Direct power BP6L15 Installation manual

Full Manufacturer’s

Warranty

6L COMPRESSOR BP6L15

SAFETY AND OPERATING MANUAL

6L COMPRESSOR BP6L15

Congratulations on your purchase of a Direct Power power tool from Screwfix Direct

Ltd. We want you to continue getting the best performance from it so this handbook

includes information on safety, handling and care. Please retain this handbook in case

you need to refer to any of the information in the future.

Your Direct Power power tool comes with a 12-month guarantee, so should it develop a

fault within this period contact Screwfix Direct Ltd on Freephone

0500 41 41 41.

GUARANTEE

This Direct Power product carries a Screwfix Direct Ltd guarantee of 12 months. If

your product develops a fault within this period, you should, in the first instance

contact Screwfix Direct Ltd on Freephone 0500 41 41 41. If the fault occurs within

the first 12 months, you may return the goods for a full refund or we will repair or

replace the goods if you prefer. When repair is not practical or identical goods are

not available, alternative goods of similar specification and quality will usually be

provided but, failing this, you will be offered a partial or full refund depending on

the time period since purchase.

This guarantee specifically excludes losses caused due to:

- Fair wear and tear

- Misuse or abuse

- Lack of routine maintenance

- Failure of consumable items (such as batteries)

- Accidental damage

- Cosmetic damage

- Failure to follow manufacturer’s guidelines

- Loss of use of the goods

- Repairs attempted by anyone, unless authorised by Screwfix Direct Ltd.

This guarantee does not affect your statutory rights. This guarantee is only valid in

the UK.

For further technical advice, spare parts or repair service (outside of guarantee)

please contact the customer helpline number on 0845 607 6380.

SAFETY INSTRUCTIONS

WARNING! Read all instructions. Failure to follow all instructions listed

below may result in electric shock, fire and/or serious injury.

SAVE THESE INSTRUCTIONS

1) Work area

a) Keep work area clean and well lit. Cluttered and dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust. Power tools create sparks which

may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions

can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way.

Do not use any adapter plugs with earthed (grounded) power tools. Unmodified

plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric shock if

your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power

tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or

unplugging the power tool. Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric

shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating

a power tool. Do not use a power tool while you are tired or under the

influence of drugs, alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

b) Use safety equipment. Always wear eye protection. Safety equipment such as

dust mask, non-skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Avoid accidental starting. Ensure the switch is in the off position before

plugging in. Carrying power tools with your finger on the switch or plugging in

power tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A

wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

6L COMPRESSOR BP6L15

e) Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of these devices can

reduce dust related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for which it was

designed.

b) Do not use the power tool if the switch does not turn it on and off. Any

power tool that cannot be controlled with the switch is dangerous and must be

repaired.

c) Disconnect the plug from the power source before making any adjustments,

changing accessories, or storing power tools. Such preventive safety measures

reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tools

operation. If damaged, have the power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc., in accordance with these

instructions and in the manner intended for the particular type of power tool,

taking into account the working conditions and the work to be performed. Use

of the power tool for operations different from intended could result in a hazardous

situation.

5) Service

a) Have your power tool serviced by a qualified repair person using only

identical replacement parts. This will ensure that the safety of the power tool is

maintained.

ADDITIONAL SAFETY INSTRUCTIONS FOR YOUR COMPRESSOR

1. Warning! If not used and maintained correctly this compressor when used with

some pneumatic tools can cause serious injury and death. Before attempting to

operate this machine, it is important that you read, understand and follow these

instructions very carefully. They are designed for the safety of yourself and others

ensuring a long and trouble free service life from your machine. If not used correctly

and as detailed in these instructions pneumatic tools can be dangerous. This product

can cause injury to the operator and others. The warnings and safety instructions

must be followed to ensure reasonable safety and efficiency in using this product.

NOTE: The operator is responsible for following the warnings and safety instructions

in this manual and on the product.

2. Ensure that this compressor is disconnected from the mains supply when not in

use and the air receiver fully discharged before servicing, lubricating or making

adjustments and when changing accessories Always switch On and OFF using the

ON/OFF switch on the compressor before switching OFF at the mains supply.

3. Warning! When spraying paint or cleaning agents the fine mist produced could

ignite. When performing this type of operation the compressor must be a minimum

of 4 Metres away from the work area. Do not smoke and keep naked flames and

other sources of ignition well away from the work area.

4. This air compressor must be used in a suitable environment. There must be

adequate ventilation, the ambient temperature must be +5/+40°C. The working area

must be free from dust, acid vapour, explosive gasses and flammable materials.

5. Compressed air can be potentially dangerous when not used correctly. Do not

exceed the maximum rated air pressure for the accessory. Do not direct compressed

air at yourself, any other person or animals. Do not direct any liquid or any other

material that is being sprayed by yourself towards any other person or animals.

6. Only use hoses and connectors designed for use with compressed air. The

maximum working pressure of hoses and connectors must be higher than the

maximum working pressure of the compressor. Do not attempt to move the

compressor by pulling on the air hose.

7. This compressor is designed for tyre inflation, the operation of pneumatic tools,

spray painting and spraying non-corrosive cleaning agents. Do not use this

compressor for filling cylinders for breathing or diving apparatus. Compressed air

from this compressor must not be used for pharmaceutical, food or health

applications.

8. When spraying flammable liquids such as paint and non-corrosive cleaning agents

the distance between the compressor and the work area must be a minimum of 4

metres. When spraying liquids always wear a suitable face mask designed for

protection against the liquid being sprayed. Always wear approved safety glasses.

9. Do not attempt to modify the compressor or any pneumatic tools in any way. Use

only accessories and pneumatic tools that are rated for the capacity of the

compressor. Never leave the compressor pressurised.

6L COMPRESSOR BP6L15

SYMBOLS

Read the manual

Wear ear

protection

Warning Caution! Hot surface

Wear eye and

dust protection

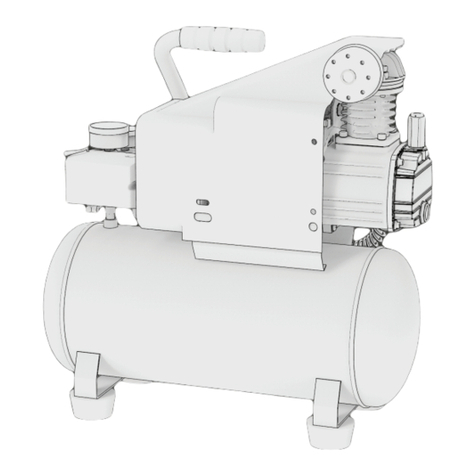

1 ON/OFF PRESSURE SWITCH

2 AIR OUTLET PRESSURE REGULATOR

3 AIR OUTLET PRESSURE REGULATOR LOCK RING

4 AIR OUTLET PRESSURE GAUGE

5 AIR OUTPUT QUICK RELEASE CONNECTOR

6 AIR RECEIVER TANK

7 AIR RECEIVER PRESSURE GAUGE

8 PRESSURE RELIEF SAFETY VALVE

9 AIR PUMP MOTOR

10 CARRYING HANDLE

11 RUBBER FOOT

12 AIR FILTER

1

2

5

4

3

6

8

7

9

10

11

12

TECHNICAL DATA

NOISE DATA

6L COMPRESSOR BP6L15

Voltage: 230V~50Hz

Input power: 1.5HP

Receiver capacity: 6L

CFM: 5.68

FAD @ 90 psi: 54L/min

Maximum pressure: 115 psi

Net weight: 13.5 kgs

As stated on the machine

OPERATION INSTRUCTIONS

Warning: Before using this compressor be sure

to read the instruction manual carefully.

1. ASSEMBLY

Remove the bung (if fitted) from the air inlet on

the cylinder head and screw in the air filter (See

Fig.2).

This is an “oil less” compressor, this means that

lubrication of moving parts is achieved by using

lubricant impregnated materials, there is therefore

no oil reservoir and the compressor can be

mounted in any orientation without the fear of

spilling oil. The only consideration when mounting

is the position of the water drain cock. Warning!

When the compressor is used for spraying paint or

spraying cleaning agents the fine mist produced

could ignite. When performing this type of

operation the compressor must be a minimum of

4 Metres away from the work area. Do not smoke

and keep naked flames and other sources of

ignition well away from the work area.

2. BASIC COMPRESSOR OPERATION

Important Note: This manual is provided to allow

the correct assembly and basic safe operation of

the compressor. It must be read in conjunction

with the manual that is supplied with any other

accessory intended for use with this compressor.

For more detailed information on the use of

compressors and accessories we strongly

recommend that you purchase a good quality

publication in order to allow you to use this

product to its full potential.

The electric motor drives an air pump which

draws in air from the atmosphere and delivers it

into the air receiver tank through the air receiver

tank supply tube. When the air pressure in the air

receiver tank reaches the operating pressure of 8

Bar the pressure switch operates and switches OFF

the mains supply to the motor.

Fig 2

6L COMPRESSOR BP6L15

At the same time the air that is in the pump

cylinder, air receiver tank, supply tube and the

pressure switch is discharged. This depressurises

the pump and the pressure regulating system

allowing the pump to re-start when the air

pressure in the air receiver tank falls below the

minimum operating pressure of 6 Bar. The

pressure switch is fitted with a delayed discharge

valve which will start the air pump motor. The

pressure relief safety valve is set to operate at 8.5

Bar and is connected directly onto the air receiver

tank and will operate if the set pressure of 8.5 Bar

is exceeded should the pressure switch fail.

3. OVERLOAD PROTECTION

This compressor is fitted with an overload

protection device, In the event that the motor

becomes too hot a thermal protection device will

cut the mains supply to the motor. When the

motor temperature returns to normal the mains

supply will be restored automatically.

4.SWITCHING ON AND OFF

Warning! Switching ON & OFF must be done

using the ON/OFF switch mounted on the

compressor. Switching the compressor OFF at the

mains supply can damage the motor and will

invalidate the guarantee.

Before switching on the power supply to the

compressor check that the ON/OFF switch is in the

OFF position (pressed in) (See Fig.3). Check that

the air outlet pressure regulator is closed (See

Fig.4). Check that the water drain cock is closed

(See Fig.5). Connect the compressor to a suitable

13A mains supply. Switch on the compressor by

pulling up the ON/OFF switch (See Fig.6). The

compressor will now start. When the air receiver

tank is pressurised to its working capacity the

compressor will automatically switch off. When

the compressor switches off there will be the

sound of leaking air while the pressure regulating

system is depressurised, this will last for only a

Fig 6

Fig 3

Fig 4

Fig 5

few seconds and is quite normal. Check all valves

and regulators for leaks.

5.CONNECTING HOSES AND ACCESSORIES

Warning! Do not operate accessories at an air

pressure greater than the maximum rated air

pressure for the accessory.

Connect a hose to the compressor using the hose

to compressor quick release connector (See Fig.7).

With a hose and accessory fitted, determine the

working pressure of the accessory by referring to

the accessory manual. Slowly open the air outlet

pressure regulator (See Fig.8) at the same time

observing the air outlet pressure gauge until the

pressure gauge reads the minimum pressure for

the accessory. Fine adjustments to the air pressure

can be made until the accessory is working at its

optimum performance.

When the correct operating air pressure has been

set, the air outlet pressure regulator can be locked

by tightening the locking ring (See Fig.9). Do not

exceed the maximum rated air pressure for the

accessory.

To disconnect a hose push the hose connector

towards the compressor and at the same time pull

back the brass collar, this will allow the hose to be

removed (See Fig.10).

Fig 7

Fig 8

Fig 10

Fig 9

6L COMPRESSOR BP6L15

MAINTENANCE

Warning! Before carrying out any maintenance or

adjustments the machine must be disconnected

from the mains power supply.

1.The compressor must be drained completely by

loosening the water drain cock. Drain the air

receiver tank daily after use.

2. The air filter can be removed for either cleaning

or replacing. Clean the air filter element after

every 100 hours of use or if low pressure is

experienced. Replace the air filter after 200 hours

of use. Note: Under no circumstances should the

compressor be operated with the air filter

removed.

3.Cleaning and maintaining the compressor

regularly will give a long and trouble free life.

Before long term storage it is advisable to give the

compressor a thorough clean. This should include

the removal of all fitted accessories. Do not use

any solvents as these can damage plastic parts.

Only use a clean cloth dampened with warm

soapy water. Any metal parts should be given a

wipe with a light machine oil to prevent rusting.

CAUTION. Water must never come into contact

with the compressor.

SPARES HELPLINE

01302 721791

ENVIRONMENTAL PROTECTION

Waste electrical products should not be

disposed of with household waste. Please

recycle where facilities exist. Check with

your Local Authority or retailer for

recycling advice.

PLUG REPLACEMENT

The fuse in the main plug of your compressor

should always be replaced with one of identical

rating.

Check the voltage given on your compressor

matches the supply voltage.

The compressor is supplied with a fitted plug,

however if you should need to fit a new plug

follow the instruction below.

IMPORTANT

The wire in the mains lead are coloured in

accordance with the following code:

Blue ---Neutral

Brown ---Live

Yellow / Green --- Earth

The wire that is coloured blue must be connected

to the terminal that is marked with the letter N.

The wire that is coloured brown must be

connected to the terminal that is marked with the

letter L. The wire that is coloured yellow / green

must be connected to the terminal that is marked

with the letter E.

A 13AMP (BS1363 or BS1363/A) plug must be

used and a 13 AMP fuse must be fitted.

E

L

BROWN

(Live)

FUSE

NFUSE

(13 amp)

BLUE

(Neutral)

GREEN & YELLOW

(Earth)

6L COMPRESSOR BP6L15

Declaration of Conformity

We, Importer

Direct Power

Yeovil

BA 22 8RT

Declare that the product

6L Compressor

BP6L15

Complies with the essential health and safety requirements of the following directives:

89/336/EEC - EMC Directive.

2006/95/EC - Low Voltage Directive.

98/37/EEC - Machinery Directive.

2000/14/EC - Noise Directive.

Standards and technical specifications referred to:

EN 55014-1: 2000/+A1: 2001/+A2: 2002

EN 55014-2: 1997/+A1: 2001

EN 61000-3-2: 2000/+A2: 2005

EN 61000-3-3: 1995/+A1: 2001

EN 61000-3-11: 2000

EN 1012-1: 1996

EN60204-1: 1997

2007

Authorised Signatory

Date: 13/02/07

Signature:

Name: David Withington

Nutool Ltd

Quality Manager

Table of contents

Other Direct power Air Compressor manuals

Popular Air Compressor manuals by other brands

Sundyne

Sundyne LMC 341F Instruction and operation manual

EINHELL

EINHELL TE-AC 270/50/10 Original operating instructions

Little Labs

Little Labs LL2A Operator's manual

Ryobi

Ryobi P739 Operator's manual

METZGER Technik

METZGER Technik DELTA 2 Series Technical manual

Parkside

Parkside PDSS B2 Operation and safety notes

Sears

Sears 176 owner's manual

Hyundai

Hyundai HHC315C user manual

Welbilt

Welbilt Multiplex APKV3D Installation, operation and maintenance manual

Delta

Delta 66-750 instruction manual

Campbell Hausfeld

Campbell Hausfeld HU500000 operating instructions

STEELE PRODUCTS

STEELE PRODUCTS Quietzone SP-CE155QT owner's manual