Page 8of 10

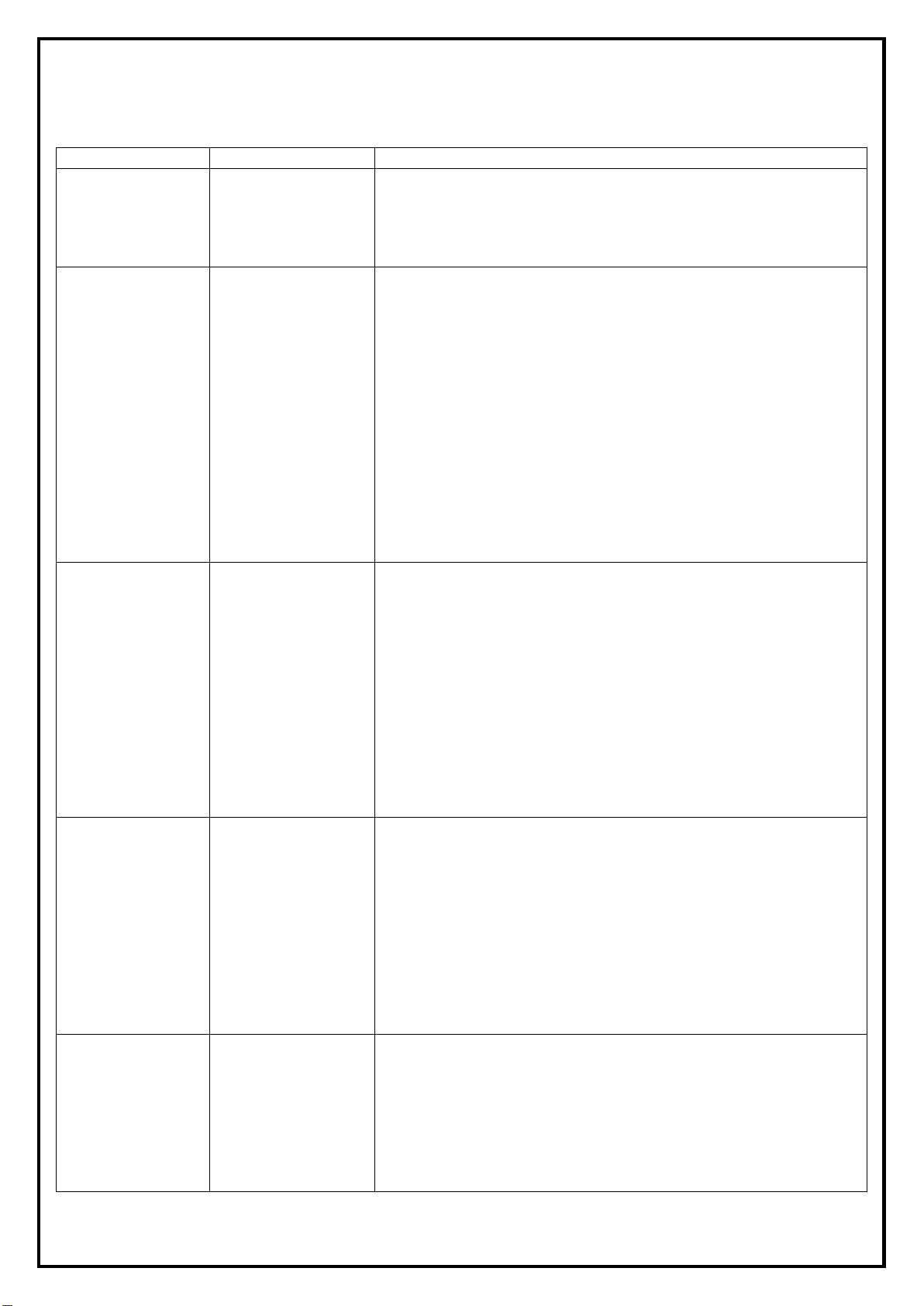

3. pH testing equipment can range from a cheap test pen right

up to lab grade equipment. Before coming to a conclusion on

pH issues, it is best to ensure the equipment used to measure

the pH of the RO water is of high standards and suitable for

reading pH levels in low EC water (i.e. The guy at the pool

shop is not going to cut it). We have access to high quality

testing equipment and frequently test our units and conduct

research. If you feel that there is an issue with your pH, please

the water (New

System)

2. Residue

3. Contamination

1. If you are using an alkaline filter system, the unit requires

adequate flushing before first use. Usually all taste is gone

within a week of use. This taste is normal and in most cases is

your body adjusting to the high pH water (which some people

can describe as a slight metallic taste).

2. The filters are dry packed, the carbons, alkaline filters will

have ‘fines’ on them as they are granular medias, this will go

away with flushing. The membrane has a food grade preserve

inside it to prevent contamination during storage, this will also

flush away quickly.

3. Bacterial contamination is highly unlikely, but not

impossible. If there is a strong ‘foul smell’ or organic taste to

the water, it is possible that there is some form of

contamination. Contact us straight away so we can rectify (or

diagnose) the problem if there is one present.

Higher than the

inlet water (or the

same).

2. Alkaline Filter

3. Expired Filters

4. Mixed Up Drain

Line and Drinking

Line

1. While filters are new, it is normal for the TDS to be elevated

while the system is flushing. Continue flushing the system &

contact support if the high TDS persists.

2. Alkaline filters will naturally increase the TDS of the water,

especially when new. If you have low TDS water already, it is

possible for the TDS level out of the alkaline filter to be higher

than your inlet water. This is because you are adding minerals

back into the water therefore increasing the TDS and alkalinity.

3. If the filters have not been changed as per the

recommendations, it is likely that the increased TDS is due to

the filters needing replacing.

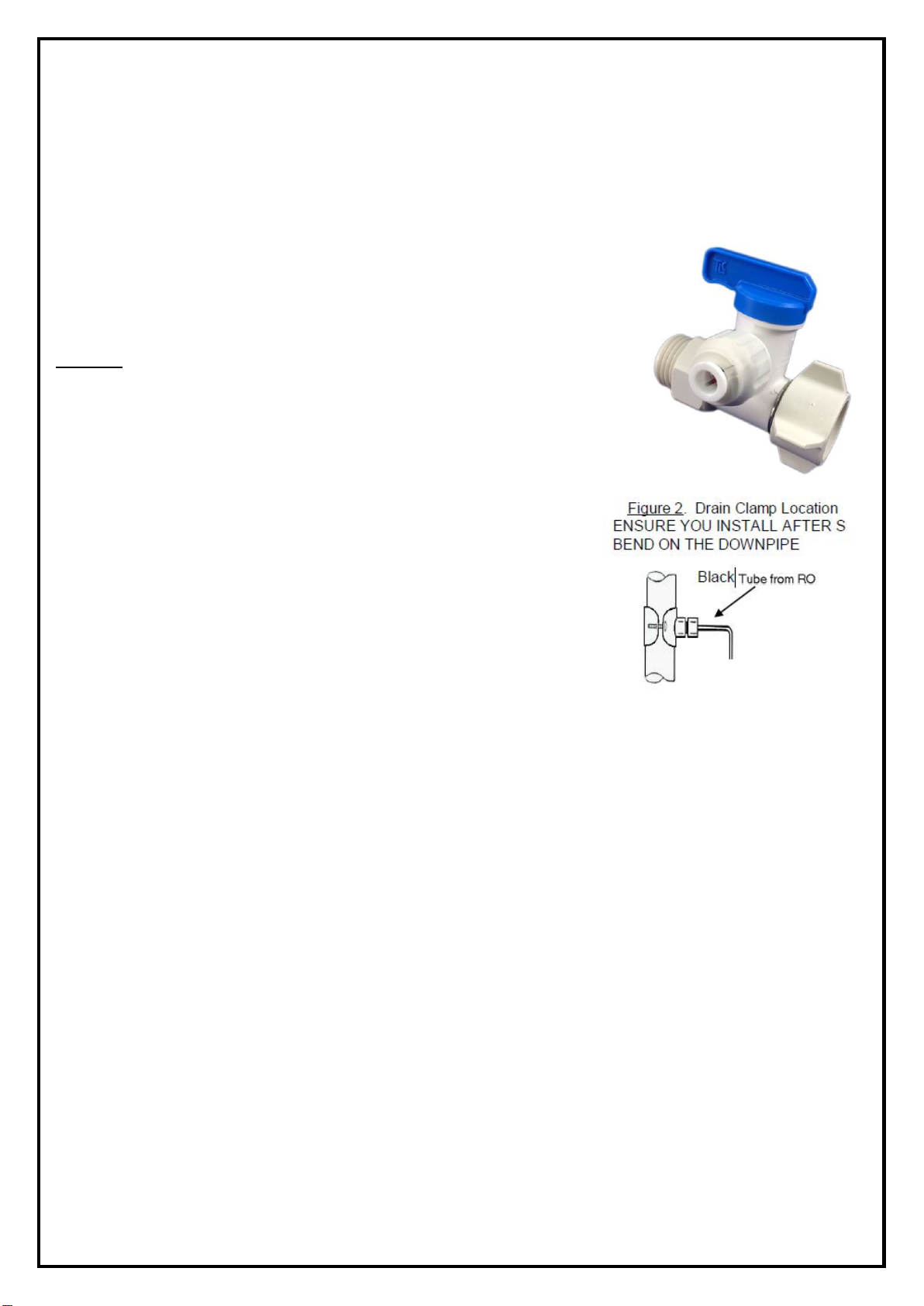

4. This is common as sometimes the lines may be mixed up.

Make sure that the tubing connected to the ‘Drain Line’ flow

restrictor is being run to waste, do not use this water for

drinking. Your drinking water line should be marked with either

‘outlet’, ‘Drinking Water’ or ‘Aquarium Water’.

suddenly slowed

down to a trickle

pressure

2. Tank Bladder

Rupture

3. Blocked filters

1. Over time, air can slowly leak out of a RO tank. Sometimes

this is more noticeable at the time you change your filters. An

indication that this has occurred is that the tank will be very

heavy (full of water) but no water comes out the tap. The

solution is to disconnect the tank (after shutting down the

system). Then empty all water from the tank, or as much as

possible. Add air pressure into the tank equal to 7psi.

Reconnect the tank and let it fill and try again.

2. Depress the air valve on the side of the tank – if water

comes out the air valve the bladder is ruptured. Or if you add

air to the tank and the air comes out the inlet/outlet valve it is

also ruptured. – The tank will need to be replaced.

3. It is unlikely that the filters would be totally blocked but it is

possible. Check the feed water conditions and replace the

filters if they are passed the recommended change times.

running to waste

1. When the system is newly installed or you have just

changed the filters, there is a considerable amount of air in the

system. This air can become trapped in air pockets and if they