CHAPTER 1:

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

1. The sand lters are designed to work with water

temperature between 32ºF and 113ºF. The

lter should never be operated outside of these

temperatures or damage may occur.

2. The installation should be carried out in accordance

to the safety instructions of swimming pools and

the specic instructions for each facility.

3. The user should make sure that the installation is

carried out by qualied authorized persons and that

these persons have rst carefully read the following

instructions. Incorrectly installed equipment may

fail, causing sever injury or property damage.

4. The operating safety of the lter is only guaranteed if

the installation and operation instructions are

correctly followed.

5. To reduce the risk of injury, do not permit children

to use this product.

6. Chemical spills and fumes can weaken Swimming

Pool or Spa. Corrosion can cause lters and other

equipment to fail, resulting in severe injury or

property damage. Do not store pool chemicals near

your equipment.

7. Any modication of the lter is not authorized. The

supplier assumes no liability for the damage and

injuries caused by unauthorized replacement parts

and accessories.

Sand Filtration System Working Principle

Incoming water from the piping system is automatically

directed by the Multi-Port Valve to the top of the lter

bed. As the water is pumped through the lter sand,

dirt and debris are trapped by the lter bed, and ltered

out. The ltered water is returned from the bottom of

the lter tank, through the Multi-Port Valve and back

through the piping system.

CHAPTER 2: PREPARATION BEFORE INSTALL

▲WARNING This product should be installed and

servicedonlybyaqualiedprofessional.

1.

Position the lter next to the Swimming Pool or Spa.

2. The lter should be placed on a level concrete

slab, very rm ground, or equivalent. Ensure that

the ground will not subside, preventing any strain

from the attached plumbing.

3. Position the lter so that the piping connections,

Multi-Port Valve and winter drain is convenient and

accessible for operation, servicing and winterizing.

4. Ensure that the compliance label is facing the

front to allow easy identication in the case of

service difculties.

CHAPTER 3: INSTALLATION INSTRUCTIONS

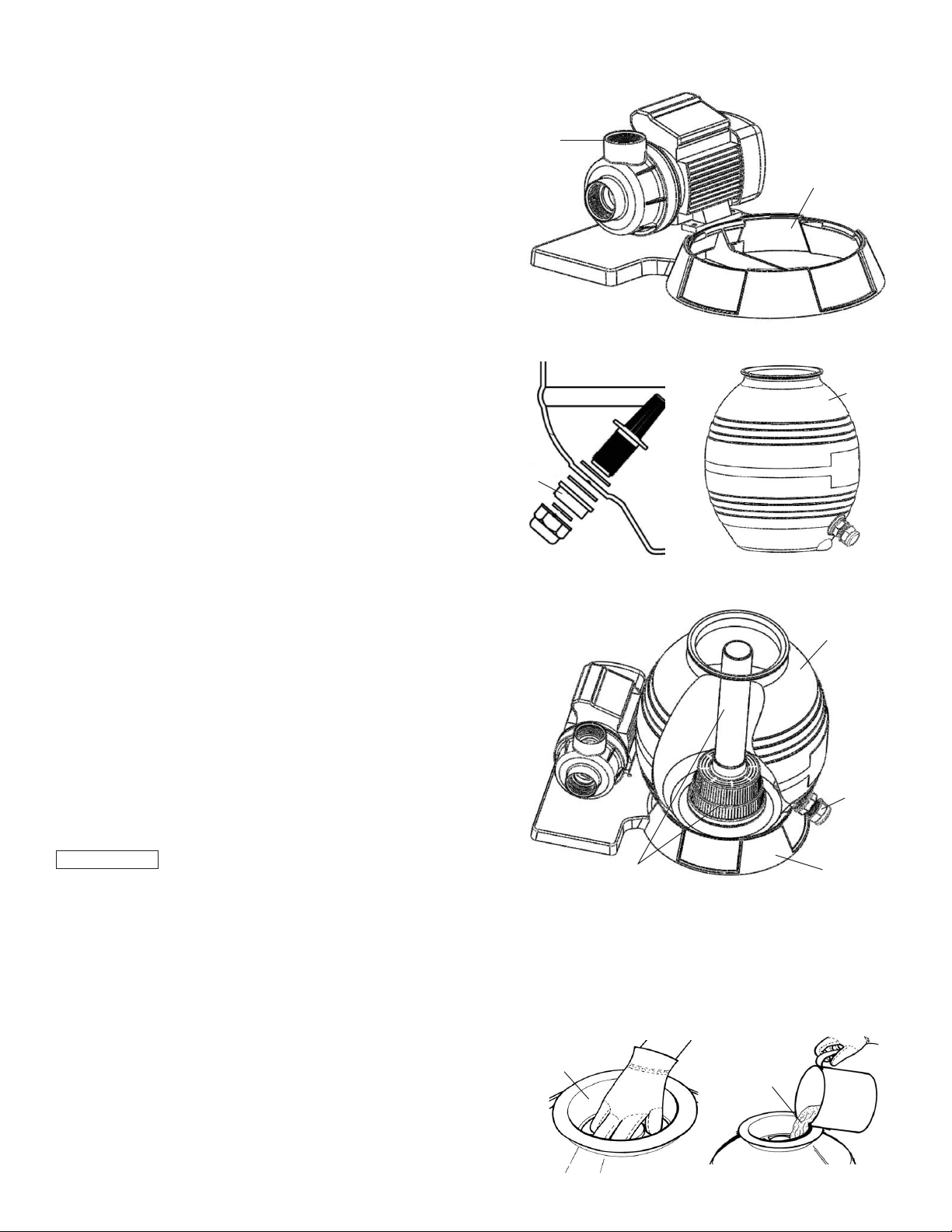

1. Mount the pump to Sand Filter Support by using

the nuts and bolts.

2. Install the Drain Plug Assembly to the Sand Tank.

3. Mount Sand Tank to Sand Filter Support. Drain Plug

is on the outside.

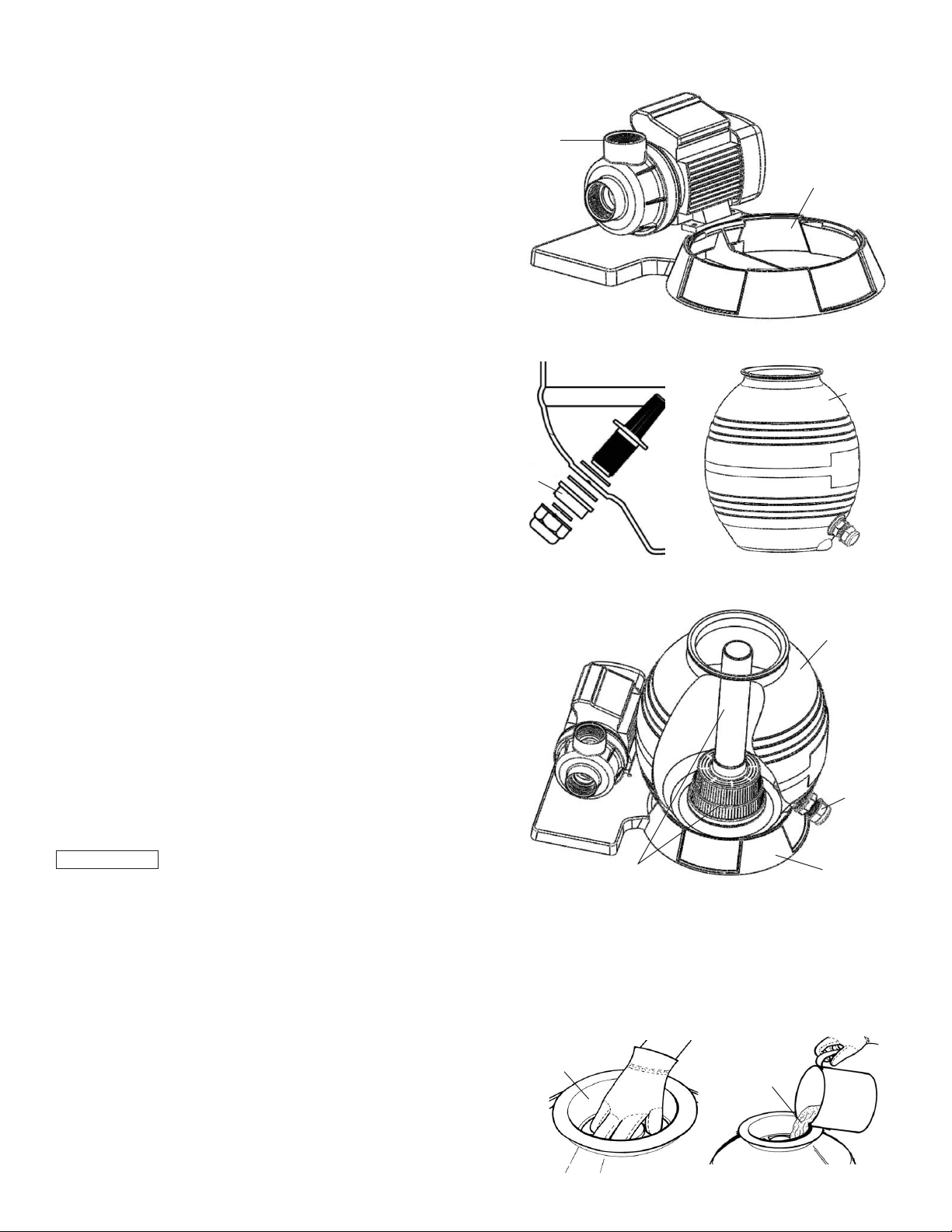

4. Insert the Filter Assembly with Stand Pipe inside

the Sand Tank as pictured above. Then place the

Stand Pipe Blocker over the Sand Tank’s mouth

to prevent sand from getting into the Stand Pipe

and to keep the Stand Pipe in place. Then pour the

Silica Sand (41.8 lbs) into the Sand Tank.

6950 51st Street Kenosha WI 53144|Orders and Customer Care: 1-800-574-7665|Fax: 1-800-323-5932|Doheny.com

Sand Filter

Support

Sand Filter

Support

Pump

Drain

Plug

Drain

Plug

Sand

Tank

Sand

Tank

Filter Assembly

with Stand Pipe

Stand Pipe

Blocker

Silica

Sand