2Mounting- and operating instruction SAFEMASTER STS / 08.01.21 en / XXXX

Index

Page

1. General ......................................................................................................................................................................................................................... 3

1.1 Safety Notes ............................................................................................................................................................................................................... 3

1.2 Mounting rules and type numbering ........................................................................................................................................................................... 3

1.3 Key transfer plan......................................................................................................................................................................................................... 4

1.4 Recommended mounting position.............................................................................................................................................................................. 4

1.5 Recommended ergonomic mounting height............................................................................................................................................................... 4

1.6 Safety condition of the modules during assembly / modification ................................................................................................................................ 5

1.7 Operating a module during composition of a unit....................................................................................................................................................... 5

2. Mounting ...................................................................................................................................................................................................................... 6

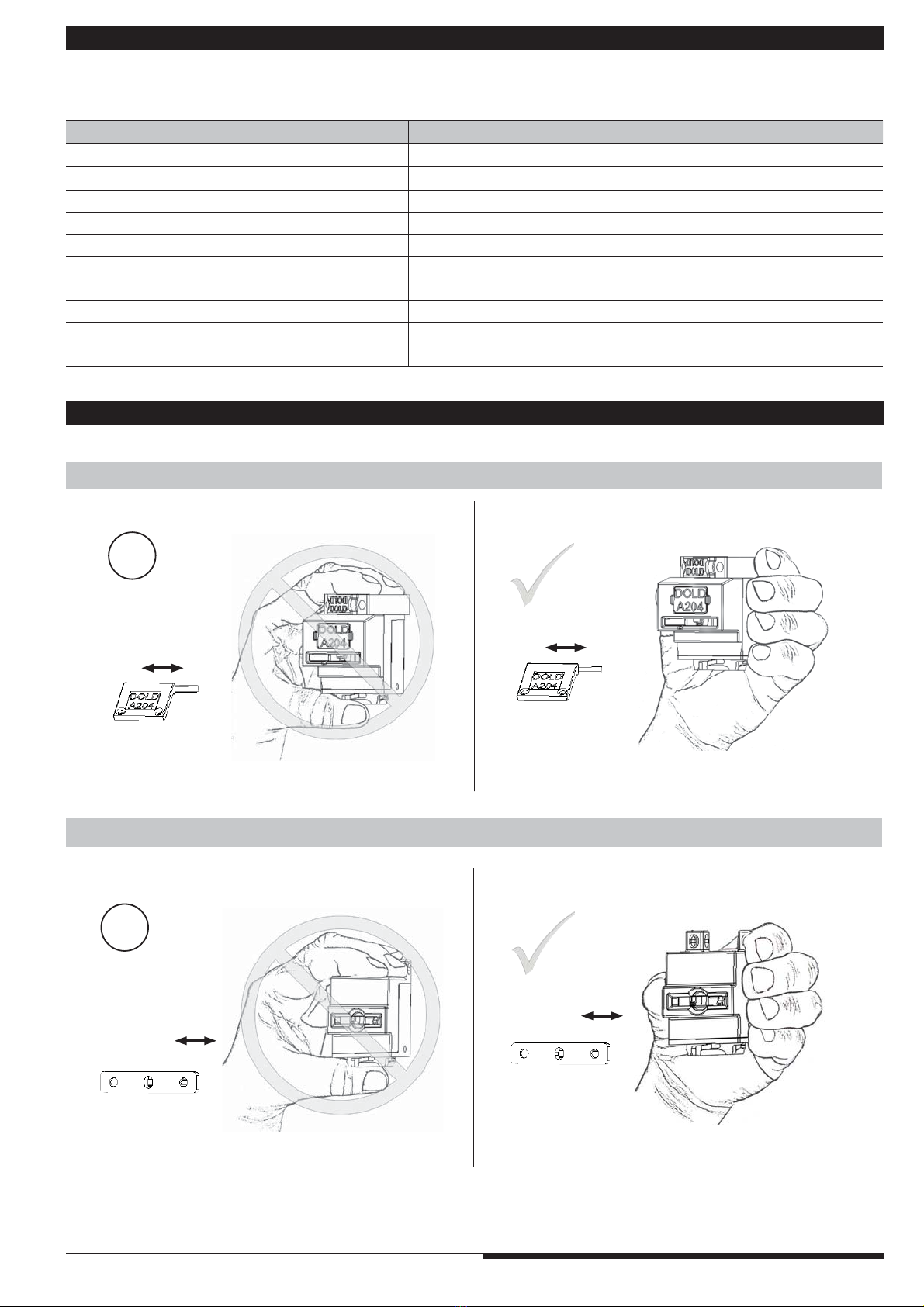

2.1 Actuator modules and key modules............................................................................................................................................................................ 6

2.2 Modifying a unit or extending...................................................................................................................................................................................... 6

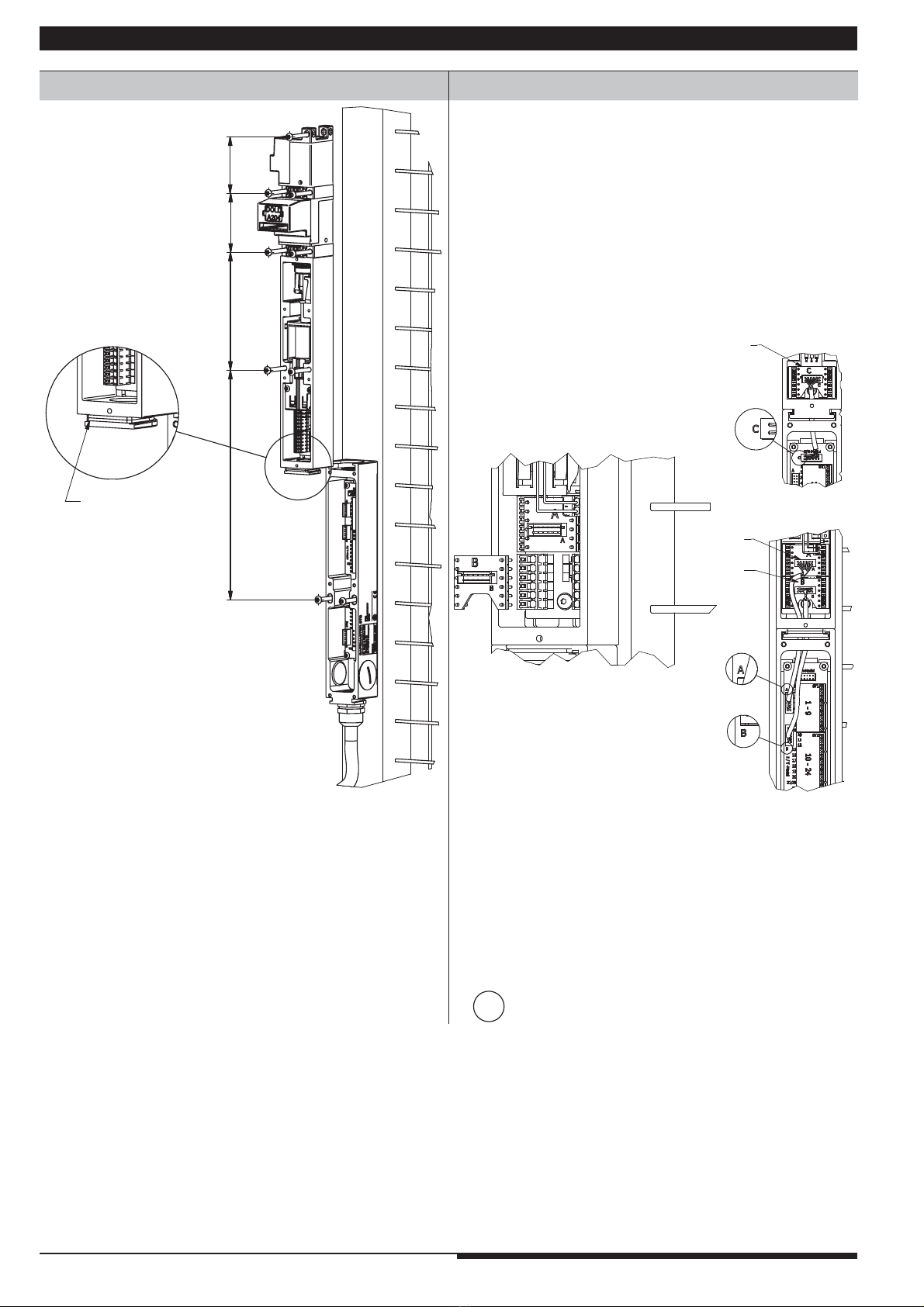

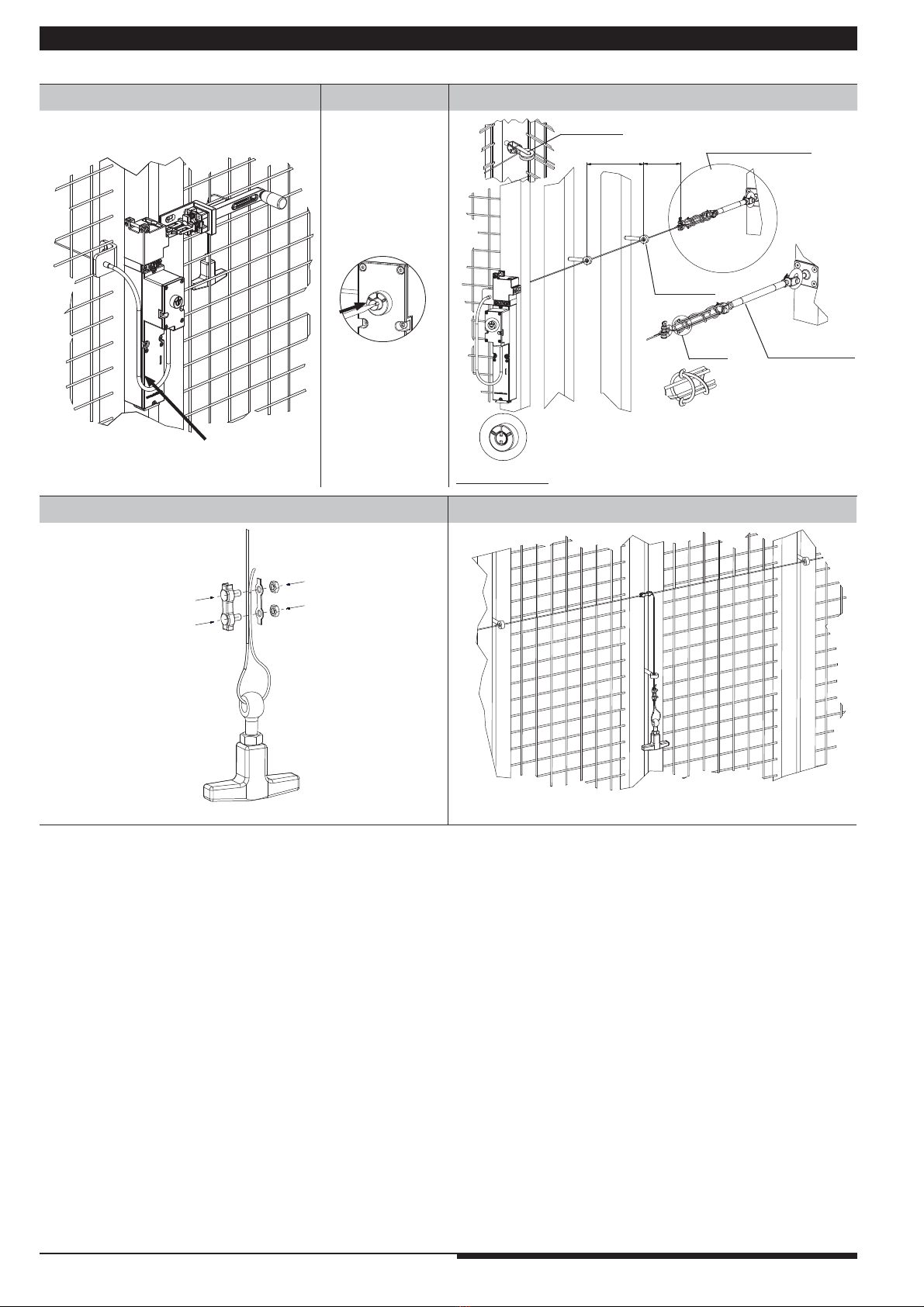

2.3 Units and a safety guards........................................................................................................................................................................................... 7

2.4 Option module ............................................................................................................................................................................................................ 8

2.5 Escape release......................................................................................................................................................................................................... 10

2.6 Mounting dimensions of actuators and actuator modules ........................................................................................................................................ 12

2.10 Door Handle Actuator TG ...................................................................................................................................................................................... 18

2.11 Power Interlocking .................................................................................................................................................................................................. 19

Mounting remarks........................................................................................................................................................................................................... 20

3. Circuit diagrams and connection examples ................................................................................................................................................................ 21

3.1 Circuit diagrams for switching modules (SX-, SV-, RX-, RV-modules)...................................................................................................................... 21

3.2 Circuit diagrams for solenoid locking modules (ZRX, YRX, ZAX, YAX-modules)...................................................................................................... 22

3.4 Terminal designation option module ......................................................................................................................................................................... 25

3.5 Connection examples Power Interlocking................................................................................................................................................................. 26

4. Operation .................................................................................................................................................................................................................... 28

4. 5. Solenoid locking module with escape release ........................................................................................................................................................ 29

4.6 F-Kit .......................................................................................................................................................................................................................... 30

4.7 Power Interlocking .................................................................................................................................................................................................... 31

4.7 Power Interlocking .................................................................................................................................................................................................... 32

5. Cleaning...................................................................................................................................................................................................................... 33

6. Lubrication .................................................................................................................................................................................................................. 33

Notes .............................................................................................................................................................................................................................. 33

7. Test / Inspection .......................................................................................................................................................................................................... 34

7.1 System blocking as safety function........................................................................................................................................................................... 37

8. Repairs ....................................................................................................................................................................................................................... 37

Frequently asked questions – FAQs............................................................................................................................................................................... 38

Notice ............................................................................................................................................................................................................................. 39

Notice ............................................................................................................................................................................................................................. 40

Notice ............................................................................................................................................................................................................................. 41