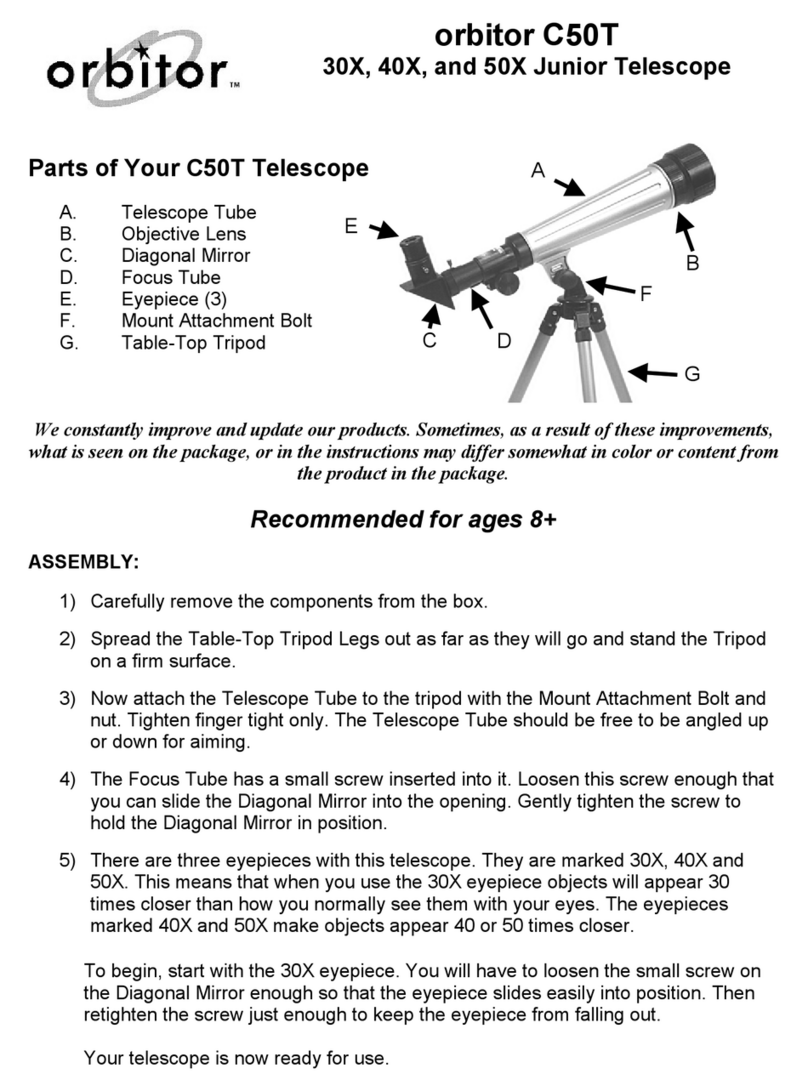

DiscMounts Alt-Azimuth DM-6 User manual

The DiscMounts Alt-Azimuth DM-6 (02-03-17)

DM-6 DiscMounts mounting specifications

•Azimuth axis (Tripod) mounting hole: 3/8”-16 centered on 6” disc.

•Altitude axis mounting holes: 5/16” - 18 spaced 3” apart

•Weight (no options, no saddle plate): 16.2 lbs.

•Dimensions: Head only: 7 1/2” long, 6” wide, 8 3/8” high

•Load weight: approximately 40 pounds (load weight can very up or down

depending on the length and diameter of telescope tube assembly).

• All aluminum is Hard Coat Type-3 anodized, and machined to close tolerance

from sold blocks of aircraft grade aluminum.

DiscMounts Saddle and Dovetail System

3” wide dovetail compatible with the Losmandy “D” series (G-11) dovetail system.

The 8” Tilt-in Saddle can be used as a conventional slide through, or the more

user-friendly tilt in!

With the optional 8” Converter (8” Tilt-in Saddle-3 or above) Vixen Style Dovetail

Plates and Astro Physics (AP) SB Series Dovetail Plates may also be used.

Top and rear cover plate installation.

The cover plates slide into channels on the top and rear of the DiscMount.

Note that there is a small indentation on one side of the top cover plate

(Automatic Lock); this must align with the plunger on the side of the DiscMount

(Sky Commander cover plates have indentations on each side).

Adjusting the DiscMount

You should take a moment and skim through the adjustment procedures

and also the hints.

The balance procedures seem complicated but are actually simple. This is

probably the first time that you have used a mount with total friction control.

When heavy eyepieces and higher powers are used, more care should be taken

when using the balance procedure. The first time the DiscMount is adjusted,

make the adjustments in the daytime using terrestrial objects. After the

adjustments are completed you may find yourself playing with the friction

adjustments until your new DiscMount settles in. After the friction system settles

in, adjustments will only be needed if your heaviest eyepiece is replaced or if the

telescope configuration is changed.

Friction Adjusting Wrench

The friction-adjusting wrench is stored on a magnet strip, located under the

top cover, on the left side, near the Azimuth disc.

Preliminary friction adjustments

Note: The purposes of the preliminary adjustments are: 1) to insure some

friction exists between the disc, 2) to become familiar with the location of the

friction-adjusting nuts, 3) and to become familiar with the direction to turn the

friction-adjusting nuts.

Mount the DM-6 to the tripod using the captive knob provided with the

DiscMounts tripod. Do not install the telescope.

For the initial setup, it will be easier if the top and rear covers are removed.

(If the Sky Commander option is installed, disconnect and remove the Sky

Commander and push the cable into the DiscMount.) Slide the top cover plate

off first, followed by the rear cover plate. The friction-adjusting nuts are the large

nuts located on the end of each axis shaft.

Using the adjusting wrench provided, tighten the nut on the Azimuth (AZ)

axis so some tension is felt as the mount is rotated about the axis. Now tighten

the nut on the Altitude (Alt) axis so friction is felt as the axis is rotated. The

altitude friction should be tightened so that it is just barely able to rotate.

Using the Saddle and Dovetail System

The dovetail system, is divided into two separate assemblies: the 8” Tilt-in

Saddle, which mounts to the Altitude disc of the DM-6, and the dovetail plate

which is mounted to the telescope rings (dovetail plates are available to fit most

ring mount configurations).

On DiscMounts dovetails there is a ¼-20 hole at each end that can be fitted

with an Allen Head Cap Screw (one is supplied with the optional DiscMounts 9”

Dovetail Plates) to be used as a slide through safety stop.

Installing the telescope

On the outside disc near the top of the Altitude axis there are two small

screw holes. These holes can be used with the optional Starbeam Angle Adapter

for mounting accessories, such as pointers and unit digit finders. There are also

two additional holes used to mount the 8” Tilt-in Saddle. If you are standing and

looking at the blue logo, the telescope can be arranged so that the saddle is

mounted on the left side or right side (mounts with the Optional Sky Commander

Push-to system are shipped with for the saddle to be installed on the left side).

This is a personal preference. If you use your right eye for looking through the

telescope, try placing the telescope on the left side. If you use your left eye

mount the telescope to the right side. This option places the body on the outside

of the tripod. Having the telescope to the side may seem awkward at first, but it

is actually more convenient, even more so when an observing chair is used.

Mount the telescope mounting rings to the dovetail plate (CAUTION make

sure the screws do not go all the way through the rings and damage the

telescope). Tilt or slide the dovetail with rings into the tilt-in saddle so that the

telescope ring knobs or screws will be on top. Tighten both saddle locking knobs

down onto the dovetail plate. Make sure the clamps are in the top and bottom

dovetail V. Next, place the telescope in the mounting rings. Adjust the telescope

in the rings so that it is balanced (altitude axis not rotating). Continue tightening

the rings to prevent the telescope from sliding out. Keep in mind that best

balance will be completed below.

Best balance (Altitude (Alt) axis)

Balance should be performed first with the telescope set up with no

eyepiece (worst case light), then again with the heaviest eyepiece (worst case

heavy).

The Disc Mount will handle approximately 21/2 pounds’ weight difference.

The weight spread can be larger or smaller depending on the weight, length of

the telescope, the height the heaviest eyepiece is above the center of gravity,

and the highest power being used. My 5.5” diameter, f-7, 24lb., refractor works

well when adjusted with a 0-21/2 pound differential. The movement at 250 power

is still smooth.

Worst case light balance

Install the telescope onto the DiscMount. Remove the front telescope dust

cover. Pull the dew shield out and rack the focuser all the way in. Install your

right angle diagonal (if it will stay in place when eyepieces are changed). If a

camera used for terrestrial photography will be used, then leave the diagonal out.

The idea is to set up the telescope in the lightest configuration that will be used.

Using the adjusting wrench provided, loosen the friction-adjusting nut on

the Altitude axis about ¼turn, Now slide the telescope in the rings until it is

balanced (note the telescope does not abruptly fall like most mounts when slight

imbalance occurs. If the DiscMount has friction between the disc, the telescope

will slowly rotate). Now mark the position of the telescope in the rings (a small

piece of masking tape on the tube in front of the ring will work fine).

Worst case heavy balance

Keep in mind that if a right angle diagonal (etc.) is used with heavy

eyepieces, the center of gravity moves up (the tilt-in saddle mounting holes are

slightly off center to help compensate). Install the heaviest eyepiece (or camera

for terrestrial photography). Rack the eyepiece out to approximate infinity focus

or a little past. Rebalance the telescope and mark the tube. Now slide the

telescope in its rings so it is positioned half way between the two marks. Tighten

the telescope mounting rings so the telescope cannot slide out. Add friction by

tightening the friction-adjusting nut on the altitude axis. Add enough friction so

the telescope stays in place (doesn’t move up or down). Now add a little more

friction to compensate for minor focus changes.

The DiscMount will work very well in this configuration. Some slight friction

adjustments might be needed until the mount breaks in.

Personally I like a lot of friction! I have gotten use to it and like the feel! I have

found that extra friction helps over shooting the object. When you stop the

telescope stops.

Binocular viewers!

Bino’s generally use two light eyepieces so are not a problem, if the bino is

left in when the adjustments are made. It is also possible to adjust the telescope

so that the bino can be removed and a diagonal be put in it’s place. It all depends

on what the total amount of weight is and how much friction you as the observer

are satisfied with.

Final tweak (if you want)!

The idea is to go back and forth from the heaviest and lightest configuration

to find the best balance and the least amount of friction required keeping the

telescope from moving.

With the telescope in worse case heavy and the telescope positioned half

way between the marks. Position the focuser at infinity or a little further out.

Loosen the friction-adjusting nut until the telescope just starts to rotate (A very

slight adjustment is all that is required.). Now slowly slide the telescope in its

mounting rings until the telescope is balanced (not moving). Don’t touch the

friction adjustment.

Change the telescope back to worst case light. If the telescope does not

move, loosen the friction very slightly until it starts to move. Back to worse case

heavy. Does the telescope move? If no, loosen the friction very slightly until it

starts to move. Slide the telescope in its mounting rings until balanced. Than

back to worse case light.

With the friction slightly loosened you will reach a point where the telescope

will slowly rotate at the same speed in worse case heavy and worse case light.

This is the balance point where the least amount of friction is needed to keep the

telescope from moving.

Tighten the telescope mounting rings so the telescope can’t slide out. Adjust the

friction-nut only tight enough to keep the telescope in place wherever it is placed.

Azimuth axis friction adjustment

The Azimuth axis should be adjusted with a little more tension then the

Altitude axis! There should be enough tension to insure the disc are pulled

together and not held in place just by the weight of the mount. To little friction will

result in vibration caused by the axis jumping, rather then sliding on the friction

disc.

You will find that as you become familiar with the mount, adjustments will

only be made if you change your heaviest eyepiece or telescope configuration.

While the DiscMount is new you may also see minor changes, until the friction

system settles in.

Install the rear cover plate and top cover plate. The azimuth axes can be

adjusted from the front by sliding the wrench under the Altitude axis disc. The

Altitude axis can be adjusted by sliding back the top cover plate about a ¼”.

Make sure the ring knobs or screws are tight. Don’t forget to put the

wrench back on the magnet located under the top cover!

Some hints

1- Once the balance and friction are close, only very slight adjustments are

required. The patent pending variable friction adjustment system will stay

wherever you set it.

2-Keep the weight spread down. If the diagonal is always being used. Do the

adjustments with the diagonal installed. As long as there is friction between the

disc the telescope will not take off and crash. If a slight imbalance occurs the

telescope will slowly rotate.

3-Focus on a star in the worse case heavy configuration and measure the

position of the focuser tube. Use this position for worse case heavy adjustments.

4-I use my telescope for astronomical, nature viewing/photography, with and

without bino’s! So I have marked several positions on the dovetail with a pencil

or tape depending on the configuration to be used, then it’s easy to slide the

telescope in the saddle for each configuration. Friction seldom needs to be

adjusted!

5-Art and drafting supply stores sell a masking type tape that will not leave glue

on your tube when making initial adjustments and it’s easy to write on. It’s made

to tape paper down and be removed without damage.

6-If you’re using one eyepiece such as a zoom eyepiece, or the camera is

staying in, a rough balance is all that's needed.

7-The capability of the mount is limited to the smoothness required at the highest

power (low power is more forgiving) and the maximum friction that is comfortable

to use!

8-The DM-6 has extremely high rigidity. Vibration originates from the tripod and

the mounting system used to couple the telescope to the disc. The closer the

telescope tube is mounted to the altitude disc the less tripod vibration will be felt.

Also the more rigid the ring system is the less vibration will be noticed. Two rings

are better than one. Low profile rings are better than tall rings.

9-If you’re taking terrestrial pictures and using low powers to scan, try adding a

little extra friction. Sometimes a little extra friction reassures the mind.

10-This is your mount. Experiment with the friction system! If you have marked

or measured the balance point it’s easy to go back.

Sky Commander Installation

Note: When the Sky Commander is ordered at the same time as the DM-6 mount

head the encoders and cable are installed and tested at the factory.

The Sky Commander shelf:

The Top Shelf assembly is installed at the factory with the cable end tucked

inside the top of the Sky Commander mount. Unless otherwise requested the

shelf is mounted so the telescope will mounted on the LEFT side. The shelf may

be pulled back to allow friction adjustment.

Attach the Velcro strip to the back of the Sky Commander and to the top

shelf. Make sure the Velcro does not cover the battery compartment of the Sky

Commander. I have found that installing the Velcro in a cross works best. Place

the Velcro vertical on the shelf and horizontal on the back of the Sky

Commander.

The automatic locking pin can be adjusted by inserting a small flat blade

screwdriver in the hole at the top of one side plate near the logo. Adjust the

tension so the top plate locks when pushed all the way in and releases when

pulled out. Only slight adjustments are needed. When the spring pin is operating

properly you can hear a click as the ball locks in place.

For detailed Sky Commander operation please refer to the Sky Commander

Manual.

Setup parameters (See Sky Commander manual for details):

Hold “Up” and “Down” Arrows while powering up. Use Up/Down arrows to scroll,

Left/Right arrows to select. Use reversing arrow button to enter into memory on

each selection. CAPITAL letters mean the item is selected!

Scope Mount---DOB germn

Set Hemisphere---NORTH south

RA Direction---NORM rev (REV for Sky Commanders with white face)

DEC Direction---NORM rev (telescope mounted on left side)

RA Encoder Res---04000

DEC Encoder Res---04000

FasTrk ON/OFF---OFF on (can be on if optional external power is used)

Sidereal Clock---ON off

RS-232 Baud Rate---user selected if RS-232 port is used

SiTech Mode---OFF on

Ash Tripod

Specifications

Top plate: 6” diameter with captive 3/8”-16 mounting knob. All aluminum is Hard

Coat anodized, and machined to close tolerance from sold blocks!

Height:

•Standard Tripod: from ground to base 43” to center of Alt axis 47.5” (optional

DM-6 8” Extender adds 8” to height of tripod)

Legs: 3” wide, 1 1/4 thick, solid Ash, non-adjustable.

Leg spread circle: approximately 37” to 39” adjustable.

Weight (aprox):

•Standard Tripod: 16.2 lbs.

Maximum load weight including mount head: 50 lbs. (with spreader braces

installed).

Installing the Tripod Brace Straps

The tripod brace straps should be used at all times; they stop the legs from

sliding out and add to the rigidity of the tripod. Install each brace loosely at first,

and then adjust the legs. Now go back and tighten each knob. When not in use

the legs can be stored on the tripod legs using the hole in the center of each

brace.

Ash Wood Tripod Care

Ash is a very hard and durable wood but some care is needed to keep the finish

looking new. Before putting your tripod away wipe the moister off with a clean

soft cloth. If you have one of the older standard tripods with the Water Clear

lacquer finish then occasionally wipe it down with a good grade of non-pigmented

furniture wax. For the hand rubbed oil finish tripods, use a 30% boiled linseed oil

and 70% turpentine mixture (available at most hardware and building product

stores such as Home Depot). Please follow the warnings on each can, and apply

the oil in a well-ventilated area. Wipe on with a soft rag, let dry for about 20

minutes, and wipe off with a clean lent free rag (such as an old tee shirt). About

every 6 months is all that is needed, but you can add coats of oil at any time, if

you get it on the aluminum wipe it off with a rag. The bottom of the legs will get

marks and dings (so do metal legs) just oil them from time to time (make sure the

oil on the legs is dry before you put them on carpet).

Warranty

The DiscMounts and DiscMounts accessories come with a one-year

warranty from date of shipment on parts and labor to the original owner. If the

DiscMounts or its associated parts fail due to defective material or workmanship

within one year of shipment, the unit or parts will be repaired or replaced free of

charge. The unit or parts will be shipped free of charge 1 way (USA customers

only). Damage done due to incorrect installation or abuse is not covered by this

warranty. All returns must be approved prior to shipping back for this warranty to

remain in force. Pleased call (954) 475-8574 for return authorization.

Patents

The DiscMounts’ are manufactured under the following Patent:

Disc-Based Alt-Azimuth Telescope Mount Number US 7,382,533

How to Contact DiscMounts if you have Question

E-Mail:

Phone:

(954) 475-8574 (8:00AM to 5:00PM EST)

Letter:

DiscMounts, Inc.

Attention: Tom Peters

1570 SW 139 Ave.

Davie, FL 33325

Table of contents