DMC HPU13M User manual

DATASHEET

Read and understand all of the instructions and safety

information in this manual before operating or servicing

this tool.

HPU13M

Battery-powered Pump

HPU13M-DS REV. A ©2014 DANIELS MANUFACTURING CORP.

ALL RIGHTS RESERVED 526 Thorpe Rd. • Orlando, FL 32824 USA • 407-855-6161

www.dmctools.com

HPU13M Battery-powered Pump

HPU13M-DS REV. A ©2014 DANIELS MANUFACTURING CORP.

ALL RIGHTS RESERVED 526 Thorpe Rd. • Orlando, FL 32824 USA • 407-855-6161

www.dmctools.com

2

Description

The DMC HPU13M Battery-powered Pump is a dual-stage

pump that develops a maximum of 700 bar (10,000 psi).

This pump is intended to provide hydraulic power for remote

crimping tools.

This pump has a factory-set internal pressure relief valve.

Fill unit with hydraulic oil before

operating pump.

Failure to ll unit with oil will result in

damage to the pump.

Safety

Safety is essential in the use and maintenance of DMC tools

and equipment. This instruction manual and any markings on

the tool provide information for avoiding hazards and unsafe

practices related to the use of this tool. Observe all of the

safety information provided.

Purpose of this Manual

This manual is intended to familiarize all personnel with the

safe operation and maintenance procedures for the DMC

HPU13M Battery-powered Pump.

Keep this manual available to all personnel.

Replacement manuals are available upon request at no charge

at www.dmctools.com

Do not discard this product or throw away!

All specications are nominal and may change as design improvements occur.

Daniels Manufacturing Corp. shall not be liable for damages resulting from

misapplication or misuse of its products.

KEEP THIS MANUAL

Table of Contents

Description...............................................................................2

Safety .......................................................................................2

Purpose of this Manual ............................................................2

Important Safety Information ..............................................3–5

Identication ............................................................................6

Specications ...........................................................................6

Features of the Pump ...............................................................7

Setup ........................................................................................7

Operation..............................................................................8–9

Maintenance...........................................................................10

Troubleshooting .....................................................................11

Limitation of Liability and Warranty .....................................12

HPU13M Battery-powered Pump

HPU13M-DS REV. A ©2014 DANIELS MANUFACTURING CORP.

ALL RIGHTS RESERVED

526 Thorpe Rd. • Orlando, FL 32824 USA • 407-855-6161

www.dmctools.com

3

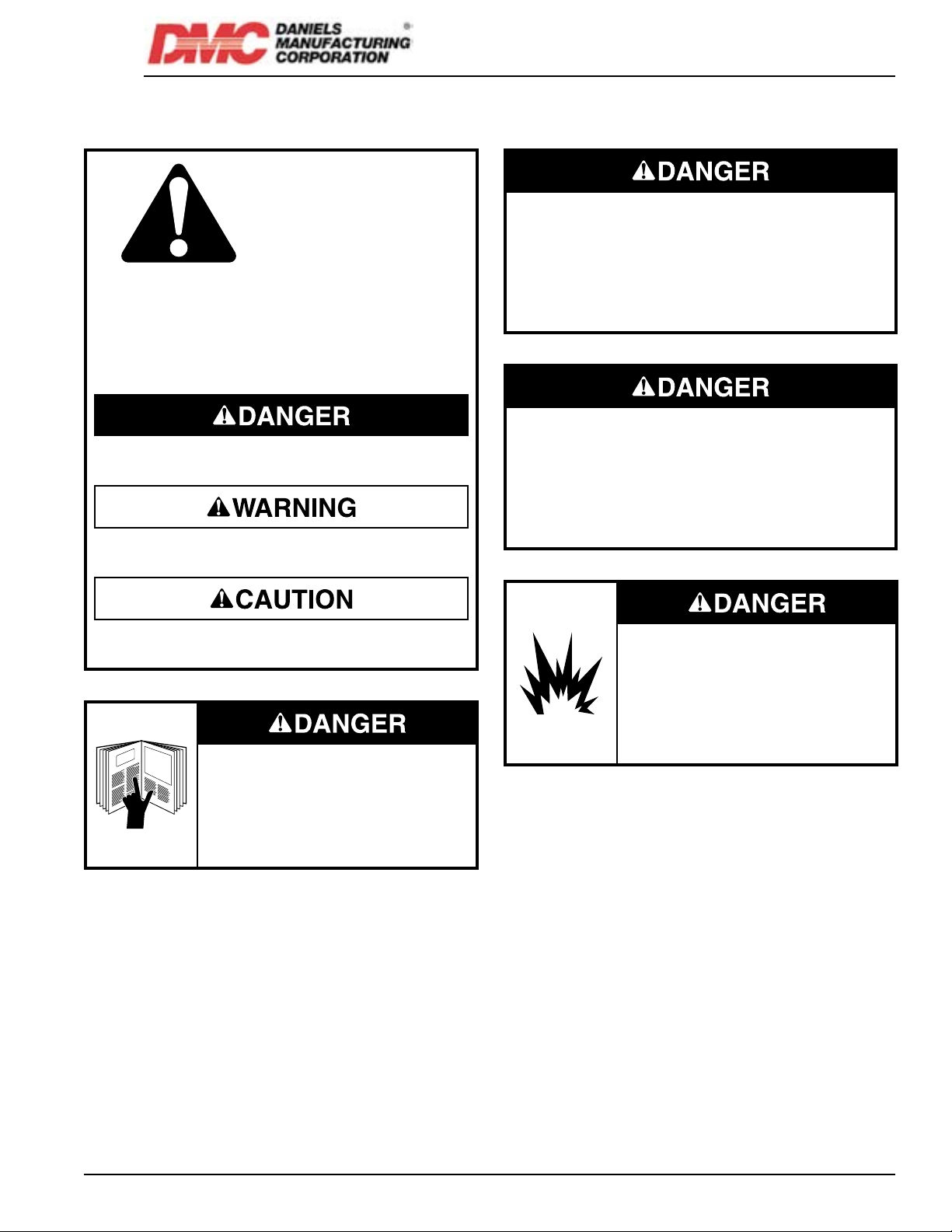

IMPORTANT SAFETY INFORMATION

SAFETY

ALERT

SYMBOL

This symbol is used to call your attention to hazards or

unsafe practices which could result in an injury or prop-

erty damage. The signal word, dened below, indicates

the severity of the hazard. The message after the signal

word provides information for preventing or avoiding the

hazard.

Immediate hazards which, if not avoided, WILL result in

severe injury or death.

Hazards which, if not avoided, COULD result in severe

injury or death.

Hazards or unsafe practices which, if not avoided, MAY

result in injury or property damage.

Read and understand all of the instruc-

tions and safety information in this

manual before operating or servicing

this tool.

Failure to observe this warning will

result in severe injury or death.

Do not connect the pump to any system or system compo-

nent other than those supplied by DMC. Other manufactur-

ers’ components may not withstand the maximum pressure

and may fail. Nearby personnel can be injured by ying

components and hydraulic oil.

Failure to observe this warning will result in severe injury

or death.

Do not alter the internal high-pressure relief valve setting.

Altering this setting will change the maximum pressure the

pump can develop, which can cause a component failure.

Nearby personnel can be injured by ying components and

hydraulic oil.

Failure to observe this warning will result in severe injury

or death.

Do not use this pump in a hazardous

environment. Hazards include am-

mable liquids, gases, or other materials.

Using this pump in a hazardous environ-

ment can result in a re or explosion.

Failure to observe this warning will

result in severe injury or death.

HPU13M Battery-powered Pump

HPU13M-DS REV. A ©2014 DANIELS MANUFACTURING CORP.

ALL RIGHTS RESERVED 526 Thorpe Rd. • Orlando, FL 32824 USA • 407-855-6161

www.dmctools.com

4

IMPORTANT SAFETY INFORMATION

Electric shock hazard:

• Do not expose power tools to rain.

• Do not immerse the pendant switch in

water or other liquid.

• Do not crimp live cables or conduc-

tors. Before starting to work, make sure

there are no live lines in the work area.

Failure to observe these warnings could

result in severe injury or death.

Skin injection hazard:

• Do not use hands to check for leaks.

• Depressurize hydraulic system before

servicing or disconnecting the hose.

High pressure oil easily punctures skin,

causing serious injury, gangrene, or death.

If injured, seek medical help immediately

to remove oil.

Wear eye protection when using this tool.

Failure to wear eye protection could result

in serious eye injury from ying debris or

hydraulic oil.

Inspect pump, hoses, couplers, and ttings for wear or

damage. Replace worn, damaged, or missing components

with DMC replacement parts. Worn or damaged compo-

nents can fail, resulting in injury.

Failure to observe this warning could result in severe injury

or death.

Fill unit with hydraulic oil before

operating pump.

Failure to ll unit with oil will result in

damage to the pump.

• Do not use hose or cord to pull, lift, or carry the equip-

ment. Misuse will damage the hose or cord.

• To avoid accidental start-up, turn the program selection

switch to position 7 before transporting the tool.

Failure to observe these precautions may result in injury or

property damage.

Make sure all hose ttings are properly seated before start-

ing the pump. Incomplete connections may not allow the

accessory’s ram to retract after the hydraulic operation is

nished.

HPU13M Battery-powered Pump

HPU13M-DS REV. A ©2014 DANIELS MANUFACTURING CORP.

ALL RIGHTS RESERVED

526 Thorpe Rd. • Orlando, FL 32824 USA • 407-855-6161

www.dmctools.com

5

IMPORTANT SAFETY INFORMATION

Cutting hazard:

• Remove battery before changing dies,

adapters, or jaws.

• Keep hands away from the head when

in operation.

Failure to observe these warnings could

result in severe injury or death.

Do not dispose of batteries in a re. They will vent fumes

and may explode.

Failure to observe this warning could result in severe

injury from harmful fumes or burns from ying debris.

Inspect tool and blades before use. Replace any worn or

damaged parts. A damaged or improperly assembled tool

can break and strike nearby personnel.

Failure to observe this warning could result in severe injury

or death.

• Do not use this tool for continuous use. After 100

cycles, allow the tool to cool for 15 minutes.

• Do not secure this tool in a vise.

• This tool may be used in damp or wet environments;

however, air-drying is recommended before use if the

tool becomes soaked. Damage may result when the tool

is operated prior to thorough drying when electrical

components are soaked.

• Use this tool for the manufacturer’s intended purpose

only.

Failure to observe these precautions may result in injury

or property damage.

Do not allow anything to contact the battery terminals.

• Do not immerse the batteries in liquid. Liquid may

create a short circuit and damage the battery. If batter-

ies are immersed, contact your service center for proper

handling.

• Do not place the battery into a pocket, tool pouch, or

tool box with conductive objects. Conductive objects

may create a short circuit and damage the battery.

• Do not place a battery on moist ground or grass.

Moisture may create a short circuit and damage the

battery.

Failure to observe these precautions may result in injury

or property damage.

• Do not store the battery at more than 122 °F (50 °C)

or less than –4 °F (–20 °C). Damage to the battery can

result.

• Do not use another manufacturer’s charger. Other

manufacturers’ chargers may overcharge and damage

the battery.

• Do not attempt to open the battery. It contains no user-

serviceable parts.

Failure to observe these precautions may result in injury

or property damage.

Use all appropriate and applicable personal safety equip-

ment as required such as safety shoes, hard hat, and safety

glasses. Follow all safety rules and regulations for the job.

Failure to comply may result in personal injury or property

damage.

Do not perform any service or maintenance other than as

described in this manual. Injury or damage to the tool may

result.

Failure to observe this precaution may result in injury and

property damage.

Note: Keep all decals clean and legible, and replace when

necessary.

HPU13M Battery-powered Pump

HPU13M-DS REV. A ©2014 DANIELS MANUFACTURING CORP.

ALL RIGHTS RESERVED 526 Thorpe Rd. • Orlando, FL 32824 USA • 407-855-6161

www.dmctools.com

6

Identication

Specications

Dimensions

Length............................................................................................................. 14.0" (356 mm)

Width ................................................................................................................ 6.5" (165 mm)

Height ............................................................................................................. 11.5" (292 mm)

Weight ..................................................................................................................10.8 lb (4.9 kg)

Reservoir Capacity................................................................................................0.80 qt (0.76 l)

Maximum Operating Pressure...................................................................... 10,000 psi (700 bar)

Operating Temperature Range ................................................. 10 °F to 104 °F (-12°C to 40 °C)

Dual-Stage Pumping Action

Rapid Advance .......................................................................................................... 0.9 l/min

At Full Pressure......................................................................................................... 0.3 l/min

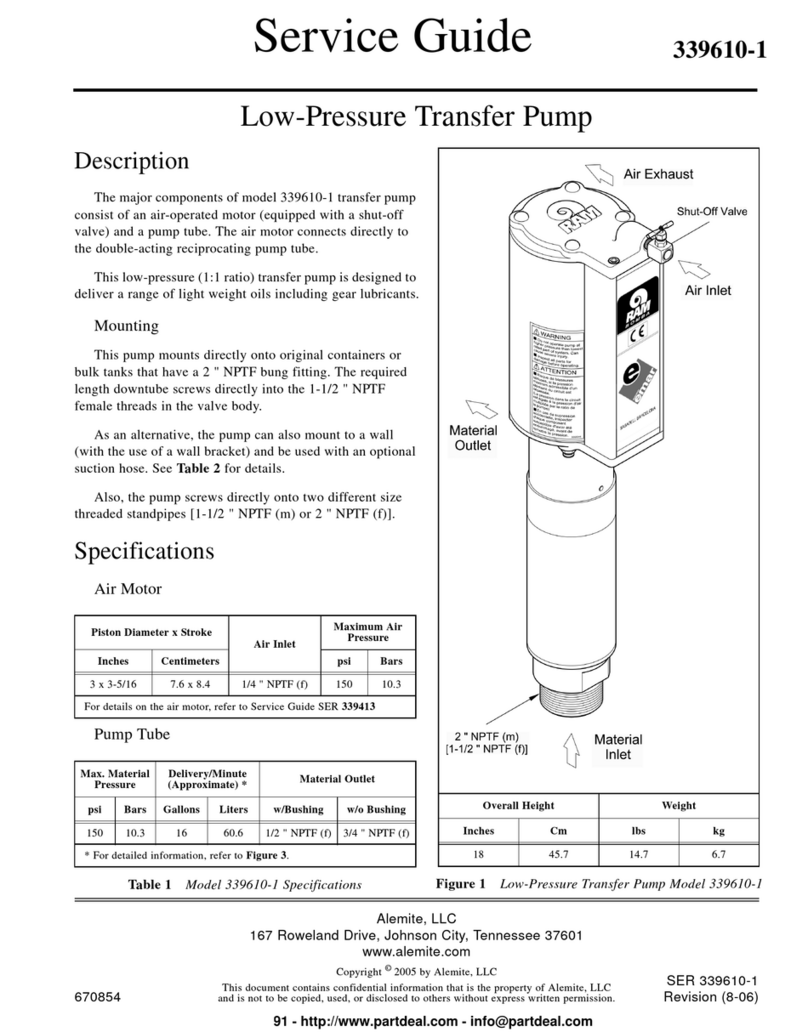

1. 3/8" Female Coupler

2. Program Selection Switch

3. LED Display

4. LED (red)

5. Forward and Return Switch

6. Oil Plug (on back)

8A

8B

9

10

2

3

4

5

6

7

11

1

7. Battery Lock

8A. Battery (active)

8B. Battery (storage)

9. Pendant Switch Socket

10. Storage Compartment

11. Emergency Stop Button

HPU13M Battery-powered Pump

HPU13M-DS REV. A ©2014 DANIELS MANUFACTURING CORP.

ALL RIGHTS RESERVED

526 Thorpe Rd. • Orlando, FL 32824 USA • 407-855-6161

www.dmctools.com

7

SetupFeatures of the Pump

• This pump is equipped with a brake, which stops the

forward motion of the piston/dies when the trigger is

released.

• The unit is equipped with a double piston pump, which is

characterized by a rapid approach of the dies toward the

connector and a slow crimping motion.

• All tool functions can be controlled by the rocker trigger,

resulting in easy handling.

• The pump is equipped with a microprocessor, which

indicates service intervals and low battery charges. It also

performs internal checks, sending out acoustical and optical

warning signals in case of a detected fault.

• The pump can be operated and transported in all positions

without any oil leakages.

• This tool is equipped with a circuit board, incorporating

several important features to inform the user about the

current status of the unit.

• Before operating the pump, the charging level of the battery

should be tested. A low charging level can be detected by

the LCD display.

• The pressure units may be displayed in bar or psi. To change

the units, set the selection switch to 7, depress the pendant

toggle three times, and then hold the toggle switch to change

the display.

• An optional foot pedal actuator (HPU13M-FP) is available

for purchase through DMC and can be used in place of the

provided hand pendant. To us the foot pedal, remove the

hand pendant from the Pendant Switch Socket (item 9) and

install the foot pedal connector into that Socket.

Hydraulic Connection

1. Clean all couplers, threaded ttings, ports, and the area

around all ports.

2. Remove any dust caps from couplers.

3. Hand-tighten all couplings rmly (until all threads are

fully engaged). Do not use tools.

HPU13M Battery-powered Pump

HPU13M-DS REV. A ©2014 DANIELS MANUFACTURING CORP.

ALL RIGHTS RESERVED 526 Thorpe Rd. • Orlando, FL 32824 USA • 407-855-6161

www.dmctools.com

8

Operation

Inspect pump, hoses, couplers, and ttings for wear or

damage. Replace worn, damaged, or missing components

with DMC replacement parts. Worn or damaged compo-

nents can fail, resulting in injury.

Failure to observe this warning could result in severe injury

or death.

Electric shock hazard:

This tool is not insulated. When using

this unit near energized electrical

lines, use proper personal protective

equipment.

Failure to observe this warning could

result in severe injury or death.

Wear eye protection when operating or

servicing this tool.

Failure to wear eye protection could

result in serious eye injury from ying

debris or hydraulic oil.

Cutting hazard:

• Remove battery before changing dies,

adapters, or jaws.

• Keep hands away from the head when

in operation.

Failure to observe these warnings could

result in severe injury or death.

Skin injection hazard:

• Do not use hands to check for leaks.

• Depressurize hydraulic system before

servicing or disconnecting the hose.

High pressure oil easily punctures skin,

causing serious injury, gangrene, or death.

If injured, seek medical help immediately

to remove oil.

Electric shock hazard: The owner of this tool must be

certain that all users of this tool are trained in the applicable

safety codes and standards as well as in the safe use of this

tool and its accessories.

Failure to observe this warning could result in severe injury

or death.

• Do not use this tool for continuous use. After

100 cycles, allow the tool to cool for 15 minutes.

• Do not secure this tool in a vise. This tool is designed

for hand-held operation.

• Use this tool for the manufacturer’s intended purpose

only.

Failure to observe these precautions may result in injury

or property damage.

Procedure for depressurizing the hydraulic system:

1. Disconnect the pump from the power source.

2. Press down on the manual release shaft and allow the

ram to retract fully.

3. Disconnect the hose slowly to release any trapped

pressure.

Charging the Battery

Read the instructions supplied with the battery charger.

HPU13M Battery-powered Pump

HPU13M-DS REV. A ©2014 DANIELS MANUFACTURING CORP.

ALL RIGHTS RESERVED

526 Thorpe Rd. • Orlando, FL 32824 USA • 407-855-6161

www.dmctools.com

9

Operation (cont’d)

LED Indicator (red)

This tool is equipped with a special circuit board incorporating

several important features to inform the user about the current

status of the unit. The LED signals in the following cases:

What happens Signal What it means

Flashing light for

2 seconds

Battery is inserted in

tool.

Constant light for

20 seconds at end of cycle

Battery charge is below

17 V at beginning of

cycle.

Tool will not start, and

constant light for 20 seconds

when trigger is released

Battery charge is below

16 V at beginning of

cycle.

Tool will stop, and

constant light for

20 seconds after trigger is

released

Battery voltage drops

below 13 V during cycle.

Tool will stop, and ashing

light for 20 seconds when

trigger is released

Motor current exceeds

20 A during cycle.

Circuit has become too

hot.

Flashing light and audible

alert for 3 seconds after

cycle

Serious error—Crimping

pressure has not been

reached while motor was

running.

Flashing light and audible

alert for 1 second after

cycle

Error—Required

crimping pressure

has not been reached.

Operator has interrupted

crimping cycle manually

while motor was not

running.

Operating Procedure

1. Connect the male coupling of the hydraulic hose to the

female coupling of the pump.

2. Select the correct working unit for the intended

application.

3. Connect the tool head to the pump via the hydraulic hose.

• Do not operate the pump without a working unit.

• Before operating the pump, check the oil level and

adjust if necessary.

Failure to observe these precautions may result in injury

or property damage.

4. Connect the pendant switch, which the pump recognizes

through a special coding. The built-in trigger will be deac-

tivated accordingly.

5. Plug the battery (and spare battery, if using) into the

socket.

6. The pump is now ready to operate, and the LCD display is

activated.

7. Select the program for the intended application by turning

the selection knob or the data function.

8. Initiate the working cycle by activating the advance func-

tion of the forward and return switch.

Note: The retraction button of the forward and return switch

is always active and can be actuated at any time and in any

program.

HPU13M Battery-powered Pump

HPU13M-DS REV. A ©2014 DANIELS MANUFACTURING CORP.

ALL RIGHTS RESERVED 526 Thorpe Rd. • Orlando, FL 32824 USA • 407-855-6161

www.dmctools.com

10

Maintenance

Wear eye protection when operating or

servicing this tool.

Failure to wear eye protection could

result in serious eye injury from ying

debris or hydraulic oil.

Skin injection hazard:

Do not use hands to check for oil leaks.

Oil under pressure easily punctures skin.

If injured, seek medical attention imme-

diately to remove oil.

Failure to observe this warning could

result in serious injury, gangrene, or

death.

Do not use solvents or ammable liquids

to clean the tool body. Solvents or am-

mable liquids could ignite and cause

serious injury or property damage.

Cutting hazard:

• Remove battery before changing dies,

adapters, or jaws.

• Keep hands away from the head when

in operation.

Failure to observe these warnings could

result in severe injury or death.

Relief valve adjustments must be done by an

authorized service center.

Daily

Before use:

1. Inspect the tool for wear or damage, such as cracks,

gouges, or chips.

2. Inspect the tool for damage or leaks.

After use:

1. Use a damp cloth and mild detergent to clean the housing.

Allow the housing to dry.

2. Store the tool in a cool, dry place.

3. If necessary, recharge the batteries. Refer to the instruc-

tions supplied with the battery charger.

Monthly

1. Thoroughly clean all surfaces.

2. Check the oil level.

Annually or After 10,000 Cycles

1. Replace the hydraulic oil.

2. Send the tool to DMC for inspection.

Checking the Hydraulic Fluid Level

The pump has an oil plug with inspection glass, which can be

used to determine the proper oil level. If the oil level is too

low, the reservoir must be lled.

The following hydraulic oils are suitable for a temperature

range of 10 °F to 104 °F (-12°C to 40 °C):

• Hydraulic oils based on Ester: Rivolta S.B.H. 11, Shell

Naturell HF-E 15.

• Mineral oils: Shell Tellus T 15, AVIA HVI 15, Mobil DTE

11, NUTO H 15, Rando HD-Z15, Agip OSO 15, BP Energol

HLP 15.

• Other equivalent oils.

HPU13M Battery-powered Pump

HPU13M-DS REV. A ©2014 DANIELS MANUFACTURING CORP.

ALL RIGHTS RESERVED

526 Thorpe Rd. • Orlando, FL 32824 USA • 407-855-6161

www.dmctools.com

11

Problem Possible Cause Probable Remedy

Tool is inoperative. Dirt, contaminants, etc., in tool. Clean tool.

Tool battery contacts damaged. Reform contacts.

Tool components worn or

damaged.

Return tool to DMC.

Motor is inoperative. Low or uncharged battery. Try known charged battery. Inoperative battery may be dis-

charged or may have reached life expectancy.

Broken switch components. Return tool to DMC.

Motor runs but tool will not

complete a cycle.

Oil level low. Return tool to DMC.

Air in hydraulic system. Start pump and hold retract button simultaneously. Run for

approximately 10 seconds, and then attempt to cut. If unsuc-

cessful, return tool to DMC.

Cold oil. Start pump and hold retract button simultaneously to warm

oil. Store tool in warm area.

Dies stop during operation. Oil level low. Return tool to DMC.

Air in hydraulic system. Start pump and hold retract button simultaneously. Hold for

approximately 10 seconds.

LED glows for 20 seconds. Battery charge low. Charge or replace battery.

Tool loses oil. Damaged internal seal. Return tool to DMC.

Troubleshooting

Before You Begin

1. Make sure that the battery is charged. Recheck the battery

after several minutes to make sure the battery is holding

its charge.

2. Use a nonammable contact cleaner or pencil eraser to

clean the electrical contacts on the battery and tool.

3. Reinstall the battery and check the tool again.

DMC offers complete refurbishing and recalibration services.

DMC specially engineers and manufactures complete tool kits to satisfy individual customer

requirements, such as total aircraft support general shop maintenance or production, on board

ship and vehicle service, etc.

Limitation of Liability

DANIELS MANUFACTURING CORPORATION IS NOT LIABLE FOR

CONSEQUENTIAL OR SPECIAL DAMAGES OF ANY NATURE OR KIND RESULTING

FROM THE USE, OR MISUSE, OF ANY OF ITS PRODUCTS. OWNERS AND USERS

OF DMC PRODUCTS ASSUME FULL RESPONSIBILTY FOR INSTRUCTING THEIR

EMPLOYEES IN THE PROPER AND SAFE USE OF SUCH PRODUCTS.

.......................................................................................................................................................

Limited Warranty

DMC (Daniels Manufacturing Corporation) warrants each new product sold by it to be free

from defects in material and workmanship under normal use and service. DMC’s obligation

under this warranty is limited to the free correction or, at DMC’s option, the refund of the

purchase price of any such product which proves defective in normal service within ninety

(90) days after delivery to the rst user, provided that the product is returned to DMC with

all transportation charges prepaid and which shall appear to DMC’s satisfaction, after DMC’s

inspection, to have been defective in material and workmanship, it being understood that

DMC products are not consumer products. This warranty shall not cover any damage to

any product which, in the opinion of DMC, was caused by normal wear, misuse, improper

operation, tampering, neglect or accident. This warranty is in lieu of all other warranties

express or implied. No warranty, express or implied, is made or authorized to be made or

assumed with respect to products of Daniels Manufacturing Corporation other than those

herein set forth.

HPU14M-DS REV. A ©2014 DANIELS MANUFACTURING CORP.

ALL RIGHTS RESERVED 526 Thorpe Rd. • Orlando, FL 32824 USA • 407-855-6161

www.dmctools.com

12

Table of contents

Popular Water Pump manuals by other brands

Pfeiffer Vacuum

Pfeiffer Vacuum UNO 6 operating instructions

Clarke

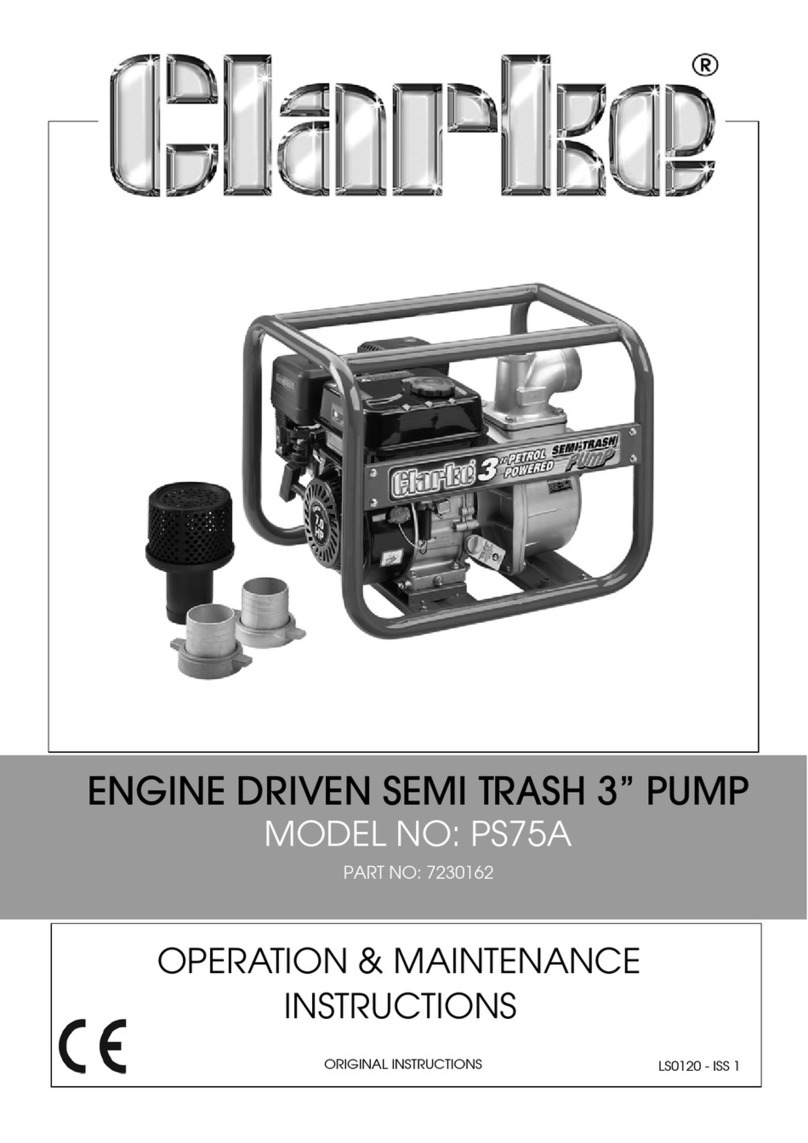

Clarke PS75A Operation & maintenance instructions

Regulus

Regulus CSE MIX W8-SC 1M Installation and operation manual

salmson

salmson Nexis x-care Installation and starting instructions

SPIDO

SPIDO Subinox 6 instruction manual

jbc

jbc DU 1191 instruction manual

Giant

Giant Triplex Ceramic Plunger Pump LP350 Operating instructions/ repair and service manual

Sealey

Sealey SDW50A instructions

BE

BE SP-550SD Operation manual

M&C

M&C MP Series instruction manual

Golander pump

Golander pump BT100F operating manual

WITA

WITA Delta HE 35 series Original installation and operating instructions