5

31076041.02 09/2015 EN/DE/FR/ES

EN

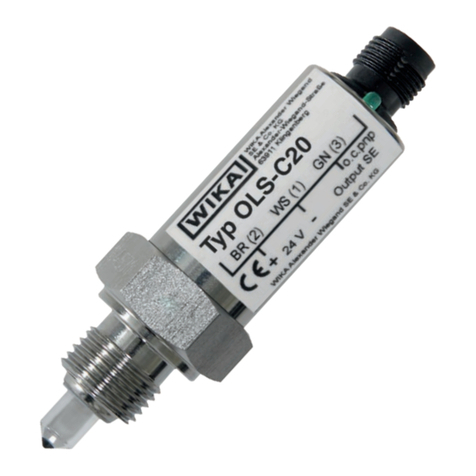

WIKA operating instructions optoelectronic level switches, models OLS-C

2. Design and function

2.1 Description

This instrument is used for the

detection of limit levels in liquids.The

measuring principle is independent

of refractive index, colour, density,

conductivity and dielectric constant.

The switches consist of an infrared

LED and a phototransistor.The light

of the LED is directed into a prism. So

long as the sensor tip of the prism is

in the gas phase, the light is reflected

within the prism to the receiver. When

the liquid in the vessel rises and wets

the glass tip, the infrared lightbeam

into the liquid is interrupted and only a

small portion reaches the receiver.

The integrated switch electronics offer an automatic adjustment so

that there is a wide field of application. For the output, there is an

O.C. pnp-transistor switching output or a relay switching output.

2.2 Instrument construction

Depending on the switch type, the instruments are fitted with

different process connections.These contain a glass prism and the

electronics responsible for the evaluation.

2. Design and function

Operating principle

Gas

Liquid