INSTALLATION, OPERATION AND

MAINTENANCE INSTRUCTIONS

Save These Instructions

Document No.: 48-00003 Revision A Page: 10

PUMP SPEED AND HORSEPOWER

This unit is equipped with a gear reducer that turns the pump shaft

at a reduced speed relative to the motor shaft. It is available in

multiple speed (flow) and HP (pressure) options. Please see the

“Product Overview” section for details on the gear reducer and HP

specifications for your model to determine flow and pressure

performance. Be sure to take this into consideration when verifying

the applicability of this unit for pumping/filtration applications.

HOSE CONNECTIONS

Use of high quality camlock fittings with locking levers is

recommended to avoid hazardous spills.

REVERSE ROTATION

The FS1 SERIES systems are not designed to be operated in

reverse rotation.

PUMP BYPASS FEATURE

The pump end on this unit is a Dixon Pumps positive displacement

pump. Positive displacement pumps require a bypass mechanism to

relieve the pressure in the system when there is a blockage, valve,

or nozzle on the discharge side of the pump.

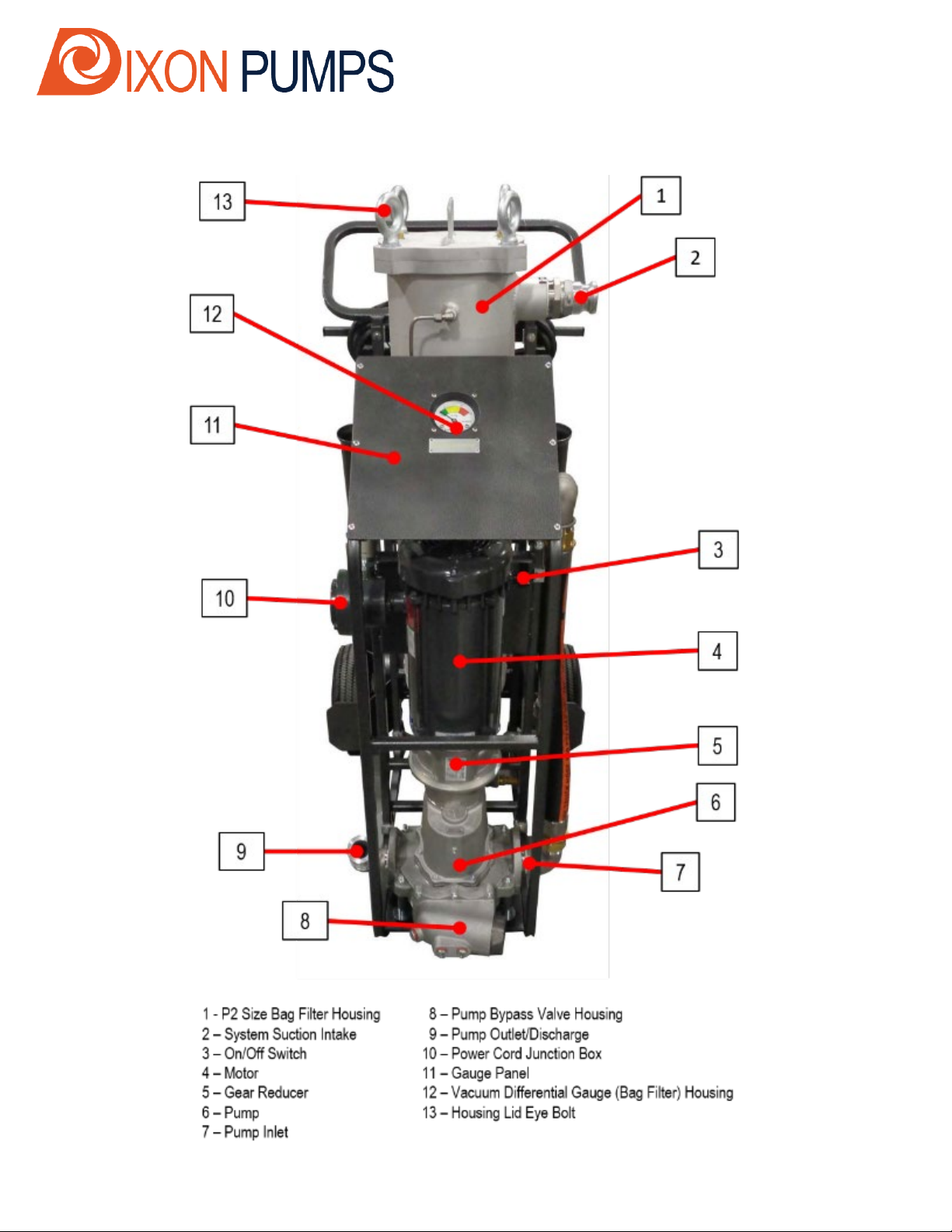

FILTER HOUSINGS – FILTER ELEMENT ACCESS

The filter housing is equipped with a removable lid that is secured

with four eye bolts. After relieving pressure in the system, the

housing lid can be removed by loosening all four bolts and

completely removing three of them. One of the eye bolts can be left

in place to hold the lid as it is rotated out of the way.

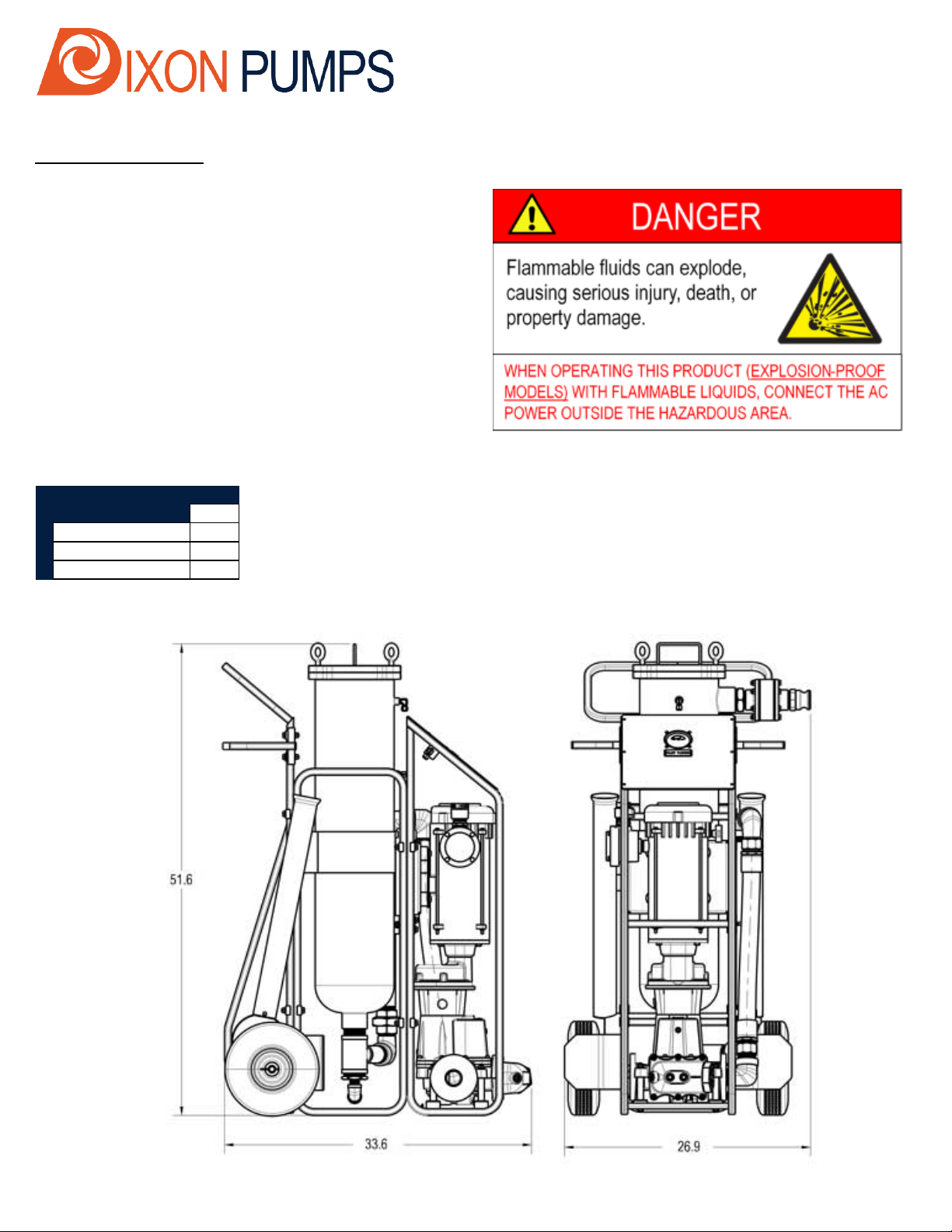

WHEN PUMPING FLAMMABLE LIQUIDS WITH

EXPLOSION-PROOF MODELS,

ALL HOSE COUPLINGS MUST BE EXPLOSION

PROOF RATED. ALL HOSE MUST HAVE A

STATIC WIRE, AND MUST ALSO BE UL LISTED

FOR CLASS 1, DIV 1, GROUP D, CLASS 2,

GROUP F AND G (CANADA: MUST BE CSA LISTED)

Flammable fluids can explode,

causing serious injury, death, or

property damage.

Flammable fluids can explode,

causing serious injury, death, or

property damage.

WHEN PUMPING FLAMMABLE FLUIDS SUCH AS

GASOLINE (NFPA CLASS I LIQUIDS) WITH EXPLOSION-

PROOF MODELS, DO NOT ALLOW THE PUMP TO STAY

IN BYPASS FOR LONGER THAN ONE (1) MINUTE.

WHEN CHANGING FILTERS, TIGHTEN FILTER HOUSING

LIDS BY HAND. DO NOT USE TOOLS ON FILTER

HOUSING EYE BOLTS. OVERTIGHTENING CAN RESULT

IN DEFORMATION OF THE CANISTER LID AND FAILURE

OF LIQUID-TIGHT SEAL!

Hazardous pressure can cause

personal injury or property damage

WHEN REPLACING FILTER ELEMENTS, MAKE SURE THE

PUMP IS OFF AND THE PRESSURE IS RELIEVED BEFORE

OPENING THE FILTER HOUSING LID.

WHEN USING A SHUT-OFF NOZZLE, THE PUMP WILL

OPERATE IN THE BY-PASS MODE (FLUID WILL

CIRCULATE AROUND INSIDE THE PUMP THROUGH THE

BYPASS FLOWPATH) IF THE NOZZLE IS IN THE “OFF”

(CLOSED) POSITION. THE PUMP SHOULD NOT BE

OPERATED FOR MORE THAN FIVE (5) MINUTES IN FULL

BY-PASS MODE FOR NFPA CLASS II AND CLASS III