2

Content

Thanks for using the product.........................................................................................................1

Chapter 1 Human-Machine Interface...........................................................................................4

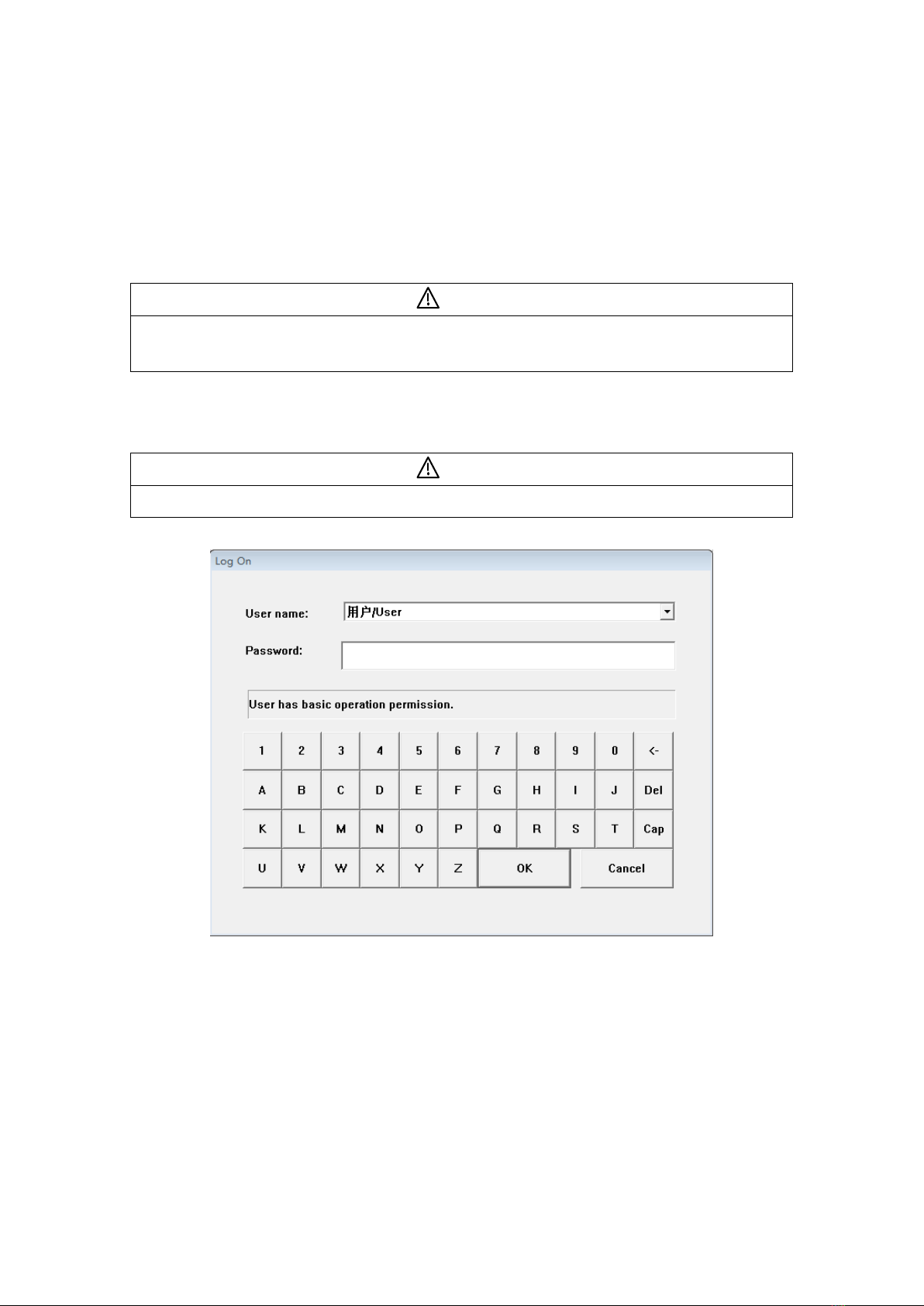

1.1 Log-In.....................................................................................................................................4

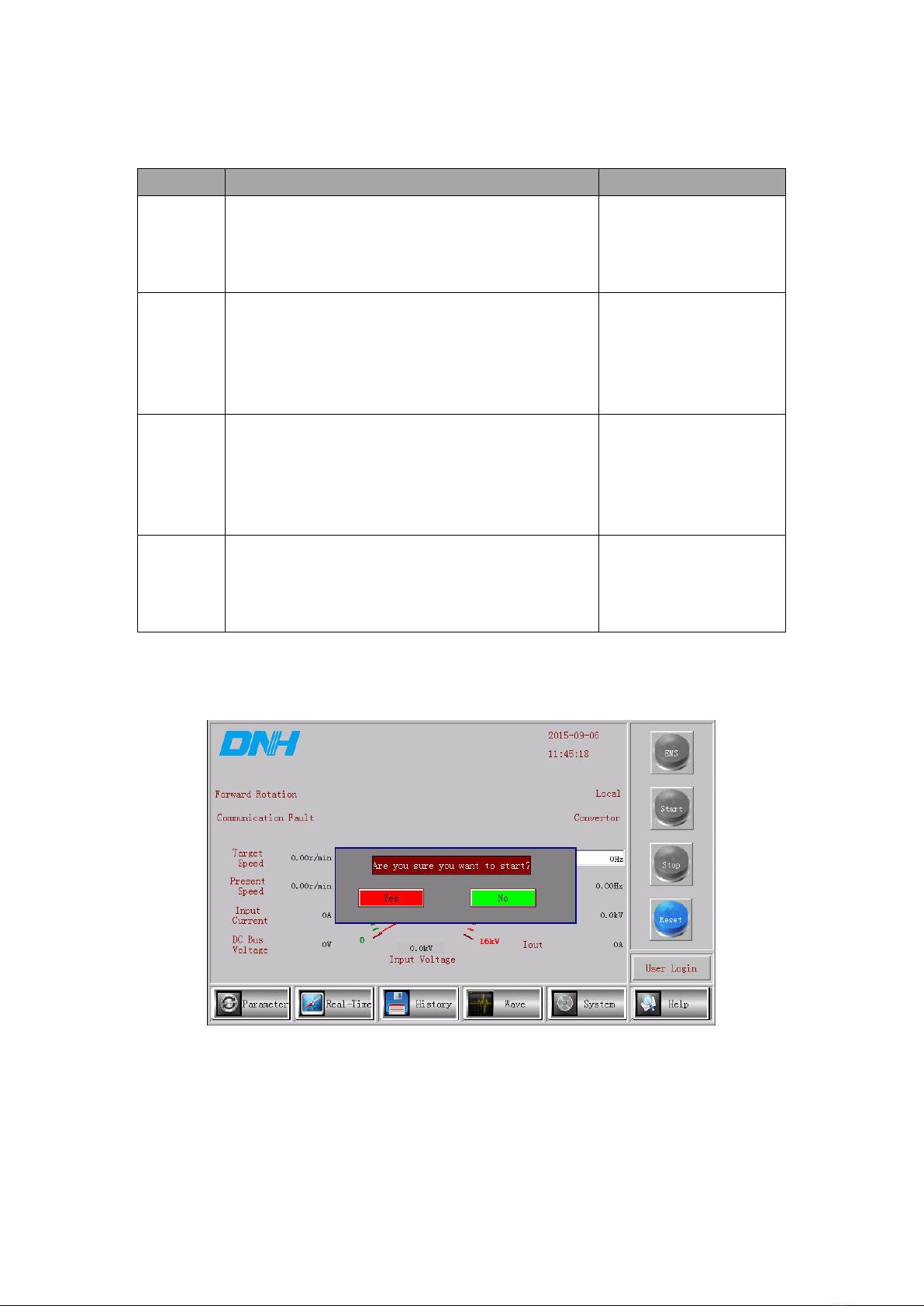

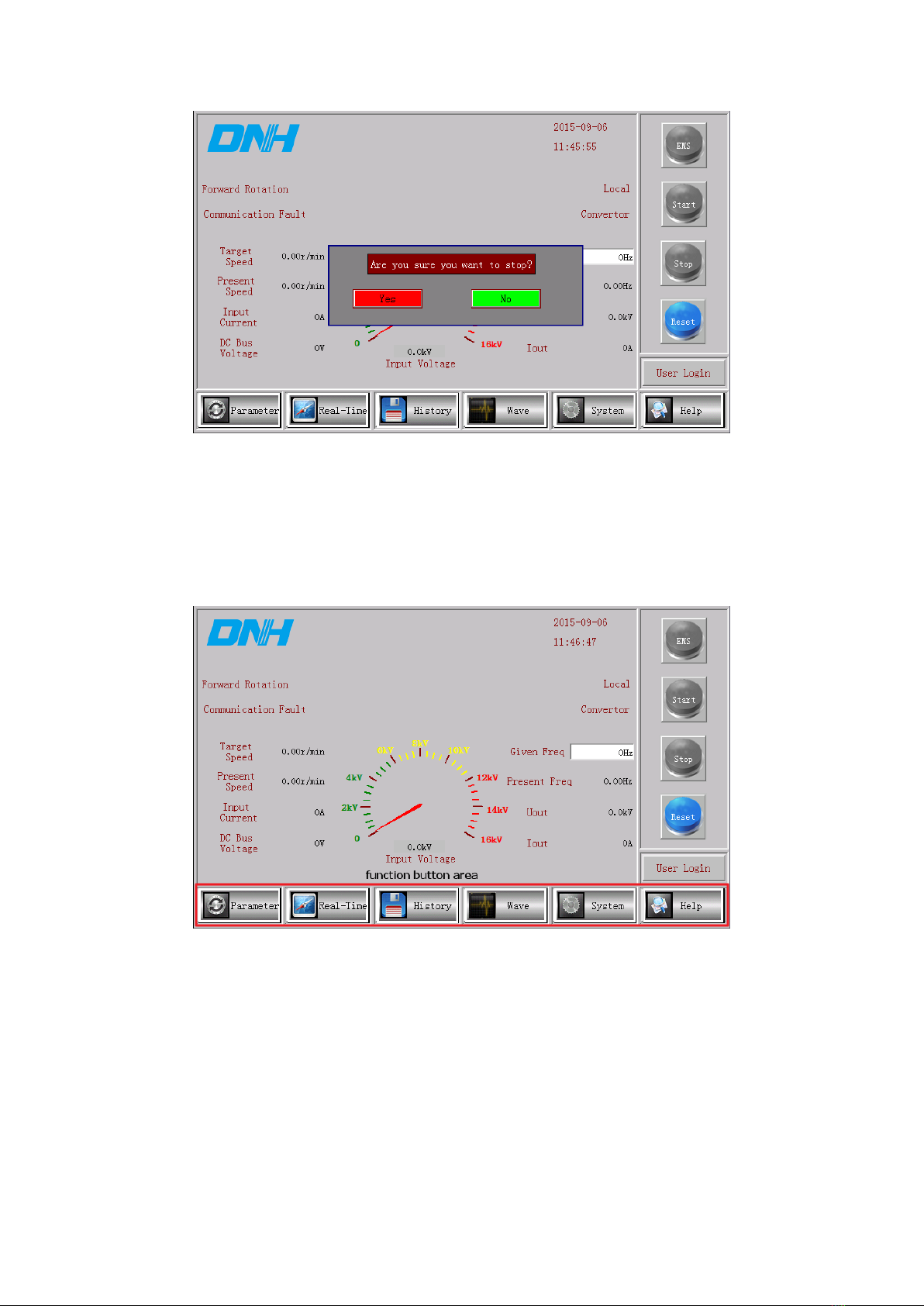

1.2 Main Screen...........................................................................................................................5

1.2.1 Control Button Area .........................................................................................................5

1.2.2 Function Button Area .......................................................................................................7

1.2.3 State Display Area............................................................................................................7

1.3 Parameter Setup Screen .......................................................................................................9

1.3.1 Speed Regulation Parameters...........................................................................................9

1.3.2 Control Parameters.........................................................................................................12

1.3.3 vector Parameters...........................................................................................................13

1.3.4 Motor Parameters...........................................................................................................15

1.3.5 Communication Parameters ...........................................................................................15

1.3.6 Sensor/Measurement Range...........................................................................................16

1.4 Real Time Data Screen .......................................................................................................16

1.4.1 System State...................................................................................................................17

1.4.2 Inverter Unit State..........................................................................................................18

1.4.3 Digital Port State............................................................................................................19

1.4.4 Analog Port State............................................................................................................20

1.4.5 Data State .......................................................................................................................21

1.4.6 Synchronoscope .............................................................................................................21

1.5 Historical Data Screen ........................................................................................................22

1.5.1 Fault History ..................................................................................................................22

1.5.2 Alarm History.................................................................................................................23

1.5.3 Operating Record ...........................................................................................................24

1.5.4 Runtime Log ..................................................................................................................24

1.6 Waveform Display Screen ..................................................................................................25

1.6.1 Instantaneous Curve.......................................................................................................25

1.6.2 Running Curve ...............................................................................................................26

1.6.3 Fault Record...................................................................................................................27

1.7 Help Screen..........................................................................................................................28

Chapter 2 Trial Run......................................................................................................................31

2.1 Trial Run Steps ....................................................................................................................31