DMX Drain 5X™Installation Manual

ii

Contents

1.0 Getting Started ........................................................................................... 3

1.1 Supplies Required........................................................................................................ 3

1.2 Recommended Tools................................................................................................... 4

1.3 Preparing the Site........................................................................................................ 4

1.4 Where to Begin?.......................................................................................................... 5

2.0 Block or Poured Concrete Foundations .................................................. 6

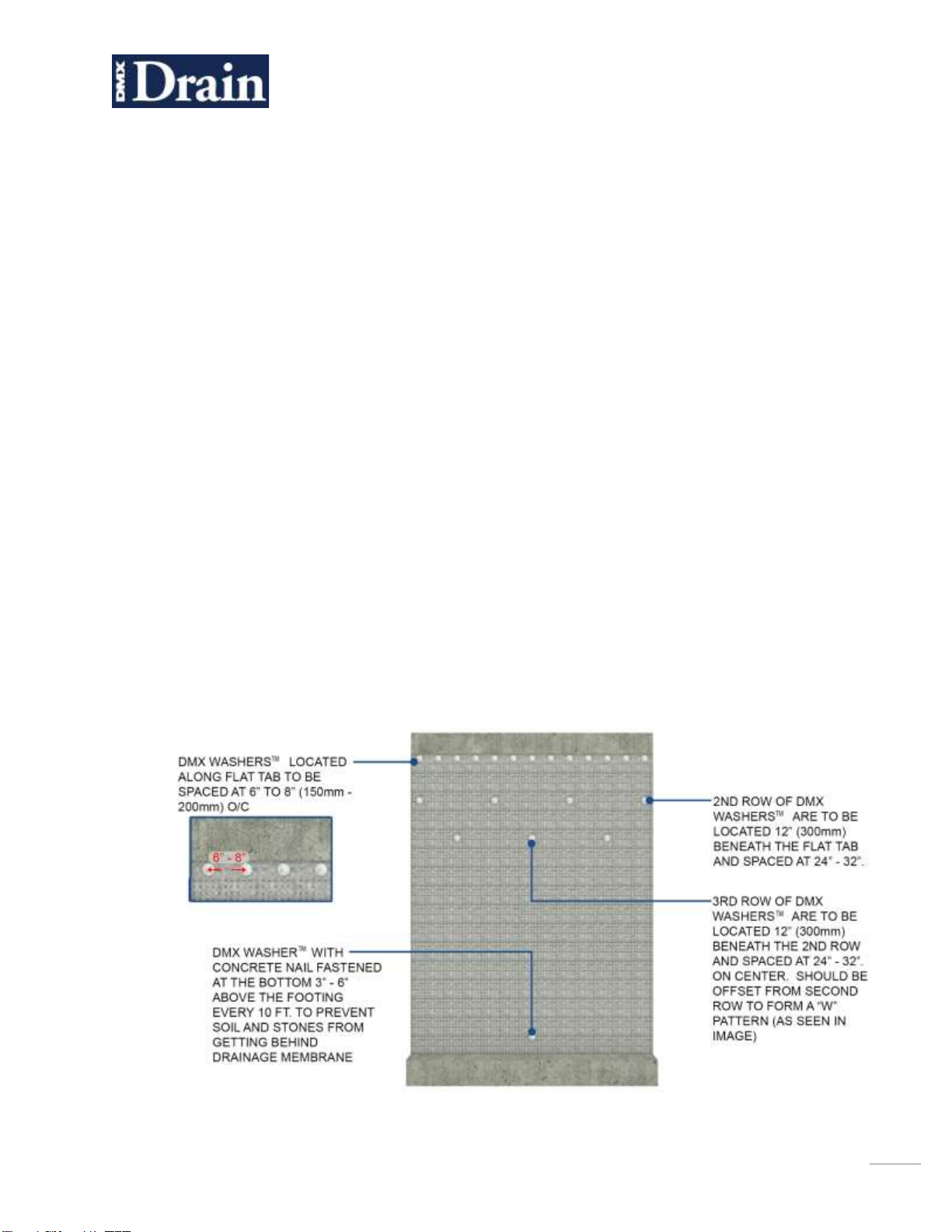

2.1 Installing DMX Drain 5X™ ........................................................................................... 6

2.2 Wrapping Around Corners ........................................................................................... 7

2.3 Joining Rolls of DMX Drain 5X™ ................................................................................. 8

2.4 Around Foundation Openings...................................................................................... 9

2.5 Change in Grade ........................................................................................................10

2.6 Sealing End of Roll .....................................................................................................11

2.7 Around Service Entries...............................................................................................12

3.0 Insulated Concrete Form (ICF) Foundations......................................... 15

3.1 Installing DMX Drain 5X™ ..........................................................................................16

3.2 Wrapping Around Corners ..........................................................................................17

3.3 Joining Rolls of DMX Drain 5X™ ................................................................................18

3.4 Around Foundation Openings.....................................................................................19

3.5 Change in Grade ........................................................................................................20

3.6 Sealing End of Roll .....................................................................................................21

3.7 Around Service Entries...............................................................................................22

4.0 General...................................................................................................... 25

4.1 Clean up & Inspection.................................................................................................25

4.2 Repairs.......................................................................................................................25

4.3 Backfilling ...................................................................................................................25

4.4 Health and Safety .......................................................................................................25

4.5 Limitations ..................................................................................................................25

5.0 Table of Figures ....................................................................................... 26