DIVERSITECH FRED SR2 Manual

Visit our Website for more information on this product

www.diversitech.ca

1200 55th Avenue, Montreal, Quebec H8T 3J8

READ AND SAVE THESE INSTRUCTIONS

FRED SR2 CFRED SR1 C

FRED SR2FRED SR

Operation & Maintenance Manual

FRED SR | SR2 | SR1 C | SR2 C

Table of Contents

SECTION 1 – SAFETY PRECAUTIONS OF FUME & DUST EXTRACTION/COLLECTION .................................................................................................................................................3

1.1 Symbols ...........................................................................................................................................................................................................................................................................................3

1.2 User Responsibility ...................................................................................................................................................................................................................................................................3

1.3 Fume Extraction Hazards .....................................................................................................................................................................................................................................................3

1.4 Dust Collection Hazards .......................................................................................................................................................................................................................................................4

1.5 Safety Stickers .............................................................................................................................................................................................................................................................................4

SECTION 2 – SPECIFICATIONS ...................................................................................................................................................................................................................................................................................4

2.1 Diagram & Description ....................................................................................................................................................................................................................................................................................4

2.2 Product Specifications .......................................................................................................................................................................................................................................................................................5

2.3 Filter Specifications ...............................................................................................................................................................................................................................................................................................5

2.4 Dimension ..................................................................................................................................................................................................................................................................................................................6

SECTION 3 – SETUP / INSTALLATION .................................................................................................................................................................................................................................................................6

3.1 To Setup or Install Safely ..................................................................................................................................................................................................................................................................................7

3.2 Un-Packaging ..........................................................................................................................................................................................................................................................................................................7

3.3 Tools Required ........................................................................................................................................................................................................................................................................................................7

3.4 Mounting Options ..................................................................................................................................................................................................................................................................................................7

3.5 Electrical Options ...................................................................................................................................................................................................................................................................................................7

SECTION 4 – OPERATION ..............................................................................................................................................................................................................................................................................................7

4.1 To Operate Safely ..................................................................................................................................................................................................................................................................................................8

4.2 Controls ........................................................................................................................................................................................................................................................................................................................8

4.3 Pre-Use Checklist ..................................................................................................................................................................................................................................................................................................8

4.4 Principles of Operation ......................................................................................................................................................................................................................................................................................9

4.5 Failure Event .............................................................................................................................................................................................................................................................................................................9

4.6 ICS-360 Injection Cleaning System .......................................................................................................................................................................................................................................................10

SECTION 5 – MAINTENANCE & TROUBLESHOOTING .........................................................................................................................................................................................................................10

5.1 To Maintain this Product Safely ................................................................................................................................................................................................................................................................10

5.2 Tools Required ....................................................................................................................................................................................................................................................................................................10

5.3 Routine Maintenance Schedule ................................................................................................................................................................................................................................................................11

5.4 Troubleshooting Procedure ........................................................................................................................................................................................................................................................................12

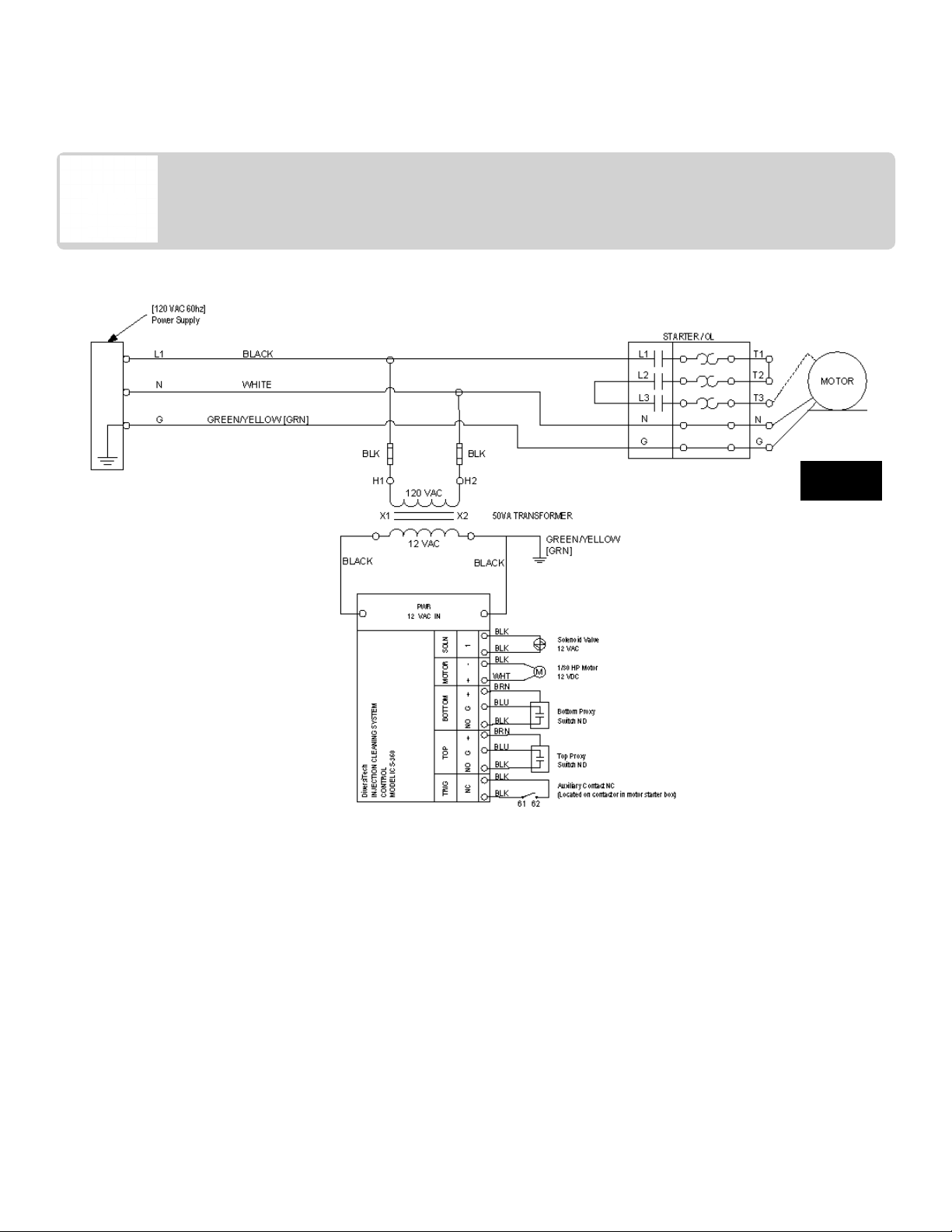

APPENDIX 1A – ELECTRICAL DIAGRAM MANUAL [120 VAC] Single Phase Power ......................................................................................................................................................13

APPENDIX 1B – ELECTRICAL DIAGRAM MANUAL [230/460/575v] 3-Phase Power .....................................................................................................................................................14

APPENDIX 2 – MAINTENANCE RECORD ........................................................................................................................................................................................................................................................15

APPENDIX 3 – ARM-TO-BLOWER DIRECT INSTALLATION ................................................................................................................................................................................................16,17, 18

APPENDIX 4 - ARM TO REMOTE MOUNT BRACKET INSTALLATION ................................................................................................................................................................................19,20

APPENDIX 5 – SAMPLES SAFETY STICKERS ...............................................................................................................................................................................................................................................21

NOTES..................................................................................................................................................................................................................................................................................................................................22,23

Limited Equipment Warranty ..................................................................................................................................................................................................................................................................Back Cover

Freight Claims ...................................................................................................................................................................................................................................................................................................Back Cover

Return Material Policy ..................................................................................................................................................................................................................................................................................Back Cover

Revised March 2019 [E N]

!

!

!

!

!

3

1.3 Fume Extraction Hazards

1.2 Users Responsability

1.1 Symbols

HOT

PARTS

MOVING

PARTS

ELECTRIC

SHOCK

WARNING!

DANGER!

• Breathing smoke, fumes, or dusts produced in applications such as welding, cutting, grinding, painting, deburring

are hazardous to user’s health. Proper ventilation or use of well maintained fume extraction and/or dust collection

equipment helps the user avoid these hazards.

• Breathable contaminants may not be visible or have an odor.

• Stop operation and leave the area immediately if 1) breathing becomes difficult, 2) experience dizziness,

impaired vision, 4) or eye/nose/mouth irritation.

• Improper use can be hazardous.

• All users must carefully read and understand this instruction manual prior to use

• No objects, such as tools, should be placed on the machine.

• When moving machine, care should be taken to ensure the users feet remain clear of the wheels.

• Machine weights 474 lbs without a capture arm, proper care should be taken when moving.

• Motor should not contact any objects, and all motor repairs should be performed while the power switch is off and

the power source is disconnected. Operator should not touch motor during use.

• Blower assembly should not contact any objects, and all blower repairs should be performed while the power switch

is off and the power source is disconnected. Operator should not touch blower during use.

• For maintenance of any and all components, power switch must be off and the power source disconnected

• It is your responsibility to follow all applicable ANSI, OSHA, UL, CSA, National & Local Fire Codes, and other

regulatory guidelines covering the safe use of equipment that extracts fumes, collects dusts, and exhausts

filtered air either indoors or outdoors.

• Before use, inspect the unit for damage and verify it is working properly.

• Only qualified persons should install, operate, maintain, or repair this unit.

• Do not modify or repair the unit with parts or accessories not supplied by the manufacturer.

• Consult filter manufacturer’s instructions for filter use and reuse, including instructions for cleaning.

This manual uses several

symbols to highlight specific

hazards. Be familiar with

these symbols and when

you see them in this

manual, read adjoining

warning text to avoid the

hazard.

Do not use this equipment:

• To extract combustible dusts, liquid vapors, aggressive fumes such as acids.

• To extract smoke or fumes above 180°F / 82°C.

• If the power cord has been damaged or ground (third prong) removed.

• Without a filter.

This manual contains specific cautionary statements related to worker safety. To protect yourself and

others, read this manual thoroughly and follow as directed before use. Not all hazards of fume & dust

control are listed in this manual, and no hazards related to welding, cutting, grinding, painting, deburring

or other applications are listed. Consult a qualified safety professional.

DO

NOT

USE

READ

BEFORE

USE

SECTION 1 - SAFETY PRECAUTIONS OF FUME & DUST EXTRACTION/COLLECTION

FRED-SR

Single Arm, Self-Cleaning, Mobile

Fume Extractor

FRED-SR2

Dual Arm, Self-Cleaning, Mobile

Fume Extractor

FRED-SR2C

Dual Arm, Self-Cleaning, Mounted

Fume Extractor

FRED-SR1

Single Arm, Self-Cleaning, Mounted

Fume Extractor

4

2.1 Diagram & Description

SECTION 2 - SPECIFICATIONS

1.4 Dust Collection Hazards

1.5 Safety Stickers

• Dusts from many metalwork, welding, cutting, grinding, painting, or deburring applications can be combustible.

• Do not use or install equipment where any potential for combustible fumes or dusts are present, until a

qualified person has indicated it is safe to do so.

• Never use or install equipment where the potential for combustible fumes or dusts are present without a

fire/explosion protection system.

• If you are unsure if the product you purchased is correct for your application, call Diversitech at 1-800-361-3733.

• This machine is equipped with safety stickers to remind operators of the inherent dangers during use and maintenance.

• The stickers are only reminders, and all safety precautions contained in this manual must be well understood and adhered to by all users.

• See APPENDIX 5: Sample Safety Stickers for example of stickers applied to machine.

Model

Nominal

Airflow

(CFM)

Motor

(H.P)

Power Cord

Length

(ft.)

Arm

Length

(ft.)

Phase

(Hz)

@120V

(amps)

@230V

(amps)

@440V

(amps)

@575V

(amps)

FRED SR Portable Fume Collector with externally articulated manual capture arm

FRED-SR

1200 1.5 1P/60Hz 13.2 --- --- --- 15 10/13

1800 3.0 3P/60Hz --- 7.1 3.7 3.2 --- 10/13

2500 5.0 3P/60Hz 13.0 6.5 5.0 --- 10/13

FRED-SR Portable Fume Collector with Fume Tracker™ hands-free capture arm

FRED-SR-T

1200 1.5 1P/60Hz 13.2 --- --- --- 15 10/13

1800 3.0 3P/60Hz --- 7.1 3.7 3.2 --- 10/13

2500 5.0 3P/60Hz 13.0 6.5 5.0 --- 10/13

FRED-SR2 Portable Fume Collector with two externally articulated manual capture arms

FRED-SR2 2500 5.0 3P/60Hz 13.0 6.5 5.0 --- 10/13

FRED SR2 C Fume Collector with two externally articulated manual capture arms

FRED-SR2 C 2500 5.0 3P/60Hz 13.0 6.5 5.0 --- 10/13

5

For information on inspecting and cleaning filter, or purchasing replacement filters, contact Diversitech at 1-800-361-3733.

2.2 Product Specifications

Description Stage Part # Filter Area Filter

Efficiency Reusable

Nano-Fiber Filter Primary S-IA-21NF 190 SQ.FT. MERV 15 Yes

Polyester Filter Primary S-IA-21PT 105 SQ.F T. M ERV 11 Yes

HEPA Filter After-Filter S-SR-1009 24” × 36” × 5-7/8” MERV 17 No

2.3 Filter Specifications

Model

Arm

Length

(ft.)

Arm

Diameter

(in.)

Footprint (in.)

Width

[a]

Height

[C]

Length

[b] [d] [e] [f] [g]

FRED SR Portable Fume Collector with externally articulated manual capture arm

FRED-SR

10 632.5 115 33 13 60 34 18.5

13 632.5 128 33 13 60 60 18.5

FRED-SR Portable Fume Collector with Fume Tracker™ hands-free capture arm

FRED-SR-T

10 732.5 115 33 13 60 34 18.5

13 732.5 128 33 13 75 34 18.5

FRED-SR2 Portable Fume Collector with two externally articulated manual capture arms

FRED-SR2

10 (x2) 6 (x2) 32.5 115 33 13 60 34 18.5

13 (x2) 6 (x2) 32.5 128 33 13 60 60 18.5

2.4 Dimensions

6

!

7

3.1 To Setup or Install Safely

3.2 Un-Packaging

3.4 Mounting Options

• If you purchased a mobile model, see APPENDIX 3: Installation of Fred SR/SR2.

• If you purchased a wall/ceiling mounted model, see APPENDIX 6: Installation of Fred SR2 C/SR1 C.

3.5 Electrical Options

SECTION 3 - PRE-INSTALLATION

• Single-Phase Unit: See APPENDIX 1A: Electrical Diagram [120 VAC] Single-Phase Power for wiring

instructions. Have a certified electrician install unit according to local regulations.

• 3-Phase Unit: See APPENDIX 1B: Electrical Diagram [230/460/575 VAC] 3-Phase Power for wiring instructions.

Have a certified electrician install unit according to local regulations.

3.3 Tools Required

1. 7/16 Socket or Wrench

2. 9/16 Socket or Wrench

3. Torque Wrench

The tools above are required for unit assembly.

1. Immediately upon receiving the unit, carefully examine the carton for damage during transit.

2. Use lift forks or truck to move

3. Remove packing material.

4. Avoid tipping or inverting during handling.

5. The item serial number, model, and electrical ratings are listed on the nameplate. Record this information in the

Maintenance Record provided in APPENDIX 2: Maintenance Record, or your own preventative maintenance system.

• Do not place unit near flammables or combustible surface.

• Refer to SECTION 2: Specifications, to know the electrical requirements of the unit you are

installing and ensure adequate input power that is properly sized, rated, and protected.

• This unit must be grounded for safe operation.

!

8

4.2 Controls

4.1 To Operate Safely

4.3 Pre-Use Checklist

• Read and understand SECTION 1: Safety Precautions and ensure SECTION 3: Pre-Installation has been followed.

• Before plugging unit in to an input power source, look at the manufacturer’s label located on the exterior of the unit

and ensure the source is correctly sized in terms of Voltage and Amperes.

• Prior to use in your application, turn the unit ON, and perform a function test. To do so:

1. LOOK: Have the front and back doors been closed properly.

2. Turn switch to ON position.

3. LOOK: Is the unit level, stable, and that nothing is obstructing the extraction path.

4. LISTEN: Does the motor and suction sound smooth and within expected volumes.

5. FEEL: Place your hand on top of the unit and sense for unexpected vibration. Place you hand in front of

the intake hood/surface and sense for expected level(s) of suction.

• Inform all potential users of this equipment where they may find and review this manual.

• The machine controls are basic, and consist solely of a power switch with ON and OFF positions.

• If the machine is equipped with a Minihelic differential pressure gauge, the Minihelic should

read between .8 and 4.2 inches W.C. during normal operation.

• For a reading of more than 4 inches W.C, consult SECTION 5: Maintenance

and Troubleshooting as filter servicing may be required.

• Read and understand SECTION 1: Safety Precautions and SECTION 4: Operation before use

• Read and understand all Material Safety Data Sheets and Manufacturer’s instructions of all

process materials, consumables, and equipment used in conjunction with this equipment.

• Keep away from all mechanical moving parts including motor, gears, and other pinch points.

• Do not use product without first confirming if a Spark Arrestor is required and installed for

the type of dust, or fumes you are extracting and/or collection. If you are unsure, call a

Diversitech representative at 1-800-361-3733.

SECTION 4 - OPERATION

9

4.4 Principles of Operation

This product is designed to capture and clean smoke and dust from medium & heavy duty welding, soldering, and grinding applications. When operating,

air is drawn in to the nozzle, passes through the 7” diameter hose, then through the air cleaner’s filtration system, and is exhausted through the rear

discharge.

This product consists of four basic components:

1. Capture Arm(s)

2. A blower

3. Cartridge Filter

4. Motor & Electrical assemblies

5. ICS-360 Injection Cleaning System

6. Dust Drawer (Mobile) or Hopper (Ceiling Mount)

• The operator is to positon the machine within operating distance, and activate the caster wheel brakes.

• The operator can then position the capture arm close enough to the worksite to capture all dust and fumes that will be produced.

• Ensuring that all safety procedures have been followed, the operator can turn on the machine and begin working.

• When not in use, the machine should be turned off.

4.5 Failure Event

4.6 ICS-360 Injection Cleaning System

If, for some reason, during operation there is an accident, a blockage occurs, the Minihelic displays abnormal pressure differences, or the machine begins to act

abnormally, the operator should immediately shut off the machine. This is considered a machine failure and the following steps should be taken:

This product consists of four basic components:

1. Turn the power switch to the OFF position.

3. Seek medical attention if an accident occurred.

4. Follow the guidelines in SECTION 5: Maintenance and Troubleshooting.

Remember, under no circumstance should the machine be turned back on while performing maintenance.

The ICS-360 Injection Cleaning System works to blow particulate off the filter and into the dust drawer in a cycle that takes approximately 8 minutes to complete.

The cycle initiates automatically each time the units turned off. If the cycle has started and the unit is turned back on, the ICS-360 will recommence cleaning from the

last position the next time the unit switched off.

STATUS LIGHTS

A Fault Alert

BSolid > Cleaning

Flashing > Homing

C Trigger

D Top Switch

E Bottom Switch

F Motor Up

G Motor Down

H Solenoid 1

I Solenoid 2

J Power 12VAC

!

!

!

10

EYE

PROTECTION RESPIRATOR GLOVES

WASTE

CONTAINER

REPLACEMENT

FILTER

(if required)

5.1 To Maintain this Product Safely

5.2 Tools Required

• Read and understand SECTION 1: Safety Precautions and SECTION 4: Operation before maintenance.

• Do not breathe the dust collected from product while changing/cleaning filters or performing maintenance on this

product.

• Disconnect power before performing any maintenance on unit, including filter inspection. The input power to this unit is

high voltage, and touching any live electrical parts can cause fatal shocks or severe burns. Do not touch live electrical

parts.

• Keep away from all mechanical moving parts including motor, gears, and other pinch points while operating.

• Operating this unit causes some parts to heat to a point that will burn bare hands. Before maintenance allow parts to

cool, or use proper tools and personal protection equipment during maintenance.

SECTION 5 - MAINTENANCE & TROUBLESHOOTING

Frecuency Manual Reference

Pre-Use

• Perform pre-use inspection to ensure operating correctly. 4.3

ISC-360 Self-Cleaning Cycle

• Automatically initiated each time unit is turned OFF. 4.5

Every (1) Week - Empty Dust Drawer

• Remove dust drawer and deposit accumulated particulate in appropriate waste container. Refer to local regulations

regarding disposal procedures as some captured contaminants may be flammable, explosive, or toxic.

• Recommended frequency is one week, but may be less or more depending of application.

As Required – Replace Filter

1. Replace Filter

Every (12) months Inspect Basic Components

1. Clean unreadable labels and exterior surfaces

2. Capture Arm: Check for tears in flex hoses and fitting of hose clamps

3. Cabinet: Look for loose wiring.

4. ICS-360 Function Test:

• Open Cabinet Door (keep open)

• Remove Filter

• Turn ON unit, and then OFF

• Observe if ICS-360 cycle initiates (normal delay of 30 seconds)

• Observe if air nozzle passes the complete range (bottom-to-top) of acme shaft.

11

5.3 Routine Maintenance Schedule

The manufacturer recommends the following routine maintenance based on light-duty use in normal operating conditions. Service more frequently if the

unit is used in severe conditions.

12

5.4 Troubleshooting Procedure

Motor

Operating

NO INTERMITTENTLY

Turn Unit

On

Motor

Operating

Air Flow

Restricted

Check Leads at

Input Power

Source

Air Flow

Restricted

Check/clean

Hood inlet &

Capture tubes

Unit Operates

Properly

Call for Service

1(800)361-3733

Call for Service

1(800)361-3733

Call for Service

1(800)361-3733

YES

ICS-360

Operating

YES

YES

YES

NO

Check Leads at

Unit

NO Call for Service

1(800)361-3733

Air Flow

Restricted

Replace

Filter

NO

YES

NO

NO

YES

13

[120 VAC] Single-Phase Power

APPENDIX 1A - ELECTRICAL DIAGRAM MANUAL

ELECTRIC

SHOCK

HAZARD

WARNING

Do not route auxiliary contact cable in

the same conduit as motor cable

NOTE

Specific transformer wiring may

differ depending on voltage

configuration.

Units in brackets [ ] refer to imperial

system values

1.5 HP [120v]

TEFC Motor

60 Hz

Disconnect power before performing any maintenance on unit, including filter

inspection. The input power to this unit is high voltage, and touching any live

electrical parts can cause fatal shocks or severe burns. Do not touch live electrical

parts.

14

[230/460/575V] 3-Phase Power

APPENDIX 1B - ELECTRICAL DIAGRAM MANUAL

ELECTRIC

SHOCK

HAZARD

WARNING

Do not route auxiliary contact cable in

the same conduit as motor cable

NOTE

Specific transformer wiring may

differ depending on voltage

configuration.

Units in brackets [ ] refer to imperial

system values

3HP [230/460/575v]

TEFC Motor

3600 RPM 60 Hz

Disconnect power before performing any maintenance on unit, including filter

inspection. The input power to this unit is high voltage, and touching any live

electrical parts can cause fatal shocks or severe burns. Do not touch live electrical

parts.

Date Description of Service Serviced By Location Comments

MANUFACTURER: DIVERSITECH INC. MODEL N° FRED-SR SERIAL N°

SERVICE LOCATION: CONTROL N°

15

Only use manufacturer approved replacement parts on this unit.

Diversitech Inc. authorizes this page to be photocopied or otherwise reproduced as needed for management of maintenance

records.

APPENDIX 2 - MAINTENANCE RECORD

Quantity Hardware

1Mounting Plate

1 Swivel Base

8 1/4’’ Bolt, Socket Cap

81/4’’ Washer

16

Capture Arm

Swivel Base

Vent Hood

STEP 1. Unpack capture arm, hood, and base.

STEP 2. Attach swivel base to mounting plate.

APPENDIX 3 - ARM-TO-BLOWER DIRECT INSTALLATION

3.1 Unpack capture arm, hood, and base

3.2 Attach swivel base to mounting plate

• Mount Swivel Base to Mount Plate.

• Tighten all Bolts (8) with Washers (8)

• Toque each bolt to 23 N m

Quantity Hardware

1 Swivel Base

1Capture Arm Assembly

3 1/4’’ Bolt, Socket Cap

61/4’’ Washer

31/4’’ Locking Nut

31/4’’ Spacer

17

3.3 Attach capture arm to swivel base

STEP 3. Attach capture arm to swivel base.

• Insert Spacers (3) between Capture Arm Mounting Bracket.

• Thread Bolts (3) with Washers (3) through Mounting Bracket and Spacers.

• Mount Capture Arm Assembly to Swivel Base.

• Thread Washers (3) and Locking Nuts (3) to Bolts (3)

• Tighten all Bolts (3) to Locking Nuts (3)

• Toque each bolt to 40 N m

Quantity Hardware

1Fred-SR Assembly

2Hose Clamps

1 Flex Hose

18

STEP 4. Install flex hose.

3.4 Install flex hose

• Mount Flex Hose to Swivel Base and Capture Arm.

• Tighten Both Hose Clamps.

Quantity Hardware

1Bracket

8 Press-in Nut for Sheet Metal, 1/4”-20 Thread Size

STEP 2. Description of the bracket assembly.

4.1 Wall mount bracket standard assembly

• Mount Swivel Base to Remote Mount Bracket.

• Tighten all Bolts (8) with Washers (8)

• Toque each bolt to 23 N m

Quantity Hardware

1Motor Blower Assembly

1 Swivel Base

8 1/4’’ Bolt, Socket Cap

81/4’’ Washer

Quantity Hardware

1 Swivel Base

1J-Bracket

3 1/4’’ Bolt, Socket Cap

61/4’’ Washer

31/4’’ Lock Nut. Socket Cap

• Mount J-Bracket to Swivel Base

• Tighten all Bolts (8) with Washers (8) and Nuts (3)

• Toque each bolt to 34 N m

4.3 Attach J-Bracket to Arm Swivel

STEP 3. Attach J-Bracket to Arm Swivel.

• Mount Swivel Base to Remote Mount Bracket.

• Tighten all Bolts (8) with Washers (8)

• Toque each bolt to 23 N m

4.2 Attach swivel base to remote mount bracket

STEP 3. Attach capture arm to swivel base.

19

APPENDIX 4 - ARM TO REMOTE MOUNT BRACKET INSTALLATION

4.4 Attach Capture Arm to Swivel Base (J-Bracket)

Quantity Hardware

1 Swivel Base with J-Bracket

1Capture Arm Assembly

3 3/8’’ Bolt, Socket Cap

63/8’’ Washer

33/8’’ Lock Nut. Socket Cap

Quantity Hardware

1Extractor Arm Assembly

2Hose Clamps

1 Flex Hose

• Mount Flex Hose to Swivel Base and capture Arm.

• Tighten Both Hose Clamps.

STEP 5. Install Flex Hose.

4.5 Install Flex Hose

• Insert J-Bracket between Capture Arm Mounting Bracket.

• Thread Bolts (3) with Washers (3) through Mounting Bracket and J-Bracket.

• Thread Washers (3) and Locking Nuts (3) to Bolts (3)

• Tighten all Bolts (3) to Locking Nuts (3)

STEP 4. Attach Capture Arm to Swivel Base. (J-Bracket)

20

This manual suits for next models

3

Table of contents

Other DIVERSITECH Ventilation Hood manuals

Popular Ventilation Hood manuals by other brands

ELICA

ELICA Mezzano Series Use, care and installation guide

Zanussi

Zanussi ZHC 955 Operating and installation instructions

Whirlpool

Whirlpool UXI6536BS0 Use & care guide

Koncar

Koncar NO90LIG instruction manual

Amana

Amana UXT4030AYS Installation instructions and use and care guide

NuTone

NuTone AHDA1 Series Installation use and care manual