che ical hazards.

Go to table of contents

DCS_Direct_Jet_1024UVMVP

_Getting_Started_Guide_1.2_030314

7 | P a g e

Getting

Started With

the Hardware

Go to table of contents

DCS_Direct_Jet_1024UVMVP

_Getting_Started_Guide_1.2_030314

8 | P a g e

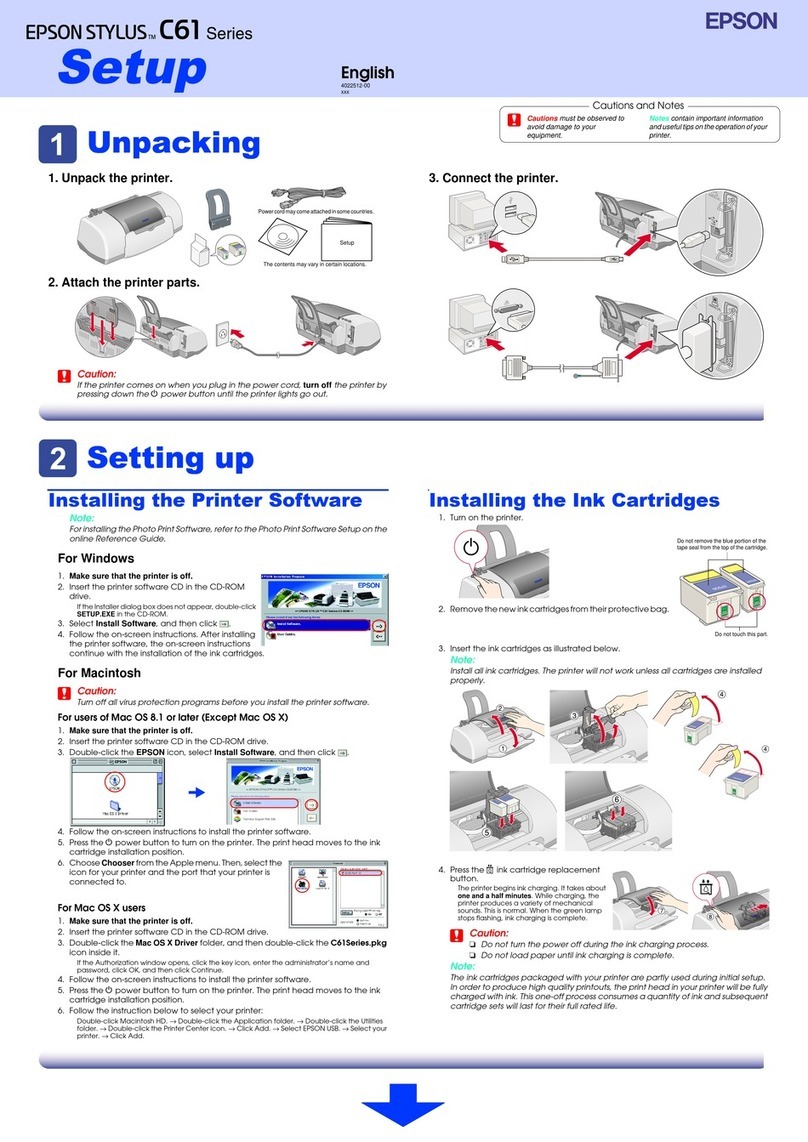

The 1024UVMVP

Below you will find diagra s of the printer and its parts. Be sure to fa iliarize yourself with all

the individual parts and descriptions of the printer as they will be referred to later in this guide.

Front View

Go to table of contents

DCS_Direct_Jet_1024UVMVP

_Getting_Started_Guide_1.2_030314

9 | P a g e

Rear View

Bulk Ink S stem

Go to table of contents

DCS_Direct_Jet_1024UVMVP

_Getting_Started_Guide_1.2_030314

10 | P a g e

Choosing a Location

Position the Direct Jet printer on a stable, level surface platfor that doesn't ove when the printer is

in operation. It is critical that the platfor be stable. An unstable platfor will significantly

i pact the graphic printing capability of the printer. The printer itself should also be level,

both lengthwise and widthwise. Make sure that it is in a well ventilated, dust-free roo .

Provide enough roo around the unit to provide access to the front, back, left and right

sides of the unit.

Turning the Printer On For the First Time

DO NOT PLUG IN THE PRINTER YET

Warning: When printer is in operation, all covers should be installed and closed with the front

cover lock screws installed and secured. The cover should only be opened by trained DCS

personnel only.

Using the provided T15 Torx tool, re ove the two front cover

lock screws.

Open the front cover using both handles.

Re ove the bolts securing print engine to shipping brackets with the

provided T-handle tool. Do not dispose of these bolts.

Go to table of contents

DCS_Direct_Jet_1024UVMVP

_Getting_Started_Guide_1.2_030314

11 | P a g e

Remove the warning label over the AC power receptacle. Plug in ain power cord and

flip ain power switch to ON.

Caution

If an extension cord is required, ensure the cord is as short as possible. To protect your printer against

da aging voltage spikes, a surge suppressor is strongly reco ended. Operate the unit only on 100-

240 VAC, 50/60Hz. The power supply on the Direct Jet is auto-switching. However, if you have any

questions about whether or not you have the correct voltage rating for the power supply DO NOT

atte pt to use the unit. Contact your dealer/representative or Direct Color Syste s directly.

The Ink Level screen will appear on the LCD Touch Screen. Silence the alar by hitting any of

the LOW ink lights. The alar will sound again in 20 inutes if a LOW tank has not been

refilled (see Filling the Bulk Ink Syste ).

Press the the top left of the LCD screen. Press and hold to raise the print engine to its

axi u height.

Re ove the tape fro the edia table and shipping

brackets.

Re ove the two brackets by unscrewing the fro the ain

channel. You cannot simpl pull these brackets out. Do not

dispose of these brackets.

Close and secure front cover.

Go to table of contents

DCS_Direct_Jet_1024UVMVP

_Getting_Started_Guide_1.2_030314

12 | P a g e

LCD Touch

Screen

HMI Version #HM140220

PLC Version #PL140218

Go to table of contents

DCS_Direct_Jet_1024UVMVP

_Getting_Started_Guide_1.2_030314

13 | P a g e

Control Screen

Your 1024UVMVP is equipped with a 3.5” (89 ) color LCD touch screen display which

provides interactive feedback, on-de and printer status, and ink levels. Switching the Main

Power on will bring up the Main Control Screen.

Press the icon at any ti e to return to this screen

Print Engine Power

The lights on this button display the current status of your 1024UVMVP

A ber Light: When the a ber light (Standby Power) is on, there is power to the printer but not the

print engine. You will not be able to print in this state but you can ove the print engine up and down

and the edia table back and forth. With the a ber light lit and by pressing the On/Off green button,

the print engine will be lifted approxi ately 3" (76 ) and the edia table will ove all the way to

the right.

Solid green: The green light will light up or blink signifying that there is power to the print engine.

Blinking green: When the green light is blinking, there is data being transferred fro the PC to

the printer or the printer is busy. After turning on the ain power, always wait 5 seconds

before turning on the print engine. Whenever the ain power switch is turned off, wait 15 – 30

seconds before turning the ain power switch back on.

Print Error

The lights on this button designate an error condition. Press this button at any ti e to bring up the

error infor ation screen.

Error Information Screen

The lights on this screen irror the lights found on the Print

Engine Power and Print Error buttons.

Press the printer state that atches the actual light configuration

of the achine to learn ore about the error.

Head Clean/Carriage Unlock

Press and hold this icon for 9 seconds to begin a light head clean. Press it briefly to unlock the

carriage.

Lift Print Engine

Pressing this button when the power is on will lift the print engine up. This should be used to

Go to table of contents

DCS_Direct_Jet_1024UVMVP

_Getting_Started_Guide_1.2_030314

14 | P a g e

raise the print engine and height sensor so when new edia is place on the edia table, it will

clear the sensor when the table oves forward.

Lower Print Engine

Pressing this button when the power is on will ove the print engine down. When you have an object

under the height sensor, the print engine will stop once the height sensor has detected the object.

When the button is released, the print engine will auto atically raise back up to a preset print height

position.

Caution

Do not ove print engine below the height of the table and substrate. Da age ay occur if the

print engine and height sensor are not lifted high enough to allow the edia placed on the edia table

to pass under without interference.

Move Media Table Left

Pressing this button will ove the table to the left unless the button is locked out (see Print Ho e).

Move Media Table Right

Pressing this button will ove the table to the right unless the button is locked out (see Print Ho e).

Trash/Paper Feed Cancel

In the event of a solid #1 light, press the Print Ho e icon followed by this icon to clear the

error and continue the job.

Print Home

This button only functions when the print engine is on. Pressing this button will bring the table to the

Print Ho e position, which is the position that the table must be in prior to sending a print job. After

the table has been sent to the Print Ho e position, the edia table controls are "locked out" (See

Slow/Unlock).

Automatic Return

Pressing this button toggles between Manual and Auto atic Return. When the light is lit, this

indicates that the Auto atic Return ode is enabled. In this ode, the table will return to Print

Ho e on its own after a print job. When in Manual ode, after a print job is co pleted, the table

will re ain at the left li it until the user oves it with the appropriate button.

Slow/Unlock Table

Press to unlock the table after it has been sent to the Print Ho e position. Press and hold this

button for several seconds to view the slow table ove ent

screen.

Slow Table Movement

Use the and to ove the edia table at half of the

set speed. This is helpful when setting print engine height

with a new substrate.

Go to table of contents

DCS_Direct_Jet_1024UVMVP

_Getting_Started_Guide_1.2_030314

15 | P a g e

Main Menu Screen

The Main Menu Screen can be accessed by pressing the icon at any ti e.

Ink Levels

This screen displays the current ink level for each color

within the Bulk Ink Syste .

The FULL and LOW indicator lights will illu inate to display

the current level of ink within each tank. An illu inated LOW

light indicates the need to refill that tank (see Filling the

Bulk Ink Syste ).

Manual Ink Maintenance

This function perfor s ink aintenance when required. The

Color Byte RIP will pro pt the user when it is necessary to

perfor this function. This function will also need to be

perfor ed if a solid #2 error light appears.

White Ink Circulation

This screen provides access to the Extended

Maintenance feature, displays current white circulation

schedule, and also provides the ability to anually

circulate the white ink at any ti e by touching the

CIRCULATE NOW switch. If this anual function is not

turned off, it will stop after 15 inutes.

Go to table of contents

DCS_Direct_Jet_1024UVMVP

_Getting_Started_Guide_1.2_030314

16 | P a g e

Extended Maintenance

The Bulk Ink Syste is equipped with an auto atic and

progra able white ink circulation syste . When the ain

power is on, the white ink circulation syste will

auto atically circulate the white ink for 120 seconds every

28 inutes.

When the printer will be inactive for an extended period of

ti e, use Extended Maintenance to keep the white ink

circulating. This function is only available when the print

engine is off (solid a ber). Return to the default circulation

schedule by selecting END or powering on the print engine.

Media Table Speed Change

These controls change the edia table speed when not

printing.

Warning

Media Table speed is factory calibrated and set. Only Authorized

technicians should ake changes to this original calibrated

setting.

Information Screen

This screen can be accessed by pressing the icon at any ti e.

Contact Info

DCS contact infor ation for headquarters and relevant

depart ents are available on this screen. Please contact the

appropriate depart ent via the provided contact infor ation

in the event assistance is needed.

Go to table of contents

DCS_Direct_Jet_1024UVMVP

_Getting_Started_Guide_1.2_030314

17 | P a g e

Control Panel Configuration

Button descriptions are available on the Control Panel

Configuration screen. Press any button on this screen for

ore infor ation.

Version Information

This screen displays the current version of your LCD touch

screen software.

Initial Calibration

Before proceeding with the Getting Started Guide, please refer to the

Maintenance and Troubleshooting Guide to perfor the following:

•X- and Y-axis Cleaning and Lubrication

•Head and UV LED La p Height Calibration

•X- and Y-axis ‘0’ Calibration (The Bulk Ink Syste needs to be filled and

pri ed first)

Go to table of contents

DCS_Direct_Jet_1024UVMVP

_Getting_Started_Guide_1.2_030314

18 | P a g e

Using the

1024UVMVP

Go to table of contents

DCS_Direct_Jet_1024UVMVP

_Getting_Started_Guide_1.2_030314

19 | P a g e

Understanding Functionalit

Turn on print engine by pressing . A ber light will turn off. When green light is solid, print

engine is powered on and ready.

With print engine at ax height, test basic functions of printer ove ent.

Press and hold to ove edia table all the way to the right. Media table will stop once it

has reached the right li it of printer.

Press and hold to ove edia table all the way to the left. Media table will stop once it

has reached the left li it of printer.

Press to bring the edia table to the Print Ho e position. Media table will travel to the

right li it and advance several inches to the left, and lock in the print ho e position

deactivating the and buttons.

Press to unlock the edia table fro the print ho e position. Media table will travel to

the right li it of printer and will be active again.

Test slow function by pressing and holding to view the slow speed screen.

Preparing the Media Table

Before you can place any aterials onto the edia table, you will need to prepare the table with an

appropriate hold-down device. DCS reco ends a tacky at available through a DCS authorized

distributor.

Use the following guidelines to help you prepare the printer's table:

•If you are using a at, be sure that the at is level and flat.

•To avoid bubbling of your substrate, use hold-down aterial that is of sufficient length, position

and quantity to ensure that the substrate lies flat on the table.

•Replace any hold-down device that has lost its tack or is no longer flat.

Note

Whatever hold-down ethod you use, no part of the hold-down syste should protrude above the

surface of the substrate.

Loading Substrates onto the Media Table

When loading substrates onto the table, you can ensure consistent and predictable output by following

these steps:

Bring the edia table all the way to the left, if it isn't already in that position.

Go to table of contents

DCS_Direct_Jet_1024UVMVP

_Getting_Started_Guide_1.2_030314

20 | P a g e

Press and hold until there is sufficient space between the table and the print head to

acco odate the thickness of the substrate being loaded.

Place the top left edge of the substrate flush with the top left corner of the table using the

guides to assure proper place ent. Flexible substrates ust be placed so that they are

co pletely flat on the table. Any bubbles or raised areas will cause the print heads to contact

the aterial and will cause inconsistent output.

Note

The front edia table guide (the stainless steel bar at the front of the table) can be raised by sliding it

above the surface of the edia table/tacky at to align the substrate. Make sure to slide it below

the substrate before printing. Adjust the screws on the table guide so that the guide stays in place,

but also slides without requiring tools.

Press the aterial down fir ly so that it akes contact with the tacky at or other hold-down device.

If the substrate requires cleaning, DCS reco ends an alcohol wipe.

When using the DCS tacky at with photo paper, DO NOT allow the photo paper print side to co e in

contact with the tacky at. This will per anently adhere to the tacky at, ruining both the paper and

the at.

Table of contents

Other Direct Color Systems Printer manuals