Ditch Witch FM25 User manual

FM25/FM25X

Operator’s

Manual

Issue 2.0 053-1187

FM25/FM25X Operator’s Manual Overview - 1

Overview

Chapter Contents

Serial Number Location . . . . . . . . . . . . . . . . . . . . . . 2

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Unit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . 3

• Bulleted Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

• Numbered Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Overview - 2 FM25/FM25X Operator’s Manual

Serial Number Location

Serial Number Location

Record serial numbers and date of purchase in

spaces provided. Fluid unit serial number is

located as shown.

Intended Use

The FM25/FM25X is a self-contained drilling fluid unit capable of mixing up to 950 gal (3596 L) of drilling

fluid per tank and transferring fluid under pressure to the drilling unit. It is intended for operation in ambient

temperatures from 0° to 115°F (-18° to 46°C). Use in any other way is considered contrary to the intended

use.

The FM25/FM25X can be used with Ditch Witch®drilling units and locating equipment. It should be

operated, serviced, and repaired only by persons familiar with its particular characteristics and acquainted

with the relevant safety procedures.

Item

date of manufacture

date of purchase

fluid unit serial number

engine serial number

FM25/FM25X Operator’s Manual Overview - 3

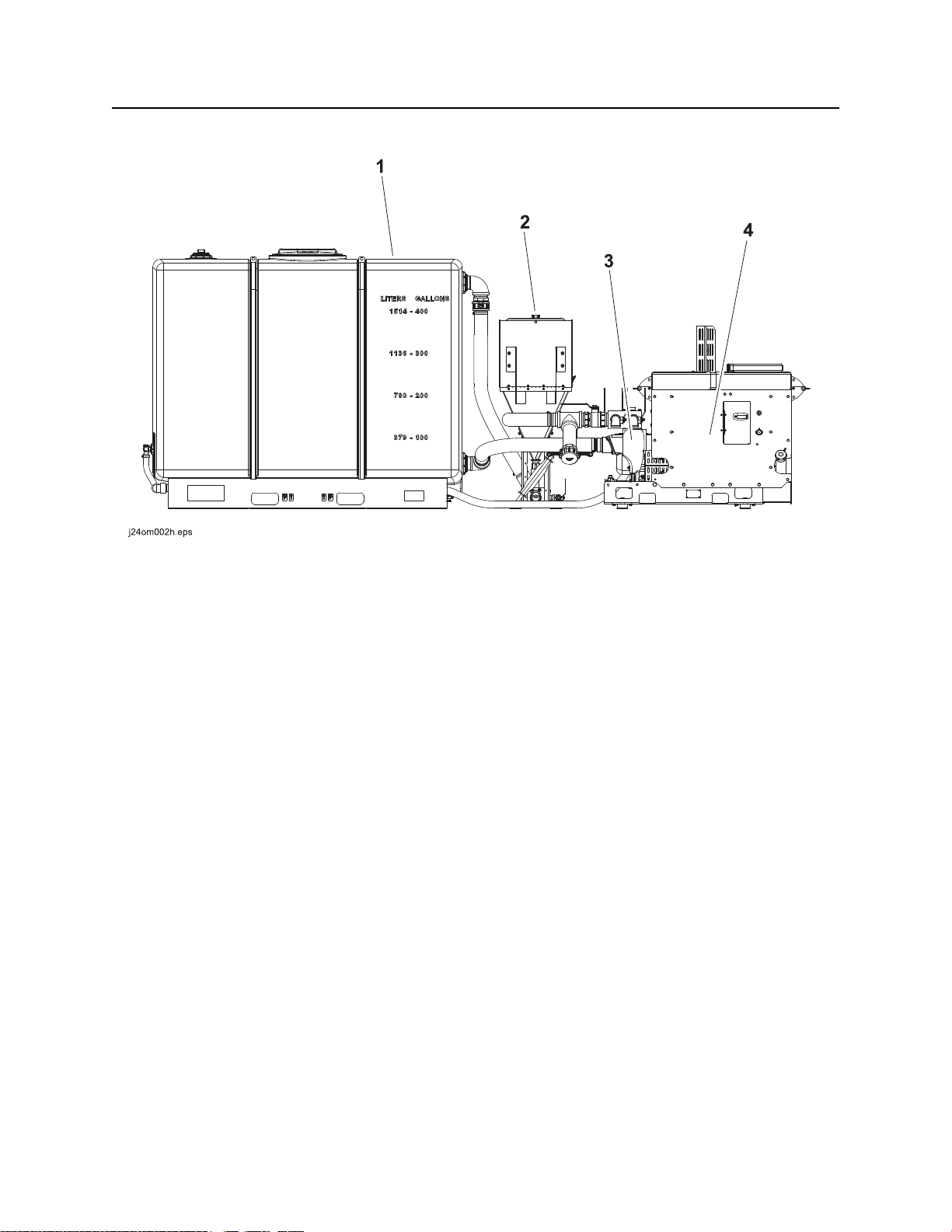

Unit Components

Unit Components

About This Manual

This manual contains information for the proper use of this machine. See the beige Operation Overview

pages for basic operating procedures. Cross references such as “See page 50” will direct you to detailed

procedures.

Bulleted Lists

Bulleted lists provide helpful or important information or contain procedures that do not have to be

performed in a specific order.

Numbered Lists

Numbered lists contain illustration callouts or list steps that must be performed in order.

1. tank

2. hopper

3. pumps

4. power unit

Overview - 4 FM25/FM25X Operator’s Manual

FM25/FM25X Operator’s Manual Foreword - 5

Foreword

This manual is an important part of your equipment. It provides safety information and operation

instructions to help you use and maintain your Ditch Witch®equipment.

Read this manual before using your equipment. Keep it with the equipment at all times for future reference.

If you sell your equipment, be sure to give this manual to the new owner.

If you need a replacement copy, contact your Ditch Witch dealer. If you need assistance in locating a

dealer, visit our website at www.ditchwitch.com or write to the following address:

The Charles Machine Works, Inc.

Attn: Marketing Department

PO Box 66

Perry, OK 73077-0066

USA

The descriptions and specifications in this manual are subject to change without notice. The Charles

Machine Works, Inc. reserves the right to improve equipment. Some product improvements may have

taken place after this manual was published. For the latest information on Ditch Witch equipment, see your

Ditch Witch dealer.

Thank you for buying and using Ditch Witch equipment.

Foreword - 6 FM25/FM25X Operator’s Manual

FM25/FM25X

Operator’s Manual

Issue number 2.0/OM-11/17

Part number 053-1187

Copyright 2007, 2017

by The Charles Machine Works, Inc.

and Ditch Witch are registered trademarks of The Charles Machine Works, Inc.

This product and its use may be covered by one or more patents at http://patents.charlesmachine.works.

FM25/FM25X Operator’s Manual Contents - 7

Contents

Overview

machine serial number, information about the type of work this machine is designed

to perform, basic machine components, and how to use this manual

1

Foreword

part number, revision level, and publication date of this manual, and factory contact

information

5

Safety

machine safety alerts and emergency procedures 9

Controls

machine controls, gauges, and indicators and how to use them 19

Operation Overview

an overview for completing a job with this machine: planning, setting up, handling

drilling fluid, and leaving the jobsite; with cross references to detailed procedures

27

Prepare

procedures for inspecting the jobsite and preparing the jobsite for work 31

Transport

procedures for lifting and hauling 35

Drilling Fluid Concepts

procedures for selecting fluid additives, determining fluid requirements, and

measuring viscosity

39

Complete the Job

procedures for rinsing and storing equipment 45

Service

service intervals and instructions for this machine including lubrication, replacement

of wear items, and basic maintenance

47

Specifications

machine specifications including weights, measurements, power ratings, and fluid

capacities

63

Support

the warranty policy for this machine, and procedures for obtaining warranty

consideration and training

67

Service Record

a record of major service performed on the machine 71

Contents - 8 FM25/FM25X Operator’s Manual

FM25/FM25X Operator’s Manual Safety - 9

Safety

Chapter Contents

Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

California Proposition 65 Warning . . . . . . . . . . . . 10

Emergency Procedures . . . . . . . . . . . . . . . . . . . . . 11

• Electric Strike Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

• If an Electric Line is Damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

• If a Gas Line is Damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

• If a Fiber Optic Cable is Damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

• If Machine Catches on Fire. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Safety Alert Classification . . . . . . . . . . . . . . . . . . . 15

Machine Safety Alerts. . . . . . . . . . . . . . . . . . . . . . . 16

Safety - 10 FM25/FM25X Operator’s Manual

Guidelines

Guidelines

When you see this safety alert sign, carefully read and follow all instructions.

YOUR SAFETY IS AT STAKE. Read this entire section before using your equipment.

Follow these guidelines before operating any jobsite equipment:

• Complete proper training and read operator’s manual before using equipment.

• Mark proposed path with white paint and have underground utilities located before working. In the US

or Canada, call 811 (US) or 888-258-0808 (US and Canada). Also contact any local utilities that do not

participate in the One-Call service. In countries that do not have a One-Call service, contact all local

utility companies to have underground utilities located.

• Classify jobsite based on its hazards and use correct tools and machinery, safety equipment, and work

methods for jobsite.

• Mark jobsite clearly and keep spectators away.

• Wear personal protective equipment.

• Review jobsite hazards, safety and emergency procedures, and individual responsibilities with all

personnel before work begins. Safety videos are available from your Ditch Witch®dealer or at

www.ditchwitch.com/safe. Safety Data Sheets (SDS) are available at www.ditchwitch.com/support.

• Fully inspect equipment before operating. Repair or replace any worn or damaged parts. Replace

missing or damaged safety shields and safety signs. Contact your Ditch Witch dealer for assistance.

• Use equipment carefully. Stop operation and investigate anything that does not look or feel right.

• Do not operate machine where flammable gas may be present.

• Only operate equipment in well-ventilated areas.

• Contact your Ditch Witch dealer if you have any question about operation, maintenance, or equipment

use.

• Complete the equipment checklist located at www.ditchwitch.com/safe.

California Proposition 65 Warning

This product may contain chemicals known to the State of California to cause cancer, birth defects, or other

reproductive harm.

• battery posts, terminals and related accessories

• engine exhaust

• ethylene glycol

FM25/FM25X Operator’s Manual Safety - 11

Emergency Procedures

Emergency Procedures

Before operating any equipment, review emergency procedures and check that all safety precautions have

been taken.

Electric Strike Description

When working near electric cables, remember the following:

• Electricity follows all paths to ground, not just path of least resistance.

• Pipes, hoses, and cables will conduct electricity back to all equipment.

• Low voltage current can injure or kill. Many work-related electrocutions result from contact with less

than 440 volts.

Most electric strikes are not noticeable, but indications of a strike include:

• power outage

•smoke

•explosion

• popping noises

• arcing electricity

If any of these occur, assume an electric strike has occurred.

Jobsite hazards could cause death or serious injury. Use

correct equipment and work methods. Use and maintain proper safety

equipment.

EMERGENCY SHUTDOWN - Turn ignition switch to stop position or push remote engine stop button (if

equipped).

Electric shock will cause death or serious injury. Stay

away. 274-049

Safety - 12 FM25/FM25X Operator’s Manual

Emergency Procedures

If an Electric Line is Damaged

If you suspect an electric line has been damaged and you are on truck or trailer, DO NOT MOVE.

Remain on truck or trailer and take the following actions. The order and degree of action will depend on the

situation.

• Warn people nearby that an electric strike has occurred. Instruct them to leave the area and contact

utility.

• Do not allow anyone into area until given permission by utility company.

• Do not allow anyone to touch equipment.

If you suspect an electric line has been damaged and you are off truck or trailer, DO NOT TOUCH

EQUIPMENT. Take the following actions. The order and degree of action will depend on the situation.

• LEAVE AREA. The ground surface may be electrified so take small shuffle steps with feet close

together to reduce the hazard of being shocked from one foot to the other.

• Contact utility company to shut off power.

• Do not return to area or allow anyone into area until given permission by utility company.

FM25/FM25X Operator’s Manual Safety - 13

Emergency Procedures

If a Gas Line is Damaged

If you suspect a gas line has been damaged, take the following actions. The orders and degree of action

will depend on the situation.

• Immediately shut off engine(s), if this can be done safely and quickly.

• Remove any ignition source(s), if this can be done safely and quickly.

• Warn others that a gas line has been cut and that they should leave the area.

• Leave jobsite as quickly as possible.

• Immediately call your local emergency phone number and utility company.

• If jobsite is along street, stop traffic from driving near jobsite.

• Do not return to jobsite until given permission by emergency personnel and utility company.

Fire or explosion possible. Fumes could ignite and cause

burns. No smoking, no flame, no spark. 275-419 (2P)

Explosion possible. Serious injury or equipment damage could occur.

Follow directions carefully.

Safety - 14 FM25/FM25X Operator’s Manual

Emergency Procedures

If a Fiber Optic Cable is Damaged

Do not look into cut ends of fiber optic or unidentified cable. Vision damage can occur. Contact utility

company.

If Machine Catches on Fire

Perform emergency shutdown procedure and then take the following actions. The order and degree of

action will depend on the situation.

• Immediately move battery disconnect switch (if equipped and accessible) to disconnect position.

• If fire is small and fire extinguisher is available, attempt to extinguish fire.

• If fire cannot be extinguished, leave area as quickly as possible and contact emergency personnel.

FM25/FM25X Operator’s Manual Safety - 15

Safety Alert Classifications

Safety Alert Classifications

These classifications and the icons defined on the following pages work together to alert you to situations

which could be harmful to you, jobsite bystanders or your equipment. When you see these words and

icons in the book or on the machine, carefully read and follow all instructions. YOUR SAFETY IS AT

STAKE.

Watch for the three safety alert levels: DANGER, WARNING and CAUTION. Learn what each level

means.

indicates a hazardous situation that, if not avoided, will result in death or serious injury.

This signal word is to be limited to the most extreme situations.

indicates a hazardous situation that, if not avoided, could result in death or serious injury.

indicates a hazardous situation that, if not avoided, could result in minor or moderate injury.

Watch for two other words: NOTICE and IMPORTANT.

NOTICE indicates information considered important, but not hazard-related (e.g., messages relating to

property damage).

IMPORTANT can help you do a better job or make your job easier in some way.

Safety - 16 FM25/FM25X Operator’s Manual

Machine Safety Alerts

Machine Safety Alerts

1

Lift point. See Transport chapter for more information.

2

Tiedown point. See Transport chapter for more information.

3

Misuse of machine can cause death or serious

injury. Read and understand operator’s manual and all other safety

instructions before use.

4

Hot parts. Contact can cause burns. Do not touch

unit cool. Wear gloves.

5

Moving parts. Contact can cause serious injury.

Stay away.

FM25/FM25X Operator’s Manual Safety - 17

Machine Safety Alerts

6

Silica dust. Exposure can cause lung disease. Use

breathing protection.

7

Buried electric lines. Contact will cause death or

serious injury. Know locations of lines. Stay away.

Safety - 18 FM25/FM25X Operator’s Manual

Machine Safety Alerts

Tanks

1

Buried electric lines. Contact will cause death or

serious injury. Know locations of lines. Stay away.

2

Tiedown location. See Transport chapter for more information.

3

Lift point. See Transport chapter for more information.

This manual suits for next models

1

Table of contents