6

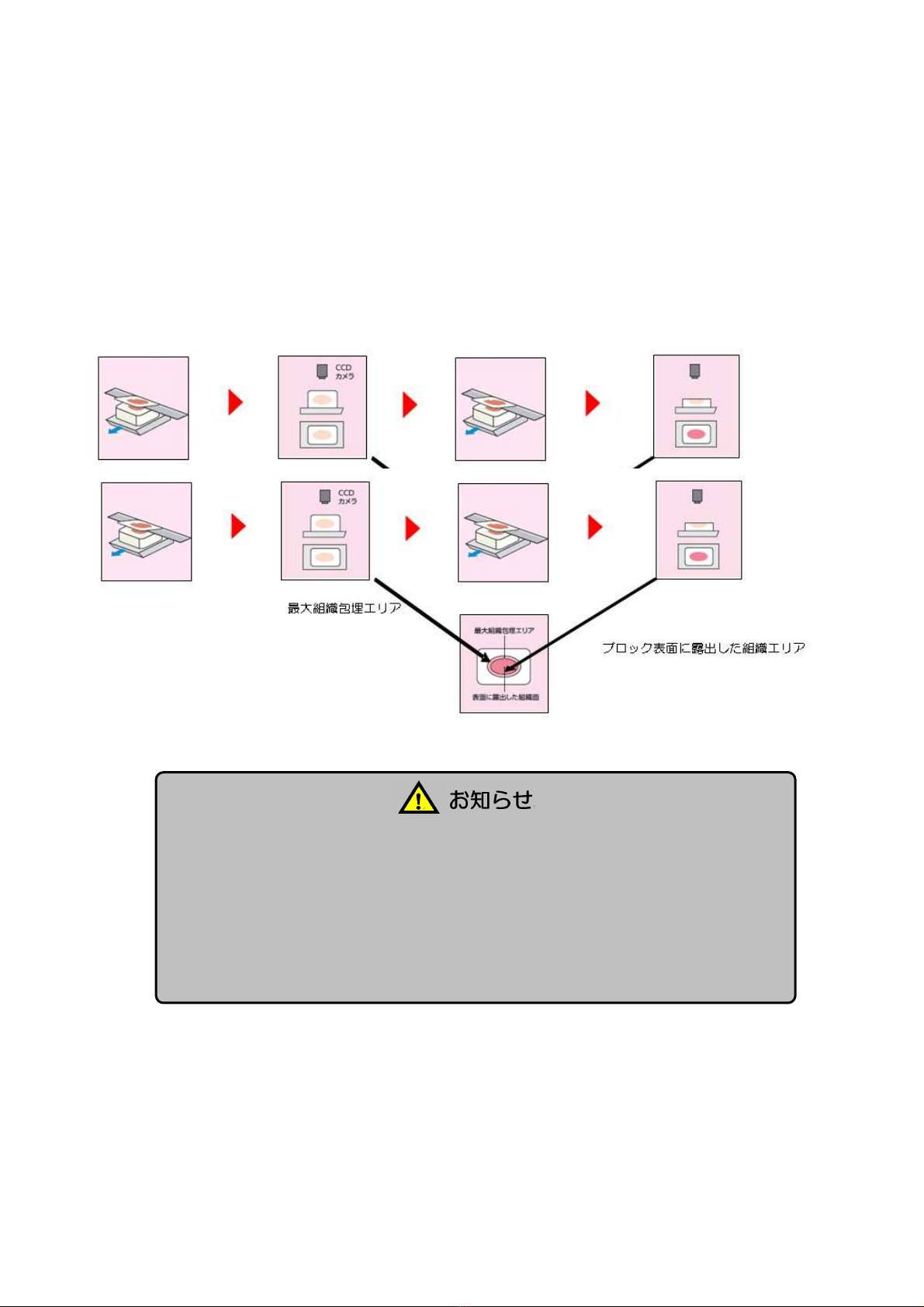

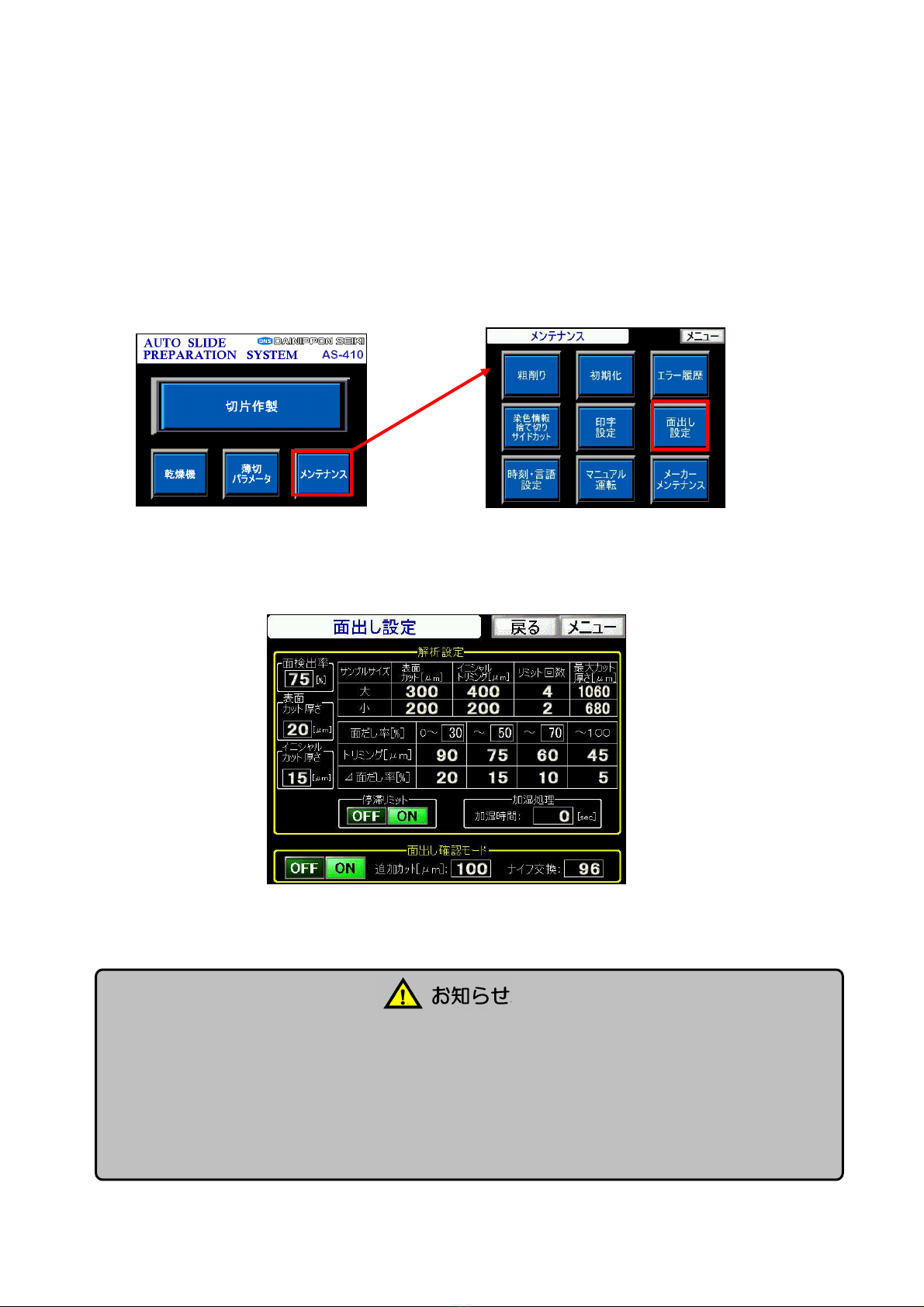

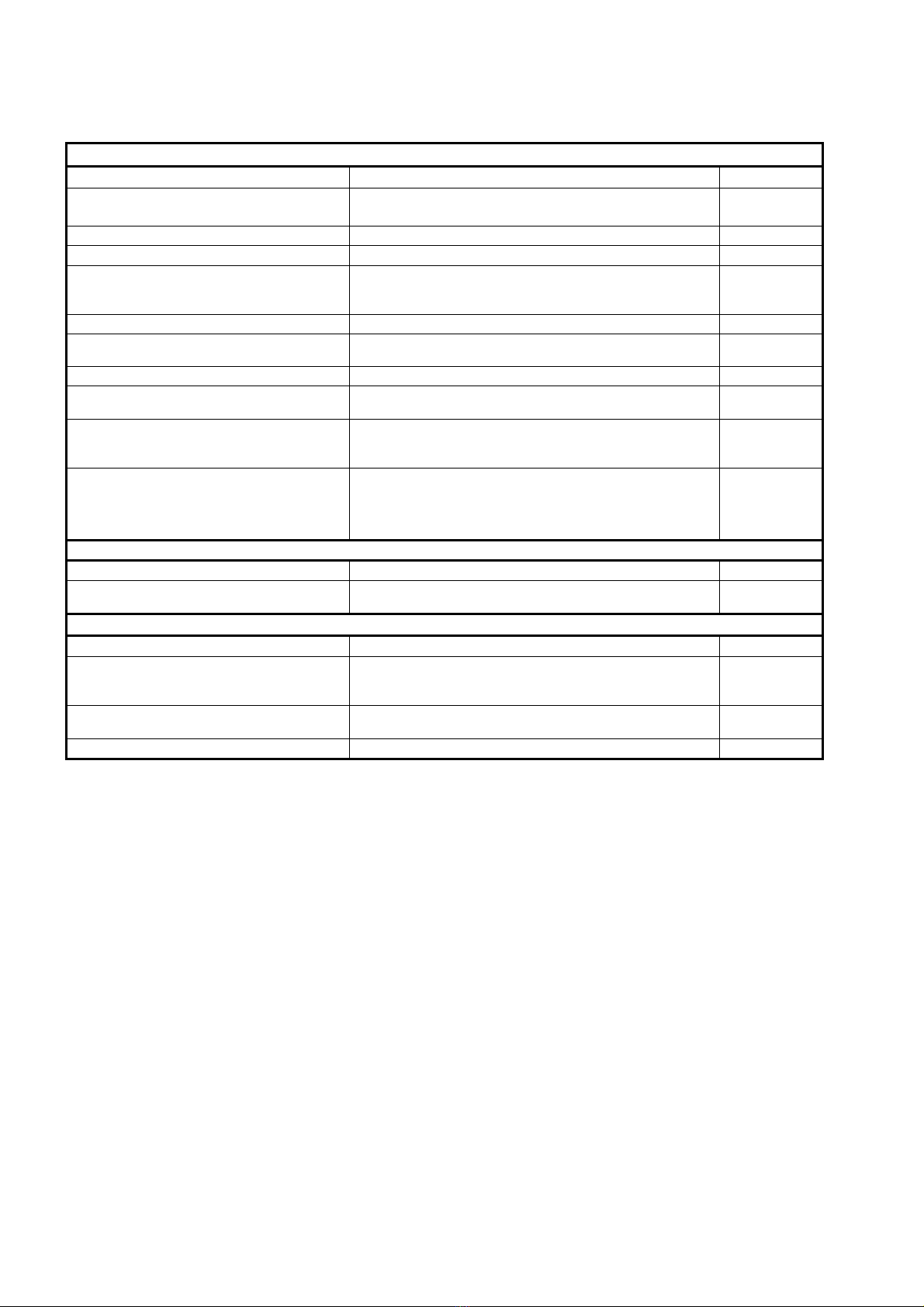

Chart 1. Auto Trimming Setting items

Basic auto trimming setting

On-screen item Description

Setting range

Surface detection ratio (Threshold)

(%)

Size of tissue specimen on paraffin surface compare to

the entire tissue size. 1 to 99

1st Thickness

Thickness of 1st surface trimming per single slicing.

3 to 30

2nd Thickness

Thickness of 2nd initial trimming per single slicing.

3 to 30

Sample Size

Sample block surface size

Reguler: 24x37mm to 16x16mm Small :15x15mm to

under

―

Surface trimming (1st trimming) (μm)

Amount of rough-cut before detecting entire tissue size. 0 to 999

Initial trimming (2nd trimming) (μm)

Amount of rough cut before detecting tissue size on

paraffin surface.

1 to 999

Retry count

Maximum number of the retry-trimming.

1 to 99

Maximum volume (thickness)

Max. limit of thickness of rough-cut during auto trimming

function.

―

Wait limit

In case of failing to reach threshold after auto trimming,

the machine will:

On: make tissue slides Off: skip slide sectioning

―

Trimming rate (%) The amount of additional trimming (rough-cut) if the

surface detection ratio does not exceeded the

threshold.

The rough-cut volume is determined by the

increased volume (δ Threshold).

1 to 99

1 to 999

- 99 to 99

Humidification treatment

On-screen item Description

Setting range

Humidifying time

Length of humidification before measuring the tissue size

on paraffin surface.

0 to 999

Auto trimming manual check mode

On-screen item Description

Setting range

ON,OFF

ON: Apply Auto Trimming to all sample blocks first,

check, then start sectioning of the blocks. OFF: Apply

Auto Trimming and sectioning to each block one by one.

Add trimming (μm)

Amount of additional trimming after checking the image

on Auto Trimming screen. 0 to 999

Blade Change

Number of blocks to apply Auto Trimming per blade