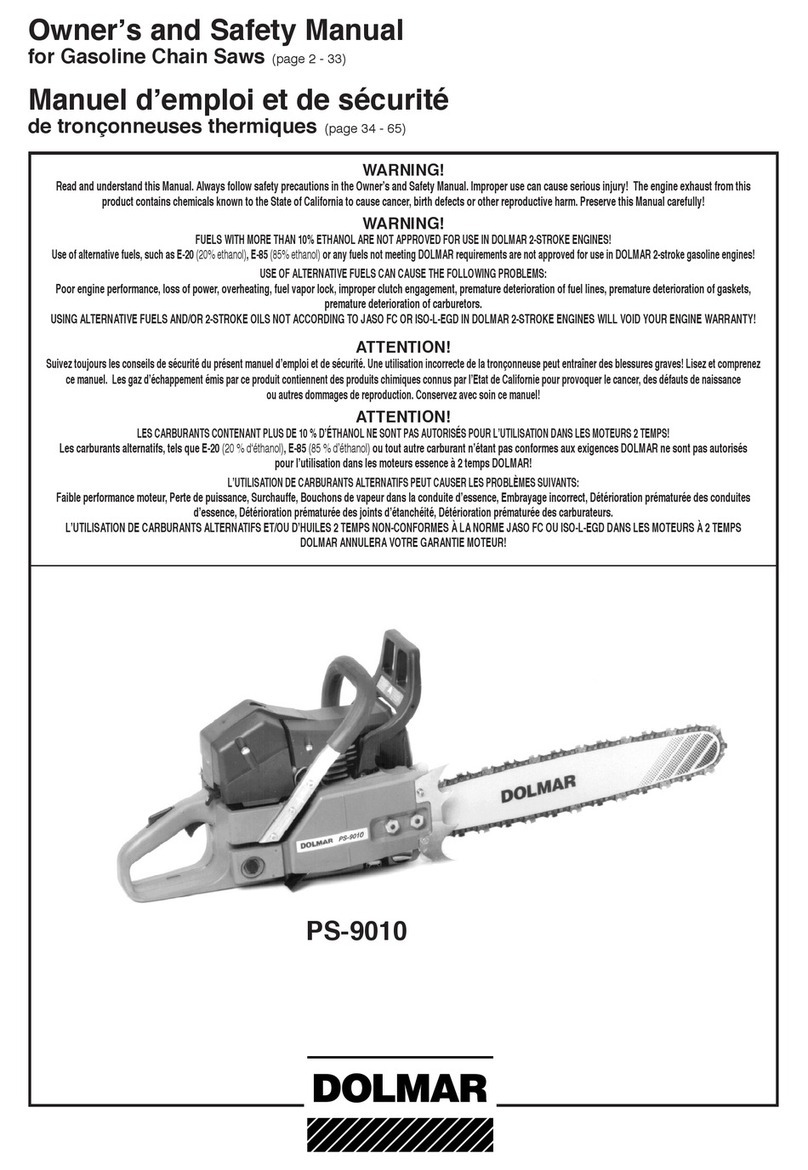

Safety precautions for chain saw operators

While operating the chain saw please observe the

following rules:

a) Contact of the guide bar nose with any object

should be avoided.

b) Tip contact may cause the guide bar to move

suddenly upward and backward, which may cause

serious or fatal injury.

c) Always operate the chain saw with both hands.

WARNING!

Readandfollowallsafetyprecautionsintheowner’s

manual. Failure to follow instructions could result in

serious injury. It is recommended to lend the chain

saw only to people who are experienced in working

with chain saws. Always hand over the Owner’s and

Safety Manual.

WARNING!

This chain saw is capable of severe kickback

that could result in serious injury to the operator.

Do not operate this chain saw unless you have

extraordinary cutting needs and experience in and

special training for dealing with kickback. Chain

are available.

WARNING!

Kickbackmayoccurwhenthenoseortipoftheguide

bar touches an object, or when the wood closes in

and pinches the saw chain in the cut. This contact

mayabruptly stopthesawchain andinsomecases

maycausea lightning fastreverse reaction, kicking

the guide bar up and back towards the user, or push

the guide bar back towards the operator. Kickback

may cause you to lose control of the saw.

As a chain saw user, you can take several steps to

reduce the risk of a kickback and potential injury.

A. Withabasicunderstandingofkickback,youcan

reduceoreliminatetheelementof surprise.Itisa

sudden surprise that contributes to accidents.

hands, your right hand on the rear grip and

your left hand on the tubular handle, when the

maintain control of the saw. Don’t let go!

C. Make sure that the area in which you are cutting

is free from obstructions. Do not let the nose of

the guide bar contact the log, branch, or any

other obstructions which could be hit while you

are operating the saw.

D. Do not overreach or cut above shoulder

height.

E. Follow manufacturer’s sharpening and main-

tenance instructions for the saw chain.

by the manufacturer or the equivalent.

Additional safety precautions

The following additional safety precautions must be

observed by all users of chain saws:

1. Do not operate a chain saw when you are fatigued.

protective gloves; and eye, hearing, and head

protection devices.

3. Use caution when handling fuel. Move the chain

saw at least 10 feet (3 m) from the fueling point

before starting the engine.

4. Do not allow other persons to be near the chain

saw when starting or cutting with the chain saw.

Keep bystanders and animals out of the work

area.

5. Do not start cutting until you have a clear work

area, secure footing, and a planned retreat path

from the falling tree.

6. Keep all parts of your body away from the saw

chain when the engine is running.

7. Before you start the engine, make sure that the

saw chain is not contacting anything.

8. Carry the chain saw with the engine stopped,

the guide bar and saw chain to the rear, and the

9. Do not operate a chain saw that is damaged, is

improperly adjusted, or is not completely and

securely assembled. Be sure that the saw chain

stops moving when the throttle control trigger is

released.

brush and saplings because slender material

may catch the saw chain and be whipped toward

12. When cutting a limb that is under tension be alert

for springback so that you will not be struck when

13. Keep the handles dry, clean, and free of oil or fuel

mixture.

14. Operate the chain saw only in well-ventilated

areas.

15. Do not operate a chain saw in a tree unless you

16. All chain saw service, other than the items listed

in the owner’s manual maintenance instructions,

should be performed by DOLMAR. (For example,

if improper tools are used to remove the

17. When transporting your chain saw, use the chain

protection cover.

18. Low kickback bars and low kickback chains are

designed to reduce the risk of kickback injury.

Ask your DOLMAR dealer about these devices.