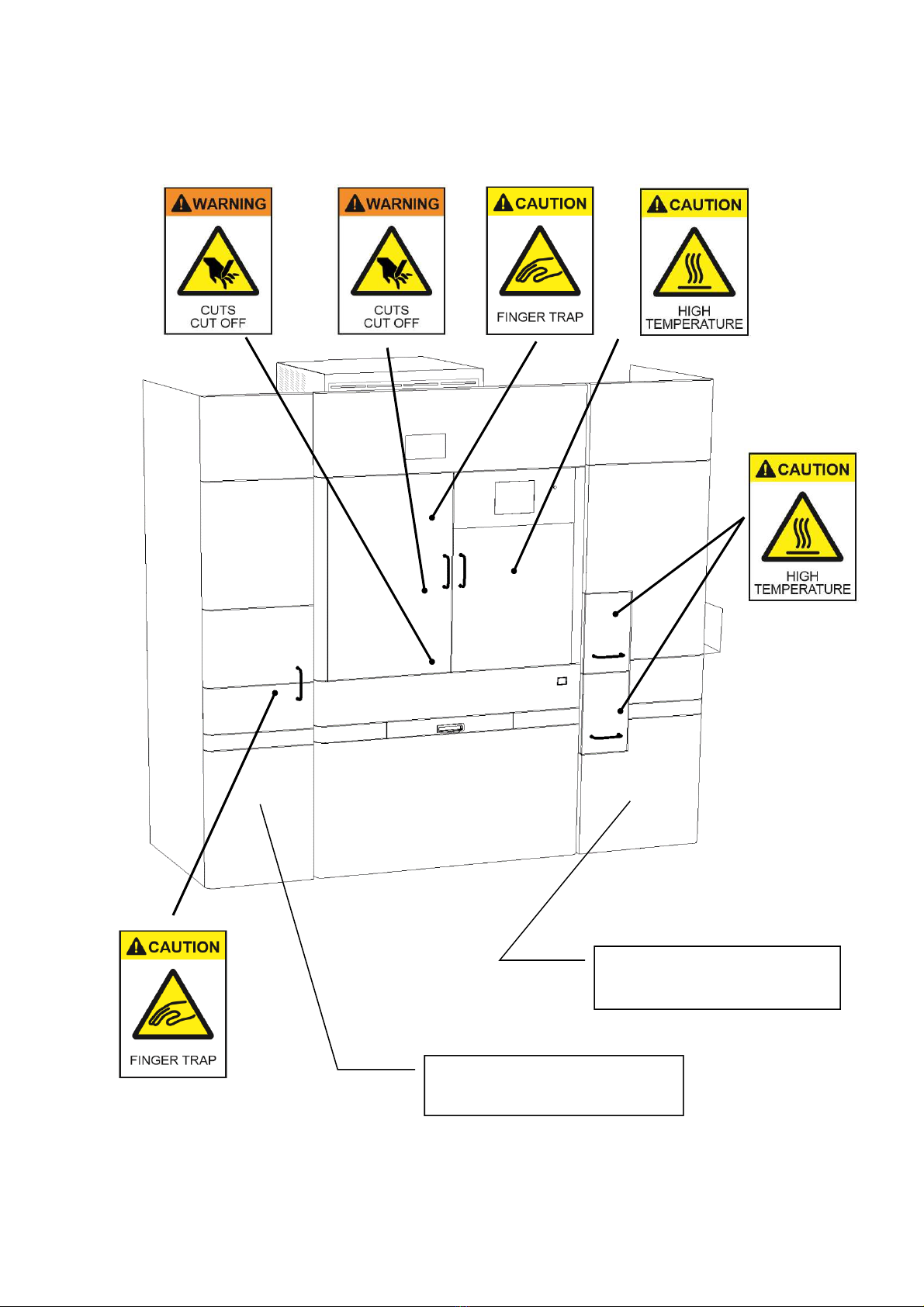

For Safe and Correct use

AS-410M Auto Slide Preparation System

5

Ensure horizontal installation. Tilted installation may

cause this System to malfunction, leading to an

This System is NOT explosion-proof. Use the

System only in a well-ventilated room.

< Warnings/ Instructions >

● Installation

●Use of fire

●Disassembly and modification

● Repair

●Abnormalities in the System

●Power plugs

●Power cords

When detecting scratches in the power cord, broken

wire, or poor contact, stop using the System

immediately and contact us for repair.

Do not bend, pull, twist, or extend the power cords.

Failure to comply may lead to system breakdown or

fire.

Do not touch a power plug with a wet hand. Failure to

comply may result electric shock. Always pull the

power plug to unplug it. Never pull on the power cord.

In the case of smoke or abnormal noise from this

System, stop use immediately, turn off the power

switch, unplug the power plug from the power outlet,

and contact us for repair.

In the case of system failure, stop using the System

immediately and contact us for repair. Avoid

continued use without repair. Also avoid repair by

unauthorized service personnel. Failure to comply

may lead to system breakdown or an accident.

Never attempt to disassemble or modify this

System. Failure to comply may lead to system

breakdown or an accident.

! Warning

! Warning

! Warning

! Warning

! Warning

! Warning

! Warning

! Warning